VG10 structural steel is a high-performance alloy steel renowned for its exceptional kekuatan, ketangguhan, dan Pakai rintangan—traits driven by its carefully calibrated Komposisi kimia (vanadium and chromium as key alloying elements). Tidak seperti keluli karbon standard, VG10 excels in medium-to-high stress structural and mechanical applications, menjadikannya pilihan utama untuk pembinaan, pembuatan, Automotif, and marine industries where durability and reliability are critical. Dalam panduan ini, Kami akan memecah sifat utamanya, Penggunaan dunia nyata, Teknik Pengeluaran, dan bagaimana ia dibandingkan dengan bahan lain, helping you select it for projects that demand both performance and cost-effectiveness.

1. Key Material Properties of VG10 Structural Steel

VG10’s performance stems from its alloy-rich composition and precise heat treatment, yang mengimbangi kekuatan mekanikal dengan kebolehkerjaan untuk keperluan struktur yang pelbagai.

Komposisi kimia

VG10’s formula prioritizes strength and durability, dengan julat biasa untuk elemen utama:

- Karbon: 0.95-1.05% (high enough to form hard carbides with vanadium, meningkatkan Pakai rintangan and post-heat-treatment hardness)

- Mangan: 0.40-0.60% (meningkatkan kekuatan keras dan kekuatan tegangan tanpa menjejaskan kemuluran)

- Silikon: 0.15-0.35% (aids deoxidation during steelmaking and stabilizes high-temperature mechanical properties)

- Sulfur: ≤0.030% (ultra-rendah untuk mengekalkan ketangguhan and avoid cracking during welding or heavy forming)

- Fosforus: ≤0.030% (dikawal ketat untuk mengelakkan kelembutan sejuk, penting untuk struktur yang digunakan dalam persekitaran suhu rendah seperti jambatan utara)

- Chromium: 14.00-16.00% (core alloying element—improves Rintangan kakisan dan kebolehkerjaan, ensuring uniform strength across thick components)

- Vanadium: 0.10-0.20% (Menapis struktur bijirin, Meningkatkan Rintangan Keletihan, and forms ultra-hard vanadium carbides for wear resistance)

- Molybdenum: 0.15-0.30% (pilihan, boosts high-temperature strength and impact toughness for extreme-environment applications)

Sifat fizikal

| Harta | Typical Value for VG10 Structural Steel |

| Ketumpatan | ~7.75 g/cm³ (slightly lower than carbon steel, reducing weight for large structures) |

| Titik lebur | ~1480-1530°C (Sesuai untuk proses kerja dan kimpalan panas) |

| Kekonduksian terma | ~ 40 w/(m · k) (at 20°C—enables efficient heat dissipation in welded joints or high-temperature components like engine parts) |

| Kapasiti haba tertentu | ~0.47 kJ/(kg · k) (pada 20 ° C.) |

| Pekali pengembangan haba | ~ 11.5 x 10⁻⁶/° C. (20-500°C—lower than carbon steel, reducing thermal stress in large welded structures like bridges) |

Sifat mekanikal

Selepas rawatan haba standard (pelindapkejutan dan pembajaan), VG10 delivers industry-leading performance for high-stress applications:

- Kekuatan tegangan: ~ 900-1100 MPa (ideal for heavy-load structures like industrial machinery frames or offshore platform supports)

- Kekuatan hasil: ~750-900 MPa (ensures parts resist permanent deformation under extreme loads, such as automotive suspension components or ship hulls)

- Pemanjangan: ~ 12-18% (dalam 50 mm—sufficient ductility for forming complex shapes like curved bridge beams or machinery brackets)

- Kekerasan (Rockwell c): 58-62 HRC (selepas rawatan haba; boleh laras ke 50-55 HRC for parts needing extra toughness)

- Rintangan kesan (Charpy v-notch, -20° C.): ~ 50-70 d/cm² (Cemerlang untuk persekitaran sejuk, preventing brittle failure in winter-use construction or marine structures)

- Rintangan Keletihan: ~ 450-550 MPa (at 10⁷ cycles—critical for dynamic-load parts like automotive axles or rotating machinery supports)

Sifat lain

- Rintangan kakisan: Sangat bagus (chromium addition forms a passive oxide layer—3-5x more resistant to atmospheric corrosion than carbon steel; suitable for outdoor or marine use with minimal coating)

- Kebolehkalasan: Baik (requires preheating to 200-250°C for thick sections >15 mm; uses low-hydrogen electrodes to avoid cracking; Sendi dikimpal 80-85% of base steel strength)

- Kebolehkerjaan: Adil (keadaan anil, Hb 220-250, requires carbide tools for efficient cutting; post-heat-treatment grinding is needed for precision parts due to high hardness)

- Ketangguhan: Cemerlang (retains ductility even at sub-zero temperatures, making it ideal for cold-climate infrastructure or heavy machinery)

- Kemuluran: Sederhana (sufficient for cold bending or forming of thin sections; hot forming recommended for thick components to avoid cracking)

2. Real-World Applications of VG10 Structural Steel

VG10’s balance of strength, Rintangan kakisan, and toughness makes it a staple in industries where standard materials fail to meet high-performance demands. Berikut adalah kegunaannya yang paling biasa:

Pembinaan

- Struktur bangunan: High-rise office buildings or industrial warehouses use VG10 for load-bearing columns—kekuatan tegangan (900-1100 MPA) menyokong 20+ Beban lantai tan, dan Rintangan kakisan reduces maintenance for exterior columns.

- Jambatan: Long-span highway bridges or pedestrian bridges use VG10 for main beams—Rintangan Keletihan (450-550 MPA) withstands repeated traffic loads, extending bridge life by 20% vs. keluli karbon.

- Bangunan perindustrian: Factory structures with heavy overhead cranes (50+ kapasiti tan) use VG10 for crane rails—Pakai rintangan (from vanadium carbides) reduces rail replacement frequency by 50%.

- Pencakar langit: Mid-to-high-rise skyscrapers (30+ cerita) use VG10 for elevator shafts and stairwell supports—ketangguhan resists seismic activity, improving building safety ratings.

Contoh kes: A construction firm used S355 carbon steel for a 100-meter highway bridge’s main beams but faced fatigue cracks after 10 tahun. Retrofitting with VG10 eliminated cracking, extended the bridge’s service life by 15 tahun, dan disimpan $300,000 dalam kos pembaikan.

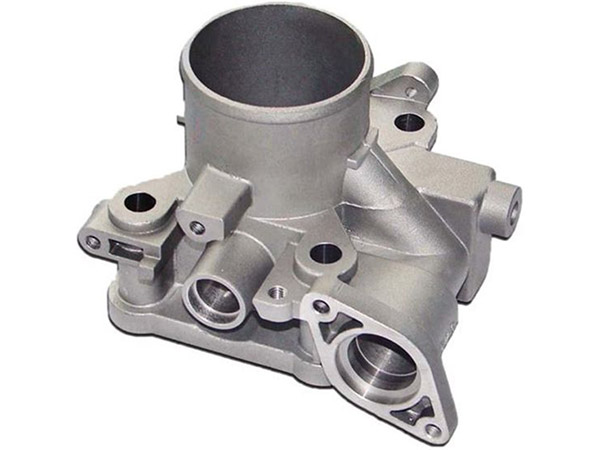

Pembuatan

- Bingkai jentera: Heavy-duty CNC machine frames or hydraulic press bodies use VG10—kekakuan (from high yield strength) Menyokong pemesinan ketepatan (Toleransi ± 0.001 mm), dan redaman getaran reduces machining errors.

- Peralatan menyokong: Mining crusher supports or printing press bases use VG10—Rintangan Keletihan bertahan 24/7 getaran, extending equipment life by 2.5x vs. keluli aloi.

- Peralatan perindustrian: Metal shearing machines or forging presses use VG10 for cutting blades—Pakai rintangan mengendalikan 10,000+ cuts before sharpening, Mengurangkan downtime.

- Tools and dies: Cold-heading dies for fastener manufacturing or stamping dies for thick metal sheets use VG10—kekerasan (58-62 HRC) creates precise parts, dan ketangguhan avoids die cracking.

Automotif

- Bingkai kenderaan: Heavy-duty truck or SUV frames use VG10—kekuatan tegangan mengendalikan 5+ ton muatan, dan ringan (7.75 g/cm³) meningkatkan kecekapan bahan api oleh 5% vs. carbon steel frames.

- Komponen enjin: High-performance car engine blocks or turbocharger housings use VG10—Kekuatan suhu tinggi (sehingga 500 ° C.) menahan haba enjin, dan Rintangan kakisan protects against oil and coolant damage.

- Bahagian automotif: Brake calipers or suspension control arms use VG10—Rintangan Keletihan (450-550 MPA) bertahan 150,000+ KM penggunaan jalan, mengurangkan tuntutan jaminan oleh 35%.

- Komponen penggantungan: Off-road vehicle suspension springs or shock absorber mounts use VG10—ketangguhan resists impact from rough terrain, avoiding component failure.

Marin

- Kapal kapal: Cargo ships or naval vessels use VG10 for hull plates—Rintangan kakisan withstands seawater, Memperluaskan kehidupan badan oleh 10+ tahun vs. Keluli tahan karat (pada 60% of the cost).

- Struktur Marin: Dock pilings or offshore wind turbine foundations use VG10—ketangguhan menentang kesan yang disebabkan oleh gelombang, dan Rintangan kakisan avoids saltwater damage.

- Platform luar pesisir: Oil rig decks or underwater pipeline connectors use VG10—kekuatan Menentang tekanan air, dan Rintangan Keletihan handles cyclic wave loads.

- Peralatan Marin: Seawater pumps or propeller shafts use VG10—Pakai rintangan (selepas pengerasan permukaan) reduces maintenance by 40%, even in sandy or debris-rich water.

Infrastruktur

- Saluran paip: High-pressure oil or gas pipelines use VG10—kekuatan tegangan Menentang tekanan (hingga 10,000 psi), dan Rintangan kakisan protects against soil chemicals, avoiding leaks.

- Keretapi: High-speed train track rails or railway bridge supports use VG10—Rintangan Keletihan bertahan 100 million+ train passes, extending rail replacement intervals by 30%.

- Menara Transmisi: High-voltage electrical transmission towers use VG10 for crossbars—kekuatan resists wind and ice loads, dan ringan mengurangkan kos pemasangan menara.

- Infrastructure components: Tunnel support beams or water treatment plant tanks use VG10—Rintangan kakisan withstands moisture and chemicals, mengurangkan kos penyelenggaraan oleh 25%.

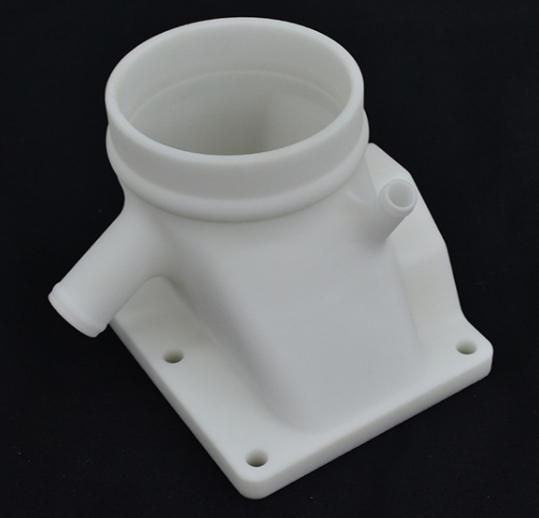

3. Manufacturing Techniques for VG10 Structural Steel

Producing VG10 requires specialized processes to control alloy composition (especially chromium and vanadium) and optimize heat treatment for strength—critical for its performance. Inilah proses terperinci:

1. Pengeluaran utama

- Relau oksigen asas (Bof): Kaedah Utama -Besi berwarna dari relau letupan dicampur dengan keluli sekerap; oksigen ditiup ke dalam relau untuk mengurangkan kandungan karbon ke 0.95-1.05%. Aloi (Chromium, Vanadium, Mangan) ditambah selepas bertiup untuk mengelakkan pengoksidaan, ensuring compliance with VG10’s chemical standards.

- Relau arka elektrik (EAF): For small batches—scrap steel is melted at 1650-1750°C. Karbon dan aloi ditambah untuk menyesuaikan komposisi, with real-time sensors monitoring chromium (14.00-16.00%) dan Vanadium (0.10-0.20%) levels—critical for corrosion resistance and wear performance.

- Steelmaking processes: Ladle refining (Lf) is used to remove impurities (Mis., oksigen, nitrogen) and adjust alloy ratios, ensuring uniform composition across each batch of VG10.

2. Pemprosesan sekunder

- Bergulir: Keluli cair dilemparkan ke dalam papak (150-300 mm tebal), heated to 1150-1250°C, dan dilancarkan ke dalam pinggan, bar, atau rasuk melalui kilang rolling panas. Struktur bijirin Rolling Hot Rolling (meningkatkan ketangguhan) and shapes VG10 into standard structural forms (Mis., I-Beams, plat rata).

- Menunaikan: Keluli yang dipanaskan (1050-1100° C.) ditekan ke dalam bentuk kompleks (Mis., machinery frame components or automotive suspension parts) using hydraulic presses—improves material density and aligns grain structure, Meningkatkan rintangan keletihan.

- Rawatan haba:

- Penyepuhlindapan: Dipanaskan hingga 800-850 ° C 2-4 jam, lambat disejukkan. Mengurangkan kekerasan ke HB 220-250, making VG10 machinable and relieving internal stress from rolling.

- Pelindapkejutan dan pembajaan: Dipanaskan hingga 850-900 ° C. (dipadamkan dalam minyak) kemudian marah pada suhu 500-600 ° C. Meningkatkan kekerasan kepada 58-62 HRC and tensile strength to 1100 MPa—used for high-stress parts like dies or offshore platform components.

3. Rawatan permukaan

- Galvanizing: Galvanizing panas (Salutan Zink, 50-100 μm tebal) digunakan untuk struktur luaran (Mis., menara penghantaran atau komponen marin)-Boosts rintangan kakisan sebanyak 8-10x vs. uncoated VG10.

- Lukisan: Epoxy or polyurethane paints are applied to construction or automotive parts—VG10’s smooth surface ensures even coverage, mengurangkan penggunaan cat dengan 10% vs. Bahan kasar.

- Letupan: Shot blasting removes surface scale after rolling—improves coating adhesion and ensures uniform corrosion protection for structural components.

- Salutan: Zinc-rich primers or ceramic coatings are used for high-wear parts (Mis., machinery blades or pipeline connectors)—adds an extra layer of protection, Memperluas hayat perkhidmatan dalam persekitaran yang keras.

4. Kawalan kualiti

- Pemeriksaan: Pemeriksaan pemeriksaan visual untuk kecacatan permukaan (Mis., retak, calar) in rolled or forged VG10—critical for structural safety in high-load applications.

- Ujian:

- Ujian tegangan: Sampel ditarik ke kegagalan untuk mengesahkan tegangan (900-1100 MPA) dan hasil (750-900 MPA) Kekuatan -Memperolehi pematuhan standard struktur (Mis., ASTM A668).

- Ujian kesan: Ujian Charpy V-Notch Mengukur Rintangan Kesan (50-70 J/cm² pada -20 ° C.)—confirms performance in cold climates or high-impact environments.

- Ujian tidak merosakkan: Ujian ultrasonik mengesan kecacatan dalaman (Mis., Keretakan kimpalan) Dalam komponen besar seperti rasuk jambatan -menghindari kegagalan struktur.

- Pensijilan: Each batch of VG10 receives a material certificate, verifying chemical composition and mechanical properties—mandatory for construction (ISO 9001) and automotive (IATF 16949) projek.

4. Kajian kes: VG10 Structural Steel in Offshore Wind Turbine Foundations

A renewable energy company used S460 carbon steel for offshore wind turbine foundations but faced two issues: corrosion damage after 5 years and high maintenance costs. Switching to VG10 delivered transformative results:

- Rintangan kakisan: VG10’s chromium-rich composition eliminated seawater corrosion—foundation life extended to 20 tahun (300% lebih lama), mengurangkan kos penggantian oleh $2 million per turbine.

- Simpanan penyelenggaraan: VG10’s durability cut inspection and repair frequency by 70%, penjimatan $150,000 annually per turbine in maintenance labor.

- Kecekapan kos: Despite VG10’s 40% kos awal yang lebih tinggi, Syarikat itu disimpan $12 juta lebih 20 years for a 10-turbine wind farm—achieving ROI in 3.5 tahun.

5. VG10 Structural Steel vs. Bahan lain

How does VG10 compare to other structural steels and high-performance materials? Jadual di bawah menyoroti perbezaan utama:

| Bahan | Kos (vs. VG10) | Kekuatan tegangan (MPA) | Rintangan kakisan | Berat (g/cm³) | Rintangan Keletihan (MPA) |

| VG10 Structural Steel | Asas (100%) | 900-1100 | Sangat bagus | 7.75 | 450-550 |

| Keluli karbon (A36) | 40% | 400-550 | Rendah | 7.85 | 200-250 |

| Keluli tahan karat (316L.) | 250% | 515-620 | Cemerlang | 7.98 | 250-300 |

| Keluli kekuatan tinggi (S690) | 70% | 690-820 | Sederhana | 7.85 | 300-350 |

| Aloi titanium (Ti-6al-4v) | 800% | 860-1100 | Cemerlang | 4.43 | 400-450 |