If you’ve ever wondered how automotive fuel lines achieve that smooth, durable finish while maintaining critical performance standards, you’re in the right place. Fuel injection surface treatment is a vital step in manufacturing high-quality fuel delivery systems, ensuring they can withstand harsh conditions under the hood. Dalam panduan ini, we’ll walk you through every stage of the process, why each step matters, and how it impacts the final product’s performance. Let’s dive in!

Understanding Fuel Injection Surface Treatment: Kenapa pentingnya

Before we get into the step-by-step process, Mari kita jelaskan apa fuel injection surface treatment actually is. Ringkasnya, it’s a series of specialized procedures applied to fuel lines after their initial (molding) to enhance their surface properties. These treatments aren’t just about making the parts look good—they’re essential for:

- Resisting oil and chemical corrosion: Fuel lines come into constant contact with gasoline, diesel, and additives, so their surfaces must repel these substances.

- Improving durability: Underhood temperatures can reach 120°C (248° f) or higher, so surfaces need to withstand extreme heat without degrading.

- Ensuring proper fit and function: Smooth surfaces prevent leaks and ensure tight connections with other components.

- Enhancing longevity: A well-treated surface can extend a fuel line’s lifespan by up to 30% compared to untreated alternatives, according to industry studies.

The Pre-Treatment Phase: Setting the Stage for Success

Before any actual surface treatment begins, thorough preparation is key. Think of it like painting a wall—you wouldn’t skip sanding and cleaning first, right? The same logic applies here.

Material Inspection and Preparation

Pertama, every fuel line undergoes a careful inspection. Manufacturers check for:

- Visible defects like cracks, gelembung, or uneven thickness

- Proper dimensions to ensure they fit the treatment equipment

- Consistency in material composition (usually oil-resistant, high-temperature-resistant rubber)

If any issues are found, the parts are either repaired or rejected. Statistics show that proper pre-inspection reduces treatment defects by 45% in mass production settings.

Pembersihan: Removing Contaminants

Next comes cleaning—a critical step that can make or break the entire treatment process. During manufacturing, fuel lines pick up various contaminants:

- Release agents from molding processes

- Dust and debris from the factory environment

- Oils from handling equipment

Cleaning methods typically include:

- Ultrasonic cleaning: Uses high-frequency sound waves in a cleaning solution to dislodge tiny particles. Effective for reaching intricate areas.

- Pressure washing: Applies pressurized water or cleaning agents to remove surface grime. Often used for larger, less detailed components.

- Solvent cleaning: Involves wiping or immersing parts in solvents that dissolve oils and greases. Common solvents include isopropyl alcohol and specialized industrial cleaners.

A study by the Automotive Component Manufacturers Association found that inadequate cleaning leads to 60% of surface treatment failures, emphasizing just how important this step is.

Core Surface Treatment Processes for Fuel Injection Components

Once the parts are clean and prepped, it’s time for the main surface treatments. These processes vary depending on the specific requirements of the fuel line, but here are the most common ones:

Deburring: Smoothing Rough Edges

After extrusion molding, fuel lines often have sharp edges or small protrusions called burrs. These can:

- Cause leaks when connected to other components

- Create turbulence in fuel flow

- Wear down seals over time

Deburring methods include:

- Mechanical deburring: Using brushes, abrasive wheels, or tumbling machines to grind down burrs.

- Thermal deburring: Applying a controlled explosion in a sealed chamber to burn off burrs (effective for hard-to-reach areas).

- Chemical deburring: Using chemical solutions to dissolve burrs without damaging the main structure.

Most manufacturers aim for a burr size of less than 0.02mm after treatment, as larger burrs can compromise performance.

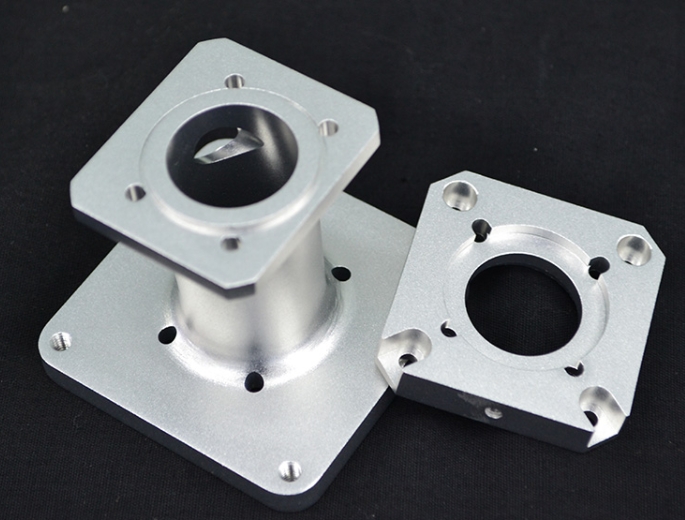

Menggilap: Achieving a Smooth Finish

Polishing takes the surface smoothness a step further. It involves:

- Using abrasive materials (like sandpaper or polishing compounds) to remove micro-imperfections

- Buffing the surface to create a uniform texture

- Ensuring consistent friction levels across the entire surface

A smooth surface is crucial because it:

- Reduces fuel flow resistance

- Minimizes the risk of bacterial growth in biofuel applications

- Improves the adhesion of any additional coatings

Polishing can reduce surface roughness from an average of 5μm (micrometers) to less than 0.5μm, as measured by profilometer tests.

Coating Application: Adding Protective Layers

Dalam banyak kes, fuel lines receive specialized coatings to enhance their performance. Common coatings include:

- Fluoropolymer coatings: Provide excellent chemical resistance and low friction. Ideal for high-performance vehicles.

- Silicone coatings: Offer superior heat resistance, making them suitable for parts near engines.

- Epoxy coatings: Provide good adhesion and corrosion resistance for general-purpose use.

The coating application process typically involves:

- Preparing the coating material according to manufacturer specifications

- Applying the coating using methods like spraying, dipping, or brushing

- Curing the coating at specific temperatures (usually between 80°C and 150°C) for a set time

Coating thickness is carefully controlled, usually between 20-50μm, to balance protection with flexibility—fuel lines need to bend without cracking their coatings.

Decontamination: Final Clean Before Inspection

After treatment, a final decontamination step ensures no residues from the treatment processes remain. This might involve:

- Rinse with deionized water to remove chemical residues

- Drying in controlled environments to prevent water spots

- Air blowers to remove any loose particles

This step is especially important for fuel lines used in sensitive applications, like in electric hybrid vehicles where cleanliness standards are even higher.

Quality Control: Ensuring Surface Treatment Meets Standards

You wouldn’t want a poorly treated fuel line in your car, and manufacturers feel the same way. That’s why rigorous quality control is built into every stage of surface treatment.

Inspection Methods for Treated Surfaces

Manufacturers use a variety of methods to check surface quality:

- Visual inspection: Using magnifying glasses or microscopes to check for defects like cracks, uneven coating, or remaining burrs.

- Adhesion testing: Using tape tests or pull tests to ensure coatings stick properly to the surface.

- Thickness measurement: Using devices like magnetic gauges or eddy current probes to verify coating thickness.

- Surface roughness testing: Using profilometers to measure the texture of the surface against specifications.

Key Performance Metrics

Here’s a table showing the typical standards fuel injection surface treatments must meet:

| Metric | Acceptable Range | Testing Method |

| Surface Roughness | < 0.8μm | Profilometer |

| Coating Thickness | 20-50μm | Magnetic Gauge |

| Adhesion Strength | > 5N/cm | Pull Test |

| Rintangan kimia | No visible damage after 500 hours in fuel immersion | Immersion Test |

| Heat Resistance | No cracking after 1000 cycles of -40°C to 120°C | Thermal Cycling Test |

These strict standards ensure that fuel lines can perform reliably in the demanding environment of a vehicle’s engine compartment.

How Surface Treatment Fits Into the Overall Fuel Line Production Process

Surface treatment doesn’t happen in isolation—it’s part of a larger manufacturing journey. Let’s see where it fits:

- Penyediaan bahan: High-quality rubber materials are selected and mixed with additives.

- Rubber Mixing: Materials are blended to achieve the right properties.

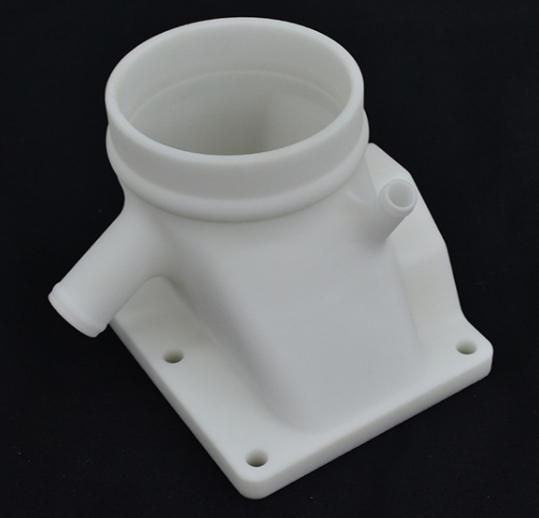

- Extrusion Molding: The rubber is shaped into fuel line tubes.

- Cooling and Solidifying: The newly formed tubes are cooled to set their shape.

- Surface Treatment: All the processes we’ve discussed (pembersihan, deburring, polishing, coating).

- Final Quality Inspection: Comprehensive testing of all properties.

- Packaging and Shipping: Protected packaging to prevent damage during transport.

As you can see, surface treatment is the step that transforms a basic molded part into a high-performance component ready for real-world use.

Common Challenges in Fuel Injection Surface Treatment (and How to Solve Them)

Like any manufacturing process, surface treatment has its challenges. Here are some common issues and how manufacturers address them:

Uneven Coating Application

Problem: Coatings might be thicker in some areas and thinner in others, leading to inconsistent performance.

Penyelesaian: Using automated spraying systems with precise pressure control and regular calibration checks. Some manufacturers also rotate parts during coating to ensure even coverage.

Poor Adhesion of Coatings

Problem: Coatings peel or chip off, exposing the underlying material.

Penyelesaian: Improving pre-treatment cleaning processes and adding a primer layer before the main coating. Proper curing temperatures are also critical—too low and the coating won’t bond; too high and it might degrade.

Contamination After Treatment

Problem: Parts get dirty again before inspection or packaging.

Penyelesaian: Implementing cleanroom environments for post-treatment handling and using protective covers immediately after treatment.

Yigu Technology’s Perspective on Fuel Injection Surface Treatment

Yigu Technology emphasizes that fuel injection surface treatment is the bridge between basic manufacturing and high-performance components. Advanced surface treatment ensures fuel lines meet strict safety and durability standards, directly impacting vehicle reliability. Investing in precision in every treatment step, from cleaning to coating, is key to delivering products that excel in real-world automotive environments.

Soalan Lazim:

1. Why can’t fuel lines skip surface treatment?

Surface treatment is essential because molded fuel lines have imperfections that can cause leaks, reduce durability, or impair fuel flow. Without treatment, they’d be more prone to corrosion, wear, and failure, especially under the harsh conditions of engine operation.

2. How long does the surface treatment process take for fuel lines?

The total time varies by manufacturer and part complexity, but a typical surface treatment process takes 2-4 hours per batch. This includes cleaning (30-60 minit), deburring and polishing (45-90 minit), coating application (30-60 minit), curing (30-60 minit), and final inspection (15-30 minit).

3. Are there environmental considerations in surface treatment?

Ya, manufacturers are increasingly using eco-friendly cleaning agents and water-based coatings to reduce environmental impact. Many also implement recycling systems for cleaning solutions and coating materials, minimizing waste and harmful emissions.