Titanium steel (a titanium-alloyed steel or high-titanium stainless steel variant) is a high-performance material celebrated for its exceptional nisbah kekuatan-ke-berat, Rintangan kakisan, dan biokompatibiliti—traits shaped by its unique Komposisi kimia (titanium as a key alloying element, paired with iron, Karbon, and other metals). Unlike standard carbon or stainless steels, titanium steel excels in extreme environments (suhu tinggi, cecair yang menghakis) and specialized fields (Aeroangkasa, perubatan), making it a top choice for industries where performance and reliability are non-negotiable. Dalam panduan ini, Kami akan memecah sifat utamanya, Penggunaan dunia nyata, Teknik Pengeluaran, dan bagaimana ia dibandingkan dengan bahan lain, helping you select it for projects that demand innovation and durability.

1. Key Material Properties of Titanium Steel

Titanium steel’s performance stems from titanium’s ability to refine grain structure, enhance corrosion resistance, and reduce weight—balancing strength with practicality for specialized applications.

Komposisi kimia

Titanium steel’s formula prioritizes performance, dengan julat biasa untuk elemen utama (berbeza mengikut gred, Mis., Ti-6Al-4V steel alloy):

- Titanium: 0.50-6.00% (core alloying element—improves Rintangan kakisan by forming a stable oxide layer, refines grains for strength, and reduces density)

- Besi: Keseimbangan (logam asas, provides structural strength)

- Karbon: 0.03-0.15% (low content to avoid carbide formation, which can reduce corrosion resistance and ductility)

- Mangan: 0.30-1.00% (enhances hardenability and tensile strength without compromising titanium’s benefits)

- Silikon: 0.15-0.50% (aids deoxidation during steelmaking and stabilizes high-temperature mechanical properties)

- Sulfur: ≤0.030% (ultra-rendah untuk mengekalkan ketangguhan and avoid cracking during welding or forming)

- Fosforus: ≤0.030% (dikawal ketat untuk mengelakkan kelembutan sejuk, critical for low-temperature applications like aerospace)

- Elemen aloi: Aluminium (2.00-6.00%, meningkatkan kekuatan), Vanadium (1.00-4.00%, Meningkatkan rintangan keletihan), Nikel (1.00-3.00%, Meningkatkan kemuluran)—used in high-grade titanium steel for aerospace/medical use.

Sifat fizikal

| Harta | Typical Value for Titanium Steel (Ti-6Al-4V Variant) |

| Ketumpatan | ~4.43 g/cm³ (50% lighter than carbon steel, 30% lighter than stainless steel—critical for weight-sensitive applications) |

| Titik lebur | ~1660-1720°C (higher than stainless steel, suitable for high-temperature environments like aircraft engines) |

| Kekonduksian terma | ~16 W/(m · k) (at 20°C—lower than steel, but paired with heat-resistant alloys for high-temperature stability) |

| Kapasiti haba tertentu | ~0.61 kJ/(kg · k) (at 20°C—higher than steel, enabling better heat absorption in cyclic-temperature applications) |

| Pekali pengembangan haba | ~8.6 x 10⁻⁶/°C (20-500°C—lower than steel, reducing thermal stress in welded structures like aerospace components) |

Sifat mekanikal

Titanium steel delivers industry-leading performance for extreme and specialized applications:

- Kekuatan tegangan: ~860-1100 MPa (higher than most stainless steels, ideal for load-bearing aerospace or medical implants)

- Kekuatan hasil: ~790-950 MPa (memastikan bahagian menentang ubah bentuk kekal di bawah beban berat, such as aircraft landing gear or orthopedic rods)

- Pemanjangan: ~ 10-15% (dalam 50 mm—sufficient ductility for forming complex shapes like surgical instruments or engine parts)

- Kekerasan (Rockwell c): 30-38 HRC (balance of strength and machinability; boleh ditingkatkan ke 45 HRC via heat treatment for wear-resistant parts)

- Rintangan kesan (Charpy v-notch, 20° C.): ~ 40-60 d/cm² (good for high-stress applications, avoiding brittle failure in aerospace or marine use)

- Rintangan Keletihan: ~ 400-500 MPa (at 10⁷ cycles—critical for dynamic parts like aircraft turbine blades or medical implant stems)

Sifat lain

- Rintangan kakisan: Cemerlang (titanium oxide layer resists seawater, asid, and industrial chemicals—50x more corrosion-resistant than carbon steel; suitable for marine or chemical processing equipment)

- Rintangan pengoksidaan: Sangat bagus (stable oxide layer retains integrity up to 600°C, making it ideal for high-temperature applications like jet engines)

- Biokompatibiliti: Cemerlang (titanium is non-toxic and non-reactive with human tissue—used in implants like hip replacements or dental crowns)

- Sifat magnet: Bukan magnet (critical for medical equipment like MRI machines or aerospace sensors that require magnetic neutrality)

- Radiation resistance: Sederhana (resists radiation damage better than aluminum, suitable for nuclear power generation components)

2. Real-World Applications of Titanium Steel

Titanium steel’s unique properties make it indispensable in industries where standard materials fail to meet performance demands. Berikut adalah kegunaannya yang paling biasa:

Aeroangkasa

- Aircraft engines: Turbine blades and combustion chambers use titanium steel—Kestabilan suhu tinggi (sehingga 600 ° C.) dan nisbah kekuatan-ke-berat reduce engine weight by 20% vs. aloi nikel, meningkatkan kecekapan bahan api.

- Airframes: Wing spars and fuselage frames use titanium steel—ringan (4.43 g/cm³) cuts aircraft weight by 15%, extending range by 100+ km per flight.

- Spacecraft components: Rocket nozzles and satellite frames use titanium steel—Rintangan kakisan withstands space radiation and extreme temperature swings (-200°C to 800°C).

- Bahagian enjin jet: Compressor blades and engine mounts use titanium steel—Rintangan Keletihan (400-500 MPA) mengendalikan 10,000+ kitaran penerbangan, Mengurangkan downtime penyelenggaraan.

Contoh kes: A leading aerospace manufacturer used nickel alloys for aircraft turbine blades but faced high fuel costs due to weight. Switching to titanium steel reduced blade weight by 30%, cutting fuel consumption by 8% per flight—saving $1.2 million annually for a 50-plane fleet.

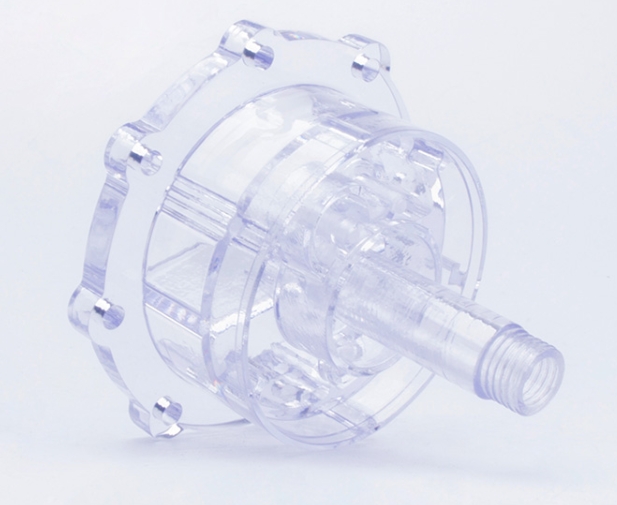

Perubatan

- Implan: Hip and knee replacements use titanium steel—biokompatibiliti avoids tissue rejection, dan kekuatan matches human bone density (reducing implant loosening over time).

- Instrumen pembedahan: Scalpels and bone drills use titanium steel—Rintangan kakisan menahan pensterilan autoklaf (134° C., tekanan tinggi), dan sharpness retention extends instrument life by 3x vs. Keluli tahan karat.

- Peranti ortopedik: Spinal rods and bone plates use titanium steel—Kemuluran enables custom shaping to fit patient anatomy, dan bukan magnet property is safe for MRI scans.

- Dental applications: Dental implants and crowns use titanium steel—biokompatibiliti fuses with jawbone (Osseointegration), dan Rintangan kakisan withstands saliva and food acids.

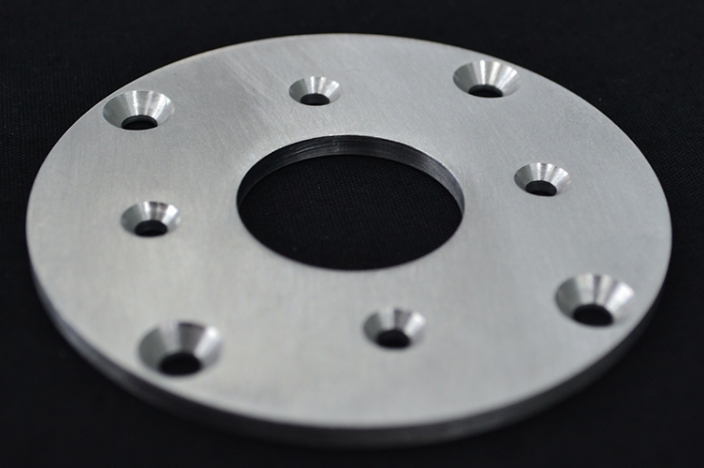

Marin

- Komponen kapal: Propeller shafts and hull plates use titanium steel—Rintangan kakisan withstands seawater, extending component life by 10+ tahun vs. Keluli tahan karat.

- Peralatan Marin: Submarine pressure hulls and offshore platform legs use titanium steel—nisbah kekuatan-ke-berat reduces hull thickness by 25%, improving buoyancy and fuel efficiency.

- Struktur luar pesisir: Oil rig risers and underwater pipelines use titanium steel—Rintangan kakisan resists saltwater and oil-based fluids, avoiding leaks and environmental damage.

- Bahagian tahan kakisan: Seawater pumps and valves use titanium steel—Pakai rintangan (selepas pengerasan permukaan) reduces maintenance by 40%.

Automotif

- Komponen enjin: High-performance car turbochargers and piston rods use titanium steel—Kekuatan suhu tinggi (sehingga 600 ° C.) mengendalikan haba enjin, dan ringan reduces rotational mass, improving acceleration.

- Bahagian berprestasi tinggi: Racing car chassis and suspension components use titanium steel—nisbah kekuatan-ke-berat cuts vehicle weight by 8%, enhancing speed and handling.

- Struktur ringan: Kenderaan elektrik (EV) battery frames use titanium steel—Rintangan kakisan protects batteries from moisture, dan ringan offsets battery weight, extending EV range by 50+ km.

Perindustrian

- Peralatan pemprosesan kimia: Acid storage tanks and reaction vessels use titanium steel—Rintangan kakisan withstands sulfuric acid (98% Konsentrasi) and chlorine gas, avoiding leaks and downtime.

- Power generation components: Nuclear reactor control rods and gas turbine parts use titanium steel—radiation resistance dan Kestabilan suhu tinggi ensure safe, long-term operation.

- Jentera Perindustrian: High-speed printing press rollers and textile machine parts use titanium steel—Pakai rintangan extends part life by 2x vs. Keluli tahan karat, mengurangkan kos penggantian.

3. Manufacturing Techniques for Titanium Steel

Producing titanium steel requires specialized processes to handle titanium’s reactivity and ensure alloy uniformity—critical for performance. Inilah proses terperinci:

1. Pengeluaran utama

- Titanium extraction: Titanium is mined as rutile (TiO₂), then converted to titanium tetrachloride (TiCl₄) via chlorination. TiCl₄ is reduced with magnesium to produce sponge titanium (pure titanium porous material).

- Melting processes:

- Vacuum arc remelting (Kami): Sponge titanium, besi, and other alloys are melted in a vacuum arc furnace (1700-1800° C.) to avoid oxidation—ensures uniform alloy distribution and removes impurities.

- Lebur rasuk elektron (Ebm): Used for high-grade titanium steel (Mis., implan perubatan)—electron beam melts materials in a vacuum, producing ultra-pure ingots with minimal defects.

- Pemutus ingot: Molten titanium steel is cast into ingots (100-500 diameter mm) for secondary processing—slow cooling ensures grain refinement and avoids internal cracks.

2. Pemprosesan sekunder

- Bergulir: Ingots are heated to 900-1000°C and rolled into plates, bar, or sheets via hot rolling mills. Struktur bijirin Rolling Hot Rolling (meningkatkan kekuatan) and shapes titanium steel into standard forms (Mis., aircraft-grade sheets or medical implant bars).

- Menunaikan: Heated titanium steel (850-950° C.) ditekan ke dalam bentuk kompleks (Mis., turbine blades or implant stems) using hydraulic presses—improves material density and aligns grain structure, Meningkatkan rintangan keletihan.

- Penyemperitan: Heated titanium steel is pushed through a die to create long, bentuk seragam (Mis., aircraft frame rails or medical spinal rods)-Ia untuk bahagian volum tinggi dengan keratan rentas yang konsisten.

- Pemesinan: Titanium steel is machined using carbide tools or laser cutting—high cutting speeds (100-200 m/my) are needed due to its toughness; coolant is mandatory to avoid overheating and tool wear.

- Rawatan haba:

- Penyepuhlindapan: Heated to 700-800°C for 1-2 jam, disejukkan udara. Mengurangkan tekanan dalaman dan melembutkan bahan (ke 30 HRC), making it machinable for precision parts like surgical instruments.

- Solution treatment and aging: Heated to 920-960°C (solution treated), dipadamkan, then aged at 500-600°C. Increases strength to 1100 MPA dan kekerasan untuk 38 HRC—used for aerospace turbine blades or high-performance automotive parts.

3. Rawatan permukaan

- Anodizing: Titanium steel is anodized to thicken its oxide layer (5-20 μm)—enhances Rintangan kakisan and adds color (used for medical implants or decorative aerospace components).

- Salutan: Pemendapan wap fizikal (Pvd) salutan (Mis., Titanium nitride, Timah) are applied to cutting tools or industrial parts—boosts wear resistance by 3x, memanjangkan bahagian kehidupan.

- Lukisan: High-temperature ceramic paints are applied to aerospace components (Mis., casing turbin)—adds extra heat resistance, protecting titanium steel at temperatures up to 800°C.

- Pengerasan permukaan: Low-temperature nitriding (500-550° C.) forms a hard nitride layer (5-10 μm)—used for medical implant surfaces to improve wear resistance and osseointegration.

4. Kawalan kualiti

- Pemeriksaan: Pemeriksaan pemeriksaan visual untuk kecacatan permukaan (Mis., retak, keliangan) in rolled or forged titanium steel—critical for aerospace and medical safety.

- Ujian:

- Ujian tegangan: Sampel ditarik ke kegagalan untuk mengesahkan tegangan (860-1100 MPA) dan hasil (790-950 MPA) strength—ensures compliance with aerospace/medical standards (Mis., ASTM F136 for implants).

- Ujian kakisan: Ujian semburan garam (ASTM B117) verify corrosion resistance—titanium steel should show no rust after 1000+ hours of exposure.

- Ujian tidak merosakkan: Ultrasonic and X-ray testing detect internal defects (Mis., voids in ingots)—avoids failures in critical parts like aircraft engines.

- Pensijilan: Each batch of titanium steel receives a material certificate, verifying chemical composition and mechanical properties—mandatory for aerospace (AS9100) dan perubatan (ISO 13485) aplikasi.

4. Kajian kes: Titanium Steel in Medical Hip Implants

A leading medical device manufacturer used stainless steel for hip implants but faced two issues: 15% of patients experienced implant loosening after 5 tahun, dan 8% had allergic reactions. Switching to titanium steel delivered transformative results:

- Biokompatibiliti: Titanium steel’s non-toxic nature eliminated allergic reactions—reducing patient complications by 8%, penjimatan $500,000 annually in warranty claims.

- Ketahanan: Titanium steel’s kekuatan and osseointegration (bone fusion) reduced implant loosening to 3%—extending implant life to 15+ tahun (vs. 10 tahun untuk keluli tahan karat).

- Patient Outcomes: Lighter titanium steel implants (40% lighter than stainless steel) reduced post-surgery pain and shortened recovery time by 2 weeks—boosting patient satisfaction scores by 25%.

5. Titanium Steel vs. Bahan lain

How does titanium steel compare to other high-performance materials? Jadual di bawah menyoroti perbezaan utama:

| Bahan | Kos (vs. Titanium Steel) | Kekuatan tegangan (MPA) | Ketumpatan (g/cm³) | Rintangan kakisan | Biokompatibiliti |

| Titanium Steel (Ti-6al-4v) | Asas (100%) | 860-1100 | 4.43 | Cemerlang | Cemerlang |

| Keluli tahan karat (316L.) | 30% | 515-620 | 7.98 | Sangat bagus | Baik |

| Keluli karbon (A36) | 15% | 400-550 | 7.85 | Rendah | Miskin |

| Aloi aluminium (7075-T6) | 40% | 570-590 | 2.81 | Baik | Miskin |

| Aloi nikel (Inconel 718) | 250% | 1240-1380 | 8.22 | Cemerlang | Miskin |

Kesesuaian aplikasi

- Aeroangkasa: Titanium steel outperforms aluminum (lebih kuat) and nickel alloy (lebih murah, lebih ringan)—ideal for engine parts and airframes.

- Perubatan: Titanium steel is the gold standard for implants—better biocompatibility than stainless steel, no allergic reactions, and longer life.

- Marin: Titanium steel’s corrosion resistance matches nickel alloy but is 60% lighter—suitable for ship components and offshore structures.

- Perindustrian: Titanium steel is more corrosion-resistant than stainless steel for chemical processing—avoids leaks and reduces maintenance.

Yigu Technology’s View on Titanium Steel

Di Yigu Technology, titanium steel stands out as a game-changer for high-performance industries. Itu unmatched strength-to-weight ratio, biokompatibiliti, dan Rintangan kakisan Jadikan ia sesuai untuk pelanggan di aeroangkasa, perubatan, and marine sectors. We recommend titanium steel for critical applications—aircraft engines, hip implants, offshore structures—where it outperforms standard materials in durability and safety. Walaupun ia lebih mahal di pendahuluan, its long lifespan and low maintenance deliver ROI in 3-5 tahun. Titanium steel aligns with our goal of providing innovative, sustainable solutions that push industry boundaries.

Soalan Lazim

1. Is titanium steel suitable for everyday consumer products (Mis., cookware)?

Titanium steel is technically suitable, but its high cost (10x more expensive than stainless steel) makes it impractical for most consumer goods. It’s better reserved for critical applications (Aeroangkasa, perubatan) di mana prestasi membenarkan kos.