O curto vs.. Real Answer

How much does a 3D printed metal part cost? A resposta rápida é frustrantemente obscura: em qualquer lugar, desde menos de cem dólares por uma pequena peça de aço inoxidável até dezenas de milhares por uma grande, parte complexa de Inconel. Não existe um preço único porque o custo não é um simples preço de etiqueta – it’s a complex calculation. The only way to get a true answer is to build a complete picture of the Total Cost of Ownership (TCO).

To understand the real investment, we must look beyond the printer and the powder. The true cost is a system of connected expenses. We will break down this system by looking at five key cost areas: Material, Machine & Depreciation, Trabalho, Hidden Post-Processing, and Strategic Costs (contra. CNC). This approach moves the conversation from a simple price question to a strategic financial analysis.

Ao final deste guia, you will understand:

- A detailed breakdown of material costs per cubic centimeter for common metal types.

- The real cost of machine ownership, including depreciation and modern service models.

- O “hidden factory” of labor and post-processing that is often overlooked.

- A framework for comparing the cost against traditional CNC machining to find your break-even point.

Foundation: Material and Machine

The most visible and often largest initial investments in metal additive manufacturing (SOU) are the raw materials and the printing hardware. These two elements form the foundation of your part cost, and understanding their details is the first step in creating an accurate budget.

Metal Powder Costs

A matéria-prima, typically a fine metal powder, is a primary and ongoing driver of part cost. Unlike traditional manufacturing where you might buy a standard metal bar, AM powders are highly engineered materials with specific characteristics for flow, particle size distribution, e pureza. The cost is best understood not just per kilogram, but per cubic centimeter (cm³), as this directly relates to the volume of your final part.

The price varies significantly based on the metal type, market demand, e volume de pedidos. Below is a table of estimated costs for common metal powders in 2025. We calculate the cost per cm³ using the formula: `Cost per cm³ = (Price per kg / 1000) * Densidade (g/cm³)`

| Metal Type | Estimated Price per kg | Approx. Densidade (g/cm³) | Estimated Cost per cm³ |

| Stainless Steel 316L | $50 – $100 | 8.0 | $0.40 – $0.80 |

| Aluminum AlSi10Mg | $60 – $120 | 2.67 | $0.16 – $0.32 |

| Titanium Ti6Al4V (Nota 5) | $300 – $500 | 4.43 | $1.33 – $2.22 |

| Inconel 718 | $200 – $400 | 8.19 | $1.64 – $3.28 |

| Copper C18150 | $150 – $250 | 8.89 | $1.33 – $2.22 |

Factors influencing these prices include metal complexity (Inconel and Titanium are more expensive to produce than steel), powder quality (higher sphericity and fewer satellite particles command a premium), e tamanho do lote (bulk orders significantly reduce the per-kilogram cost).

Machine Purchase Costs

The metal 3D printer itself represents the largest capital expenditure (CapEx). The market offers a wide range of systems, which can be grouped into general tiers.

Opção 1: Outright Purchase (CapEx)

- Entry-Level/Desktop Systems: $100,000 – $250,000. This category includes some bound metal deposition (BMD) systems and smaller laser powder bed fusion (LPBF) machines designed for research, peças pequenas, e prototipagem.

- Mid-Range Production Systems: $250,000 – $750,000. This is the workhorse category for many service bureaus and in-house production facilities. These are typically single-laser LPBF systems with robust monitoring and established workflows.

- High-End, Multi-Laser Systems: $750,000 – $2,000,000+. These are large-format machines equipped with multiple lasers (from two to twelve or more) designed for high-throughput production of large parts or batches of smaller parts.

When you purchase a machine, its cost must be spread over its useful life. This is Machine Depreciation, a real and calculable operating expense. A simple straight-line depreciation model illustrates this: um $500,000 machine with a 5-year operational lifespan has a depreciation cost of $100,000 por ano. If you run that machine 24/7 (8,760 hours/year), the depreciation cost alone is approximately $11.41 for every hour it operates.

Opção 2: Subscription & Service Models

A growing trend, particularly for companies wary of high CapEx, is the adoption of Hardware-as-a-Service (HaaS) or leasing models. These turn a large capital expense into a predictable operational expense (OpEx).

- Como funciona: Instead of buying the machine, you pay a monthly or quarterly fee that often bundles the hardware, service/maintenance contract, and sometimes even software and training.

- Prós: Lower initial investment, predictable costs, access to the latest technology without long-term commitment, and bundled support.

- Contras: Higher total cost over the long term compared to an outright purchase, no asset ownership, and potential limitations in the contract.

This choice between CapEx and OpEx is a strategic one, dependent on your company’s financial structure, risk tolerance, and long-term AM strategy.

The Hidden Factory Costs

A raw part emerging from a metal 3D printer is rarely a finished component. The steps required to take a part from the build plate to its final, usable state constitute a “hidden factory” of labor and processing. Underestimating these costs is the single most common mistake new adopters make, leading to significant budget overruns.

The Human Element

Metal 3D printing is not a fully automated “lights-out” processo. It requires skilled human intervention at every stage of the workflow, and this labor is a significant operational cost.

- Pré-processamento: This is the digital preparation phase. A skilled AM Engineer must orient the part on the build plate, design and generate complex support structures, and run simulations to predict thermal stress. This requires specialized software and expertise.

- Operação: A trained technician is needed for machine setup, which includes loading powder, preparing the build plate, and running calibration checks. During the build, which can last for days, the machine requires periodic monitoring.

- Pós-processamento: This is the most labor-intensive stage. It involves a technician safely removing the part from the machine, de-powdering it, and then executing the various finishing steps discussed below.

In the US and EU, realistic hourly rates are approximately $30-$50 per hour for a skilled technician and $50-$90+ per hour for an experienced AM Engineer. These costs must be factored into every single part you produce.

The Post-Processing Steps

This series of mandatory steps is the most frequently overlooked cost center. Each step adds time, custo, and complexity to the workflow.

1. Remoção da Estrutura de Suporte

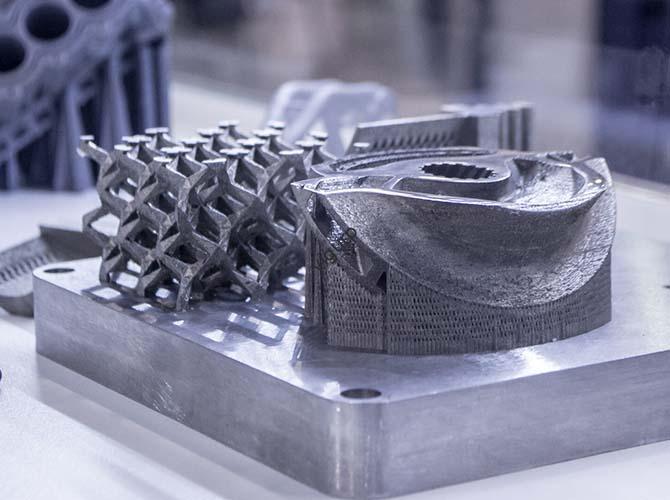

Supports are intricate metal lattices printed along with the part. They are essential for anchoring the part to the build plate, supporting overhangs, and managing thermal stress. Depois de imprimir, they must be removed. This is often a manual process using hand tools, but for robust supports or internal channels, it may require secondary machining operations like wire EDM or milling. The time and cost associated with support removal can be substantial, especially for complex geometries.

2. Stress Relief & Tratamento térmico

This step is non-negotiable for most parts made with laser powder bed fusion. The rapid heating and cooling during the printing process builds up immense internal stress within the metal. If not relieved, the part can warp or even crack when cut from the build plate. The part, while still attached to the plate, must undergo a precise thermal cycle in a specialized vacuum or inert gas furnace. A typical furnace cycle can take 8-24 hours and cost several hundred to over a thousand dollars per batch, depending on the metal type and furnace size.

3. Hot Isostatic Pressing (HIP)

For applications where material integrity is paramount, como aeroespacial, médico, e energia, Hot Isostatic Pressing is a critical step. HIP is a process that subjects the part to high temperature and high-pressure gas (typically Argon) to eliminate any internal microporosity left over from the printing process. This densifies the material to nearly 100% of its theoretical maximum, dramatically improving its fatigue life and mechanical properties. HIP is a specialized industrial process that is often outsourced, adding a significant cost (por exemplo, $500 – $2,000+ per batch) and several days to the lead time.

4. Acabamento de Superfície & Usinagem

The as-printed surface of a metal AM part is typically rough (Rá 10-20 µm). To meet final specifications, further steps are almost always required. This can include bead blasting for a uniform matte finish, tumbling for deburring, ou, most commonly, Usinagem CNC. Critical features like mating surfaces, furos roscados, and high-tolerance bores must be machined to achieve the required precision and surface finish. This final machining step adds another layer of cost and programming time.

The Strategic Decision

Understanding the component costs is only half the battle. The ultimate decision to invest in or use metal 3D printing is a strategic one. It requires a clear-eyed analysis of when this technology provides a true financial advantage over traditional methods and how to calculate its total cost in a way that enables apples-to-apples comparisons.

Break-Even Point Analysis

The central question for many is: when is metal 3D printing more cost-effective than CNC machining? The answer lies in understanding the fundamental cost structures of each technology and identifying the break-even point.

A comparative analysis reveals their opposing strengths:

Usinagem CNC

- Cost Structure: High initial setup costs (ferramentas, jogos, CAM programming) but a decreasing per-part cost as volume increases.

- Complexidade: Cost increases significantly with geometric complexity. Cortes inferiores, bolsos fundos, and complex curves require more setups, ferramentas especializadas, and longer machining times.

- Material: High material waste. O “buy-to-fly” razão (the weight of the raw material block vs. the weight of the final part) can be 10:1 or higher for complex aerospace parts.

3D Metal Printing

- Cost Structure: Virtually no tooling or setup-specific costs. The cost per part is relatively stable, regardless of whether you print one or ten.

- Complexidade: Complexity is essentially free. An intricate, topology-optimized lattice structure costs roughly the same to print as a solid block of the same volume. This allows for part consolidation, combining multiple simple parts into one complex, high-performance component.

- Material: Extremely low material waste. Only the material needed for the part and its supports is used, with unused powder being recyclable.

The break-even point is where the cost lines of these two processes intersect. For very low volumes (1-10 peças) or for parts with extreme geometric complexity, 3D printing is almost always cheaper. As production volume increases for a relatively simple part, the high per-part cost of AM becomes less competitive against the mass-production efficiency of CNC.

To find your sweet spot, faça essas perguntas:

- What is your required production volume? Is it a one-off prototype, a small batch of 50, or a run of 10,000?

- How complex is your part’s geometry? Can it even be made with CNC?

- Can you leverage AM’s strengths by consolidating multiple assembly components into a single printed part?

- How critical is speed for your first functional prototype? AM can deliver a part in days, while CNC tooling can take weeks.

Calculating Your True TCO

To make an informed decision, you need a practical model. Based on our experience helping hundreds of companies budget for additive manufacturing, we use a comprehensive formula to determine the true cost per part. This model synthesizes all the variables we’ve discussed.

Primeiro, you must calculate your all-in Hourly Machine Rate. This is more than just depreciation.

`Hourly Machine Rate = (Annual Machine Depreciation + Annual Service Contract + Annual Consumables & Utilities) / Total Annual Operating Hours`

Let’s use an example: um $500,000 machine depreciated over 5 anos ($100,000/yr) with a $40,000/yr service contract and $10,000/yr in consumables (filters, wipers, gás). Your total annual cost is $150,000. If you plan to run the machine for 6,000 hours per year (a realistic figure accounting for downtime), your Hourly Machine Rate is $25.

Agora, we can apply this to the complete cost of 3d metal printing formula:

`Cost per Part = (Custo de materiais) + (Machine Time * Hourly Machine Rate) + (Labor Time * Hourly Labor Rate) + (External Post-Processing Cost)`

Let’s walk through a hypothetical example: a moderately complex titanium bracket.

1. Custo de materiais: The part has a volume of 60 cm³. Using our table, we’ll estimate titanium powder at $1.80/cm³.

- Material Cost = 60 cm³ * $1.80/cm³ = $108

2. Machine Cost: The build, containing just this one part for simplicity, leva 12 hours to print.

- Machine Cost = 12 horas * $25/hora = $300

3. Labor Cost:

- Pré-processamento (Engineer): 1 hour @ $70/hr = $70

- Pós-processamento (Technician): 3 hours for de-powdering, remoção de suporte, and blasting @ $40/hr = $120

- Total Labor = $190

4. External Post-Processing Cost: The part requires stress relief and HIP, which is sent out as a batch. The allocated cost for this single part is estimated at $80.

Total Cost per Part = $108 (Material) + $300 (Machine) + $190 (Trabalho) + $80 (Pós-processamento) = $778

This detailed, bottom-up calculation provides a realistic cost far more accurate than any simple online quote. It demonstrates that the machine time and labor are often more significant cost drivers than the material itself.

Conclusion: Beyond the Price Tag

The true cost of 3d metal printing is a system of interconnected expenses, not a single number. Moving from a vague price query to a detailed TCO analysis reveals that the sticker price of the printer is just the beginning. The real costs are found in the entire process chain.

To recap, the primary cost drivers you must account for are:

- Engineered material powders, best calculated by volume (cm³).

- Machine depreciation and service contracts, calculated as an hourly rate.

- Skilled labor for preparation, operação, e acabamento.

- Mandatory, non-negotiable post-processing like heat treatment and, para peças críticas, HIP.

No entanto, a pure cost analysis is incomplete. The decision to adopt metal AM is an investment in capability. The cost must be weighed against the strategic value it unlocks: unprecedented design freedom to create lighter, mais forte, and more efficient parts; the ability to consolidate complex assemblies, reducing part count and failure points; and the agility to produce parts on-demand, slashing lead times and inventory costs.

With this comprehensive understanding of the costs, you are now equipped to move beyond the price tag and make a smart, strategic investment in the future of manufacturing.