The success of any 3D printing project hinges on choosing the right material—and with so many options available, понимание 3D printing materials features имеет решающее значение. From biodegradable PLA for eco-friendly prototypes to high-strength titanium for aerospace parts, each material has unique traits that make it ideal for specific tasks. This guide breaks down the key features of the most popular 3D printing materials, groups them by category (пластмассы, металлы, biomaterials, emerging options), and provides actionable tips to help you pick the perfect material for your project. Whether you’re a hobbyist printing a desk organizer or an engineer developing medical devices, this guide eliminates guesswork and ensures your prints meet performance and design goals.

1. Пластиковые материалы: The Most Versatile 3D Printing Option

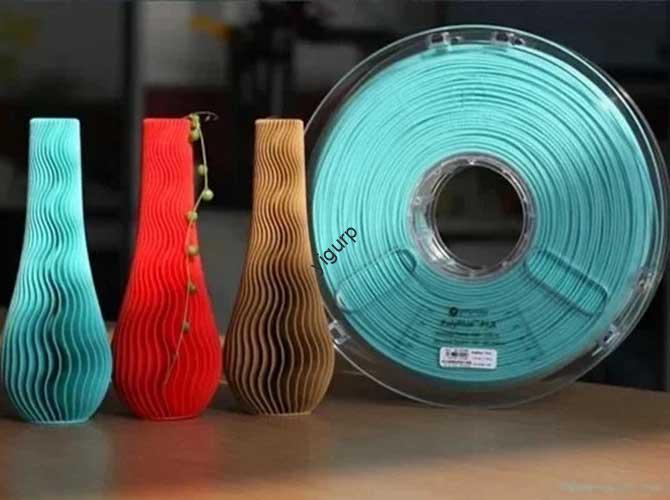

Plastics are the backbone of 3D printing—affordable, простой в использовании, and available in a range of properties. They’re ideal for prototypes, функциональные части, and decorative items, with features tailored to everything from outdoor durability to flexibility.

Key Features of Common 3D Printing Plastics

| Материал | Core Features | Сила & Долговечность | Идеальные приложения | Плюс & Минусы |

| АБС (Акрилонитрил бутадиен стирол) | Отличный воздействие сопротивления; high surface hardness; Хорошая химическая устойчивость (сопротивляется маслам, моющие средства). | Предел прочности: 40–50 МПа; Izod impact strength: 20–30 J/m. Durable for repeated use but prone to warping. | Автомобильные детали (mirror covers, Корпуса датчиков); промышленное инструменты (прижие, зажимы); игрушки (durable action figures). | ✅ Strong and chemical-resistant; ✖️ High shrinkage rate (5–8%), prone to warping; emits fumes during printing. |

| Плата (Полилактановая кислота) | Сделано из возобновляемых ресурсов (cornstarch, сахарный тростник); биоразлагаемый (breaks down in 6–24 months); Гладкая поверхность отделка; clear detail reproduction. | Предел прочности: 50–70 МПа; rigid but brittle under impact. | Eco-friendly prototypes (packaging samples); декоративные предметы (вазы, фигурки); образовательные модели (geometric shapes). | ✅ Easy to print (Нет деформации); экологически чистый; ✖️ Low heat resistance (melts at 50–60°C); хрупкий (breaks under heavy stress). |

| Петг (Полиэтилентерефталатный гликоль) | Отличный Погодная сопротивление (withstands UV, дождь, и температурные колебания); low shrinkage rate (2–4%); good water resistance; moderate flexibility. | Предел прочности: 55–75 MPa; more durable than PLA; resists bending and cracking. | Outdoor gear (плантаторы, bike fenders); функциональные части (Телефонные чехлы, бутылки с водой); электрические корпуса (Корпуса датчиков). | ✅ Balances strength and flexibility; Погода; ✖️ Slightly harder to print (needs precise temperature control); sticks tightly to beds. |

| ТПУ (Термопластичный полиуретан) | Крайний эластичность (stretches up to 300% of its original length); good abrasion resistance; мягкий, rubber-like texture. | Предел прочности: 30–60 MPa; highly flexible but less rigid than PLA/ABS. | Носимые устройства (Смотреть группы, фитнес-трекеры); схватки (ручки инструмента, Дистанционное управление); protective parts (Телефонные чехлы, laptop bumpers). | ✅ Flexible and shock-absorbent; ✖️ Slow print speed (prone to stringing); needs heated bed (40–50 ° C.) для адгезии. |

Пример реального мира: A small business wanted to print outdoor planters that would withstand rain and UV rays. PLA planters faded and cracked after 3 месяцы на улице, but PETG planters (with their weather-resistant features) stayed intact for 2 years—proving how material features directly impact performance.

2. Metallic Materials: For High-Strength, Industrial-Grade Parts

Metallic 3D printing materials are reserved for applications where strength, теплостойкость, и долговечность не подлежит обсуждению. They’re more expensive and require specialized printers (СЛМ, ДМЛС), but their features make them irreplaceable in aerospace, Автомобиль, и медицинские отрасли.

Key Features of 3D Printing Metals

| Материал | Core Features | Сила & Теплостойкость | Идеальные приложения | Почему это выделяется |

| Нержавеющая сталь | Отличный коррозионная стойкость (сопротивляется ржавчине и химикатам); Высокотемпературная сила (до 870 ° C.); Хорошая сварка. | Предел прочности: 500–700 МПа; retains strength at high temperatures. | Промышленные детали (клапаны, насос); Морские компоненты (boat hardware); Медицинские инструменты (Хирургические инструменты). | Balances corrosion resistance and strength—perfect for harsh environments (соленая вода, химикаты). |

| Алюминиевый сплав | Легкий вес (плотность: 2.7 g/cm³—1/3 the weight of steel); высокое соотношение прочности к весу; Хорошая теплопроводность. | Предел прочности: 300–500 МПа; lightweight but strong enough for structural use. | Аэрокосмические части (Римские рамки, Самолетные кронштейны); Автомобильные компоненты (Легкие детали двигателя); Электроника (радиаторы). | Reduces weight without sacrificing strength—critical for fuel efficiency in aerospace/automotive. |

| Титановый сплав | Ультра-высокое соотношение прочности к весу; биосовместимый (safe for human body); Отличная коррозионная стойкость; withstands extreme temperatures (-250° C до 600 ° C.). | Предел прочности: 800–1,200 МПа; stronger than steel but 40% зажигалка. | Медицинские имплантаты (Замена колена, зубные короны); аэрокосмические части (турбинные лезвия, rocket components); high-performance sports gear (велосипедные рамы). | Biocompatibility and extreme strength make it the gold standard for medical and aerospace applications. |

Тематическое исследование: A medical device company used titanium alloy to 3D print knee implants. The material’s biocompatibility meant it didn’t trigger immune reactions, and its strength ensured the implants lasted 15+ years—far longer than plastic alternatives. For life-critical parts, metallic materials’ features are non-negotiable.

3. Biomaterials: For Medical and Eco-Conscious Applications

Biomaterials are a specialized category of 3D printing materials designed to interact safely with living organisms or degrade naturally. Their features focus on biocompatibility, biodegradability, and mimicry of human tissues—making them ideal for medical devices and sustainable products.

Key Features of 3D Printing Biomaterials

| Материал | Core Features | Биосовместимость & Degradability | Идеальные приложения | How It Solves Problems |

| Bioactive Glass | Mimics the chemical composition of human bone; promotes tissue regeneration (bonds with bone cells over time); биоразлагаемый (breaks down as new tissue grows). | Fully biocompatible (no immune response); degrades gradually over 6–12 months. | Bone grafts (spinal fusion, fracture repair); зубные имплантаты (tooth root replacements); раненные поправки (releases healing ions). | Eliminates the need for second surgeries to remove implants—biodegrades as the body heals. |

| Hydroxyapatite | Main mineral component of human bone and teeth; отличный Биосовместимость (integrates with surrounding tissue); slow biodegradation (lasts 1–2 years). | Предел прочности: 100–150 МПа; matches bone density. | Dental fillings (natural-looking, биосовместимый); Костные каркасы (supports new bone growth); cosmetic surgery (facial implants). | Reduces rejection risk—body recognizes it as “natural” tissue; no toxic byproducts during degradation. |

Для чаевого: Always verify biomaterials’ certification (НАПРИМЕР., FDA approval for medical use)—not all “bio” labeled materials meet safety standards for human contact.

4. Emerging Materials: Pushing the Boundaries of 3D Printing

New 3D printing materials are constantly being developed, offering innovative features that expand what’s possible. From lightweight composites to conductive plastics, these materials are transforming industries like aerospace, Электроника, and renewable energy.

Key Features of Emerging 3D Printing Materials

| Материал | Core Features | Производительность | Идеальные приложения | Future Potential |

| Carbon Fiber Reinforced Polymers (CFRP) | Combines plastic (Плата, Петг) with carbon fiber; lightweight and ultra-strong (strength-to-weight ratio better than steel); Низкое тепловое расширение (stable at high temps). | Предел прочности: 150–300 МПа; 50% lighter than steel parts. | Аэрокосмические компоненты (Дрон Крылья, satellite parts); racing gear (велосипедные рамы, helmet shells); Промышленные инструменты (heavy-duty clamps). | Will replace metal in more applications as costs drop—critical for electric vehicles (reducing weight = extending range). |

| Проводящие материалы | Embedded with conductive particles (углеродные нанотрубки, серебро); transmits electricity; compatible with 3D printing (no special equipment needed for basic use). | Электрическая проводимость: 1–100 S/m (varies by particle concentration); flexible options available. | Electronic prototypes (датчики, круговые платы); носимые технологии (smart gloves, фитнес-трекеры); антенны (маленький, custom-shaped). | Enables “printed electronics”—devices where circuits are 3D printed directly onto parts, сокращение времени сборки. |

Пример: A startup developing a smart gardening sensor used conductive PETG to print the sensor’s housing. The material transmitted data (moisture levels) without needing separate wires—simplifying design and cutting production costs by 40%. Emerging materials like this blur the line between “part” and “function.”

5. How to Choose the Right 3D Printing Material

With so many materials available, use this step-by-step framework to narrow down your options based on your project’s needs:

Шаг 1: Define Your Project’s Core Requirements

Спросите себя:

- Что будет делать часть? (НАПРИМЕР., hold weight, withstand heat, flex)

- Где это будет использоваться? (НАПРИМЕР., на открытом воздухе, in the human body, on a desk)

- What’s your budget? (пластмассы: \(15- )50/кг; металлы: \(100- )500/кг)

Шаг 2: Match Requirements to Material Features

| Требование | Material Recommendation | Почему это работает |

| Eco-Friendly | Плата | Биоразлагаемый, made from renewable resources. |

| Outdoor Durability | Петг, АБС | Weather-resistant, УФ-стабильный. |

| Высокая сила | Carbon Fiber Reinforced Polymers, Титановый сплав | Ультрапроницаемый, Высокая прочность на растяжение. |

| Medical Use | Титановый сплав, Hydroxyapatite | Биосовместимый, safe for human body. |

| Гибкость | ТПУ | Эластичный, растягивается без лома. |

Шаг 3: Test Before Scaling

Always print a small sample (НАПРИМЕР., a 5cm x 5cm square) to test material features:

- Для силы: Bend or apply pressure to the sample—does it hold up?

- For weather resistance: Leave the sample outside for a week—does it fade or crack?

- For biocompatibility: (Medical use only) Test with cell cultures or consult a certification body.

Перспектива Yigu Technology

В Yigu Technology, we help clients across industries match 3D printing materials to their needs. Для начинающих, we recommend PLA (легко печатать) or PETG (versatile for indoor/outdoor use). Для промышленных клиентов, carbon fiber composites cut weight by 30% против. металл, while titanium alloy meets aerospace/medical standards. Самая большая ошибка, которую мы видим? Overlooking material features like heat resistance—e.g., using PLA for a car’s engine bay part (it melts!). We always guide clients to prioritize performance first: а \(50/kg material that works is cheaper than a \)15/kg material that fails. As new materials emerge, we’ll keep integrating them to help clients innovate faster.

Часто задаваемые вопросы

- Which 3D printing material is best for beginners?

PLA is ideal—it’s easy to print (Нет деформации), доступный (\(15- )30/кг), and forgiving of imperfect settings. You’ll get smooth, detailed prints with minimal effort—perfect for learning the basics.

- Can I use plastic materials for outdoor projects?

Да, but choose PETG or ABS. PETG has better weather resistance (УФ-стабильный, водонепроницаемый) and lower shrinkage than ABS. Avoid PLA—it fades and becomes brittle in sunlight/rain within 3–6 months.

- Are metallic 3D printing materials worth the cost?

Для высокопроизводительных приложений (аэрокосмическая, медицинский), yes—they offer strength and durability no plastic can match. For hobbyists or low-stress parts, plastics are more cost-effective. A titanium medical implant (\(500- )1,000) длится 15+ годы, while a plastic alternative ($50) may need replacement every 2–3 years.