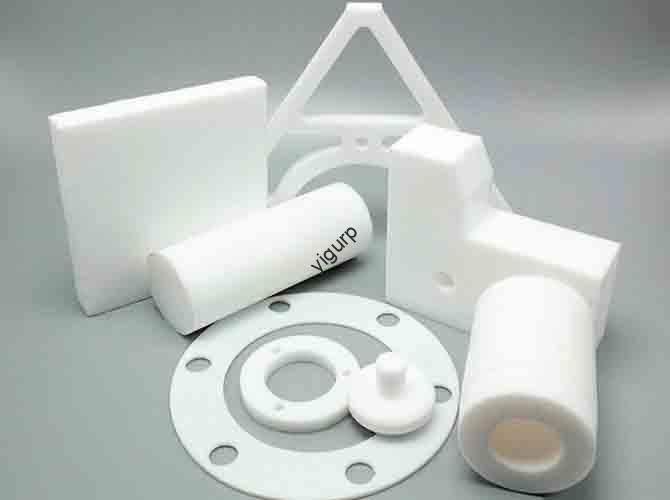

Our Polytetrafluoroethylene PTFE Teflon CNC Machining Services

At Yigu Technology, we specialize in high-precision Polytetrafluoroethylene (PTFE) Teflon CNC Machining—delivering custom, tight-tolerance parts that leverage the exceptional properties of this high-performance plastic. Whether for aerospace, medical, or industrial needs, our expert team combines advanced CNC Milling and CNC Turning with rigorous quality control to turn your designs into reliable, cost-effective components.

Understanding PTFE Teflon and CNC Machining

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is a versatile fluoropolymer celebrated as a top-tier engineering polymer. Its unique material profile—including chemical resistance, low friction, and thermal stability—makes it ideal for demanding applications.

CNC Machining (Computer Numerical Control Machining) is an automated machining process that uses pre-programmed software to control tools like mills, lathes, and drills. When paired with PTFE, this technology ensures consistent, precise shaping of the material, even for complex geometries. Below is a breakdown of key material properties of PTFE that drive its use in CNC machining:

| Material Property | Description | Typical Value |

| Chemical Resistance | Resists nearly all industrial chemicals and solvents | Unaffected by 99% of common chemicals |

| Thermal Stability | Operates reliably in extreme temperatures | -200°C to +260°C (-328°F to +500°F) |

| Coefficient of Friction | One of the lowest among solid materials | 0.04 (static) / 0.02 (dynamic) |

| Electrical Insulation | Excellent insulator across frequencies | Volume resistivity: 10¹⁸ Ω·cm |

Our Capabilities: Delivering Precision You Can Trust

At Yigu Technology, our PTFE Teflon CNC Machining capabilities are tailored to meet diverse industry needs. We don’t just machine parts—we solve engineering challenges with a focus on quality and efficiency. Here’s a detailed look at what we offer:

| Capability | Key Features | Applications |

| Precision Machining | Achieves tight tolerances (down to ±0.001 inches) and consistent dimensional accuracy | Aerospace components, medical device parts |

| Custom Machined Parts | Works with unique designs, from simple washers to complex housings | Industrial equipment, electronic enclosures |

| High-Tolerance Machining | Complies with tolerance standards (e.g., ISO 8062) and uses advanced measurement techniques | Automotive sensors, pharmaceutical processing parts |

| Complex Part Production | Handles intricate geometries via multi-axis CNC machines | Robotics components, chemical processing valves |

| Rapid Prototyping | Delivers functional prototypes in 3–5 business days | Product development, design validation |

| Production Machining | Scales from small batches (10–50 parts) to high-volume runs (10,000+ parts) | Mass-produced industrial tools, consumer electronics parts |

| Quality Assurance | Implements inspection methods like CMM (Coordinate Measuring Machine) and visual checks | All industries, especially medical and aerospace |

Process: Step-by-Step PTFE CNC Machining

Our PTFE Teflon CNC Machining process is designed to maximize precision, minimize waste, and ensure on-time delivery. Each step is optimized for PTFE’s unique characteristics (e.g., low rigidity, high thermal expansion):

- Design & Programming: Our engineers review your 3D models (CAD files) to create toolpaths for CNC Milling or CNC Turning. We select the right cutting techniques to avoid material deformation.

- Material Preparation: We source high-quality PTFE Resin or filled grades (e.g., glass-filled PTFE) and cut them into blanks that fit our machines.

- Machine Setup: Technicians calibrate CNC machines, install specialized tools (e.g., carbide end mills for PTFE), and set up fixtures to secure the material. Proper tool selection and machine setup prevent vibration, which can ruin precision.

- Machining Operations: We execute core processes like drilling operations (for holes) and grinding processes (for smooth surfaces). Our machines run 24/7 for high-volume orders, with real-time monitoring to catch issues early.

- Surface Treatment: After machining, parts undergo polishing (for a smooth finish) or coating (for added protection). For bonding needs, we use adhesive bonding techniques tested for PTFE compatibility.

Inspection & Quality Control: Every part is checked using tools like micrometers and CMMs to verify dimensional accuracy and adherence to tolerance standards. Only parts that pass 100% inspection move to packaging.

Materials: Choosing the Right PTFE Grade

Not all PTFE is the same—different grades are formulated to enhance specific properties. At Yigu Technology, we offer a range of materials to match your application’s needs:

| PTFE Grade | Key Additives | Enhanced Properties | Ideal Applications |

| Virgin PTFE | None | Pure chemical resistance, non-stick properties | Food processing equipment, chemical tanks |

| Glass-Filled PTFE | Glass fibers (10–40%) | Higher rigidity, reduced creep | Bearings, valve seats, aerospace brackets |

| Carbon-Filled PTFE | Carbon particles (10–30%) | Improved wear resistance, electrical conductivity | Electrical contacts, industrial gears |

| Bronze-Filled PTFE | Bronze particles (20–60%) | High load-bearing capacity, thermal conductivity | Pistons, hydraulic seals, automotive parts |

| Specialty PTFE Grades | Ceramic, graphite, or metal oxides | Customized properties (e.g., UV resistance, low outgassing) | Space applications, medical implants |

Surface Treatment: Enhancing PTFE Part Performance

While PTFE’s natural properties are impressive, surface treatment can elevate its functionality for specific uses. Our treatments are tailored to improve adhesion, durability, or aesthetics:

- Polishing: Creates a smooth, glossy surface that reduces friction and prevents debris buildup. Used for parts like bearings and sliding components.

- Coating: Applies thin layers (e.g., PFA or FEP) to enhance chemical resistance or add color. Common in food processing and medical devices.

- Painting: Uses specialized, PTFE-compatible paints for branding or corrosion protection. Ideal for industrial tools and consumer-facing parts.

- Sandblasting: Creates a matte, textured surface that improves grip or adhesion for bonding. Used in automotive and aerospace assemblies.

- Heat Treatment: Subjects parts to controlled heating/cooling to reduce internal stress and improve dimensional stability. Critical for high-temperature applications.

Adhesive Bonding: Pre-treats surfaces (e.g., with plasma) to enable strong bonding to metals or other plastics. Essential for multi-material components.

Tolerances: Achieving Precision in PTFE Machining

PTFE’s low rigidity and thermal expansion make tight tolerances a challenge—but our expertise ensures consistent accuracy. Below is a breakdown of our typical tolerances and the methods we use to maintain them:

| Tolerance Type | Typical Range | Measurement Technique | Industry Use Case |

| Precision Tolerances | ±0.001 to ±0.005 inches | CMM (Coordinate Measuring Machine) | Medical device components (e.g., catheters) |

| Tight Tolerances | ±0.005 to ±0.010 inches | Micrometers, calipers | Aerospace fasteners, electronic connectors |

| General Tolerances | ±0.010 to ±0.020 inches | Visual inspection, gauges | Industrial washers, non-critical spacers |

We follow global tolerance standards (e.g., ANSI/ASME Y14.5M) and use statistical process control (SPC) to ensure every batch meets your requirements.

Advantages: Why Choose PTFE Teflon CNC Machining?

PTFE Teflon CNC Machining offers unmatched benefits for industries that demand reliability and performance. Here’s how it stands out:

- Chemical Resistance: PTFE resists acids, bases, and solvents—making it ideal for chemical processing and lab equipment.

- Thermal Stability: It performs in extreme temperatures (-200°C to +260°C) without degrading, perfect for aerospace and automotive under-the-hood parts.

- Low Coefficient of Friction: Its non-stick surface reduces wear and energy loss, used in bearings and conveyor belts.

- Electrical Insulation: Excellent for electronic components (e.g., circuit boards) as it doesn’t conduct electricity.

- Non-Stick Properties: Prevents material buildup in food processing equipment (e.g., baking molds) and medical devices.

- Dimensional Stability: With proper machining, PTFE parts maintain shape even under stress, critical for precision tools.

Cost-Effective Production: CNC automation reduces waste and labor costs, especially for high-volume orders.

Applications Industry: Where PTFE CNC Parts Shine

Our PTFE Teflon CNC Machined parts are used across 8 key industries, each leveraging PTFE’s unique properties:

| Industry | Common Applications | Key PTFE Benefits Used |

| Automotive | Gaskets, sensor housings, fuel system components | Chemical resistance, thermal stability |

| Aerospace | Valve seats, wire insulation, engine parts | High-temperature performance, low outgassing |

| Electronics | Circuit board insulators, connector housings | Electrical insulation, dimensional stability |

| Medical | Catheter tips, surgical instrument components | Biocompatibility, chemical resistance |

| Industrial Equipment | Bearings, pump seals, conveyor belt parts | Low friction, wear resistance |

| Chemical Processing | Tank liners, valve components, piping | Chemical resistance, corrosion protection |

| Food Processing | Baking molds, conveyor belts, mixer parts | Non-stick properties, food safety compliance |

| Pharmaceutical | Processing equipment parts, drug delivery components | Sterilizability, chemical resistance |

Case Studies: Real-World Success with Yigu Technology

Case Study 1: Aerospace Valve Components

- Challenge: A leading aerospace client needed high-tolerance PTFE valve seats that could withstand 250°C temperatures and fuel exposure.

- Solution: We used carbon-filled PTFE and CNC Turning to achieve ±0.002 inch tolerances. We added a heat treatment step to reduce stress.

- Result: 100% of parts passed inspection, and the client reported zero failures in 2 years of use. Lead time was reduced by 30% compared to their previous supplier.

Case Study 2: Medical Catheter Tips

- Challenge: A medical device company required custom machined PTFE catheter tips with a smooth finish to prevent tissue irritation.

- Solution: We used virgin PTFE and CNC Milling with a polishing step. We implemented CMM inspections to ensure a ±0.001 inch tolerance.

- Result: The tips met FDA biocompatibility standards, and the client scaled production from 500 to 10,000 parts/month with consistent quality.

Case Study 3: Industrial Pump Seals

- Challenge: An industrial client needed bronze-filled PTFE pump seals to handle abrasive fluids and high pressure.

- Solution: We selected 40% bronze-filled PTFE for wear resistance and used drilling operations to create precise holes for installation.

Result: The seals lasted 5x longer than rubber alternatives, reducing the client’s maintenance costs by 40%.

Why Choose Us: Yigu Technology’s Edge in PTFE CNC Machining

When you partner with Yigu Technology for PTFE Teflon CNC Machining, you get more than just parts—you get a trusted engineering ally. Here’s why clients choose us:

- Expertise in PTFE Machining: Our team has 15+ years of experience working with PTFE and its filled grades, understanding how to overcome its unique machining challenges.

- High-Quality Products: We use only premium PTFE Resin and follow strict quality control processes (ISO 9001 certified) to ensure every part meets your specs.

- Experienced Machinists: Our technicians are trained on the latest CNC equipment and undergo regular upskilling to handle complex projects.

- Excellent Customer Service: We assign a dedicated account manager to every project, providing regular updates and addressing questions promptly.

- Fast Turnaround Times: Our 24/7 machining operations enable us to deliver prototypes in 3–5 days and production runs in 1–2 weeks.

- Competitive Pricing: We optimize our processes to reduce waste, passing savings to you without compromising quality.

Commitment to Innovation: We invest in new technologies (e.g., 5-axis CNC machines) to expand our capabilities and offer better solutions.