No mundo acelerado da manufatura, encontrar um método de processamento que equilibre a precisão, qualidade, e eficiência é um desafio constante. O processo de corte a laser has emerged as a solution, abordando pontos problemáticos, como precisão inconsistente das peças, pós-processamento demorado, e desperdício de materiais. Este artigo se aprofunda nas principais vantagens do corte a laser, backed by real data and industry examples, to help you decide if it’s the right fit for your production needs.

1. Unmatched High Precision: Meeting the Strictest Design Specifications

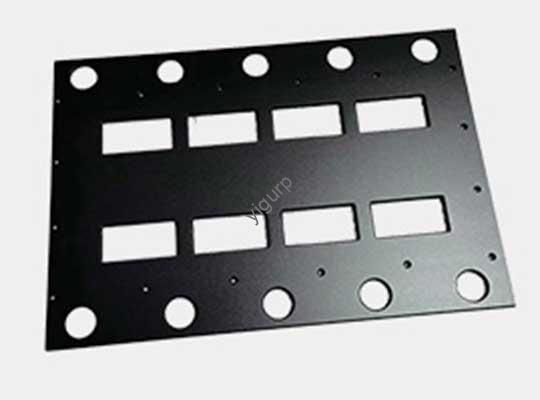

For manufacturers working on complex parts—from aerospace components to electronic enclosures—precision is non-negotiable. Traditional cutting methods (like plasma or waterjet cutting) often fall short, leading to parts that don’t align with design blueprints and require costly reworks.

O processo de corte a laser solves this with exceptional precision, thanks to its focused, high-energy laser beam. Key metrics include:

- Positioning accuracy: Up to 0.05milímetros—equivalent to the thickness of a human hair.

- Repeated positioning accuracy: Up to 0.02milímetros—ensuring every part in a batch is identical.

This level of precision lets manufacturers produce intricate, detailed parts that adhere strictly to design specs. Por exemplo:

A medical device company uses laser cutting to create tiny, complex holes (0.1mm in diameter) in surgical instruments. Before switching to laser cutting, they relied on mechanical drilling, which had a positioning error of 0.2mm—causing 15% of instruments to fail quality checks. With laser cutting, their failure rate dropped to just 2%, saving $50,000 annually in rework costs.

Another example: An automotive supplier uses laser cutting to make custom gaskets for engine components. The 0.02mm repeated accuracy ensures each gasket fits perfectly, reducing engine leaks by 40% compared to gaskets made with traditional die-cutting.

2. Excellent Cutting Quality: Minimizing Post-Processing Work

Post-processing—like deburring, polishing, or trimming—adds time and cost to production. Traditional cutting methods often leave rough edges, rebarbas, or uneven cuts, forcing teams to spend hours refining parts.

O processo de corte a laser delivers top-tier quality, minimizing or even eliminating post-processing. Here’s how:

- Narrow cut width: Typically between 0.10–0.20mm (also called the “kerf width”). This thin cut means less material is wasted and parts have sharp, clean edges.

- Smooth cutting surface: No burrs, and surface roughness controlled within Ra12.5μm—so smooth that parts can often be used directly without polishing.

A furniture manufacturer specializing in metal frames is a perfect example. They used to spend 2 hours per batch of frames deburring edges after using plasma cutting. After switching to laser cutting, the smooth surfaces required just 10 minutes of light cleaning per batch—freeing up 110 hours of labor monthly to focus on other tasks.

A study by the Fabricators & Associação de Fabricantes (FMA) found that manufacturers using laser cutting reduce post-processing time by an average of 65% compared to traditional methods.

3. Impressive High Efficiency: Speeding Up Production Cycles

In today’s competitive market, slow production cycles can mean missing deadlines and losing customers. Traditional cutting methods are often limited by speed, especially when working with thick or hard materials.

O processo de corte a laser boosts efficiency with its fast, automated operation—powered by multi-axis CNC systems that control the laser beam with precision. Cutting speeds vary by material, but even for tough metals, the numbers are impressive:

| Material Type | Laser Cutting Speed | Traditional Plasma Cutting Speed | Speed Improvement |

| Carbon Steel (10milímetros) | Up to 1.6m/min | Up to 0.8m/min | 100% |

| Aço inoxidável (5milímetros) | Up to 3.5m/min | Up to 1.2m/min | 192% |

| Alumínio (3milímetros) | Up to 2.8m/min | Up to 0.9m/min | 211% |

A metal fabrication shop in Texas saw the benefits firsthand. They used to cut 50 carbon steel sheets (10mm thick) per day with plasma cutting, taking 8 horas. With laser cutting, they now cut 120 sheets in the same time—doubling their daily output and allowing them to take on 3 new clients.

Another example: A signage company uses laser cutting to produce custom metal signs. The fast speed lets them turn around orders in 1–2 days, compared to 3–5 days with waterjet cutting. This faster turnaround increased their customer retention rate by 25%.

4. Minimal Material Deformation: Protecting Heat-Sensitive Materials

Heat-sensitive materials (like aluminum, thin steel, or plastic) are easily warped or damaged by traditional cutting methods, which generate large heat-affected areas (HAAs). Warped parts are unusable, leading to material waste and lost time.

O processo de corte a laser uses a non-contact method with a small heat-affected area—meaning the material around the cut stays cool and stable. This minimal heat input reduces deformation to almost zero, tornando-o ideal para:

- Thin materials (as thin as 0.1mm).

- Heat-sensitive metals (like aluminum or brass).

- Parts requiring tight dimensional tolerances.

A electronics manufacturer uses laser cutting to cut thin aluminum sheets for smartphone casings. With traditional shearing, 8% of casings warped due to heat, leading to \(12,000 in material waste monthly. Laser cutting reduced warpage to 0.5%, cutting waste costs by \)11,400.

A aerospace supplier also benefits: They use laser cutting to make thin titanium parts for aircraft engines. The minimal deformation ensures the parts meet strict aerospace standards (ISO 9001), with zero rejects in the last 6 months.

5. Great Flexibility: Cutting Complex Patterns with Ease

Traditional cutting methods often require custom dies, moldes, or tooling for complex patterns—costly and time-consuming to create, especially for small batches or one-off projects. This inflexibility limits design creativity and slows down prototyping.

O processo de corte a laser offers unmatched flexibility, thanks to its non-contact nature and CNC control. Key benefits include:

- No need for custom tooling: The laser beam is controlled by software, so changing patterns takes just minutes (by updating the design file).

- Ability to cut complex shapes: Intricate patterns, curves, buracos, and notches—even those with tight angles or fine details—are easy to achieve.

- Compatibility with multiple materials: Works on metals (aço, alumínio, latão), plásticos, madeira, and even glass.

A jewelry designer uses laser cutting to create custom metal pendants with intricate floral patterns. Before laser cutting, they used hand engraving, which took 4 hours per pendant. With laser cutting, they can produce 10 pendants in the same time, and switch between patterns in 5 minutos. This flexibility let them launch a “custom pendant” line that now makes up 30% of their revenue.

A prototyping shop also relies on laser cutting’s flexibility. They create custom plastic prototypes for startups, often changing designs 2–3 times per project. Without laser cutting, they’d need to make new dies for each design—adding \(500–\)1,000 per prototype. Laser cutting eliminates this cost, making prototyping more affordable for small businesses.

6. Strong Environmental Protection: Creating a Safe, Clean Workplace

Manufacturing processes that generate harmful waste or fumes pose risks to workers’ health and lead to costly environmental compliance issues. Traditional cutting methods (like plasma cutting) produce smoke, dust, and metal slag, requiring expensive ventilation systems and safety gear.

O processo de corte a laser is a clean, eco-friendly option:

- No chemical changes: Unlike some etching processes, laser cutting doesn’t use toxic chemicals, so there’s no chemical waste to dispose of.

- Minimal waste: The narrow cut width (0.10–0.20mm) reduces material waste by up to 30% compared to plasma cutting.

- Low emissions: Modern laser cutting machines are equipped with built-in exhaust systems that capture most fumes, improving air quality in the workplace.

A contract manufacturer in California switched to laser cutting to meet strict environmental regulations. Previously, their plasma cutting operations generated 50kg of metal slag monthly, which required special disposal ($200 per month). Laser cutting reduced slag to 5kg monthly, cutting disposal costs by 90%. Additionally, worker complaints about fumes dropped by 70%, improving morale and reducing sick days.

Yigu Technology’s Perspective on the Advantages of Laser Cutting Process

Na tecnologia Yigu, we see laser cutting as a cornerstone of modern manufacturing. Its high precision solves our clients’ biggest pain point—consistent part quality—while its efficiency cuts production time by up to 50%. We’ve helped automotive clients reduce rework costs by 40% using laser cutting’s accuracy, and signage clients double output with its fast speeds. We also prioritize eco-friendly solutions, so laser cutting’s low waste aligns with our sustainability goals. Moving forward, we’ll integrate laser cutting with AI-driven design tools to unlock even more efficiency, helping clients stay competitive in a fast-changing industry.

Perguntas frequentes:

1. Is laser cutting’s high precision only beneficial for small parts?

Não. Laser cutting’s precision works for both small and large parts. Por exemplo, a shipbuilding company uses laser cutting to cut large steel plates (3m x 6m) for hull components, ensuring the plates fit together with 0.05mm accuracy—reducing welding time by 25% compared to traditional cutting.

2. Does laser cutting’s fast speed compromise quality?

Not at all. The laser beam’s high energy and CNC control let it cut quickly while maintaining narrow cut widths (0.10–0.20mm) and smooth surfaces. A study by the Laser Institute of America found that laser cutting can maintain quality even at maximum speed—unlike plasma cutting, which often sees quality drop as speed increases.

3. Is laser cutting cost-effective for small-batch production?

Sim. Unlike traditional methods that require expensive tooling for small batches, laser cutting uses software-controlled patterns—no tooling costs. A small electronics company producing 50 custom enclosures monthly saves \(3,000 annually with laser cutting, compared to die-cutting (which requires \)500 tooling per enclosure design).