Our Nylon 3D Printing Services

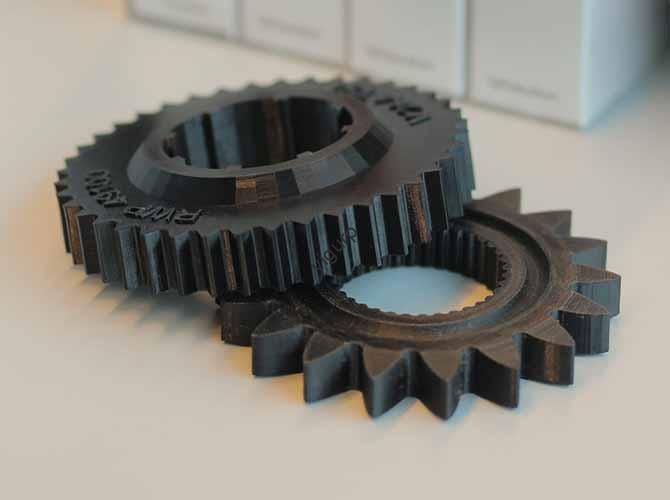

Unlock the future of manufacturing with Nylon 3D Printing—where additive manufacturing meets unmatched versatility. From high-precision prototypes to large-scale production runs, our nylon-based polymer printing solutions deliver durable, lightweight parts tailored to industries like automotive, aerospace, and medical. Whether you need complex geometries or strict dimensional accuracy, we combine cutting-edge processes with expert service to turn your ideas into reality—fast, cost-effectively, and reliably.

What Is Nylon 3D Printing?

At its core, Nylon 3D Printing is a specialized branch of additive manufacturing (AM) that uses nylon (a flexible, strong thermoplastic polymer) as the primary build material. Unlike traditional subtractive methods (which remove material from a block), this technology builds objects layer by layer—enabling designs that would be impossible with techniques like CNC machining or injection molding.

Nylon itself is a key advantage: it offers an ideal balance of strength, flexibility, and heat resistance, making it suitable for both functional prototypes and end-use parts. When paired with 3D Printing technologies like SLS or FDM, it becomes a powerful tool for industries seeking to reduce lead times, cut costs, and innovate faster.

| Key Term | Definition |

| 3D Printing | A process that creates three-dimensional objects from digital models layer by layer. |

| Nylon | A thermoplastic polymer known for durability, flexibility, and heat resistance. |

| Additive Manufacturing | The broader category of technologies (including 3D printing) that build parts additively. |

| Polymer Printing | Additive manufacturing using plastic-based materials (like nylon) as the build medium. |

Our Nylon 3D Printing Capabilities

We pride ourselves on offering a full suite of capabilities to meet the unique needs of every project. Whether you’re a startup needing a single prototype or a large enterprise requiring mass production, our services are designed to deliver quality, speed, and precision.

Core Capabilities Breakdown

| Capability | Description | Ideal For |

| Custom Printing | Fully tailored solutions to match your exact design specifications, from material choice to surface finish. | One-off prototypes, custom end-use parts. |

| High Precision | Prints with tight dimensional accuracy (down to ±0.1mm) and consistent layer adhesion, ensuring parts meet strict industry standards. | Medical devices, aerospace components. |

| Large Scale Production | Ability to scale from small batches (10–50 parts) to high-volume runs (1,000+ parts) without compromising quality. | Automotive parts, consumer product components. |

| Complex Geometries | Expertise in printing intricate designs—including hollow structures, lattice patterns, and undercuts—that traditional manufacturing can’t achieve. | Lightweight aerospace parts, custom jigs. |

Our team works closely with you to understand your goals, whether that’s reducing weight for an aerospace project or enhancing durability for a medical device. No design is too complex—we turn even the most challenging concepts into functional, high-quality parts.

Nylon 3D Printing Processes

The success of nylon 3D printing depends on choosing the right process for your project. Each technique has unique strengths, and we leverage the best-in-class methods to optimize results for your application.

Key Processes Compared

| Process | How It Works | Advantages | Best For |

| Sintering | Uses heat to fuse small nylon particles (powder) into a solid part, without melting the material completely. | High strength, minimal waste, complex geometries. | Functional prototypes, end-use parts. |

| Fused Deposition Modeling (FDM) | Melts nylon filament and extrudes it through a nozzle, building layers on a heated bed. | Low cost, easy to use, wide material compatibility. | Prototypes, low-volume functional parts. |

| Selective Laser Sintering (SLS) | Uses a high-powered laser to selectively fuse nylon powder particles, creating detailed, strong parts. | Excellent precision, no need for support structures, high durability. | Aerospace components, medical implants. |

| Layer-by-Layer Fabrication | The foundational principle of all 3D printing—builds parts one thin layer (0.1–0.3mm) at a time, ensuring design accuracy. | Enables complex shapes, consistent quality, customizable layer height. | All nylon 3D printing applications. |

Each process is paired with rigorous quality checks to ensure every part meets your specifications. For example, SLS is our go-to for aerospace parts due to its ability to produce lightweight, high-strength components with tight tolerances.

Materials Used in Nylon 3D Printing

The choice of material is critical to the performance of your 3D-printed part. We offer a range of nylon-based materials, each engineered for specific applications—from flexible prototypes to heat-resistant end-use parts.

Material Options & Their Benefits

| Material | Key Properties | Industry Applications |

| Nylon 12 | High impact resistance, excellent chemical resistance, and low moisture absorption. | Automotive hoses, medical devices, aerospace components. |

| Nylon 6 | High tensile strength, good heat resistance (up to 220°C), and cost-effective. | Consumer products, electrical components, structural parts. |

| Composite Materials | Nylon blended with additives (e.g., carbon fiber, glass fiber) for enhanced strength or flexibility. | High-stress parts (e.g., automotive brackets, drone frames). |

| Filaments | Ready-to-use nylon strands for FDM printing, available in various colors and grades. | Prototyping, low-volume production, custom decorative parts. |

We also offer material testing services to help you select the best option for your project. For example, if you need a part that can withstand high temperatures (like an engine component), we’ll recommend a heat-resistant nylon composite over standard Nylon 6.

Surface Treatment for Nylon 3D Prints

While 3D-printed nylon parts are functional right off the printer, surface treatment can enhance their appearance, durability, or performance. We offer a range of post-processing options to meet your needs—from a smooth finish for consumer products to a protective coating for industrial parts.

Common Surface Treatment Methods

| Treatment | Purpose | Result |

| Sanding | Removes layer lines and rough edges to create a smooth surface. | Matte finish, improved tactile feel. |

| Painting | Adds color or branding to parts, using nylon-compatible paints for adhesion. | Custom colors, enhanced aesthetics. |

| Coating | Applies a protective layer (e.g., UV-resistant, water-resistant) to extend part life. | Increased durability, resistance to environmental damage. |

| Polishing | Uses chemical or mechanical methods to achieve a glossy, high-end finish. | Reflective surface, premium appearance. |

For example, a medical device might require a biocompatible coating to meet regulatory standards, while a consumer product could benefit from painting to match a brand’s color scheme. Our team will recommend the right treatment based on your part’s intended use.

Tolerances & Quality Control in Nylon 3D Printing

Tolerances—how closely a printed part matches its digital design—are make-or-break for industries like aerospace and medical. We prioritize dimensional accuracy and tight tolerances to ensure every part performs as expected, and our quality control (QC) processes leave no room for error.

Tolerance Levels & QC Measures

| Aspect | Details |

| Precision Levels | Our printers achieve tolerances of ±0.1mm for small parts (under 100mm) and ±0.1% for larger parts—exceeding industry standards for nylon 3D printing. |

| Dimensional Accuracy | Every part is measured using 3D scanners and calipers to verify it matches the CAD model, with deviations logged and corrected immediately. |

| Tight Tolerances | For critical applications (e.g., medical implants), we offer tolerances as tight as ±0.05mm, using high-precision SLS printers and advanced calibration. |

| Quality Control | Our QC process includes pre-print material checks, in-process layer inspections, and post-print functional testing (e.g., stress tests, heat resistance tests). |

We also provide a detailed QC report with every order, so you can be confident your parts meet all specifications. For example, an aerospace client recently required parts with ±0.08mm tolerance—our team delivered 100% compliance, verified via third-party testing.

Advantages of Nylon 3D Printing

Nylon 3D printing offers a host of benefits over traditional manufacturing methods, making it a top choice for forward-thinking industries. These advantages translate to faster time-to-market, lower costs, and more innovative designs.

Key Advantages at a Glance

| Advantage | How It Benefits You |

| Cost-Effective | Eliminates the need for expensive molds or tooling (saving up to 50% on prototype costs) and reduces material waste (SLS uses 95% of powder). |

| Rapid Prototyping | Turns a digital design into a physical part in days (not weeks), allowing for faster testing and iteration. |

| Lightweight | Nylon parts are up to 30% lighter than metal equivalents, without sacrificing strength—ideal for aerospace and automotive (reducing fuel consumption). |

| Durable | Nylon’s inherent strength and flexibility make parts resistant to impact, wear, and temperature changes—extending their lifespan. |

For example, a automotive client used our nylon 3D printing service to prototype a new engine component. They cut prototyping time from 6 weeks (with injection molding) to 5 days and reduced costs by 40%—all while testing 3 design iterations to optimize performance.

Industry Applications of Nylon 3D Printing

Nylon 3D printing is versatile enough to serve nearly every industry, from healthcare to consumer goods. Its unique combination of strength, flexibility, and precision makes it a go-to solution for solving complex manufacturing challenges.

Industry Use Cases

| Industry | Common Applications | Why Nylon 3D Printing Works |

| Automotive | Prototypes (e.g., dashboard components), end-use parts (e.g., air ducts), custom jigs. | Lightweight, heat-resistant, cost-effective for low-volume runs. |

| Aerospace | Engine parts, brackets, interior components (e.g., seat frames). | High strength-to-weight ratio, tight tolerances, compliance with aerospace standards. |

| Medical | Surgical guides, custom implants (e.g., hip replacements), prosthetics. | Biocompatible options, customizable to patient anatomy, durable. |

| Consumer Products | Phone cases, toys, household items (e.g., kitchen utensils). | Customizable designs, colorful finishes, lightweight. |

One of our recent medical projects involved 3D printing custom surgical guides for a orthopedic clinic. Using Nylon 12, we created guides tailored to each patient’s anatomy—reducing surgery time by 25% and improving accuracy.

Manufacturing Techniques Integration

Nylon 3D printing doesn’t replace traditional manufacturing—it enhances it. We specialize in integrating 3D Printing with techniques like CNC machining and injection molding to create hybrid solutions that combine the best of both worlds.

Integration Examples

| Traditional Technique | How We Integrate with 3D Printing | Benefit |

| CNC Machining | Use 3D printing to create a rough part, then CNC machine critical surfaces for ultra-tight tolerances. | Combines 3D printing’s speed with CNC’s precision. |

| Injection Molding | 3D print low-cost molds for small-batch production (instead of expensive metal molds), then switch to injection molding for high volumes. | Reduces upfront costs for startups, enables fast scaling. |

| Casting | 3D print detailed molds for casting metal or resin parts, eliminating the need for hand-carved molds. | Faster mold creation, more complex cast part designs. |

| 3D Printing Integration | Embed 3D-printed components (e.g., lightweight lattice structures) into traditionally manufactured parts (e.g., metal frames) for enhanced performance. | Reduces weight, improves strength, adds functionality. |

For example, a consumer electronics client needed 500 custom phone cases. We 3D printed a mold in 2 days (vs. 4 weeks for a metal mold), used it to injection mold the cases, and delivered the order in 10 days—saving the client 60% on mold costs.

Case Studies: Success Stories with Nylon 3D Printing

Our clients’ success is our success. Below are real-world examples of how we’ve used nylon 3D printing to solve complex challenges and deliver results.

Case Study 1: Aerospace Component Prototyping

- Client: A leading aerospace manufacturer.

- Challenge: Need a lightweight, high-strength prototype for a new engine bracket—with a 2-week deadline.

- Solution: Used SLS printing with Nylon 12 composite (reinforced with carbon fiber) to create the bracket.

- Results: Delivered the prototype in 7 days, which was 40% lighter than the metal version and met all strength tests. The client later ordered 500 end-use parts.

Case Study 2: Medical Prosthetic Customization

- Client: A pediatric hospital.

- Challenge: Create affordable, custom prosthetics for children (who outgrow parts quickly).

- Solution: Used FDM printing with flexible Nylon 6 filament, tailored to each child’s measurements.

- Results: Reduced prosthetic cost by 70% (vs. traditional methods) and cut delivery time from 4 weeks to 5 days. Over 100 children have received parts.

Case Study 3: Automotive Production Scaling

- Client: A startup electric vehicle (EV) maker.

- Challenge: Scale from 100 to 10,000 interior door handles, without investing in expensive molds.

- Solution: Combined 3D printing (for initial 500 parts) with injection molding (for high-volume runs), using 3D-printed molds.

Results: Scaled production in 6 weeks (vs. 3 months with traditional molds) and saved $150,000 in tooling costs.

Why Choose Us for Nylon 3D Printing?

With so many 3D printing providers, what sets us apart? We combine technical expertise, quality service, and customer-centric support to ensure your project is a success—from concept to delivery.

Our Differentiators

| Factor | What We Offer |

| Expertise | Our team has 10+ years of experience in nylon 3D printing, with certifications in aerospace and medical standards (e.g., ISO 13485). |

| Quality Service | Dedicated project managers who guide you through every step—from design feedback to post-processing—and keep you updated in real time. |

| Fast Turnaround | Standard prototypes delivered in 3–5 days; large-scale production in 2–4 weeks (faster than 80% of competitors). |

| Customer Support | 24/7 access to our technical team for questions or adjustments, plus a 100% satisfaction guarantee (we reprint parts if they don’t meet specs). |

We don’t just print parts—we partner with you to solve problems. Whether you need help optimizing a design for 3D printing or scaling production, we’re with you every step of the way.