Our PC Vacuum Casting Services

Looking for a high-precision, cost-effective solution for small-batch plastic part production? PC Vacuum Casting delivers exceptional dimensional accuracy, smooth surface finishes, and fast turnaround times—perfect for prototyping, low-volume manufacturing, and custom components across industries. At Yigu Technology, we combine decades of expertise with advanced techniques to bring your designs to life with unmatched quality.

What is PC Vacuum Casting?

Understanding the Definition of PC Vacuum Casting is the first step to leveraging its benefits. Simply put, PC Vacuum Casting (also known as polyurethane vacuum casting) is a low-pressure casting process used to produce high-quality plastic parts from polyurethane resins. It uses a master model (often 3D-printed) to create a silicone mold, which is then filled with liquid resin under vacuum to eliminate air bubbles—resulting in parts that mimic the look and feel of injection-molded components.

This method answers the question, “What is PC Vacuum Casting?” by focusing on precision and flexibility: it’s ideal for small production runs (10–100 parts) where injection molding would be too costly. The PC Vacuum Casting Meaning extends beyond basic production—it’s a bridge between prototyping and mass manufacturing, allowing businesses to test designs and meet short-term demand without heavy upfront investment. For a quick overview, the table below summarizes its core attributes:

| Aspect | Key Detail |

| Core Purpose | Small-batch production, prototyping, custom parts |

| Primary Material | Polyurethane resins (with PC-like properties) |

| Typical Batch Size | 10–100 parts per mold |

| Lead Time | 3–7 days (from mold creation to part delivery) |

| Accuracy Level | ±0.1mm (for parts under 100mm) |

Yigu Technology’s PC Vacuum Casting Capabilities

At Yigu Technology, our PC Vacuum Casting Capabilities are built on years of hands-on experience and a commitment to excellence. We don’t just offer a service—we provide end-to-end solutions tailored to your project’s unique needs. Our Expertise in PC Vacuum Casting covers every stage, from mold design to post-processing, ensuring consistent quality across every part.

Our team’s Skills in PC Vacuum Casting include mastering complex geometries, matching custom resin properties (such as flexibility or heat resistance), and optimizing processes for faster turnaround. With Experience with PC Vacuum Casting spanning 15+ years, we’ve supported clients in automotive, electronics, medical, and consumer goods industries. The Range of PC Vacuum Casting Services we offer includes:

| Service Category | Specific Offerings |

| Mold Creation | Silicone mold design, multi-cavity molds, mold maintenance |

| Resin Selection | Over 50 resin options (rigid, flexible, transparent, flame-retardant) |

| Post-Processing | Surface treatment, painting, assembly, quality inspection |

| Design Support | DFM (Design for Manufacturability) advice, prototype refinement |

How Does PC Vacuum Casting Work?

The PC Vacuum Casting Process Flow is a structured sequence of steps that ensures precision and consistency. Unlike traditional casting methods, it relies on vacuum pressure to create bubble-free parts—here’s a breakdown of the Steps in PC Vacuum Casting:

- Master Model Preparation: First, a master model (usually 3D-printed in resin or CNC-machined) is created to match the desired part design. This model must be smooth and accurate, as it will define the mold’s shape.

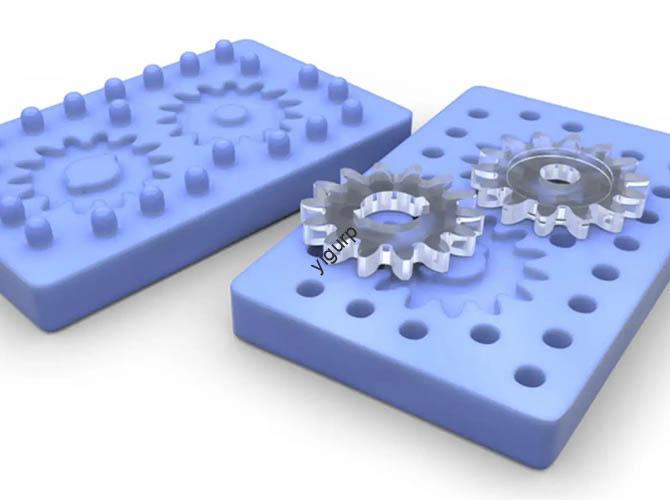

- Silicone Mold Making: The master model is placed in a mold frame, and liquid silicone is poured around it. The frame is then placed under vacuum to remove air, and the silicone cures (typically 4–8 hours) to form a flexible mold.

- Resin Casting: The silicone mold is opened, the master model is removed, and liquid polyurethane resin (colored or clear) is poured into the mold cavity. The mold is again placed under vacuum (20–50 mbar pressure) to eliminate air bubbles—this step is critical for achieving a smooth surface.

- Curing: The mold is heated to 40–60°C to speed up resin curing (1–2 hours). For larger parts, room-temperature curing may be used, though it takes longer.

- Demolding & Post-Processing: Once cured, the part is carefully removed from the mold. Post-processing steps (like trimming excess resin or Surface Treatment in PC Vacuum Casting) are then performed to finalize the part.

The Detailed Process of PC Vacuum Casting can be adjusted based on part size and resin type, but this core workflow remains consistent. To visualize the timeline, see the table below:

| Process Stage | Typical Time Required | Key Goal |

| Master Model Creation | 1–2 days | Achieve design accuracy |

| Silicone Mold Making | 1–2 days | Create durable, precise mold |

| Resin Casting | 2–4 hours | Fill mold without air bubbles |

| Curing | 1–8 hours | Ensure resin hardens fully |

| Post-Processing | 0.5–1 day | Refine part to meet specifications |

Materials Used in PC Vacuum Casting

Choosing the right Materials Used in PC Vacuum Casting is essential for meeting part performance requirements. The primary material is polyurethane resin, but there are dozens of formulations to match different needs—from rigid, PC-like resins to flexible, rubber-like options.

Suitable Materials for PC Vacuum Casting include:

- Rigid Resins: These mimic polycarbonate (PC), ABS, or nylon. They offer high impact resistance and are ideal for structural parts (e.g., electronic enclosures, automotive components).

- Flexible Resins: With shore hardness ranging from 30A to 90A, these are used for gaskets, seals, or soft-touch parts.

- Transparent Resins: Clear or tinted resins that replicate glass or acrylic, perfect for lenses or display covers.

- Specialty Resins: Flame-retardant, UV-resistant, or food-grade resins for industry-specific needs (e.g., medical devices, outdoor products).

The table below compares Common Materials in PC Vacuum Casting and their properties:

| Material Type | Shore Hardness | Tensile Strength | Key Applications |

| Rigid PC-Like Resin | 85D–95D | 50–65 MPa | Electronic enclosures, structural parts |

| Flexible Resin | 30A–90A | 5–15 MPa | Gaskets, grips, soft components |

| Transparent Resin | 80D–90D | 45–55 MPa | Lenses, display covers, light fixtures |

| Flame-Retardant Resin | 85D–90D | 48–58 MPa | Electrical parts, automotive components |

Material Selection for PC Vacuum Casting depends on factors like temperature resistance, chemical exposure, and aesthetic needs. Our team at Yigu Technology helps you choose the best material by analyzing your project’s requirements.

Surface Treatment in PC Vacuum Casting

Surface Treatment in PC Vacuum Casting is the final step to enhance part appearance, durability, and functionality. Even with a smooth mold, post-processing ensures the part meets your exact aesthetic and performance standards.

Common Surface Finishing for PC Vacuum Casting options include:

- Painting: Custom colors (matching Pantone or RAL codes) or textured paints (matte, glossy, or soft-touch) to improve appearance.

- Plating: Metallic plating (chrome, nickel, or gold) for a premium look—ideal for consumer electronics or automotive trim.

- Polishing: Achieves a high-gloss finish for transparent parts (e.g., lenses) or visible components.

- Sandblasting: Creates a matte, uniform surface to hide minor imperfections.

Post-Processing in PC Vacuum Casting not only improves aesthetics but also adds protection. For example, Surface Coatings in PC Vacuum Casting (like UV-resistant coatings) can extend part lifespan in outdoor applications. The table below highlights popular treatments and their benefits:

| Surface Treatment | Key Benefit | Ideal For |

| Custom Painting | Matches brand colors, hides surface flaws | Consumer goods, automotive parts |

| Metallic Plating | Premium, reflective finish | Electronics, decorative components |

| Polishing | High-gloss, transparent clarity | Lenses, display covers |

| UV Coating | Protects against sun damage, fading | Outdoor parts, medical devices |

Tolerances and Precision in PC Vacuum Casting

Tolerances in PC Vacuum Casting are a critical factor for parts that need to fit or function with other components. Unlike 3D printing (which can have larger variances), vacuum casting delivers exceptional precision—making it suitable for tight-tolerance applications.

The Precision of PC Vacuum Casting is typically ±0.1mm for parts under 100mm in size, and ±0.1% for larger parts (up to 500mm). These Tolerance Levels in PC Vacuum Casting are achievable thanks to:

- High-quality silicone molds (which retain detail even after multiple casts).

- Vacuum pressure (eliminates air bubbles that cause dimensional errors).

- Controlled curing temperatures (prevents resin shrinkage inconsistencies).

Accuracy of PC Vacuum Casting is comparable to low-volume injection molding but at a fraction of the cost. The table below compares tolerances across common manufacturing methods:

| Manufacturing Method | Typical Tolerance (for 100mm part) | Cost for 50 Parts | Lead Time |

| PC Vacuum Casting | ±0.1mm | 500–1,200 | 3–7 days |

| 3D Printing (SLA) | ±0.2mm–±0.3mm | 300–800 | 1–3 days |

| Injection Molding | ±0.05mm–±0.1mm | 5,000–15,000 | 2–4 weeks |

For projects requiring strict Dimensional Tolerances in PC Vacuum Casting, Yigu Technology uses advanced measurement tools (like coordinate measuring machines, CMMs) to verify part accuracy—ensuring every component meets your specifications.

Advantages of PC Vacuum Casting

The Benefits of PC Vacuum Casting make it a top choice for businesses looking to balance quality, cost, and speed. Whether you’re prototyping or producing small batches, it offers advantages that other methods can’t match.

Key Advantages of Using PC Vacuum Casting include:

- Cost-Effective for Small Batches: No expensive metal molds (like injection molding), so it’s affordable for runs of 10–100 parts.

- Fast Turnaround: From design to finished parts in as little as 3 days—ideal for tight deadlines.

- High-Quality Finishes: Smooth surfaces and fine detail replication (even for complex geometries).

- Material Flexibility: Dozens of resin options to match PC, ABS, rubber, or specialty materials.

- Low Risk: Easy to modify master models or molds if design changes are needed—unlike injection molding, where mold changes are costly.

So, Why Choose PC Vacuum Casting? It’s the perfect solution when you need production-quality parts without the upfront investment of mass manufacturing. The Strengths of PC Vacuum Casting shine in industries like automotive (for custom interior parts), electronics (for prototype enclosures), and medical (for low-volume device components).

Applications of PC Vacuum Casting by Industry

Industries Using PC Vacuum Casting span across manufacturing, thanks to its versatility and precision. From prototyping to end-use parts, it solves unique challenges in diverse sectors.

The Application Areas of PC Vacuum Casting include:

- Automotive: Custom interior trim, dashboard components, prototype sensors, and rubber gaskets.

- Electronics: Prototype phone cases, laptop enclosures, LED light housings, and connector parts.

- Medical: Low-volume surgical tool handles, diagnostic device casings, and custom prosthetic components (using biocompatible resins).

- Consumer Goods: Custom toy parts, kitchen gadget components, and cosmetic packaging prototypes.

The Market for PC Vacuum Casting is growing as more businesses adopt agile manufacturing practices—needing fast, low-cost solutions to test ideas or meet niche demand. The table below highlights industry-specific uses:

| Industry | Key Applications | Resin Type Preferred |

| Automotive | Interior trim, sensor housings | Rigid PC-like, flame-retardant |

| Electronics | Phone cases, LED housings | Rigid ABS-like, transparent |

| Medical | Surgical tool handles, prosthetics | Biocompatible, rigid or flexible |

| Consumer Goods | Toy parts, cosmetic packaging | Colorable, rigid or soft-touch |

Manufacturing Techniques in PC Vacuum Casting

Mastering Techniques in PC Vacuum Casting is what sets expert providers (like Yigu Technology) apart from basic service shops. These methods optimize quality, speed, and cost—ensuring consistent results for every project.

Key Manufacturing Methods in PC Vacuum Casting include:

- Multi-Cavity Mold Design: Creating molds with 2–8 cavities to produce multiple parts per cast—reducing lead time and cost for larger batches.

- Vacuum Pressure Optimization: Adjusting vacuum levels (20–50 mbar) based on resin viscosity—thicker resins need higher vacuum to eliminate bubbles.

- Mold Release Agents: Using food-grade or industrial release agents to prevent resin from sticking to the silicone mold—extending mold life (up to 50 casts per mold).

- Resin Degassing: Pre-degassing liquid resin before pouring to remove air bubbles—critical for transparent or thin-walled parts.

Production Techniques for PC Vacuum Casting also include quality control steps, like inline inspection of molds and post-cast dimensional checks. The Technical Aspects of PC Vacuum Casting (such as mold temperature control) are monitored closely to avoid issues like resin shrinkage or uneven curing.

PC Vacuum Casting Case Studies

Real-world PC Vacuum Casting Case Studies demonstrate how this process solves complex manufacturing challenges. Below are two examples of successful projects we’ve completed at Yigu Technology:

Case Study 1: Automotive Prototype Enclosure

- Client: A leading electric vehicle (EV) manufacturer.

- Challenge: Need 50 prototype sensor enclosures for testing—required PC-like rigidity, flame-retardant properties, and a 5-day turnaround.

- Solution: We used a 3D-printed master model to create a 4-cavity silicone mold. We selected a flame-retardant PC-like resin and optimized vacuum pressure to ensure no bubbles. Post-processing included painting to match the EV’s interior color.

- Result: Delivered 50 parts in 4 days—all meeting dimensional tolerances (±0.1mm) and passing flame-retardant tests. The client used the prototypes to validate sensor fit, saving 6 weeks of development time compared to injection molding.

Case Study 2: Medical Device Component

- Client: A medical equipment startup.

- Challenge: Need 20 custom prosthetic finger components—required biocompatible resin, flexible texture, and a smooth surface finish.

- Solution: We used a biocompatible flexible resin (Shore 50A) and created a 2-cavity mold. We added a UV-resistant coating to improve durability and performed CMM checks to ensure dimensional accuracy.

- Result: The components met FDA biocompatibility standards and were delivered in 6 days. The startup used the parts to test patient comfort, leading to a design refinement that was easily implemented with a new master model.

These Successful Projects in PC Vacuum Casting show how flexibility and precision drive customer success. Case Examples of PC Vacuum Casting like these are why businesses trust Yigu Technology for their critical projects.

Why Choose Yigu Technology for PC Vacuum Casting?

When it comes to Reasons to Choose Us for PC Vacuum Casting, Yigu Technology offers unique advantages that make us a trusted partner for businesses worldwide.

Here’s Why Select Our PC Vacuum Casting Services:

- Proven Expertise: 15+ years of experience in vacuum casting—we’ve handled over 10,000 projects across industries.

- Material Variety: Access to 50+ resin options (including biocompatible and flame-retardant grades) to match your exact needs.

- Fast Turnaround: Our streamlined process delivers parts in 3–7 days—50% faster than industry averages.

- Quality Guarantee: Every part undergoes CMM inspection and visual checks to ensure it meets your specifications.

- Cost Transparency: No hidden fees—we provide detailed quotes upfront, with options to optimize cost for your batch size.

Our Unique Selling Points of Our PC Vacuum Casting include dedicated project managers (assigned to every client) and design support—we help refine your design for better manufacturability, saving time and money on revisions.

Our Competitive Advantages of Our PC Vacuum Casting also include global logistics support—we ship parts to over 50 countries, with options for expedited delivery to meet urgent deadlines. Whether you’re a startup testing a new product or a large enterprise needing small-batch components, Why Partner with Us for PC Vacuum Casting? Because we turn your design goals into tangible, high-quality parts—on time and within budget.