Tubos PEEK: O guia definitivo para a indústria, Médico & Uso Aeroespacial

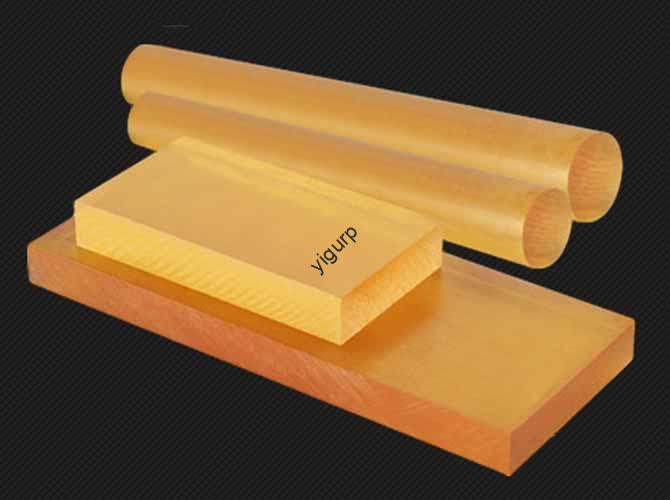

Se você é engenheiro, fabricante, ou comprador se perguntando o que são tubos PEEK e por que eles são uma virada de jogo para o seu setor, vamos direto ao ponto. ESPIAR (abreviação de Poliéter Éter Cetona) é um termoplástico de alto desempenho, e os tubos PEEK são tubos ocos feitos deste material - projetados para lidar com condições extremas que quebram plásticos ou metais comuns. […]