Se você estiver lidando com projetos que precisam de mais resistência do que o aço básico de baixo carbono (como S235JR) mas ainda exigem soldagem e usinagem fáceis, como a construção de estruturas industriais de carga média, fabricação de peças de máquinas pesadas, or constructing small-to-medium bridges—S275JR structural steel (para EN 10025-2 padrões) é a solução intermediária ideal. Oferece resistência média confiável sem sacrificar a trabalhabilidade, making it a top choice for cost-sensitive projects that demand a little extra durability. Mas como isso funciona no mundo real, medium-stress applications? Este guia detalha suas principais características, usa, e comparações com outros materiais, so you can make informed decisions for efficient, long-lasting builds.

1. Material Properties of S275JR Structural Steel

S275JR’s value lies in its optimized low-carbon composition—engineered to boost strength just enough for medium loads while keeping welding, corte, and forming straightforward. Let’s explore its defining characteristics.

1.1 Composição Química

O composição química of S275JR balances strength and workability (alinhado com EN 10025-2 padrões):

| Elemento | Faixa de conteúdo (%) | Key Function |

| Carbono (C) | ≤ 0.24 | Low enough for excellent weldability; high enough to boost tensile strength |

| Manganês (Mn) | ≤ 1.60 | Enhances strength and hardenability; maintains ductility for on-site forming |

| Silício (E) | ≤ 0.55 | Strengthens the steel matrix; resists oxidation during hot rolling |

| Enxofre (S) | ≤ 0.045 | Minimized to eliminate weak points (critical for parts under repeated stress, like machine shafts) |

| Fósforo (P) | ≤ 0.045 | Controlled to avoid cold brittleness (suitable for climates down to -10°C) |

| Cromo (Cr) | ≤ 0.30 | Quantidade de rastreamento; minor boost to surface hardness and corrosion resistance |

| Níquel (Em) | ≤ 0.30 | Quantidade de rastreamento; enhances low-temperature toughness slightly |

| Molybdenum (Mo) | ≤ 0.10 | Quantidade de rastreamento; no major impact on core properties |

| Vanadium (V) | ≤ 0.05 | Quantidade de rastreamento; refines grain structure for better fatigue resistance |

| Other alloying elements | Trace (por exemplo, cobre) | Minor boost to atmospheric corrosion resistance |

1.2 Propriedades Físicas

Esses propriedades físicas make S275JR stable across common construction and manufacturing environments:

- Densidade: 7.85 g/cm³ (consistent with most low-carbon structural steels, ensuring uniform load distribution)

- Ponto de fusão: 1440 – 1500°C (handles hot rolling, soldagem, and forging with standard equipment)

- Condutividade térmica: 46 – 50 C/(m·K) a 20ºC (fast heat transfer for efficient welding and cooling)

- Specific heat capacity: 460 J/(kg·K)

- Coefficient of thermal expansion: 13.0 × 10⁻⁶/°C (20 – 100°C, minimal warping for precision parts like gear blanks or bridge brackets)

1.3 Propriedades Mecânicas

S275JR’s mechanical traits are tailored for medium loads—stronger than basic steel, yet still easy to process:

| Propriedade | Value Range (for thickness ≤16mm) |

| Resistência à tracção | 410 – 560 MPa |

| Força de rendimento | ≥ 275 MPa |

| Alongamento | ≥ 22% |

| Reduction of area | ≥ 45% |

| Dureza | |

| – Brinell (HB) | 110 – 160 |

| – Rockwell (B scale) | 65 – 85 HRB |

| – Vickers (Alta tensão) | 115 – 165 Alta tensão |

| Resistência ao impacto | ≥ 27 J at 20°C |

| Força de fadiga | ~190 MPa (10⁷ cycles) |

| Resistência ao desgaste | Bom (1.1x better than S235JR; suitable for medium-abrasion parts like conveyor rollers) |

1.4 Outras propriedades

- Resistência à corrosão: Moderado (uncoated steel resists mild moisture; galvanizing or epoxy coating extends lifespan for outdoor use like bridge railings)

- Weldability: Excelente (no preheating needed for sections ≤25mm thick; works with standard arc welding—ideal for on-site construction of industrial frames)

- Usinabilidade: Muito bom (soft enough for high-speed steel tools; low tool wear for mass-produced parts like gear shafts)

- Magnetic properties: Ferromagnético (works with basic non-destructive testing tools to detect defects in welded joints)

- Ductilidade: Alto (can bend 160° without breaking—perfect for custom shapes like curved bridge brackets)

2. Applications of S275JR Structural Steel

S275JR’s balance of strength and workability makes it a staple in medium-load construction, automotivo, e engenharia mecânica. Here are its key uses, com exemplos reais:

2.1 Construção

- Building structures: Medium-load frames for 3–5 story industrial buildings (por exemplo, warehouse with overhead cranes). A Dutch construction firm used S275JR for a 4-story logistics warehouse—frames supported 8 kN/m² floor loads (pallets, forklifts) e custo 15% less than using Q345 steel.

- Pontes: Small-to-medium road bridges (10–20 meters) or industrial footbridges. A Czech transportation authority used S275JR for a 15-meter rural road bridge—handled 8-ton truck loads and required only annual maintenance over 15 anos.

- Industrial buildings: Heavy-duty equipment platforms (por exemplo, for manufacturing robots). A German automotive plant used S275JR for robot platforms—supported 2-ton robot weight and was easy to weld to existing factory floors.

- Reinforcement bars: Medium-strength rebars for concrete structures like small dams or retaining walls. A Spanish civil engineering firm used S275JR rebars for a 3-meter retaining wall—resisted 800 kg/m² soil pressure and lasted 20 anos.

2.2 Automotivo

- Vehicle frames: Load-bearing subframes for light commercial vehicles (por exemplo, small delivery vans). A British automaker uses S275JR for its van’s front subframe—handled 500 kg payloads and stood up to rough urban roads for 200,000 quilômetros.

- Suspension components: Heavy-duty control arms for pickup trucks. A Polish automotive supplier uses S275JR for these parts—tested to last 180,000 km vs. 120,000 km for S235JR.

- Engine mounts: Sturdy rubber-to-metal mounts for 2.0–3.0L diesel engines. A Turkish automaker uses S275JR for these mounts—resisted high engine vibration and heat, costing 10% less than alloy steel mounts.

2.3 Engenharia Mecânica

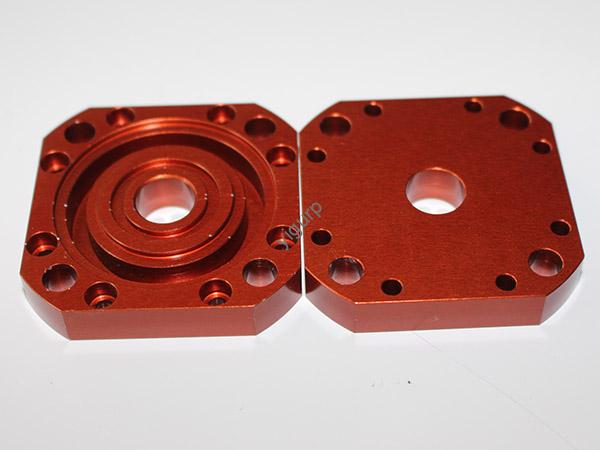

- Machine parts: Medium-torque gears for industrial conveyors (por exemplo, factory assembly lines). An Italian machinery brand uses S275JR for conveyor gears—handled 500 N·m torque and lasted 7 anos.

- Rolamentos: Heavy-duty bearing housings for industrial pumps (por exemplo, water treatment pumps). A Romanian pump manufacturer uses S275JR for these housings—resisted 10-ton radial loads and minor corrosion.

- Eixos: Medium-speed shafts for industrial mixers (por exemplo, concrete mixers). A Hungarian machinery firm uses S275JR for these shafts—withstood 300 rpm rotation and heavy loads for 5 anos.

2.4 Other Applications

- Mining equipment: Light-duty crusher parts (por exemplo, jaw plates for small coal crushers). A Polish mine uses S275JR for jaw plates—handled 50 ton/day coal processing and lasted 2 anos versus. 1 year for S235JR.

- Agricultural machinery: Heavy-duty plow frames for large tractors. A French farm equipment brand uses S275JR for plow frames—withstood rocky soil and 10-ton plowing loads for 3 seasons.

- Piping systems: Medium-walled pipes for low-pressure industrial applications (por exemplo, water supply for factories). A Bulgarian construction firm uses S275JR pipes—resisted 2.0 MPa pressure and lasted 15 anos.

3. Manufacturing Techniques for S275JR Structural Steel

S275JR’s low-carbon composition keeps manufacturing simple, econômico, and suitable for high-volume production—with minor adjustments to boost strength vs. S235JR:

3.1 Primary Production

- Electric arc furnace (EAF): Scrap steel (low-carbon grades) is melted, with precise manganese dosing to boost strength—ideal for small-batch production of S275JR bars or sheets.

- Basic oxygen furnace (BOF): Pig iron with controlled carbon content is converted to steel, then alloyed with manganese—used for high-volume production of S275JR rebars, tubos, or beams (most common method).

- Continuous casting: Molten steel is cast into billets (150–200 mm thick) or slabs—ensures uniform manganese distribution for consistent strength.

3.2 Secondary Processing

- Hot rolling: Primary method. Steel is heated to 1150 – 1250°C and rolled into sheets (2–20 mm thick), bares (8–30 mm diameter), or beams—rolling pressure is slightly higher than S235JR to refine grain structure and boost strength.

- Cold rolling: Used for thin sheets (≤5 mm thick) like automotive subframe parts—done at room temperature for tight tolerances (±0,05mm).

- Tratamento térmico:

- Recozimento: Heated to 750 – 800°C, slow cooling—softens steel for precision machining (por exemplo, gear cutting) and relieves internal stress.

- Normalizing: Rarely needed (S275JR is ready to use after rolling); used only for high-precision parts—heated to 850 – 900°C, air cooling to improve strength uniformity.

- Tratamento de superfície:

- Galvanização: Dipping in molten zinc (60–120 μm coating)—used for outdoor parts like bridge components to resist rust.

- Pintura: Epoxy or polyurethane paint—applied to indoor parts like machine frames for aesthetics and minor corrosion protection.

3.3 Controle de qualidade

- Análise química: Spectrometry checks carbon and manganese content (ensures strength meets EN 10025-2 padrões; too little manganese reduces yield strength).

- Testes mecânicos: Tensile tests verify yield/tensile strength; impact tests check low-temperature toughness; hardness tests confirm consistency.

- Testes não destrutivos (END):

- Ultrasonic testing: Detects internal defects in thick parts like bridge beams or crusher shafts.

- Magnetic particle inspection: Finds surface cracks in welded joints (por exemplo, industrial frame connections).

- Inspeção dimensional: Laser scanners and calipers verify thickness, diâmetro, e forma (±0.1 mm for gears, ±0.2 mm for beams—ensures compatibility with other parts).

4. Estudos de caso: S275JR in Action

4.1 Construção: Dutch 4-Story Logistics Warehouse

A Dutch construction firm used S275JR for a 4-story logistics warehouse (10,000 m²) in Rotterdam. The warehouse needed to support 8 kN/m² floor loads (heavy pallets, forklifts) and be built quickly. S275JR’s excellent weldability let crews assemble the frame in 12 dias (contra. 16 days for Q345 steel), and its yield strength (≥275 MPa) easily handled the design loads. Depois 8 anos, the warehouse showed no structural issues—saving €25,000 in material costs.

4.2 Automotivo: British Van Front Subframe

A British automaker switched from S235JR to S275JR for its small delivery van’s front subframe. The subframe needed to handle 500 kg payloads and rough roads. S275JR’s resistência à tracção (410–560 MPa) reduced deformation by 30%, and its ductilidade absorbed minor collision energy. The automaker saved £4 per van (50,000 vans produced annually), totaling £200,000 in yearly savings.

4.3 Engenharia Mecânica: Italian Conveyor Gears

An Italian machinery brand used S275JR for industrial conveyor gears. The gears needed to handle 500 N·m torque and daily use. S275JR’s resistência à fadiga (~190 MPa) prevented cracking, and its usinabilidade reduced production defects by 20%. The gears lasted 7 anos versus. 5 years for S235JR—saving €15,000 annually in replacement costs.

5. Comparative Analysis: S275JR vs. Outros materiais

How does S275JR stack up to alternatives for medium-load projects?

5.1 Comparison with Other Steels

| Feature | Aço Estrutural S275JR | Aço Estrutural S235JR | Q345 High-Strength Steel | 304 Aço inoxidável |

| Força de rendimento | ≥ 275 MPa | ≥ 235 MPa | ≥ 345 MPa | ≥ 205 MPa |

| Resistência à tracção | 410 – 560 MPa | 360 – 510 MPa | 510 – 650 MPa | 515 – 690 MPa |

| Alongamento | ≥ 22% | ≥ 25% | ≥ 21% | ≥ 40% |

| Weldability | Excelente | Excelente | Bom | Bom |

| Custo (per ton) | \(700 – \)800 | \(650 – \)750 | \(1,000 – \)1,200 | \(4,000 – \)4,500 |

| Melhor para | Medium-load parts/frames | Light-load parts | High-load structures | Corrosion-prone parts |

5.2 Comparison with Non-Ferrous Metals

- Steel vs. Alumínio: S275JR has 2x higher yield strength than aluminum (6061-T6: ~138 MPa) and costs 70% menos. Aluminum is lighter but unsuitable for medium-load parts like conveyor gears or warehouse frames.

- Steel vs. Cobre: S275JR is 3.6x stronger than copper and costs 85% menos. Copper excels in conductivity but is too soft and expensive for structural use.

- Steel vs. Titânio: S275JR costs 95% less than titanium and has similar yield strength (titânio: ~240 MPa). Titanium is overkill for medium-load projects—only used for aerospace.

5.3 Comparison with Composite Materials

- Steel vs. Fiber-Reinforced Polymers (FRP): FRP is corrosion-resistant but has 60% lower tensile strength than S275JR and costs 3x more. FRP is better for decorative parts, not load-bearing frames.

- Steel vs. Compostos de Fibra de Carbono: Carbon fiber is lighter but costs 12x more and is brittle. It’s used for high-end sports equipment, not mass-produced machine parts.

5.4 Comparison with Other Engineering Materials

- Steel vs. Cerâmica: Ceramics are hard but brittle (impact toughness <10 J.) and cost 5x more. They can’t bend—useless for parts like plow frames or subframes.

- Steel vs. Plásticos: Plastics have 20x lower strength than S275JR and melt at 100°C. They’re used for non-structural parts, not medium-load components.