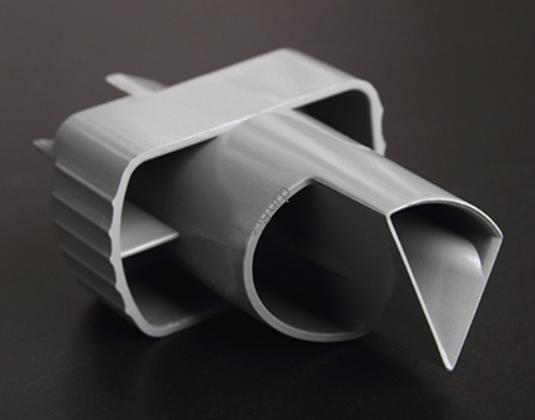

A casca no protótipo de usinagem CNC: Um guia para fabricação de precisão

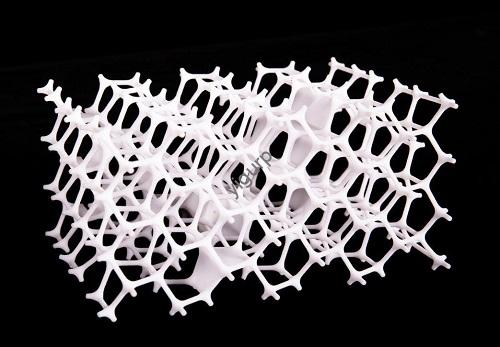

Ao desenvolver novos produtos – seja no setor aeroespacial, automotivo, ou eletrônica - o protótipo de usinagem CNC desempenha um papel crítico. Não é apenas uma simples cobertura externa; é um ambiente de teste para viabilidade de design, desempenho, e escalabilidade de produção. Este guia detalha tudo o que você precisa saber sobre protótipos de shells, desde escolhas de materiais até aplicações no mundo real, ajudando você a evitar […]