Se você está procurando “Moldagem por injeção China,” é provável que você queira saber se os fabricantes chineses podem atender às suas necessidades de produção – seja de qualidade, custo, tempo de espera, ou escalabilidade. A resposta curta é sim: A indústria de moldagem por injeção da China evoluiu de uma opção focada no orçamento para uma líder global em precisão, tecnologia, e confiabilidade, serving industries from automotive to medical devices. Neste guia, we’ll break down everything you need to know to work successfully with Chinese injection molders, avoid common pitfalls, and leverage the industry’s unique advantages.

Why Choose Injection Molding in China? Key Advantages for Global Buyers

Chinese injection molding isn’t just about lower costs anymore—it’s about a combination of benefits that make it a top choice for businesses worldwide. Let’s break down the most impactful advantages, with real-world context to back them up.

Cost Efficiency Without Sacrificing Quality

Cost remains a major draw, but it’s not just about “cheap labor.” China’s mature supply chain—from raw material suppliers (like Sinopec for plastics) to mold component manufacturers—creates economies of scale that lower per-unit costs. Por exemplo, a mid-sized U.S. electronics company we worked with reduced their injection molding costs by 35% by partnering with a Chinese molder for their plastic housing parts, while maintaining ISO 9001 quality standards.

Key Data Point: According to a 2024 report by the China Plastic Machinery Industry Association (CPMIA), labor and overhead costs for injection molding in China are 20-40% lower than in Western Europe and North America, without compromising on precision (most manufacturers now use CNC-controlled machines with ±0.005mm tolerance).

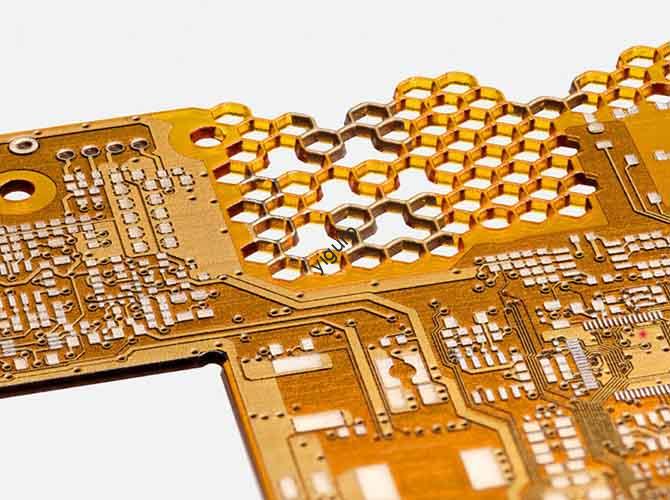

Advanced Technology and Precision Capabilities

Gone are the days when China was only known for basic molding. Hoje, top Chinese molders invest heavily in German (KraussMaffei) and Japanese (Fanuc) machines, and offer advanced processes like:

- Sobremoldagem (for soft-touch grips on tools or electronics)

- Insert molding (integrating metal parts into plastic components)

- Micro-injection molding (for tiny medical parts like catheter tips, with parts as small as 0.1g)

A case in point: A European medical device firm partnered with a Chinese molder in Suzhou to produce micro-injection-molded insulin pen components. The molder met FDA Class I requirements and achieved a 99.8% defect-free rate—on par with European suppliers, mas com 25% shorter lead times.

Scalability for High-Volume Production

China’s injection molding facilities are built for scale. Most manufacturers can quickly ramp up production from 10,000 para 1 million+ units, thanks to multiple production lines and flexible shift schedules. For instance, a global toy brand used a Guangdong-based molder to produce 5 million plastic toy parts for the holiday season—they started with a 50,000-unit sample run, and scaled up in 2 weeks without delays.

Diverse Material Options

Chinese molders have access to a wide range of plastics, including engineering-grade materials like ABS, PC, POM, and high-performance options (ESPIAR, PPS) for extreme conditions. They also excel at sustainable materials: 60% of top molders now offer bio-based plastics (por exemplo, PLA) or recycled plastic options, per a 2024 survey by Plastics Technology China. This is a big win for brands focused on sustainability—like a U.S. packaging company that switched to recycled PP for their containers, with a Chinese molder handling the material sourcing and testing.

Understanding China’s Injection Molding Landscape: Key Regions and Specializations

Not all Chinese injection molding hubs are the same—each region has unique strengths, so choosing the right location can align with your product’s needs. Here’s a breakdown of the top regions and their specializations:

| Region | Core Strengths | Key Industries Served | Example Cities |

| Guangdong | High-volume production, consumer goods focus | Electronics, toys, embalagem | Shenzhen, Dongguan |

| Jiangsu | Precision molding, medical/automotive | Medical devices, peças automotivas | Suzhou, Wuxi |

| Zhejiang | Custom molding, small-to-medium runs | Home appliances, hardware | Ningbo, Hangzhou |

| Shandong | Heavy-duty plastics, componentes industriais | Machinery, automotivo | Qingdao, Jinan |

Por exemplo, if you’re making a medical device (like a syringe), Jiangsu’s Suzhou is ideal—over 30% of China’s medical injection molders are based there, and most are certified to ISO 13485. If you need high-volume electronics parts (like phone cases), Guangdong’s Dongguan (known as the “World’s Factory”) has hundreds of molders specializing in fast-turnaround consumer goods.

How to Choose the Right Injection Molder in China: 5 Critical Steps

Choosing a molder is the most important decision—get it wrong, and you’ll face delays, quality issues, or miscommunication. Follow these steps to find a reliable partner:

Step 1: Verify Certifications (Don’t Skip This!)

Certifications prove a molder’s ability to meet global standards. For most industries, look for:

- ISO 9001: Basic quality management (required for most consumer goods)

- ISO 13485: For medical devices (mandatory if your product touches the human body)

- IATF 16949: For automotive parts (required by brands like Ford, Toyota)

- UL Certification: For plastics used in electrical products (to ensure fire safety)

Pro Tip: Ask for a copy of the certification—not just a mention on their website. A U.K. automotive supplier once discovered a “certified” molder had let their IATF 16949 expire, leading to a 6-week production delay while they found a new partner.

Step 2: Check Their Experience in Your Industry

A molder that excels at toy parts may not have the expertise for medical devices. Ask:

- How many years have you worked with [your industry]?

- Can you share case studies or references from similar clients?

- Do you have dedicated teams for [your product type] (por exemplo, micro-molding, sobremoldagem)?

Por exemplo, if you’re making auto bumpers (which require large molds and impact-resistant plastics), a molder with 10+ years in automotive will know how to avoid common issues like warping or weak points—something a generalist molder might miss.

Step 3: Evaluate Their Production Capacity and Lead Times

Be clear about your volume and timeline, and ask the molder to confirm:

- What’s your maximum monthly output for parts like mine?

- How long will a sample run take? (Typically 2-4 weeks for standard parts, 4-6 weeks for complex molds)

- What’s your backup plan if a machine breaks down? (Top molders have spare machines or partner facilities)

A Canadian furniture brand once made the mistake of hiring a small molder for 200,000 plastic chair legs—only to learn the molder could only produce 50,000 units/month. This led to a 3-month delay in their product launch.

Step 4: Assess Communication and Quality Control Processes

Miscommunication is a top complaint with overseas suppliers. Look for molders that:

- Have English-speaking project managers (not just translators)

- Provide regular updates (por exemplo, weekly reports with photos of production)

- Have a clear quality control (QC) processo: Incoming material checks → In-process inspections → Final testing (por exemplo, dimensional checks with CMM machines)

Exemplo de caso: A U.S. startup worked with a molder in Ningbo that used a shared QC app—they could log in anytime to see photos of sample parts, test results (like tensile strength), e prazos de produção. This eliminated guesswork and built trust.

Step 5: Request Samples and Audit (If Possible)

Never place a full order without seeing a sample first. The sample should match your design specs (check dimensions, material, finish) and pass any required tests (por exemplo, heat resistance for kitchenware).

If your order is high-value (>\(50,000), consider a factory audit—either in person or via a third-party (like SGS or Intertek). An audit will confirm the molder has the machines, certifications, and QC processes they claim. A European tool brand saved \)100,000 by auditing a molder that claimed to have 10 Fanuc machines—they only had 3, and the rest were outdated models.

The Injection Molding Process in China: What to Expect

Understanding the process helps you set realistic expectations and collaborate better with your molder. Here’s a step-by-step breakdown of how most Chinese molders work:

- Design Review and Mold Design: Primeiro, the molder will review your 3D CAD files (por exemplo, STL, STEP) to check for manufacturability (DFM). They may suggest changes (por exemplo, adding draft angles to make parts easier to remove from the mold) to avoid defects. Then, they’ll design the mold (typically made of steel or aluminum) and send you a mold design approval (MDA) for sign-off. This takes 1-2 weeks.

- Fabricação de moldes: The molder will machine the mold using CNC mills, Música eletrônica (electrical discharge machining), or laser cutting. For complex molds (por exemplo, with multiple cavities), this can take 3-4 weeks. They’ll test the mold with a small batch of plastic to ensure it works—this is called a “trial run.”

- Sample Production and Approval: The molder will send you samples (usually 10-50 units) for testing. You’ll check for fit, finish, e desempenho. If changes are needed (por exemplo, adjusting the mold to fix a gap), the molder will modify the mold and send new samples. This step takes 1-2 weeks.

- Mass Production: Once samples are approved, production begins. The molder will load plastic pellets into the injection molding machine, which melts the plastic and injects it into the mold under high pressure (1000-2000 bar). The plastic cools and hardens, then the mold opens, and the part is ejected. Production speed depends on part size—small parts (por exemplo, a button) can be made in 10 seconds per cycle, while large parts (por exemplo, a plastic crate) take 1-2 minutos.

- QC and Packaging: Every batch goes through QC—inspectors check for defects (por exemplo, flash, bubbles, dimensional errors) using calipers, gauges, or CMM machines. Defective parts are discarded (top molders have a <0.5% defect rate). Then, parts are packaged (per your requirements—e.g., bulk boxes, individual blister packs) and prepared for shipping.

- Shipping and Logistics: Most molders work with freight forwarders to handle shipping (by sea, air, or express). They can also help with customs documentation (por exemplo, commercial invoice, packing list) to avoid delays. Sea shipping takes 2-4 weeks (to North America/Europe), while air shipping takes 3-5 days.

Key Trends Shaping China’s Injection Molding Industry in 2024

Staying ahead of trends helps you choose a molder that can adapt to future needs. Here are the biggest trends to watch:

1. Automation and Smart Manufacturing

Top molders are using IoT (Internet of Things) to monitor machines in real time—sensors track temperature, pressure, and cycle time, and alert managers if there’s a problem. Some facilities even use robots for tasks like part ejection and packaging, which reduces labor costs and human error. According to CPMIA, 45% of large Chinese molders now use automated production lines—up from 25% em 2020.

2. Sustainability and Circular Economy

Brands worldwide are pushing for eco-friendly plastics, and Chinese molders are responding. Many now offer:

- Recycled plastics (por exemplo, rPET, rPP) that meet the same quality standards as virgin materials

- Bio-based plastics (por exemplo, PLA from corn starch) that are compostable

- Mold designs that reduce plastic waste (por exemplo, thinner walls without sacrificing strength)

UM 2024 study by the China Environmental Protection Association found that 70% of injection molders have invested in recycling equipment, e 50% offer carbon-neutral production options (by offsetting emissions with renewable energy).

3. Customization for Small-Batch Production

While China is known for high volume, there’s a growing focus on small-batch, custom molding—thanks to lower-cost aluminum molds (which are faster to make than steel molds) and digital design tools. This is great for startups or brands testing new products: You can order 100-1000 units at an affordable price, without committing to a large run.

4. Integration of 3D Printing (Fabricação Aditiva)

Some molders now use 3D printing to make mold inserts (for complex shapes) or even small-batch parts. This speeds up the sample process—instead of waiting 2 weeks for a steel insert, you can get a 3D-printed insert in 1-2 days. Por exemplo, a Chinese molder in Suzhou used 3D printing to make a mold insert for a custom phone case, cutting the sample time from 14 days to 3 days.

Yigu Technology’s Perspective on Injection Molding in China

Na tecnologia Yigu, we’ve partnered with dozens of Chinese injection molders over the past decade, and we’ve seen firsthand how the industry has matured. The biggest shift we’ve noticed is the move from “cost-first” para “value-first”—today’s top molders prioritize quality, sustentabilidade, and communication as much as price.

For businesses considering Chinese injection molding, our advice is to focus on alignment: Choose a molder that specializes in your industry, understands your quality standards, and communicates clearly. Don’t just chase the lowest price— a slightly higher cost for a reliable partner will save you time, dinheiro, and headaches in the long run. We also recommend leveraging China’s strengths in scalability and material diversity—whether you need 10,000 ou 1 million parts, or a unique material like PEEK, there’s a molder in China that can meet your needs.

Perguntas frequentes: Common Questions About Injection Molding in China

1. Is injection molding in China suitable for small businesses or startups?

Sim! Many Chinese molders now offer small-batch production (100-5000 units) with affordable aluminum molds. Startups can test their products without a large upfront investment—just make sure to choose a molder with experience in small runs and clear communication.

2. How long does it take to get parts from a Chinese molder?

Total lead time depends on complexity:

- Sample run: 2-4 weeks (projeto de molde + trial + shipping)

- Mass production (10,000-100,000 units): 4-6 weeks (produção + QC + shipping by sea)

- Rush orders: 2-3 weeks (using air shipping and expedited mold making)

3. What quality issues should I watch out for?

Common issues include flash (excess plastic on parts), deformação (parts bending after cooling), and dimensional errors. To avoid these, choose a molder with a strict QC process (ask for their defect rate—top molders have <0.5%) and request samples before full production.

4. How do I handle shipping and customs when working with a Chinese molder?

Most molders work with trusted freight forwarders who handle shipping and customs. They can provide door-to-door service, so you don’t have to deal with logistics. Make sure to confirm who is responsible for customs duties (usually the buyer, but some molders offer DDP—Delivered Duty Paid—options for an extra fee).

5. Can Chinese molders meet strict industry standards (por exemplo, FDA, automotivo)?

Absolutamente. Over 60% of top Chinese molders are certified to ISO 13485 (médico) or IATF 16949 (automotivo), and many have passed audits by global brands like Apple, Toyota, and Johnson & Johnson. Always ask for certification copies and references from clients in your industry.