Nossos serviços de usinagem CNC de politetrafluoretileno PTFE Teflon

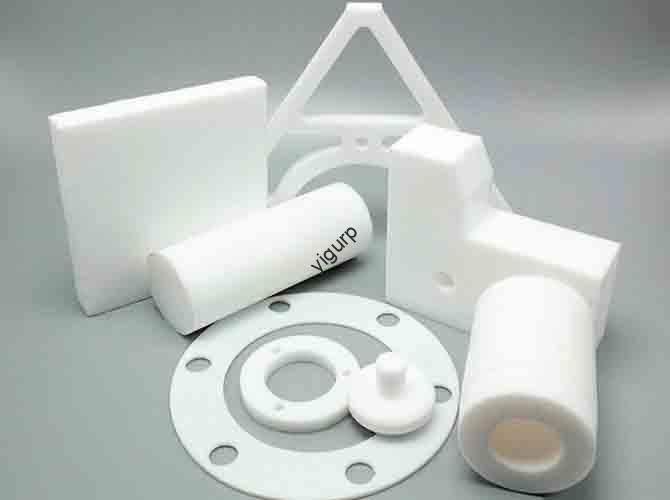

Na tecnologia Yigu, somos especializados em alta precisão Politetrafluoretileno (PTFE) Usinagem CNC de Teflon-entrega personalizada, peças de tolerância restrita que aproveitam as propriedades excepcionais deste plástico de alto desempenho. Seja para a indústria aeroespacial, médico, ou necessidades industriais, nossa equipe de especialistas combina recursos avançados Fresagem CNC e Torneamento CNC com rigoroso controle de qualidade para transformar seus projetos em confiáveis, componentes econômicos.

Noções básicas sobre PTFE Teflon e usinagem CNC

Politetrafluoretileno (PTFE), comumente conhecido pela marca Teflon, é um versátil fluoropolímero comemorado como um dos melhores polímero de engenharia. Seu perfil de material exclusivo – incluindo resistência química, baixo atrito, e estabilidade térmica – o torna ideal para aplicações exigentes.

Usinagem CNC (Usinagem de controle numérico computadorizado) é um automatizado processo de usinagem que usa software pré-programado para controlar ferramentas como moinhos, tornos, e exercícios. Quando emparelhado com PTFE, esta tecnologia garante consistência, modelagem precisa do material, mesmo para geometrias complexas. Abaixo está uma análise dos principais propriedades dos materiais de PTFE que impulsionam seu uso em usinagem CNC:

| Propriedade material | Descrição | Valor típico |

| Resistência Química | Resiste a quase todos os produtos químicos e solventes industriais | Não afetado por 99% de produtos químicos comuns |

| Estabilidade Térmica | Opera de forma confiável em temperaturas extremas | -200°C a +260°C (-328°F a +500°F) |

| Coeficiente de Atrito | Um dos mais baixos entre os materiais sólidos | 0.04 (estático) / 0.02 (dinâmico) |

| Isolamento Elétrico | Excelente isolante em todas as frequências | Resistividade de volume: 10¹⁸Ω·cm |

Nossas capacidades: Fornecendo precisão em que você pode confiar

Na tecnologia Yigu, nosso Usinagem CNC de Teflon PTFE os recursos são adaptados para atender às diversas necessidades do setor. Não fabricamos apenas peças – resolvemos desafios de engenharia com foco na qualidade e na eficiência. Aqui está uma visão detalhada do que oferecemos:

| Capacidade | Principais recursos | Aplicativos |

| Usinagem de Precisão | Conquistas tolerâncias apertadas (até ±0,001 polegadas) e consistente precisão dimensional | Componentes aeroespaciais, peças para dispositivos médicos |

| Peças usinadas personalizadas | Funciona com designs exclusivos, desde arruelas simples até caixas complexas | Equipamento industrial, gabinetes eletrônicos |

| Usinagem de alta tolerância | Cumpre com padrões de tolerância (por exemplo, ISO 8062) e usa recursos avançados técnicas de medição | Sensores automotivos, peças de processamento farmacêutico |

| Produção de peças complexas | Lida com geometrias complexas por meio de máquinas CNC multieixos | Componentes de robótica, válvulas de processamento químico |

| Prototipagem Rápida | Entrega protótipos funcionais em 3 a 5 dias úteis | Desenvolvimento de produto, validação de projeto |

| Usinagem de Produção | Balanças de pequenos lotes (10–50 peças) para corridas de alto volume (10,000+ peças) | Ferramentas industriais produzidas em massa, peças de eletrônicos de consumo |

| Garantia de qualidade | Implementos métodos de inspeção como CMM (Máquina de medição por coordenadas) e verificações visuais | Todas as indústrias, especialmente médico e aeroespacial |

Processo: Usinagem CNC PTFE passo a passo

Nosso Usinagem CNC de Teflon PTFE o processo é projetado para maximizar a precisão, minimizar o desperdício, e garantir a entrega no prazo. Cada etapa é otimizada para as características únicas do PTFE (por exemplo, baixa rigidez, alta expansão térmica):

- Projeto & Programação: Nossos engenheiros revisam seus modelos 3D (Arquivos CAD) para criar caminhos de ferramenta para Fresagem CNC ou Torneamento CNC. Nós selecionamos o certo técnicas de corte para evitar a deformação do material.

- Preparação de Materiais: Fornecemos produtos de alta qualidade Resina PTFE ou notas preenchidas (por exemplo, PTFE com enchimento de vidro) e corte-os em espaços em branco que caibam em nossas máquinas.

- Configuração da máquina: Técnicos calibram máquinas CNC, instalar ferramentas especializadas (por exemplo, fresas de topo de metal duro para PTFE), e configurar acessórios para proteger o material. Apropriado seleção de ferramentas e configuração da máquina evitar vibração, o que pode arruinar a precisão.

- Operações de Usinagem: Executamos processos essenciais como operações de perfuração (para buracos) e processos de moagem (para superfícies lisas). Nossas máquinas funcionam 24/7 para pedidos de alto volume, com monitoramento em tempo real para detectar problemas antecipadamente.

- Tratamento de superfície: Depois da usinagem, peças sofrem polimento (para um acabamento suave) ou revestimento (para proteção adicional). Para necessidades de ligação, nós usamos colagem adesiva técnicas testadas para compatibilidade com PTFE.

Inspeção & Controle de qualidade: Cada peça é verificada usando ferramentas como micrômetros e CMMs para verificar precisão dimensional e adesão a padrões de tolerância. Somente peças que passam 100% mudança de inspeção para embalagem.

Materiais: Escolhendo o grau correto de PTFE

Nem todos os PTFE são iguais – diferentes graus são formulados para melhorar propriedades específicas. Na tecnologia Yigu, oferecemos uma variedade de materiais para atender às necessidades da sua aplicação:

| Grau PTFE | Aditivos Chave | Propriedades aprimoradas | Aplicações ideais |

| PTFE virgem | Nenhum | Resistência química pura, propriedades antiaderentes | Equipamento de processamento de alimentos, tanques químicos |

| PTFE preenchido com vidro | Fibras de vidro (10–40%) | Maior rigidez, fluência reduzida | Rolamentos, sedes de válvula, suportes aeroespaciais |

| PTFE preenchido com carbono | Partículas de carbono (10–30%) | Melhor resistência ao desgaste, condutividade elétrica | Contatos elétricos, engrenagens industriais |

| PTFE com preenchimento de bronze | Partículas de bronze (20–60%) | Alta capacidade de carga, condutividade térmica | Pistões, selos hidráulicos, peças automotivas |

| Classes especiais de PTFE | Cerâmica, grafite, ou óxidos metálicos | Propriedades personalizadas (por exemplo, Resistência UV, baixa liberação de gases) | Aplicações espaciais, implantes médicos |

Tratamento de superfície: Melhorando o desempenho das peças de PTFE

Embora as propriedades naturais do PTFE sejam impressionantes, tratamento de superfície pode elevar sua funcionalidade para usos específicos. Nossos tratamentos são adaptados para melhorar a adesão, durabilidade, ou estética:

- Polimento: Cria um suave, superfície brilhante que reduz o atrito e evita o acúmulo de detritos. Usado para peças como rolamentos e componentes deslizantes.

- Revestimento: Aplica camadas finas (por exemplo, PFA ou FEP) para aumentar a resistência química ou adicionar cor. Comum no processamento de alimentos e dispositivos médicos.

- Pintura: Usos especializados, Tintas compatíveis com PTFE para marcas ou proteção contra corrosão. Ideal para ferramentas industriais e peças voltadas para o consumidor.

- Jateamento de areia: Cria um fosco, superfície texturizada que melhora a aderência ou adesão para colagem. Usado em montagens automotivas e aeroespaciais.

- Tratamento térmico: Submete as peças a aquecimento/resfriamento controlado para reduzir o estresse interno e melhorar estabilidade dimensional. Crítico para aplicações de alta temperatura.

Colagem adesiva: Pré-trata superfícies (por exemplo, com plasma) para permitir uma ligação forte a metais ou outros plásticos. Essencial para componentes multimateriais.

Tolerâncias: Alcançando precisão na usinagem de PTFE

A baixa rigidez e expansão térmica do PTFE tornam tolerâncias apertadas um desafio, mas nossa experiência garante precisão consistente. Abaixo está um detalhamento de nossas tolerâncias típicas e os métodos que usamos para mantê-las:

| Tipo de tolerância | Faixa típica | Técnica de medição | Caso de uso da indústria |

| Tolerâncias de precisão | ±0,001 a ±0,005 polegadas | CMM (Máquina de medição por coordenadas) | Componentes de dispositivos médicos (por exemplo, cateteres) |

| Tolerâncias rigorosas | ±0,005 a ±0,010 polegadas | Micrômetros, pinças | Fixadores aeroespaciais, conectores eletrônicos |

| Tolerâncias Gerais | ±0,010 a ±0,020 polegadas | Inspeção visual, medidores | Arruelas industriais, espaçadores não críticos |

Seguimos globalmente padrões de tolerância (por exemplo, ANSI/ASME Y14.5M) e usar controle estatístico de processo (CEP) para garantir que cada lote atenda às suas necessidades.

Vantagens: Por que escolher a usinagem CNC PTFE Teflon?

Usinagem CNC de Teflon PTFE oferece benefícios incomparáveis para indústrias que exigem confiabilidade e desempenho. Veja como isso se destaca:

- Resistência Química: PTFE resiste a ácidos, bases, e solventes, tornando-o ideal para processamento químico e equipamentos de laboratório.

- Estabilidade Térmica: Funciona em temperaturas extremas (-200°C a +260°C) sem degradar, perfeito para peças aeroespaciais e automotivas sob o capô.

- Baixo coeficiente de atrito: Sua superfície antiaderente reduz o desgaste e a perda de energia, usado em rolamentos e correias transportadoras.

- Isolamento Elétrico: Excelente para componentes eletrônicos (por exemplo, placas de circuito) pois não conduz eletricidade.

- Propriedades antiaderentes: Evita o acúmulo de materiais em equipamentos de processamento de alimentos (por exemplo, formas para assar) e dispositivos médicos.

- Estabilidade Dimensional: Com usinagem adequada, As peças de PTFE mantêm a forma mesmo sob estresse, crítico para ferramentas de precisão.

Produção econômica: A automação CNC reduz desperdícios e custos de mão de obra, especialmente para pedidos de alto volume.

Indústria de aplicações: Onde as peças CNC de PTFE brilham

Nosso PTFE Teflon usinado CNC peças são usadas em 8 indústrias-chave, cada um aproveitando as propriedades exclusivas do PTFE:

| Indústria | Aplicações Comuns | Principais benefícios do PTFE usados |

| Automotivo | Juntas, caixas de sensores, componentes do sistema de combustível | Resistência química, estabilidade térmica |

| Aeroespacial | Assentos de válvula, isolamento de fio, peças do motor | Desempenho em alta temperatura, baixa liberação de gases |

| Eletrônica | Isoladores de placa de circuito, caixas de conectores | Isolamento elétrico, estabilidade dimensional |

| Médico | Dicas de cateter, componentes de instrumentos cirúrgicos | Biocompatibilidade, resistência química |

| Equipamentos Industriais | Rolamentos, selos da bomba, peças de correia transportadora | Baixo atrito, resistência ao desgaste |

| Processamento Químico | Forros de tanque, componentes da válvula, tubulação | Resistência química, proteção contra corrosão |

| Processamento de Alimentos | Formas para assar, correias transportadoras, peças do misturador | Propriedades antiaderentes, conformidade de segurança alimentar |

| Farmacêutico | Peças de equipamentos de processamento, componentes de entrega de medicamentos | Esterilização, resistência química |

Estudos de caso: Sucesso no mundo real com a tecnologia Yigu

Estudo de caso 1: Componentes de válvulas aeroespaciais

- Desafio: Precisava-se de um cliente aeroespacial líder sedes de válvula em PTFE de alta tolerância que poderia suportar temperaturas de 250°C e exposição a combustível.

- Solução: Nós usamos PTFE preenchido com carbono e Torneamento CNC para atingir tolerâncias de ±0,002 polegadas. Adicionamos uma etapa de tratamento térmico para reduzir o estresse.

- Resultado: 100% de peças passaram na inspeção, e o cliente relatou zero falhas em 2 anos de uso. O prazo de entrega foi reduzido em 30% em comparação com seu fornecedor anterior.

Estudo de caso 2: Dicas sobre cateteres médicos

- Desafio: É necessária uma empresa de dispositivos médicos pontas de cateter de PTFE usinadas personalizadas com acabamento liso para evitar irritação dos tecidos.

- Solução: Usamos PTFE virgem e Fresagem CNC com uma etapa de polimento. Implementamos inspeções CMM para garantir uma tolerância de ±0,001 polegada.

- Resultado: As dicas atenderam aos padrões de biocompatibilidade da FDA, e o cliente escalou a produção a partir de 500 para 10,000 peças/mês com qualidade consistente.

Estudo de caso 3: Selos de bombas industriais

- Desafio: Precisava-se de um cliente industrial vedações de bomba em PTFE com preenchimento de bronze para lidar com fluidos abrasivos e alta pressão.

- Solução: Nós selecionamos 40% PTFE preenchido com bronze para resistência ao desgaste e usado operações de perfuração para criar furos precisos para instalação.

Resultado: As vedações duraram 5x mais do que as alternativas de borracha, reduzindo os custos de manutenção do cliente, 40%.

Por que nos escolher: A vantagem da tecnologia Yigu em usinagem CNC de PTFE

Quando você faz parceria com a Yigu Technology para Usinagem CNC de Teflon PTFE, você obtém mais do que apenas peças: você obtém um aliado de engenharia confiável. Veja por que os clientes nos escolhem:

- Especialização em Usinagem de PTFE: Nossa equipe tem 15+ anos de experiência trabalhando com PTFE e seus graus preenchidos, entender como superar seus desafios únicos de usinagem.

- Produtos de alta qualidade: Usamos apenas premium Resina PTFE e seguir rigorosos processos de controle de qualidade (ISO 9001 certificado) para garantir que cada peça atenda às suas especificações.

- Maquinistas experientes: Nossos técnicos são treinados nos mais recentes equipamentos CNC e passam por aprimoramento regular para lidar com projetos complexos.

- Excelente atendimento ao cliente: Atribuímos um gerente de conta dedicado para cada projeto, fornecendo atualizações regulares e respondendo a perguntas prontamente.

- Tempos de resposta rápidos: Nosso 24/7 as operações de usinagem nos permitem entregar protótipos em 3 a 5 dias e a produção em 1 a 2 semanas.

- Preços competitivos: Otimizamos nossos processos para reduzir desperdícios, repassando economias para você sem comprometer a qualidade.

Compromisso com a Inovação: Investimos em novas tecnologias (por exemplo, 5-máquinas CNC de eixo) para expandir nossas capacidades e oferecer melhores soluções.