No mundo industrial acelerado de hoje, como as empresas podem reduzir o tempo de produção, reduzir custos, e ainda atender às altas demandas de personalização? The answer lies in 3D printing fixtures—specialized tools made via 3D printing to support, segurar, e posicionar peças durante processos industriais. Ao contrário dos acessórios tradicionais, essas ferramentas combinam precisão, flexibilidade, e eficiência, making them indispensable in key sectors like aerospace and medical manufacturing. Below is a comprehensive guide to understanding, designing, and leveraging 3D printing fixtures.

1. What Are 3D Printing Fixtures, and Why Do You Need Them?

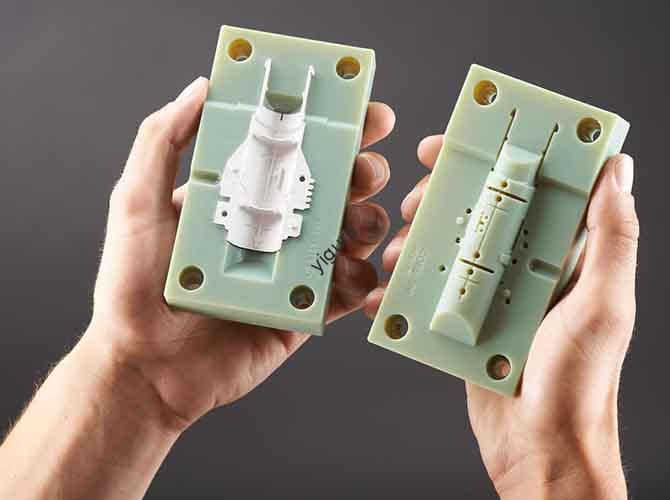

At their core, 3D printing fixtures are custom-manufactured tools created using 3D printing technology for specific industrial operations (por exemplo, sintering, conjunto, or inspection). They solve three critical pain points of traditional fixtures:

| Pain Point of Traditional Fixtures | Solution from 3D Printing Fixtures |

| Long production cycles (4–8 semanas) | Shortened lead time (3–7 dias) |

| High cost for small-batch orders | 30–50% lower manufacturing costs |

| Rigid design (hard to modify) | Fully customizable for unique workpieces |

Por exemplo, a medical device manufacturer once struggled to produce small-batch fixtures for orthopedic implant sintering. By switching to 3D printing, they reduced fixture production time from 6 semanas para 5 days and cut costs by 40%—all while ensuring the fixtures matched the implants’ exact shapes.

2. Fluxo de trabalho passo a passo: From Design to Deployment

Creating effective 3D printing fixtures follows a linear, four-stage process. Each step is critical to ensuring the final fixture meets performance and precision requirements.

Stage 1: Design personalizado & Otimização

- Needs Analysis: Primeiro, define the fixture’s purpose (por exemplo, high-temperature sintering or delicate electronic assembly) and the workpiece’s specs (tamanho, material, peso).

- Modelagem CAD: Use software like SolidWorks or AutoCAD to build a 3D model tailored to the workpiece. Por exemplo, a fixture for a titanium aerospace part would include grooves to match the part’s curved surface.

- Otimização de modelo: Adjust the design to fit 3D printing constraints—add fillets to reduce stress, optimize wall thickness (usually 2–5mm for durability), and avoid overhangs that require extra support.

Stage 2: Seleção de Materiais (The Make-or-Break Choice)

Choosing the right material ensures the fixture performs in its intended environment. Key factors include thermal stability, resistência ao desgaste, and compatibility with the workpiece.

| Tipo de material | Propriedades principais | Aplicações ideais |

| Cerâmica | Resistência a altas temperaturas (até 1.600°C), baixa expansão térmica | Powder metallurgy sintering |

| Metal (por exemplo, alumínio, aço inoxidável) | Alta resistência, resistência ao desgaste | Aerospace part assembly, heavy-load holding |

| Graphite | Excelente condutividade térmica, inércia química | High-precision electronic component processing |

Pro Tip: Always match the fixture’s thermal expansion coefficient to the workpiece. Por exemplo, if the workpiece is made of stainless steel (thermal expansion coefficient: 17.3 × 10⁻⁶/°C), choose a stainless steel fixture to avoid warping during heating.

Stage 3: 3D Printing Execution

- Preparação para impressão: Import the optimized CAD model into slicing software (por exemplo, Tratamento). Set parameters:

- Layer height: 0.1–0,2 mm (for high precision)

- Fill density: 50–80% (balances weight and strength)

- Printing speed: 30–60 mm/s (avoids layer separation)

- Impressão: Start the 3D printer (FDM for plastics, SLS for metals). The printer builds the fixture layer by layer—no molds or tooling needed.

Stage 4: Pós-processamento & Verificação de qualidade

| Etapa | Propósito | How to Do It |

| Remove Support Structures | Eliminate extra material used during printing | Use pliers for FDM parts; sandblasting for SLS parts |

| Tratamento de superfície | Improve smoothness and durability | Sand with 200–400 grit sandpaper; polish with a buffer for metal parts |

| Inspeção de Qualidade | Ensure compliance with design specs | Use a caliper to check dimensions; use a coordinate measuring machine (CMM) for high-precision parts |

3. Principais aplicações: Where 3D Printing Fixtures Shine

3D printing fixtures are not one-size-fits-all—they excel in sectors where customization and performance are non-negotiable. Here are four major use cases:

- Aeroespacial: Hold lightweight, partes complexas (por exemplo, lâminas de turbina) during drilling. Fixtures are made of aluminum for strength and low weight.

- Médico: Support custom orthopedic implants (por exemplo, substituições de quadril) during sintering. Ceramic fixtures withstand high temperatures without contaminating the implant.

- Eletrônica: Position tiny circuit boards during soldering. Plastic fixtures (por exemplo, PLA) are non-conductive and protect sensitive components.

- Powder Metallurgy: Shape metal powders into finished parts. Graphite fixtures ensure even heat distribution during sintering.

4. Yigu Technology’s Perspective on 3D Printing Fixtures

Na tecnologia Yigu, we’ve seen firsthand how 3D printing fixtures transform manufacturing. Many clients initially hesitate to switch from traditional fixtures, worried about cost or performance—but after testing, they’re amazed by the 30–50% cost reduction and 70% faster lead times. We recommend starting small: use 3D printing for low-volume, high-customization fixtures (por exemplo, protótipos de dispositivos médicos) before scaling up. Our team also helps optimize designs and select materials, ensuring fixtures meet even the strictest industry standards (por exemplo, aerospace AS9100).

Perguntas frequentes: Your Top 3D Printing Fixture Questions Answered

Q1: Can 3D printing fixtures replace all traditional fixtures?

No—for high-volume production (10,000+ unidades), traditional fixtures (por exemplo, CNC-machined metal) may still be cheaper. But for small batches, protótipos, ou peças personalizadas, 3D printing fixtures are far more cost-effective.

Q2: How long does a 3D printing fixture last?

It depends on the material and usage. Metal fixtures can last 2–5 years (for regular use), while ceramic fixtures last 3–7 years in high-temperature environments. Plastic fixtures (por exemplo, PLA) are best for short-term projects (6–12 meses).

Q3: Do I need special software to design 3D printing fixtures?

Basic CAD software (por exemplo, Fusão 360) works for simple fixtures. Para projetos complexos (por exemplo, peças aeroespaciais), use specialized software like ANSYS to simulate stress and thermal performance before printing.