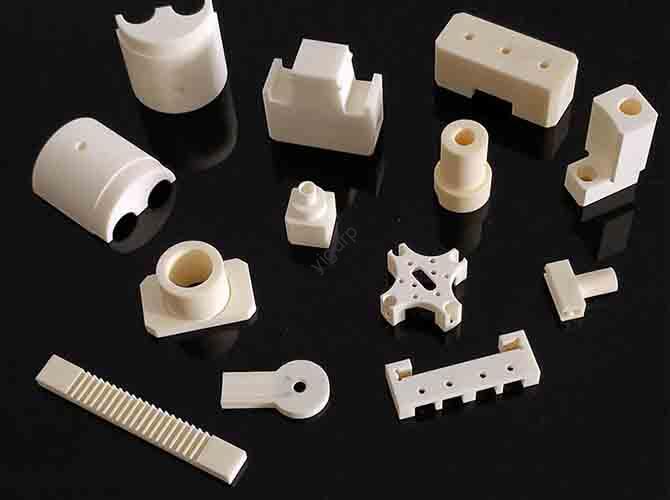

Our Polyphenylene Oxide PPO CNC Machining Services

Unlock precision and performance with Polyphenylene Oxide (PPO) CNC Machining from Yigu Technology. As a leading provider of high-performance material processing, we specialize in crafting custom machined parts for industries like automotive, aerospace, and electronics—combining thermal stability, chemical resistance, and tight dimensional control to turn your engineering visions into reality. Whether you need rapid prototyping or high-volume production, our expertise in engineering plastic machining delivers cost-effective, high-quality solutions that meet the strictest standards.

What Is Polyphenylene Oxide (PPO) CNC Machining?

Polyphenylene Oxide (PPO) is a high-performance thermoplastic polymer and engineering plastic renowned for its exceptional mechanical and thermal properties. When paired with CNC Machining—a computer-controlled machining process that uses tools like mills and lathes to shape materials—PPO transforms into precision components for critical applications.

At its core, PPO CNC machining leverages the unique material properties of PPO, such as low water absorption, excellent electrical insulation, and resistance to harsh chemicals, to create parts that outperform traditional plastics in demanding environments. Unlike manual machining, CNC technology ensures consistent accuracy across every part, making it ideal for projects requiring repeatability and reliability.

Our Capabilities: Delivering Precision You Can Trust

Yigu Technology’s PPO CNC Machining capabilities are designed to meet the most complex manufacturing needs. Our team combines advanced equipment with decades of expertise to offer a full range of services, all backed by rigorous quality assurance protocols.

| Capability | Key Features | Typical Applications |

| Precision Machining | Achieves tolerances as tight as ±0.005mm; ideal for intricate geometries | Electronic connectors, medical parts |

| Custom Machined Parts | Tailored to your design specs (CAD/CAM compatible); no minimum order size | Aerospace components, industrial tools |

| High-Tolerance Machining | Complies with ISO 9001 and AS9100 standards for dimensional accuracy | Automotive sensors, precision gears |

| Complex Part Production | Handles undercuts, thin walls, and deep holes with advanced 5-axis CNC | Medical device housings, aerospace brackets |

| Rapid Prototyping | Turnaround times as fast as 24–48 hours for prototype validation | Product development, design testing |

| Production Machining | Scalable to 10,000+ units/month with consistent quality control | Consumer goods components, industrial fasteners |

Every project undergoes strict inspection—from raw material testing to final dimensional checks—to ensure we meet or exceed your expectations.

Process: How We Machin PPO with CNC Technology

The PPO CNC Machining process at Yigu Technology follows a structured workflow to ensure precision and efficiency. Each step is optimized for PPO’s unique properties (e.g., low thermal conductivity) to avoid material damage and ensure consistent results.

Step 1: Design & Tool Selection

We start with your CAD files, analyzing geometries to select the right tool selection (e.g., carbide end mills for PPO’s rigidity). Our engineers adjust cutting parameters (speed, feed rate) to prevent melting—critical for maintaining dimensional accuracy.

Step 2: Machine Setup

Our CNC machines (mills, lathes) are calibrated for PPO to minimize vibration and ensure stability. We use vacuum chucks to secure PPO sheets or blocks, preventing warping during machining.

Step 3: Machining Operations

- CNC Milling: Used for 3D shapes, slots, and pockets; ideal for complex parts like electronic enclosures.

- CNC Turning: Creates cylindrical parts (e.g., bushings, shafts) with tight tolerances.

- Drilling Operations: Produces precise holes (as small as 0.5mm) using high-speed drills.

- Grinding Processes: Finishes surfaces to achieve smoothness (Ra < 0.8μm) for medical or aerospace applications.

Step 4: Quality Inspection

Every part is inspected using coordinate measuring machines (CMMs) and optical comparators to verify tolerance standards and ensure compliance with your specs.

Materials: Exploring PPO Grades for Your Application

Not all Polyphenylene Oxide (PPO) is the same—we offer a range of grades to match your project’s unique requirements. Each grade is selected based on factors like strength, flame resistance, and cost.

| PPO Grade | Key Properties | Recommended Industries |

| Pure PPO | High dimensional stability, excellent electrical insulation | Electronics (circuit boards), appliances |

| Modified PPO | Improved impact resistance (blended with PS or HIPS) | Automotive (interior components), consumer goods |

| Glass-Filled PPO | 10–40% glass fiber reinforcement; high strength-to-weight ratio | Aerospace (structural parts), industrial equipment |

| Flame-Retardant PPO | UL94 V-0 rating; resistance to fire and smoke | Electronics (enclosures), medical devices |

| Reinforced PPO | Mixed with carbon fiber or minerals for enhanced rigidity | Heavy machinery parts, automotive under-the-hood components |

| Specialty PPO Grades | FDA-compliant (for food/medical) or low-outgassing (for aerospace) | Medical (surgical tools), aerospace (satellite components) |

Our team works with you to select the optimal grade—balancing performance and cost-effective production for your project.

Surface Treatment: Enhancing PPO Parts’ Performance & Aesthetics

While PPO has excellent natural properties, surface treatment can further improve its functionality, durability, or appearance. We offer a range of treatments tailored to PPO’s compatibility.

| Treatment | Purpose | Benefits for PPO Parts |

| Anodizing | Creates a protective oxide layer (for metalized PPO) | Improved corrosion resistance |

| Painting | Adds color or branding; uses UV-curable paints for durability | Enhanced aesthetics, scratch resistance |

| Plating | Applies metal coatings (e.g., nickel, chrome) for conductivity or magnetism | Electrical grounding, decorative finish |

| Polishing | Smooths surface imperfections; achieves a glossy or matte finish | Improved hygiene (for medical parts), better light reflection |

| Sandblasting | Creates a textured surface (e.g., matte finish) for grip or aesthetics | Industrial tools, consumer goods handles |

| Coating | Applies protective layers (e.g., Teflon) for chemical resistance | Chemical processing equipment, medical devices |

| Heat Treatment | Reduces internal stresses post-machining; improves dimensional stability | Precision parts (gears, sensors) |

Tolerances: Achieving Precision in PPO CNC Machining

Tolerances are critical in PPO CNC machining—especially for parts used in aerospace, medical, or electronics applications. At Yigu Technology, we prioritize tight tolerances and dimensional accuracy to ensure your parts fit and function as intended.

Typical Tolerances for PPO CNC Machining

| Feature Type | Standard Tolerance | High-Precision Tolerance |

| Linear Dimensions (≤100mm) | ±0.1mm | ±0.005mm |

| Hole Diameters | ±0.05mm | ±0.002mm |

| Flatness | 0.1mm/m | 0.02mm/m |

| Concentricity | 0.05mm | 0.01mm |

To ensure accuracy, we use advanced measurement techniques (e.g., laser scanning) and inspection methods (e.g., first-article inspection) for every project. Our quality team works with you to define tolerance requirements that balance precision and cost.

Advantages: Why Choose PPO CNC Machining?

Polyphenylene Oxide (PPO) CNC Machining offers unique benefits that make it a top choice for engineering applications. Compared to other plastics (e.g., ABS, nylon) or metals (e.g., aluminum), PPO stands out for its combination of performance and value.

| Advantage | Description | Impact for Your Business |

| High Strength-to-Weight Ratio | Stronger than many plastics, lighter than metal—reduces part weight by 30–50% vs. aluminum | Lower shipping costs, improved fuel efficiency (automotive/aerospace) |

| Chemical Resistance | Resists oils, solvents, and acids (e.g., gasoline, cleaning agents) | Longer part lifespan in harsh environments |

| Thermal Stability | Operates at temperatures up to 120°C (continuous use); no melting or warping | Suitable for under-the-hood automotive parts or industrial ovens |

| Electrical Insulation | Excellent dielectric properties—ideal for high-voltage applications | Reduces risk of electrical failure (electronics) |

| Dimensional Stability | Low water absorption (<0.1%); no swelling or shrinking in humid conditions | Consistent part fit (critical for assemblies) |

| Cost-Effective Production | Faster machining speeds than metals; no secondary finishing (in many cases) | Lower per-unit costs for high-volume orders |

| Design Flexibility | CNC technology enables complex geometries (e.g., thin walls, undercuts) | Freedom to innovate in product design |

Applications Industry: Where PPO CNC Machined Parts Shine

PPO CNC Machining serves a wide range of industries, thanks to its versatility and performance. Below are key sectors where our parts add value:

- Automotive: Components like sensor housings, connector blocks, and interior trim—benefiting from PPO’s thermal stability and impact resistance.

- Aerospace: Structural brackets, electronic enclosures, and valve parts—requiring high-tolerance machining and low-outgassing PPO grades.

- Electronics: Circuit board insulators, LED heatsinks, and connector shells—leveraging PPO’s electrical insulation and flame resistance.

- Medical: Surgical tool handles, diagnostic device housings, and implant components—using FDA-compliant PPO and smooth surface treatment.

- Industrial Equipment: Gear housings, pump parts, and conveyor components—needing chemical resistance and durability.

Consumer Goods: Appliance parts (e.g., blender bases), sporting goods (e.g., bike components), and electronics casings—balancing aesthetics and performance.

Case Studies: Real-World Success with PPO CNC Machining

Case Study 1: Automotive Sensor Housing for a Global OEM

Challenge: A leading automotive manufacturer needed a sensor housing that could withstand under-the-hood temperatures (up to 110°C) and resist oil exposure.

Solution: We used glass-filled PPO and CNC milling to create a housing with a tolerance of ±0.02mm. A flame-retardant coating was added for safety compliance.

Result: 50,000+ units produced monthly with 0 defects; the part exceeded the OEM’s lifespan requirement by 2 years.

Case Study 2: Medical Device Enclosure for a Diagnostic Company

Challenge: A medical client required an enclosure for a portable diagnostic tool—needing FDA compliance, electrical insulation, and a smooth surface for cleaning.

Solution: We machined specialty FDA-compliant PPO using CNC turning and polishing (Ra < 0.4μm). A heat treatment reduced internal stresses.

Result: The enclosure passed biocompatibility testing and is now used in 20+ countries; turnaround time for prototypes was 48 hours.

Case Study 3: Aerospace Bracket for a Satellite Manufacturer

Challenge: A aerospace client needed a lightweight, high-strength bracket for a satellite—requiring tight tolerances (±0.005mm) and low-outgassing.

Solution: We used carbon-fiber reinforced PPO and 5-axis CNC milling. Inspection was done via CMM to verify compliance with AS9100 standards.

Result: The bracket met all aerospace requirements; weight was reduced by 40% compared to aluminum alternatives.

Why Choose Us: Yigu Technology’s Edge in PPO CNC Machining

When you partner with Yigu Technology for PPO CNC Machining, you gain more than a supplier—you gain a team of experts dedicated to your success. Here’s why clients trust us:

- Expertise in PPO Machining: 15+ years of experience working exclusively with engineering plastics like PPO; our engineers understand PPO’s unique machining challenges.

- High-Quality Products: Every part undergoes 3-step quality checks (raw material, in-process, final) to ensure compliance with ISO 9001 and customer specs.

- Experienced Machinists: Our team holds certifications in CNC operation and aerospace/medical manufacturing standards (e.g., AS9100, ISO 13485).

- Excellent Customer Service: A dedicated project manager works with you from design to delivery—providing regular updates and addressing questions promptly.

- Fast Turnaround Times: Prototypes in 24–48 hours; production orders shipped in 5–10 business days (faster than industry averages).

- Competitive Pricing: Our scalable production and strategic material sourcing reduce costs—passing savings to you without compromising quality.

Commitment to Innovation: We invest in advanced equipment (e.g., 5-axis CNC mills, laser scanners) to stay ahead of manufacturing trends and meet evolving client needs.