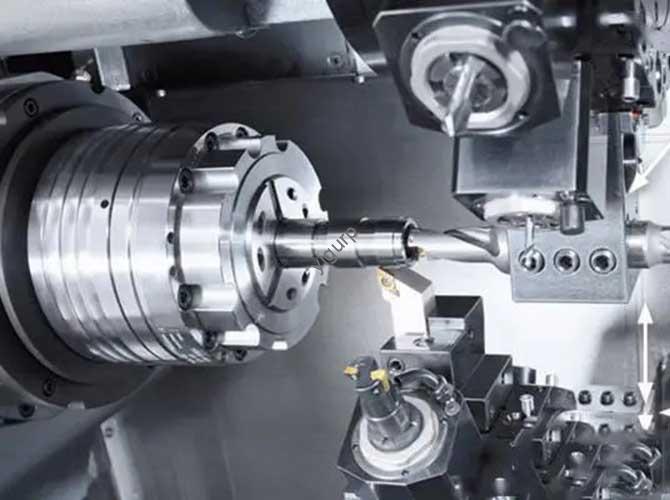

What RA Values Can the Surface Roughness of CNC Processing Reach?

Шероховатость поверхности, measured by the Ra (Arithmetic Average Deviation) ценить, is a critical indicator of CNC machining quality—it directly impacts part functionality, износостойкость, и подходит. Whether you’re making consumer goods, Промышленные компоненты, or medical implants, knowing the achievable Ra range of CNC processing and how to control it is essential. This article breaks down […]