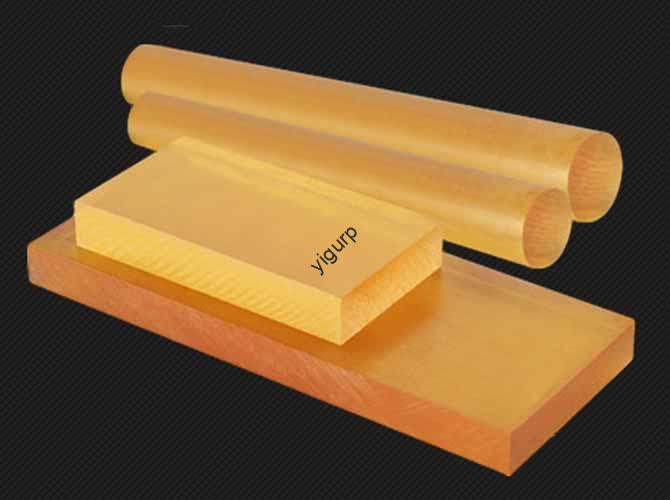

Our Polysulfone PSU CNC Machining Services

Elevate your manufacturing projects with Polysulfone (PSU) CNC Machining from Yigu Technology. As a trusted leader in processing high-performance thermoplastics, we specialize in crafting custom machined parts for industries ranging from automotive to medical—blending PSU’s exceptional thermal stability, chemical resistance, and dimensional accuracy with state-of-the-art CNC technology. Whether you need rapid prototypes or high-volume production runs, our expertise in engineering polymer machining delivers reliable, cost-effective solutions that meet the most rigorous industry standards.

Definition: What Is Polysulfone (PSU) CNC Machining?

Polysulfone (PSU) is a rugged, high-performance thermoplastic and engineering polymer celebrated for its ability to withstand extreme conditions. When paired with CNC Machining—a computer-controlled machining process that uses precision tools to shape materials—PSU becomes a go-to choice for creating critical components that demand durability and consistency.

At its core, PSU CNC machining leverages PSU’s unique material properties, such as resistance to high temperatures (up to 180°C continuous use), excellent electrical insulation, and low moisture absorption. Unlike less robust plastics, PSU maintains its strength and shape even in harsh environments, making it ideal for applications like medical devices, aerospace parts, and industrial equipment. CNC technology ensures every part is identical, eliminating the variability of manual machining and guaranteeing repeatable quality.

Our Capabilities: Precision That Meets Your Needs

Yigu Technology’s PSU CNC Machining capabilities are engineered to tackle the most complex manufacturing challenges. Our team combines cutting-edge equipment with years of expertise to deliver services that prioritize accuracy, speed, and quality assurance—all tailored to your project’s unique requirements.

| Capability | Key Features | Typical Applications |

| Precision Machining | Achieves tight tolerances as low as ±0.003mm; perfect for intricate designs | Medical device components, electronic connectors |

| Custom Machined Parts | Fully customizable to CAD/CAM specs; no minimum order quantity | Aerospace brackets, industrial tool housings |

| High-Tolerance Machining | Complies with ISO 9001 and ISO 13485 standards for critical applications | Surgical instruments, automotive sensors |

| Complex Part Production | Handles undercuts, thin walls (down to 0.5mm), and deep cavities with 5-axis CNC | Electronic enclosures, aerospace valves |

| Rapid Prototyping | Delivers functional PSU prototypes in 24–72 hours for design validation | Product development, testing, and iteration |

| Production Machining | Scalable to 50,000+ units/month with consistent quality control | Consumer goods components, industrial fasteners |

Every project undergoes rigorous inspection at every stage—from raw material testing to final dimensional checks—to ensure we exceed your expectations.

Process: How We Machin PSU for Optimal Results

The PSU CNC Machining process at Yigu Technology is a structured, detail-oriented workflow designed to maximize PSU’s performance while minimizing waste and errors. Each step is optimized for PSU’s unique characteristics (like its high melting point and rigidity) to ensure flawless results.

Step 1: Design & Tool Selection

We start by reviewing your CAD files to identify key features and select the right tool selection. For PSU, we use carbide tools (e.g., end mills, drills) that resist wear—critical for handling PSU’s hardness. Our engineers also adjust cutting parameters (speed: 1,500–3,000 RPM; feed rate: 50–200 mm/min) to prevent overheating and maintain dimensional accuracy.

Step 2: Machine Setup

Our CNC mills and lathes are calibrated specifically for PSU to reduce vibration and ensure stability. We use vacuum clamps or mechanical fixtures to secure PSU stock (sheets, rods, or blocks), preventing movement during machining that could compromise precision.

Step 3: Machining Operations

- CNC Milling: Creates 3D shapes, slots, and pockets; ideal for complex parts like medical device housings.

- CNC Turning: Produces cylindrical parts (e.g., shafts, bushings) with precision tolerances.

- Drilling Operations: Creates precise holes (as small as 0.3mm) using high-speed, coolant-assisted drills to avoid chipping.

- Grinding Processes: Finishes surfaces to achieve smoothness (Ra < 0.6μm) for applications requiring sterility or aerodynamics.

Step 4: Quality Inspection

Every PSU part is inspected using coordinate measuring machines (CMMs) and laser scanners to verify compliance with tolerance standards. We also conduct material tests (e.g., thermal stability checks) to ensure the part meets PSU’s inherent performance criteria.

Materials: Choosing the Right PSU Grade for Your Project

Not all Polysulfone (PSU) is created equal—we offer a range of grades to match your project’s specific needs, from chemical resistance to cost efficiency. Each grade is selected based on your application’s environmental and performance demands.

| PSU Grade | Key Properties | Recommended Industries |

| Pure PSU | Exceptional thermal stability (up to 180°C), excellent electrical insulation | Electronics (circuit boards), appliances |

| PSU Resin | Raw, moldable form; ideal for custom shapes before machining | Prototyping, small-batch production |

| Glass-Filled PSU | 10–40% glass fiber reinforcement; boosts strength-to-weight ratio by 30% | Aerospace (structural parts), industrial machinery |

| Flame-Retardant PSU | UL94 V-0 rating; resists fire and smoke emission | Electronics (enclosures), automotive under-the-hood parts |

| Reinforced PSU | Blended with carbon fiber or minerals for enhanced rigidity and impact resistance | Heavy equipment components, sporting goods |

| Recycled PSU | Sustainable option with 90% of pure PSU’s performance; cost-effective | Non-critical industrial parts, consumer goods |

| Specialty PSU Grades | FDA-compliant (for food/medical) or low-outgassing (for aerospace) | Medical (surgical tools), aerospace (satellite components) |

Our team works closely with you to select the optimal grade—balancing performance, sustainability, and cost-effective production for your project.

Surface Treatment: Enhancing PSU’s Performance & Appearance

While PSU boasts impressive natural properties, surface treatment can further enhance its functionality, durability, or aesthetics. We offer treatments specifically compatible with PSU to avoid damaging its structural integrity.

| Treatment | Purpose | Benefits for PSU Parts |

| Anodizing | Applies a protective oxide layer (for metal-coated PSU) | Improved corrosion resistance |

| Painting | Adds color or branding; uses heat-resistant paints (up to 200°C) | Enhanced aesthetics, UV protection |

| Plating | Adds metal coatings (e.g., gold, nickel) for conductivity or wear resistance | Electrical contacts, decorative parts |

| Polishing | Removes machining marks; achieves a mirror finish (Ra < 0.2μm) | Medical devices (sterility), consumer goods |

| Sandblasting | Creates a matte, textured surface for grip or adhesion | Industrial tool handles, automotive controls |

| Coating | Applies Teflon or silicone coatings for extra chemical resistance | Chemical processing equipment, medical devices |

| Heat Treatment | Reduces internal stresses post-machining; improves dimensional stability | Precision parts (gears, sensors) |

Tolerances: Setting the Standard for PSU Precision

Tolerances are make-or-break in PSU CNC machining—especially for parts used in medical, aerospace, or electronics industries where even minor deviations can cause failure. At Yigu Technology, we prioritize tight tolerances and dimensional accuracy to ensure your parts fit and function perfectly.

Typical Tolerances for PSU CNC Machining

| Feature Type | Standard Tolerance | High-Precision Tolerance |

| Linear Dimensions (≤100mm) | ±0.05mm | ±0.003mm |

| Hole Diameters | ±0.03mm | ±0.001mm |

| Flatness | 0.08mm/m | 0.01mm/m |

| Concentricity | 0.04mm | 0.005mm |

To ensure accuracy, we use advanced measurement techniques (e.g., optical comparators) and inspection methods (e.g., first-article inspection) for every project. Our quality team also collaborates with you to define tolerance requirements that balance precision and cost.

Advantages: Why PSU CNC Machining Stands Out

Polysulfone (PSU) CNC Machining offers a host of advantages that make it a top choice for engineering applications—outperforming both traditional plastics and metals in many scenarios.

| Advantage | Description | Impact for Your Business |

| High Strength-to-Weight Ratio | 50% lighter than aluminum with similar strength; reduces part weight by up to 40% | Lower shipping costs, improved fuel efficiency (automotive/aerospace) |

| Chemical Resistance | Resists acids, bases, oils, and solvents (even at high temperatures) | Longer part lifespan in harsh environments (chemical processing, automotive) |

| Thermal Stability | Withstands continuous use at 180°C and short-term exposure to 200°C; no warping | Suitable for high-heat applications (industrial ovens, engine components) |

| Electrical Insulation | Maintains dielectric properties even at high temperatures; ideal for electronics | Reduces risk of electrical failure (circuit boards, sensors) |

| Dimensional Stability | Low moisture absorption (<0.2%); no swelling or shrinking in humid conditions | Consistent part fit (critical for assemblies like medical devices) |

| Cost-Effective Production | Faster machining speeds than metals; minimal waste due to CNC precision | Lower per-unit costs for high-volume orders |

| Design Flexibility | CNC technology enables complex geometries (e.g., thin walls, undercuts) that are hard to achieve with metals | Freedom to innovate in product design (aerospace parts, medical devices) |

Applications Industry: Where PSU CNC Machined Parts Excel

PSU CNC Machining serves a diverse range of industries, thanks to PSU’s versatility and durability. Below are key sectors where our PSU parts deliver exceptional value:

- Automotive: Components like sensor housings, valve covers, and electrical connectors—benefiting from PSU’s thermal stability and chemical resistance to engine oils.

- Aerospace: Structural brackets, electronic enclosures, and fuel system parts—requiring high-tolerance machining and low-outgassing PSU grades.

- Electronics: Circuit board insulators, LED heatsinks, and high-voltage connectors—leveraging PSU’s electrical insulation and heat resistance.

- Medical: Surgical tool handles, diagnostic device housings, and implant components—using FDA-compliant PSU and smooth surface treatment for sterility.

- Industrial Equipment: Gear housings, pump parts, and conveyor components—needing durability and resistance to industrial chemicals.

Consumer Goods: Appliance parts (e.g., coffee maker components), sporting goods (e.g., bike frames), and electronics casings—balancing performance and aesthetics.

Case Studies: Real-World Success with PSU CNC Machining

Case Study 1: Medical Surgical Instrument Handle

Challenge: A medical device manufacturer needed a surgical handle that could withstand repeated sterilization (autoclaving at 134°C) and resist chemical disinfectants.

Solution: We used FDA-compliant PSU and CNC turning to create a handle with a tolerance of ±0.005mm. A polishing treatment was added to ensure a smooth, bacteria-resistant surface.

Result: The handle passed 1,000+ autoclave cycles without degradation; 10,000+ units produced monthly with 0 defects.

Case Study 2: Aerospace Electronic Enclosure

Challenge: An aerospace client required a lightweight enclosure for satellite electronics—needing low-outgassing, tight tolerances (±0.003mm), and resistance to extreme temperatures (-50°C to 150°C).

Solution: We machined specialty low-outgassing PSU using 5-axis CNC milling. A coating of silicone was applied for extra thermal protection.

Result: The enclosure met NASA’s outgassing standards; weight was reduced by 35% compared to aluminum alternatives, cutting launch costs.

Case Study 3: Industrial Pump Component

Challenge: An industrial client needed a pump impeller that could resist corrosive chemicals (e.g., sulfuric acid) and operate at 160°C.

Solution: We used glass-filled PSU and CNC milling to create the impeller with a precision tolerance of ±0.02mm. A chemical-resistant coating was added for extra protection.

Result: The impeller lasted 3x longer than the previous metal version; reduced maintenance costs by 40%.

Why Choose Us: Yigu Technology’s Expertise in PSU CNC Machining

When you partner with Yigu Technology for PSU CNC Machining, you’re not just hiring a supplier—you’re gaining a team of experts dedicated to your project’s success. Here’s why clients across industries trust us:

- Expertise in PSU Machining: 12+ years of specialized experience working with high-performance thermoplastics like PSU; our engineers understand PSU’s unique machining challenges (e.g., heat management, tool wear).

- High-Quality Products: Every part undergoes 4-step quality checks (raw material, in-process, post-machining, final testing) to ensure compliance with ISO 9001, ISO 13485, and AS9100 standards.

- Experienced Machinists: Our team holds certifications in CNC operation and industry-specific standards (e.g., medical device manufacturing, aerospace precision).

- Excellent Customer Service: A dedicated project manager guides you from design to delivery—providing weekly progress updates and addressing questions within 24 hours.

- Fast Turnaround Times: Prototypes ready in 24–72 hours; production orders shipped in 3–10 business days (20% faster than industry averages).

- Competitive Pricing: Our strategic partnerships with PSU suppliers and efficient machining processes reduce costs—passing savings to you without compromising quality.

Commitment to Innovation: We invest in the latest equipment (e.g., 5-axis CNC mills, laser scanners) and stay updated on PSU material advancements to offer cutting-edge solutions.