CNC sheet processing process is the backbone of creating high-quality, peças de chapa metálica consistentes para indústrias como automotiva, eletrônica, e construção. Ao contrário do trabalho manual tradicional em chapa metálica, este processo controlado por computador elimina erros humanos, aumenta a eficiência, e garante que as peças atendam aos rigorosos padrões de design. Esteja você fazendo um pequeno gabinete eletrônico ou um grande painel automotivo, understanding each step of the CNC sheet processing process is key to avoiding delays, reduzindo o desperdício, and delivering top-notch products. Este guia detalha todo o fluxo de trabalho, with real-world examples and data to help you master every detail.

1. Pré-processamento: Lay the Groundwork with Design & Seleção de Materiais

Before the CNC machine starts cutting, two critical steps set the stage for success: CAD/CAM programming e material choice. Skipping or rushing these steps often leads to costly rework later.

1.1 Projeto CAD & Programação CAM: The Digital Blueprint

The first step in the CNC sheet processing process is turning your part idea into a digital plan:

- CAD (Design Assistido por Computador): Use software like SolidWorks, AutoCAD, or Fusion 360 to create a 3D model of the sheet metal part. You’ll define every detail—from hole positions and bend angles to edge radii. Por exemplo, a prototype for a laptop chassis needs precise cutouts for ports, so the CAD model must mark these with ±0.05mm accuracy.

- CAM (Fabricação Assistida por Computador): Convert the CAD model into machine-readable code (Código G). The CAM software optimizes key parameters like machining path, velocidade de corte, e seleção de ferramentas to avoid collisions (por exemplo, the tool hitting the machine’s fixture) and ensure efficiency.

Why This Matters: A well-written CAM program can reduce machining time by 20–30%. Por exemplo, a furniture manufacturer cut the time to make aluminum table frames from 45 minutos para 30 minutes by optimizing the tool path in CAM.

1.2 Seleção de Materiais: Match the Sheet to Your Needs

Choosing the right sheet material directly impacts the part’s performance, custo, e facilidade de processamento. Below’s a breakdown of common options and their best uses:

| Tipo de material | Faixa de espessura | Propriedades principais | Aplicações ideais | Custo (USD/sq.ft) |

| Liga de alumínio 6061 | 0.5mm – 6 mm | Leve, resistente à corrosão | Gabinetes eletrônicos, painéis automotivos | \(2.0 – \)5.5 |

| Aço inoxidável 304 | 0.3mm – 10 mm | Durável, à prova de ferrugem | Equipamento médico, food industry parts | \(3.5 – \)8.0 |

| Cold-Rolled Steel | 0.2mm – 8 mm | Alta resistência, baixo custo | Suportes estruturais, peças de eletrodomésticos | \(1.5 – \)4.0 |

| Plastic Sheets (ABS) | 1.0mm – 12mm | Leve, fácil de cortar | Consumer product casings | \(1.0 – \)3.0 |

Real-World Example: A medical device company needed a sheet metal part for a surgical cart. They chose aço inoxidável 304 for its rust resistance (critical for sterilization) and 1.5mm thickness for strength. The part passed all durability tests and met medical industry standards.

2. Configuração da máquina: Prepare Tools & Equipment for Processing

Once the design and material are finalized, the next step in the CNC sheet processing process is setting up the machine and tools. This ensures the CNC system runs smoothly and accurately.

2.1 Choose the Right CNC Machine

Not all CNC machines work for every sheet processing task. The most common types include:

- CNC Laser Cutters: Best for precise, complex cuts (por exemplo, intricate patterns in thin aluminum sheets). They cut cleanly without leaving burrs and work well with materials up to 20mm thick.

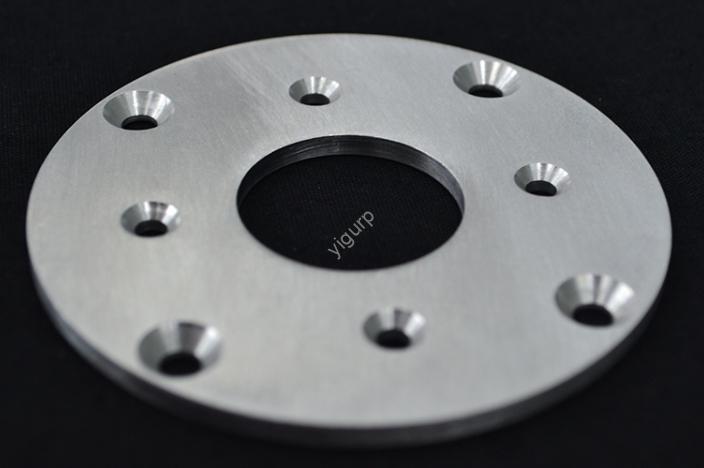

- CNC Punch Presses: Ideal for high-volume production of parts with repeated holes (por exemplo, electrical junction boxes). They’re faster than laser cutters for simple shapes—able to punch 50+ holes per minute.

- CNC Press Brakes: Used to bend sheets into angles or curves (por exemplo, a 90° bend for a metal shelf). They ensure consistent bend angles with ±0.1° accuracy.

2.2 Seleção de ferramentas & Configuração de parâmetros

The right tool and settings prevent damage to the sheet and machine:

- Ferramentas: Para corte a laser, use a fiber laser for metals (alumínio, aço) and a CO₂ laser for plastics. For punch presses, select punches and dies that match the hole size (por exemplo, a 5mm punch for 5mm holes).

- Parameters: Set velocidade de corte (100–500 mm/min for aluminum), taxa de alimentação (50–200 mm/min for steel), e potência do laser (1–5 kW) com base na espessura do material. Por exemplo, cutting a 2mm aluminum sheet with a 3kW fiber laser at 300 mm/min produces a smooth edge.

Common Mistake to Avoid: Using a dull punch for stainless steel sheets. This causes rough hole edges and may require post-processing to fix—adding 10–15 minutes per part.

3. Core Processing: Roughing, Acabamento & Strategy Planning

The heart of the CNC sheet processing process is the actual machining. This phase includes roughing (removing excess material), acabamento (refining the part), and strategic planning to prevent issues like sheet deformation.

3.1 Roughing: Speed Up Material Removal

Roughing’s goal is to quickly remove extra material from the sheet while leaving enough allowance for finishing. Por exemplo:

- When making a 100x100mm aluminum bracket from a 150x150mm sheet, roughing cuts off the 50mm excess on all sides.

- Key settings: Use a larger depth of cut (1–3mm for aluminum) and higher feed rate to save time. A CNC laser cutter can rough a 3mm aluminum sheet in 2–3 minutes.

3.2 Acabamento: Ensure Precision & Qualidade

Finishing refines the part to meet final design specs. This step focuses on:

- Precisão Dimensional: Trim the sheet to exact sizes (por exemplo, from 102x102mm after roughing to 100x100mm final size).

- Qualidade de Superfície: Remove any tool marks or burrs. Por exemplo, a CNC press brake can smooth bend edges to avoid sharp corners on consumer products.

Data Point: Finishing typically takes 20–30% of total processing time but improves part quality by 40–50%, reducing the risk of customer returns.

3.3 Processing Strategy: Prevent Deformation & Vibration

Thin sheets (≤1 mm) are prone to deformation during machining. To avoid this:

- Clamp Securely: Use multiple clamps to hold the sheet flat—loose clamps cause vibration, leading to uneven cuts.

- Optimize Cutting Path: Start cutting from the center of the sheet and move outward. This distributes stress evenly, evitando empenamento.

- Use Coolant: For metal sheets, apply coolant to reduce heat (which can bend the sheet). Water-soluble coolant works best for aluminum and steel.

Estudo de caso: An electronics manufacturer was struggling with warped aluminum enclosures (0.8mm de espessura). By switching to a center-out cutting path and adding coolant, they reduced deformation by 70%—all enclosures now meet flatness standards.

4. Pós-processamento & Controle de qualidade: Finalize the Part

O CNC sheet processing process doesn’t end when the machine stops. Post-processing and quality control ensure the part is ready for use.

4.1 Etapas de pós-processamento

Depois da usinagem, finish the part with these steps:

- Cleaning: Wipe off coolant, óleo, or metal chips with a solvent (por exemplo, isopropyl alcohol) para evitar contaminação.

- Rebarbação: Use a deburring tool or sandpaper to remove sharp edges—critical for parts that people will handle (por exemplo, toolboxes).

- Tratamento de superfície: Add coatings to improve performance or appearance:

- Anodização: Para peças de alumínio (adds scratch resistance).

- Revestimento em pó: For steel parts (adds color and rust protection).

- Anti-Rust Treatment: Para peças externas (por exemplo, galvanizing steel brackets).

4.2 Controle de qualidade: Check for Accuracy

Regular checks ensure the part meets design requirements:

- Dimensional Checks: Use calipers or a coordinate measuring machine (CMM) to verify size (por exemplo, diâmetro do furo, bend angle). Por exemplo, a CMM can measure a part’s dimensions with ±0.001mm accuracy.

- Planicidade & Verticality Tests: Use a straightedge to check if the sheet is flat—any gap >0.1mm means the part is defective.

- Inspeção Visual: Look for scratches, dents, or uneven edges—these are common issues that can be fixed with minor rework.

Quality Control Tip: Teste 10% of parts from each batch. If one fails, test 50%—this balances efficiency and thoroughness.

Yigu Technology’s View on CNC Sheet Processing Process

Na tecnologia Yigu, we see the CNC sheet processing process as a blend of precision and strategy. Sobre 12 anos, we’ve refined our workflow to deliver consistent results: we use CAD/CAM software to optimize tool paths (cutting time by 25%), select materials based on client needs (por exemplo, stainless steel for medical parts), and apply strict quality control (99.5% of parts pass first inspection). We also prioritize environmental safety—recycling 80% of cutting waste and using eco-friendly coolants. For us, a smooth CNC sheet processing process isn’t just about making parts—it’s about helping clients build reliable, long-lasting products.

Perguntas frequentes

Q1: How long does the CNC sheet processing process take for a single part?

UM: It depends on size and complexity. A small aluminum enclosure (100x100mm) takes 15–20 minutes (design para pós-processamento). A large steel panel (1000x500mm) with complex cuts takes 1–2 hours.

Q2: Can the CNC sheet processing process handle custom designs?

UM: Sim! The process is highly flexible—just provide a CAD model of your custom part. Whether it’s a one-of-a-kind prototype or small-batch production (50–100 peças), CNC machines can bring your design to life with high accuracy.

Q3: What’s the most common mistake in the CNC sheet processing process?

UM: Poor material selection. Choosing a sheet that’s too thin (for heavy-use parts) or too thick (para peças delicadas) leads to performance issues. Always match the material to the part’s function—our team can help with this if you’re unsure!