In the world of precision manufacturing, creating high-quality Teflon prototype parts demands a perfect match between material characteristics and advanced machining technology. Entre os vários métodos disponíveis, CNC Swiss machining stands out for its ability to deliver exceptional accuracy and consistency—even when working with challenging materials like Politetrafluoretileno (PTFE). Este artigo detalha todo o processo, from understanding Teflon’s unique properties to implementing strict quality control, helping you overcome common hurdles and produce top-tier Teflon prototypes.

1. Understanding Teflon (PTFE): Key Material Properties for Machining

Before diving into the machining process, it’s critical to grasp how Teflon’s properties influence every step. Ao contrário dos metais, PTFE has distinct traits that require specialized handling—ignore them, and you risk flawed prototypes, material desperdiçado, or damaged equipment.

| Material Property | Description | Impact on Machining |

| Chemical Resistance | Resistant to almost all acids, bases, and solvents | Eliminates corrosion risks but limits coolant options (must use compatible, non-reactive fluids) |

| Thermal Stability | Maintains properties between -200°C and 260°C (-328°F to 500°F) | Reduces thermal deformation during machining but requires tools that avoid excessive friction (which can cause local overheating) |

| Usinabilidade | Soft, ductile, and prone to “gumming” or melting under pressure | Demands sharp, low-friction cutting tools and optimized cutting parameters to prevent material buildup |

| Low Coefficient of Friction | One of the lowest friction coefficients of any solid material | Increases risk of part slippage during clamping—requires specialized workholding solutions |

A common question here is: Why is Teflon harder to machine than metals? The answer lies in its softness and ductility. While metals chip cleanly during cutting, Teflon tends to stretch or melt, making it difficult to achieve tight tolerances without tailored strategies.

2. Swiss Machine Technology: Why It’s Ideal for Teflon Prototypes

Swiss machine (ou Swiss-type lathe) technology is designed for precision—making it the perfect choice for Teflon prototypes that require tight dimensional control. Let’s break down the core features that make it a game-changer:

- Automatic Bar Feeding: Feeds long lengths of Teflon bar stock continuously, reducing manual intervention and ensuring consistent part-to-part accuracy. This is critical for prototypes, where small variations can render parts unusable.

- Live Tooling: Integrates rotating tools (por exemplo, exercícios, moinhos) directly into the lathe, allowing for complex operations (por exemplo, buracos, slots) in a single setup. For Teflon prototypes with intricate designs, this eliminates the need for multiple machines—reducing error and saving time.

- Guide Bushing System: Supports the bar stock close to the cutting area, minimizing deflection. Since Teflon is soft, deflection is a major risk; the guide bushing keeps the material stable, ensuring precise cuts.

- High-Speed CNC Controls: Enables precise adjustment of cutting parameters (por exemplo, spindle speed, feed rate) in real time—essential for adapting to Teflon’s unique machinability.

Resumidamente, Swiss-type lathe technology addresses Teflon’s biggest machining challenges: slippage, deflection, and inconsistent cuts. No other machining method combines stability and precision quite like it.

3. Step-by-Step Machining Process for Teflon Prototype Parts

Creating Teflon prototypes with a Swiss machine follows a linear, step-by-step process—each stage builds on the last to ensure quality. Below is a detailed breakdown, with a focus on solving common pain points:

Step 1: Part Design & Preparation

Start with a clear part design (using CAD software like SolidWorks or AutoCAD) that accounts for Teflon’s properties. Key considerations:

- Avoid sharp internal corners (Teflon can crack under stress here).

- Specify realistic tolerances (aim for ±0.01mm for most prototypes—tighter tolerances may be possible but increase cost).

- Include details for workholding (por exemplo, extra material for clamping to prevent slippage).

Step 2: Tool Selection

Choosing the right ferramentas de corte is make-or-break for Teflon machining. Ao contrário dos metais, Teflon requires tools that minimize friction and prevent melting:

| Tool Type | Recommended Material | Key Advantage |

| Turning Tools | Carbide (coated with diamond or TiAlN) | Low friction; resiste ao desgaste |

| Milling Tools | Solid carbide (4-flute) | Prevents material “gumming” |

| Drills | Carbide (with polished flutes) | Reduces chip buildup |

Pro Tip: Avoid high-speed steel (HSS) tools—they generate too much friction, leading to Teflon melting and tool wear.

Step 3: Setting Cutting Parameters

Optimizing cutting parameters (spindle speed, feed rate, depth of cut) is critical to achieving smooth acabamento superficial e tolerâncias apertadas. Below are recommended starting points for Teflon (adjust based on part complexity):

| Parameter | Recommendation | Rationale |

| Spindle Speed | 3,000–6,000 RPM | High speed reduces time in cut (minimizing heat buildup) |

| Feed Rate | 0.05–0.15 mm/rev | Slow feed prevents material stretching; fast enough to avoid gumming |

| Depth of Cut | 0.1–0.5 mm | Shallow cuts reduce deflection; deeper cuts risk tool chatter |

Step 4: Machining Execution

Load the Teflon bar stock into the Swiss machine’s automatic bar feeder, secure it with a specialized workholding (por exemplo, a soft-jaw chuck to avoid damaging the material), and start the CNC program. Monitor the first few parts closely to:

- Check for material buildup on tools (clean tools if needed).

- Verify dimensional accuracy (use calipers or micrometers).

- Ensure surface finish is smooth (no melting or burring).

4. Ensuring Quality: Control & Inspection for Teflon Prototypes

Para Teflon prototypes, quality control isn’t just a final step—it’s integrated throughout the process. The goal is to catch issues early and ensure parts meet precisão dimensional e tolerance control requirements.

Key Inspection Methods

- Dimensional Inspection: Use tools like:

- Digital calipers (for quick measurements of length/diameter).

- Coordinate Measuring Machines (CMMs) (for complex geometries—ensures accuracy within ±0.005mm).

- Surface Roughness Testing: Use a profilometer to measure surface roughness (Rá). Teflon prototypes typically require Ra values between 0.8–3.2 μm (smoother for parts requiring low friction).

- Non-Destructive Testing (NDT): For critical prototypes (por exemplo, those used in medical or aerospace), use ultrasonic testing to detect internal defects (por exemplo, rachaduras) without damaging the part.

Quality Control Checklist

- Part dimensions match CAD design (tolerance ±0.01mm).

- Surface finish is smooth (no melting, burring, or scratches).

- No internal defects (verified via NDT if required).

- Part functions as intended (por exemplo, combina com outros componentes).

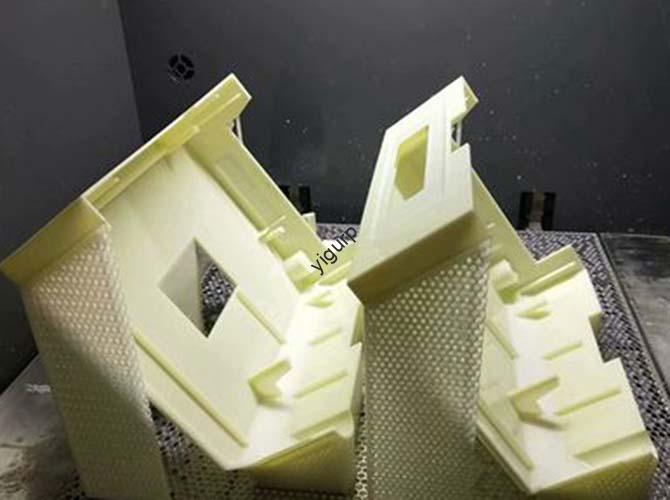

5. Yigu Technology’s Perspective on Teflon Prototype Machining

Na tecnologia Yigu, we’ve refined CNC Swiss machining for Teflon prototypes by focusing on material-machine synergy. Teflon’s low rigidity demands not just sharp tools but adaptive CNC programs—our engineers tweak feed rates in real time to avoid gumming, using diamond-coated carbide tools for consistent finishes. For prototypes, we prioritize rapid iteration: our Swiss machines with live tooling cut lead times by 30% contra. traditional methods, while our CMM-driven inspection ensures each part meets tolerances. The biggest lesson? Success lies in respecting Teflon’s uniqueness—don’t treat it like metal, and you’ll unlock its full potential.

Perguntas frequentes

1. Can Swiss machines produce Teflon prototypes with tolerances tighter than ±0.01mm?

Sim, but it depends on part complexity. For simple geometries (por exemplo, small shafts), tolerances as tight as ±0.005mm are possible with advanced Swiss machines and specialized tooling. For complex parts (por exemplo, with multiple holes), ±0.01mm is more realistic to avoid deflection.

2. What’s the biggest mistake to avoid when machining Teflon prototypes with a Swiss machine?

Using the wrong cutting tools. Many manufacturers use HSS tools (common for metals), but they generate too much friction—causing Teflon to melt and gum up the tool. Always use diamond or TiAlN-coated carbide tools.

3. How long does it take to produce a Teflon prototype with a Swiss machine?

For simple parts (por exemplo, a 20mm-long pin), lead time is 1–2 days (including design, setup, and machining). For complex parts (por exemplo, with multiple slots and holes), lead time is 3–5 days—thanks to live tooling that eliminates multiple setups.