Por que o design de corte a laser CNC é uma habilidade essencial na indústria?

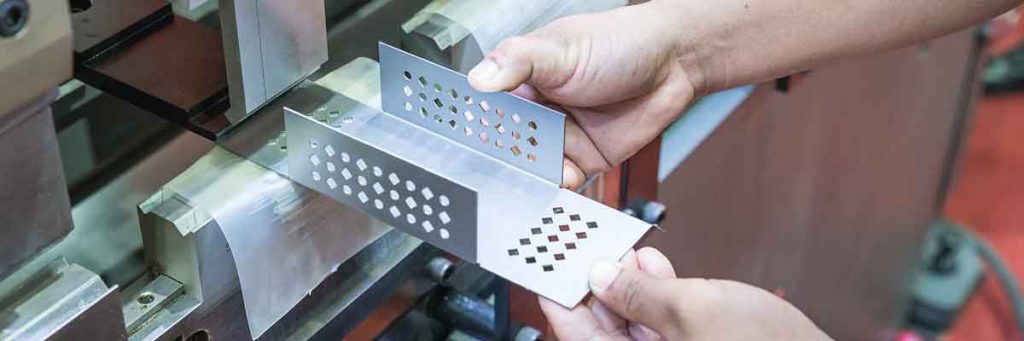

Em vários campos, como fabricação industrial, design de arte, e processamento de peças automotivas, O corte a laser CNC tornou-se o método de processamento convencional com suas vantagens de alta precisão e eficiência. No entanto, muitos usuários encontrarão problemas como “corte incompleto”, “rebarbas nas bordas”, e “erros de importação de arquivo” em operação real, e a principal razão […]