SK5 structural steel is a high-carbon, versatile alloy known for its excellent kekerasan, boleh dipercayai kekuatan tegangan, and good kebolehkerjaan—traits that make it a top pick for medium-to-high stress applications across industries. Unlike low-carbon steels, SK5 balances strength and workability, thanks to its carefully tuned Komposisi kimia (focused on carbon, Mangan, and controlled impurities). Whether you’re building mechanical parts, komponen automotif, or structural elements, SK5 delivers durability without compromising on manufacturing efficiency. Dalam panduan ini, Kami akan memecah sifat utamanya, Penggunaan dunia nyata, Kaedah pengeluaran, and how it stacks up against other materials—helping you decide if it’s the right choice for your project.

1. Material Properties of SK5 Structural Steel

SK5’s performance starts with its Komposisi kimia, which lays the groundwork for its physical, mekanikal, dan ciri -ciri fungsional. Every element is calibrated to enhance strength, kekerasan, dan kebolehgunaan.

Komposisi kimia

SK5 is a high-carbon steel with trace elements that boost performance—no unnecessary alloys, keeping it cost-effective while maintaining reliability:

- Karbon (C): 0.80-0.90% (the star element—boosts kekerasan dan kekuatan tegangan, critical for wear-resistant parts like gears or bearings)

- Mangan (Mn): 0.10-0.30% (improves hardenability, ensuring uniform strength across thick components)

- Silikon (Dan): ≤0.35% (AIDS Deoxidation semasa pembuatan keluli, preventing defects in the final product)

- Sulfur (S): ≤0.03% (strictly controlled to avoid brittleness, especially during cold working)

- Fosforus (P): ≤0.03% (minimized to prevent cold cracking, making SK5 suitable for low-temperature applications)

- Elemen jejak: Small amounts of iron oxides are removed during processing, ensuring a clean, consistent base material.

Sifat fizikal

SK5’s physical traits align with standard structural steels, menjadikannya mudah untuk disatukan ke dalam reka bentuk yang ada:

| Harta | Typical Value for SK5 Structural Steel |

| Ketumpatan | ~ 7.85 g/cm³ (same as most steels—no extra weight for transportation or installation) |

| Titik lebur | ~1450-1500°C (high enough for high-temperature applications like engine components) |

| Kekonduksian terma | ~ 45 w/(m · k) (at 20°C—efficient heat dissipation for parts that get warm, like transmission gears) |

| Kapasiti haba tertentu | ~ 0.48 kJ/(kg · k) (at 20°C—balances heat absorption and release) |

| Resistiviti elektrik | ~150 × 10⁻⁹ Ω·m (at 20°C—low conductivity, suitable for non-electrical structural parts) |

| Sifat magnet | Ferromagnet (mengekalkan magnetisme, simplifying non-destructive testing for defects) |

Sifat mekanikal

Selepas rawatan haba standard (pelindapkejutan dan pembajaan), SK5 delivers the strength needed for heavy-duty use:

- Kekuatan tegangan: ~ 800-950 MPa (strong enough to handle loads in automotive axles or structural beams)

- Kekuatan hasil: ~600-750 MPa (menentang ubah bentuk kekal, even under repeated stress)

- Kekerasan: 50-55 HRC (Rockwell c) after heat treatment—ideal for wear-resistant parts like bearings or machine shafts

- Kemuluran: ~8-12% elongation (dalam 50 mm)—enough to bend into simple shapes without cracking, though less ductile than low-carbon steels

- Kesan ketangguhan: ~20-30 J/cm² (pada suhu bilik)-Moderate, suitable for static or low-vibration applications

- Rintangan Keletihan: ~ 350-400 MPa (pada 10 ⁷ kitaran)—reliable for parts like suspension components that endure repeated stress.

Sifat lain

- Rintangan kakisan: Moderat -prestasi dengan baik dalam persekitaran kering atau dalaman, but needs painting or galvanizing for outdoor use (Mis., Rasuk pembinaan)

- Kebolehkalasan: Fair—requires preheating (200-300° C.) untuk mengelakkan retak, so best for simple welds (not complex structures like ship hulls)

- Kebolehkerjaan: Baik (sebelum rawatan haba)—annealed SK5 (hardness ~180-220 HB) cuts easily with standard tools, reducing manufacturing time

- Kebolehbaburan: Moderate—can be cold-rolled or stamped into basic shapes (Mis., kurungan), but not as flexible as low-carbon steels like S355

- Kemasan permukaan: Smooth after machining or grinding—ideal for parts that need tight tolerances (Mis., gear ketepatan).

2. Applications of SK5 Structural Steel

SK5’s blend of strength and workability makes it useful across industries—from small mechanical parts to large structural elements. Here’s where it shines:

Kejuruteraan Mekanikal

Mechanical engineers rely on SK5 for parts that need wear resistance and strength:

- Aci: Industrial machine shafts (Mis., untuk sistem penghantar) use SK5—its kekerasan resists wear from bearings, Memperluas hayat perkhidmatan oleh 30% vs. keluli rendah karbon

- Gear: Gear kecil hingga sederhana (Mis., in factory equipment) use SK5—kekuatan tegangan handles torque without tooth bending

- Galas: Precision bearings for motors use SK5—smooth surface finish reduces friction, lowering maintenance costs

- Bahagian mesin: Pengikat, pengapit, and tool holders use SK5—its kebolehkerjaan allows easy customization to fit specific equipment.

Industri automotif

SK5 is a staple in automotive manufacturing for parts that endure stress:

- Komponen enjin: Timing gears and valve stems use SK5—high-temperature resistance (sehingga 300 ° C.) mengendalikan haba enjin

- Bahagian penghantaran: Gear teeth and shift forks use SK5—Rintangan Keletihan withstands repeated gear changes (100,000+ kitaran)

- Gandar: Light truck axles use SK5—kekuatan hasil resists bending under heavy loads (hingga 5 tan)

- Komponen penggantungan: Leaf spring brackets use SK5—kekerasan resists wear from road vibrations.

Pembinaan

While not as ductile as low-carbon steels, SK5 works for specific construction needs:

- Rasuk struktur: Rasuk jangka pendek (5-10 meter) in industrial warehouses use SK5—kekuatan tegangan supports overhead cranes (hingga 10 tan)

- Lajur: Support columns in small factories use SK5—compact size saves space while handling vertical loads

- Trusses: Lightweight trusses for factory roofs use SK5—easy to cut and assemble, Mengurangkan masa pembinaan

- Jambatan: Small pedestrian bridges use SK5—with galvanizing, it resists outdoor corrosion for 15+ tahun.

Aplikasi lain

SK5 also adds value to niche industries:

- Pembuatan kapal: Small ship components (Mis., Pengikat dek) use SK5—with painting, it resists saltwater spray

- Kenderaan Keretapi: Train bogie parts (Mis., axle brackets) use SK5—Rintangan Keletihan handles track vibrations

- Jentera berat: Excavator bucket pins use SK5—Pakai rintangan extends pin life by 2 tahun vs. keluli standard

- Penjanaan kuasa: Small turbine components use SK5—high-temperature strength handles turbine heat.

Contoh kes: A European machinery maker used low-carbon steel for conveyor shafts but faced frequent wear (replacing shafts every 6 bulan). Switching to SK5 (Haba yang dirawat 52 HRC) extended shaft life to 18 kos penggantian bulan -bulan dengan $20,000 annually and reducing downtime by 40%.

3. Manufacturing Techniques for SK5 Structural Steel

Producing SK5 requires precision to control its carbon content and ensure consistent performance. Inilah proses langkah demi langkah:

1. Pembuatan keluli: Building a Clean Base

- Relau arka elektrik (EAF): The most common method—scrap steel is melted at 1,600-1,700°C. Karbon, Mangan, and silicon are added to reach SK5’s Komposisi kimia (0.80-0.90% C, 0.10-0.30% Mn). Sensors monitor elements in real time to avoid defects.

- Relau oksigen asas (Bof): Used for large-scale production—molten iron from a blast furnace is mixed with scrap. Oxygen is blown in to adjust carbon levels, then alloys are added to fine-tune properties.

- Pemutus berterusan: Molten steel is poured into a water-cooled mold to form slabs, Billet, atau batang (the most common shape for SK5). This avoids defects from ingot casting and speeds up production.

- Ingot casting: Rarely used today—reserved for custom, large-scale parts (Mis., Aci jentera berat). Molten steel is poured into molds, cooled, and then reheated for rolling.

2. Kerja panas: Shaping and Strengthening

- Rolling panas: Cast slabs are heated to 1,100-1,200°C and rolled through mills to form plates, bar, atau rasuk. Rolling panas memecah karbida besar, memperbaiki Kemuluran and uniform strength.

- Memalsukan panas: Untuk bahagian yang kompleks (Mis., gear), hot SK5 (1,000-1,100° C.) is pressed into dies. This shapes the part while aligning metal grains, meningkatkan kekuatan tegangan oleh 10-15%.

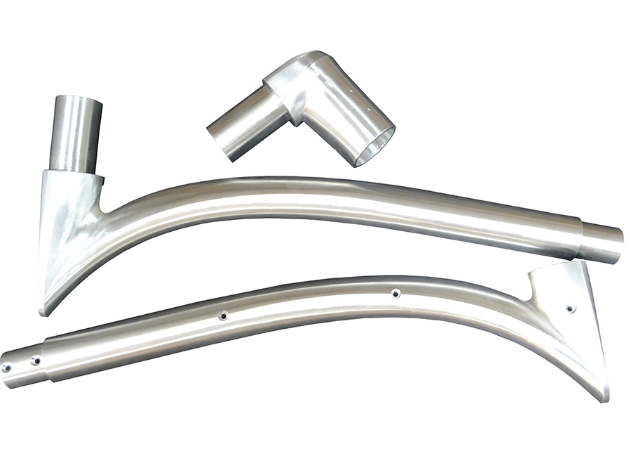

- Penyemperitan: Used for long, bahagian seragam (Mis., structural channels). Hot SK5 is pushed through a die to create the desired shape—fast and cost-effective for high-volume production.

- Hot drawing: For small-diameter parts (Mis., bolt), hot SK5 rods are pulled through a die to reduce diameter. This improves surface finish and dimensional accuracy.

- Penyepuhlindapan: After hot working, SK5 is heated to 700-750°C for 2-3 jam, Kemudian disejukkan perlahan -lahan. Ini melembutkan keluli (hardness ~180-220 HB), menjadikannya lebih mudah untuk mesin.

3. Kerja sejuk: Refining Precision

- Rolling sejuk: Used for thin sheets or bars (Mis., kurungan automotif). Cold-rolled at room temperature, it improves surface finish (Ra 0.8 μm) and increases kekerasan oleh 15-20% (no heat treatment needed for simple parts).

- Lukisan sejuk: Untuk bahagian ketepatan (Mis., bearing shafts), cold SK5 rods are pulled through a die. This creates tight tolerances (± 0.01 mm) dan permukaan licin.

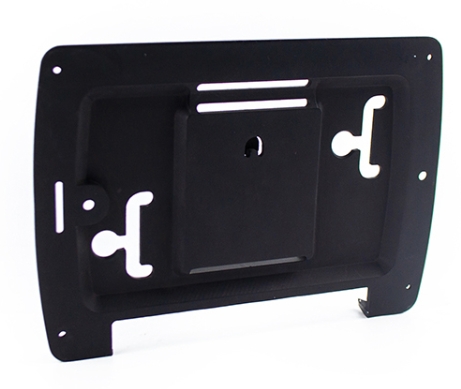

- Penempaan sejuk: Untuk kecil, bahagian kekuatan tinggi (Mis., pengikat). Cold SK5 is pressed into dies—no heating required, saving energy and reducing production time.

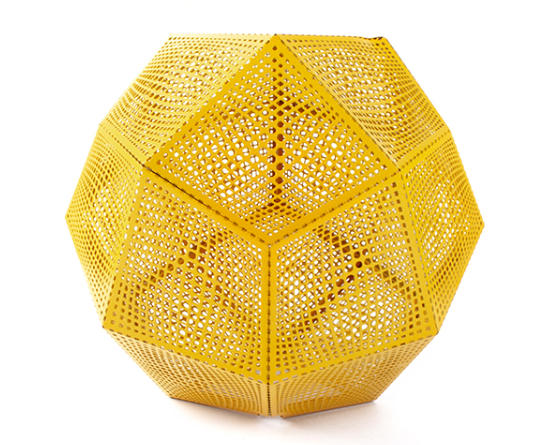

- Setem: Used for flat parts (Mis., washers or brackets). Cold SK5 sheets are stamped with a press—fast, ideal for high-volume orders (10,000+ bahagian per jam).

- Pemesinan ketepatan: CNC mills or lathes cut annealed SK5 into complex shapes (Mis., gigi gear). Itu kebolehkerjaan allows fast cutting speeds (100-150 m/my), mengurangkan kos.

4. Rawatan haba: Tuning Strength and Hardness

Heat treatment is key to unlocking SK5’s full potential—tailored to the part’s use:

- Pelindapkejutan dan pembajaan: The most common process—SK5 is heated to 800-850°C (austenitizing), dipadamkan di dalam air untuk mengeras (60-62 HRC), then tempered at 200-300°C to reduce brittleness (kekerasan terakhir 50-55 HRC). Digunakan untuk gear, galas, dan aci.

- Menormalkan: Dipanaskan hingga 850-900 ° C., disejukkan udara. Refines grain size and reduces internal stress—used for structural parts like beams or columns.

- Penyepuhlindapan: Seperti yang dinyatakan sebelum ini, softens the steel for machining—critical for parts that need complex cuts (Mis., aci ketepatan).

- Pengerasan permukaan: For parts that need a hard outer layer (Mis., gigi gear). SK5 is heated to 850-900°C, then the surface is quenched—creates a hard outer layer (55 HRC) dan teras yang sukar (40 HRC).

- Nitriding: Heated to 500-550°C in a nitrogen atmosphere. Forms a hard nitride layer (60-65 HRC) on the surface—boosts Pakai rintangan oleh 50% (Sesuai untuk galas atau aci).

4. Kajian kes: SK5 in Automotive Gear Manufacturing

A Japanese automotive supplier struggled with gear wear in small truck transmissions—using low-carbon steel, gears failed after 80,000 batu, membawa kepada tuntutan jaminan. They switched to SK5, with these results:

- Performance Upgrade: SK5 gears (Haba yang dirawat 53 HRC) bertahan 150,000 miles—double the life of low-carbon steel gears. This cut warranty costs by $150,000 setiap tahun.

- Kecekapan pembuatan: Annealed SK5’s kebolehkerjaan dibenarkan 20% faster gear cutting—production capacity increased by 1,000 gears per month, penjimatan $8,000 dalam kos buruh.

- Cost Balance: While SK5 costs 15% more than low-carbon steel, the longer gear life and faster production saved the supplier $220,000 setiap tahun.

- Kebolehpercayaan: SK5’s Rintangan Keletihan dikendalikan 100,000+ gear changes without tooth bending—customer satisfaction scores rose by 15%.

5. SK5 Structural Steel vs. Bahan lain

How does SK5 compare to other common materials? The table below breaks down key differences to help you choose:

| Bahan | Kos (vs. SK5) | Kekuatan tegangan (MPA) | Kekerasan (HRC) | Rintangan kakisan | Kebolehkerjaan | Terbaik untuk |

| SK5 Structural Steel | Asas (100%) | 800-950 | 50-55 | Sederhana | Baik | Gear, aci, small structural beams |

| S355 Keluli Struktur | 80% | 355-510 | 15-20 | Sederhana | Sangat bagus | Rasuk besar, lajur, Jambatan |

| Keluli tahan karat (304) | 300% | 515 | 18-22 | Cemerlang | Baik | Peralatan pemprosesan makanan, bahagian luar |

| Aloi aluminium (6061-T6) | 250% | 310 | 90-95 (Hb) | Baik | Sangat bagus | Bahagian automotif ringan, Komponen pesawat |

| Komposit serat karbon | 800% | 1,500+ | N/a | Cemerlang | Miskin | Bahagian berprestasi tinggi (Mis., badan kereta perlumbaan) |

Key Comparison Takeaways

- vs. S355: SK5 is stronger and harder, but S355 is more ductile and cheaper—choose SK5 for wear-resistant parts, S355 for large structural elements.

- vs. Keluli tahan karat (304): 304 resists corrosion better, but SK5 is stronger and cheaper—use 304 for outdoor/ wet parts, SK5 for dry, bahagian tekanan tinggi.

- vs. Aluminium (6061-T6): Aluminium lebih ringan, but SK5 is stronger and cheaper—pick aluminum for weight-sensitive parts, SK5 for heavy-duty use.

- vs. Serat karbon: Carbon fiber is stronger and lighter, but SK5 is far cheaper and easier to machine—use carbon fiber for high-performance needs, SK5 for everyday parts.

Yigu Technology’s View on SK5 Structural Steel

Di Yigu Technology, we see SK5 as a cost-effective workhorse for medium-stress applications. Seimbangnya kekuatan, kebolehkerjaan, and affordability make it ideal for clients in mechanical engineering and automotive manufacturing—where wear resistance and reliability matter most. While SK5 needs surface treatment for outdoor use and preheating for welding, its performance-to-cost ratio outshines many alternatives. We often recommend SK5 for gears, aci, and small structural parts, as it delivers long service life without the premium price of stainless steel or composites. For projects needing ductility (Mis., Jambatan besar), we pair SK5 with complementary materials to optimize results.

Soalan Lazim

1. Can SK5 be used for outdoor construction projects?

Ya, but it needs protection—SK5 has moderate Rintangan kakisan, so outdoor parts (Mis., beams or columns) should be painted, galvanized, or coated. With proper treatment, SK5 can last 15+ years in outdoor environments.

2. Is SK5 easy to weld?

SK5 has fair kebolehkalasan—it requires preheating to 200-300°C to prevent cracking, and post-weld annealing to reduce stress. It works best for simple welds (Mis., bracket attachments) but is not ideal for complex, high-load welds (Mis., kapal kapal).

3. How does SK5’s hardness affect its use?

SK5’s hardness (50-55 HRC selepas rawatan haba) is a strength—it makes parts wear-resistant (great for gears or bearings). Walau bagaimanapun, high hardness reduces ductility, so SK5 isn’t ideal for parts that need frequent bending (Mis., flexible brackets). Annealing can soften SK5 for machining, then heat