Our Rapid Tooling Services

Need to turn your design ideas into physical prototypes or short-run products fast? Our Rapid Tooling services deliver quick mold making, short lead times, and cost-effective tooling—backed by 3D printing expertise and CNC machining capabilities. From concept validation to fast time-to-market, we turn your vision into reality in weeks, not months.

What Is Rapid Tooling?

Rapid Tooling (also called quick mold making or prototype tooling) is a set of manufacturing techniques designed to speed up tool and mold production for short-run production, rapid manufacturing, and product testing. Unlike traditional tooling— which can take months and cost thousands—it focuses on accelerated tool development, low-cost tooling, and temporary tooling options that still meet quality standards. Key uses include validating designs, testing functional parts, and producing small batches (typically 10–10,000 units) with quick-turnaround molds. Today, additive manufacturing for molds is a game-changer here, cutting lead times by 50–70% compared to conventional methods.

Our Rapid Tooling Capabilities

At Yigu Technology, we combine advanced tech and industry expertise to deliver tooling solutions tailored to your needs. Here’s what sets our services apart:

| Capability | Key Benefits | Typical Lead Time |

| Fast tooling services | Meet tight project deadlines | 2–4 weeks |

| Rapid prototype development | Test designs early to reduce risks | 3–7 days |

| Custom tooling solutions | Match unique part geometries | 1–2 weeks (after design approval) |

| 3D printing expertise | Create complex mold features | 1–3 days |

| CNC machining capabilities | Achieve high precision for functional parts | 5–10 days |

| Material selection for rapid tooling | Choose from aluminum, resins, or composites | Included in 1-day consultation |

| Design for manufacturability (DFM) | Optimize parts to lower costs | Part of pre-production consultation |

| Project consultation | Get expert advice on process and materials | Free (30-minute sessions) |

We prioritize high-quality molds without compromising speed—our clients consistently report 30% faster project completion compared to other suppliers.

The Rapid Tooling Process: Step-by-Step

Our process is streamlined to ensure speed, quality, and flexibility. Each stage is designed to catch issues early and keep projects on track:

- Design review: Our engineers check your CAD files for manufacturability, ensuring your design works with rapid tooling techniques.

- CAD/CAM integration: We convert your design into machine-readable code for 3D printers or CNC machines.

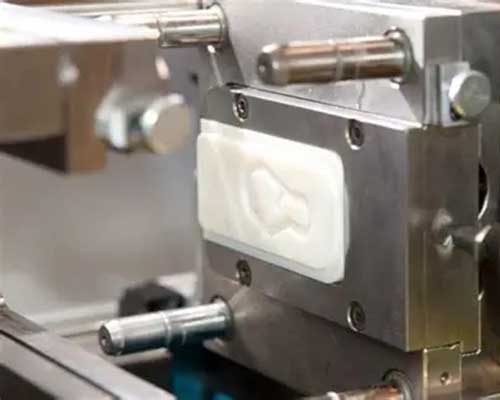

- Mold creation: We use additive manufacturing processes (like SLA or SLS) for complex molds or CNC machining processes for high-strength tools.

- Mold assembly: Parts are assembled and checked for fit—we fix any gaps or misalignments immediately.

- Quality inspection: Every mold undergoes dimensional checks using laser scanners and calipers (see Tolerances section below).

- Tool testing: We produce 5–10 test parts to validate mold performance and part quality.

- Iterative design: If adjustments are needed, we refine the mold quickly (typically 1–2 days for small changes).

- Process validation: Final tests confirm the mold meets your specs before full rapid prototyping cycles or short-run production.

This cycle ensures you get functional, reliable tools in weeks—not months.

Key Materials for Rapid Tooling

Choosing the right material is critical for mold performance and part quality. We offer a range of options to match your project’s needs:

| Material Type | Common Options | Best For |

| Aluminum alloys (e.g., 6061, 7075) | High-strength, good heat dissipation | Short-run plastic injection molding (1,000–10,000 units) |

| Soft tooling materials | Silicone, urethane | Vacuum casting, prototype parts (10–500 units) |

| Composite materials | Carbon fiber-reinforced resins | Lightweight, high-stiffness molds |

| 3D printing resins | SLA resins (rigid, flexible, or heat-resistant) | Complex molds with fine details |

| CNC machinable plastics | PEEK, ABS, nylon | Low-cost, low-volume tooling |

| Tool steel alternatives | Pre-hardened alloys (e.g., STAVAX) | Balancing cost and durability (5,000–15,000 units) |

| Epoxy-based materials | Epoxy resins with fillers | Quick, low-cost molds for non-heat-sensitive parts |

Our team helps you select materials that balance cost, speed, and performance—for example, aluminum is ideal for automotive parts, while silicone works best for medical device prototypes.

Surface Treatment for Rapid Tooling Molds

Surface finish affects both part aesthetics and functionality. We offer fast, effective treatments to meet your needs:

- Quick surface finishing: Polishing or sanding to remove 3D printing layers (1–2 days).

- Texturing for prototypes: Add patterns (e.g., leather, matte) to mimic final product feel.

- Polishing techniques: Achieve glossy finishes (Ra 0.2–0.8 μm) for consumer electronics parts.

- Painting for visualization: Apply color to prototypes for market testing.

- Coating for wear resistance: Ceramic or PTFE coatings to extend mold life (adds 1 day to lead time).

- Surface hardening: For aluminum molds—increase durability by 40% with anodization.

- Functional surface treatments: Anti-stick coatings for plastic parts or corrosion-resistant layers for outdoor use.

All treatments are completed in-house to avoid delays, ensuring your molds are ready when you need them.

Rapid Tooling Tolerances: Precision You Can Trust

Rapid tooling doesn’t mean sacrificing accuracy. We maintain tight tolerances to ensure your parts fit and function as designed:

| Tolerance Type | Typical Range | Measurement Technique |

| Prototype tolerances | ±0.1 mm (for small parts) | Laser scanning, digital calipers |

| Functional fit tolerances | ±0.05 mm (for critical joints) | Coordinate Measuring Machine (CMM) |

| Rapid tooling accuracy | ±0.02 mm/m (for mold dimensions) | Optical comparators |

Our dimensional control processes include 100% inspection of critical mold features. We also offer tolerance optimization—if your part doesn’t need ultra-tight specs, we can relax tolerances to lower costs and speed up production. Common inspection methods include visual checks, pressure testing (for fluid parts), and tensile testing (for structural parts).

Key Advantages of Rapid Tooling

Why choose rapid tooling over traditional methods? Here’s how it adds value to your project:

- Fast turnaround: Get molds in 2–4 weeks vs. 2–6 months for traditional tooling.

- Cost-effective tooling: Save 30–60% on tooling costs for small batches (no need for expensive steel molds).

- Reduced development time: Test designs early, cutting overall product development by 25–40%.

- Early design feedback: Physical prototypes let you spot flaws before full production—lowering rework costs.

- Faster time-to-market: Launch products sooner to beat competitors (critical for consumer electronics or seasonal goods).

Other benefits include design flexibility (easily modify molds) and customization (no minimum order for unique tools).

Rapid Tooling Applications & Industries

Rapid tooling is used across industries to solve unique production challenges:

| Industry | Common Applications |

| Product development | Concept validation, functional testing |

| Medical device | Prototyping surgical tools, implant components (biocompatible materials) |

| Automotive | Testing interior parts (e.g., dashboards), engine components |

| Consumer electronics | Prototyping phone cases, laptop parts (with high-gloss finishes) |

| Industrial design | Creating models for client presentations |

| Packaging | Testing bottle caps, container designs |

| Aerospace | Lightweight prototype parts (using composites) |

| Toy design | Small-batch production of new toy concepts |

For example, we helped an automotive client reduce their part testing time from 3 months to 4 weeks using aluminum rapid tooling—saving them $50,000 in development costs.

Manufacturing Techniques for Rapid Tooling

We use a mix of cutting-edge techniques to create molds quickly and accurately:

| Technique | How It Works | Best For |

| 3D printing for molds (SLA, SLS, FDM) | Builds molds layer-by-layer from resin or plastic | Complex geometries, fine details |

| CNC machining for rapid tooling | Mills blocks of aluminum/plastic into molds | High-strength, high-precision tools |

| Laser cutting | Cuts flat materials (e.g., plastic sheets) for simple molds | Low-cost, 2D/2.5D molds |

| Wire EDM | Uses electrical discharge to cut hard materials | Intricate mold features (e.g., small holes) |

| Vacuum casting | Uses silicone molds to cast plastic parts | Prototype batches (10–500 units) |

| Silicone molding | Creates flexible molds for complex parts | Rubber or plastic prototypes |

We select the technique based on your design, volume, and material needs—for example, SLA 3D printing for a phone case mold or CNC machining for an automotive bracket tool.

Our Rapid Tooling Case Studies

Don’t just take our word for it—here’s how we’ve helped clients succeed:

Case Study 1: Medical Device Prototyping

A client needed 50 prototype surgical retractors to test ergonomics. We used silicone molding (soft tooling material) and delivered parts in 5 days. The client made minor design tweaks, and we produced a second batch in 3 days. Result: They validated the design 8 weeks faster than planned and saved $30,000 in tooling costs.

Case Study 2: Automotive Short-Run Production

An auto parts maker needed 500 custom door handles for a limited-edition model. We used aluminum alloy molds and CNC machining, delivering the handles in 3 weeks. The molds were durable enough for 1,000 units—giving the client room to increase production later. Result: They launched the model 1 month early and met 100% of customer demand.

Case Study 3: Consumer Electronics Design Iteration

A startup wanted to test 3 versions of a wireless earbud case. We used 3D printing resins to create molds for each design, delivering test parts in 4 days. After feedback, we refined the best design and produced 100 final prototypes in 1 week. Result: The startup secured funding by showing physical samples to investors.

Why Choose Yigu Technology for Rapid Tooling?

We’re not just a supplier—we’re your partner in fast, high-quality manufacturing. Here’s what makes us different:

- Expertise in rapid tooling: 10+ years of experience across industries (medical, automotive, electronics).

- Proven track record: 98% of projects are delivered on time, with 95% customer satisfaction.

- Advanced technology: In-house 3D printers (SLA, SLS, FDM), CNC machines, and CMMs for precision.

- Quick response times: We answer quotes within 24 hours and start design reviews in 1–2 days.

- Competitive pricing: Up to 40% lower costs than traditional tooling suppliers.

- Strong R&D focus: We invest in new materials (e.g., bio-based resins) to improve speed and sustainability.

- Customer support: A dedicated engineer manages your project from start to finish—no middlemen.

We tailor every solution to your goals, whether you need a single prototype or 10,000 short-run parts.