If you’re tackling heavy-duty projects—like long-span bridges, Talian paip tekanan tinggi, or industrial machinery—that demand exceptional strength and durability, SA 723 keluli struktur adalah penyelesaian anda. Defined by ASTM A723 standards, this low-alloy steel balances robust mechanical performance with workability, making it a top choice for engineers and project managers. Panduan ini memecah semua yang anda perlukan untuk dipilih, gunakan, and maximize SA 723 for critical applications.

1. Material Properties of SA 723 Keluli struktur

SA 723’s performance stems from its precision-engineered properties, tailored to meet ASTM A723’s requirements for high-strength structural and pressure-containing use. Mari kita pecahkan mereka dengan jelas.

Komposisi kimia

TheKomposisi kimia of SA 723 is optimized to enhance strength, ketangguhan, and corrosion resistance—with controlled alloying elements to avoid brittleness. Di bawah adalah kerosakan biasa (per ASTM A723):

| Elemen | Julat Kandungan (wt%) | Peranan utama |

|---|---|---|

| Karbon (C) | 0.20 maks | Boosts strength while preserving weldability (lower C = less cracking risk) |

| Mangan (Mn) | 1.60 maks | Enhances toughness and grain refinement (menghalang retak semasa membentuk) |

| Silikon (Dan) | 0.60 maks | Bertindak sebagai deoxidizer (membuang oksigen untuk mengelakkan kecacatan berliang dalam produk akhir) |

| Fosforus (P) | 0.025 maks | Ketat terhad (high P causes cold brittleness—critical for low-temperature use) |

| Sulfur (S) | 0.025 maks | Minimized to avoid hot cracking during welding or forging |

| Chromium (Cr) | 0.80 maks | MeningkatkanRintangan kakisan dan kekuatan suhu tinggi (ideal for marine or industrial environments) |

| Molybdenum (Mo) | 0.30 maks | Improves high-temperature stability and creep resistance (useful for heat-exposed parts) |

| Nikel (Dalam) | 0.80 maks | Meningkatkan suhu rendahkesan ketangguhan (performs reliably at -40°C) |

| Vanadium (V) | 0.10 maks | Refines grain structure to boost both strength and ductility |

Sifat fizikal

These traits determine how SA 723 behaves in real-world conditions—from weight calculations to temperature fluctuations:

- Ketumpatan: 7.85 g/cm³ (selaras dengan keluli struktur yang paling banyak, simplifying project weight estimates for large components like bridge beams)

- Titik lebur: ~1460–1520°C (compatible with standard welding and heat treatment processes)

- Kekonduksian terma: 41 W/(m · k) (spreads heat evenly, reducing warping during welding or high-temperature operation)

- Pekali pengembangan haba: 13.2 × 10⁻⁶/° C. (low enough to handle seasonal temp swings in buildings or pipelines)

- Resistiviti elektrik: 0.19 × 10⁻⁶ Ω · m (not used for electrical applications, but useful for safety planning in industrial settings)

Sifat mekanikal

SA 723’s mechanical strength makes it suitable for heavy load-bearing and high-stress applications. Here are its key performance metrics (Selepas pelindapkejutan dan pembiakan):

- Kekuatan tegangan: 550-700 MPa (can withstand intense pulling forces—ideal for bridge cables or pipeline segments)

- Kekuatan hasil: 380 MPa min (maintains shape under heavy loads—critical for columns, aci, and pressure vessel walls)

- Kekerasan: 170-210 HB (resists wear from friction, soil, or moving parts—durable for gears or plows)

- Kesan ketangguhan: ≥ 40 J pada -40 ° C. (performs reliably in freezing climates like Alaska or Siberia, mengelakkan kegagalan rapuh)

- Kemuluran: ≥ 18% pemanjangan (can bend or form into curved shapes—e.g., bridge arches—without cracking)

- Rintangan Keletihan: Excellent for cyclic stress (suitable for machine parts that move repeatedly, Seperti penggelek penghantar)

- Kekuatan patah: Sangat tinggi (prevents sudden failure in high-pressure pipelines or earthquake-prone building frames)

Sifat utama lain

- Kebolehkalasan yang baik: Works with standard methods (Saya, TIG, Kimpalan tongkat) when using low-hydrogen consumables—no specialized equipment needed for on-site assembly.

- Kebolehbaburan yang baik: Boleh digulung panas, cold-bent, atau dipalsukan menjadi bentuk yang kompleks (Mis., custom machine housings or tapered bridge beams).

- Rintangan kakisan: Performs well in mild industrial, rural, or coastal environments (enhanced with coatings like galvanizing for saltwater or acidic conditions).

- Ketangguhan: Maintains strength across an extreme temperature range—from -40°C (freezing) to 65°C (hot deserts).

2. Applications of SA 723 Keluli struktur

SA 723’s high strength and versatility make it a go-to for industries that need reliability in demanding conditions. Begini cara menyelesaikan masalah dunia nyata:

Pembinaan

The primary use of SA 723 adalahpembinaan, where it’s trusted for heavy load-bearing structures:

- Komponen keluli struktur: Supports for industrial factories, loji kuasa, and stadiums.

- Rasuk dan lajur: Untuk bangunan bertingkat tinggi, Jambatan jangka panjang, dan lebuh raya lebuh raya (handles heavy traffic or wind loads).

- Jambatan: Deck trusses, jeti, and suspension cables (resists fatigue from constant traffic).

- Bingkai bangunan: Seismic-resistant structures in earthquake-prone regions (Mis., California or Japan).

- Kajian kes: A construction firm used SA 723 beams for a 500-meter-long highway bridge in Canada. Keluli kesan ketangguhan (-40Prestasi ° C.) withstood harsh winters, dan itu kekuatan hasil supported 100,000-lb trucks without extra supports. Selepas 10 tahun, inspections showed no signs of wear or corrosion (with minimal painting).

Kejuruteraan Mekanikal

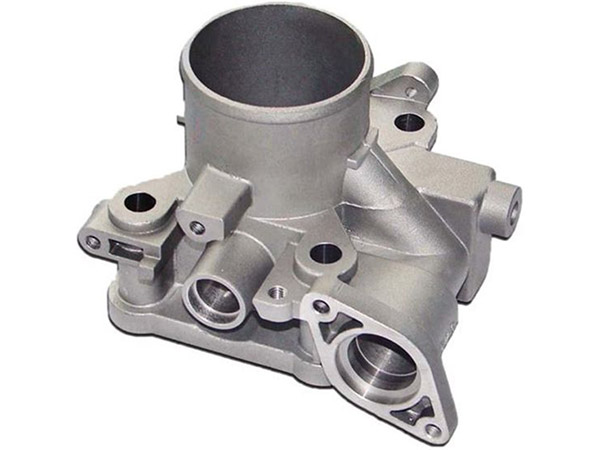

Mechanical engineers rely on SA 723 for durable, bahagian tekanan tinggi:

- Gear: Itu kekerasan dan Rintangan Keletihan prevent wear in heavy machinery (Mis., mining crushers or factory presses).

- Aci: Handles rotational stress in industrial pumps, turbin, dan sistem penghantar (common in manufacturing plants).

- Bahagian mesin: Heavy-duty housings, pengikat, and hydraulic components (cost-effective for high-performance equipment).

- Contoh: A mining equipment maker switched to SA 723 for crusher shafts. The shafts lasted 5x longer than mild steel alternatives—cutting downtime by 45% dan penjimatan $180,000 setiap tahun dalam penggantian.

Industri Pipeline

SA 723 digunakan untukoil and gas pipelines in medium-to-high-pressure applications:

- Ideal for long-distance pipelines (Mis., cross-country natural gas lines) that need to handle 8–12 MPa pressure. Itu Kekuatan patah menghalang kebocoran, dan itu Rintangan kakisan (dengan salutan epoksi) protects against soil moisture.

- Kajian kes: An energy firm used SA 723 for a 1,200-km crude oil pipeline in the U.S. Midwest. The pipeline operates at 10 MPa pressure and crosses farmland and rivers. Selepas 8 tahun, no leaks or corrosion were found—outperforming the previous carbon steel pipeline (which needed repairs every 3 tahun).

Industri Marin

For marine environments that need strength and corrosion resistance:

- Struktur kapal: Hull frames, deck supports, and cargo hold components (resists saltwater corrosion with zinc coating).

- Platform luar pesisir: Legs, pendakap, and equipment racks (handles wave stress and salt spray).

- Contoh: A shipyard used SA 723 for an offshore supply vessel’s hull. Keluli Rintangan kakisan (with marine-grade paint) bertahan 7 years at sea—no rust or thinning, even in storm-prone areas.

Jentera pertanian

For heavy-duty farm equipment that faces rough terrain:

- Tractor parts: Bingkai, transmission cases, and axle housings (handles bumps and heavy loads).

- Bajak dan Harrows: Resists wear from rocks and compacted soil (cheaper than stainless steel but more durable than mild steel).

3. Manufacturing Techniques for SA 723 Keluli struktur

Producing SA 723 requires precision to meet ASTM A723’s strict standards. Berikut adalah kerosakan langkah demi langkah:

Proses pembuatan keluli

Dua kaedah utama digunakan, depending on volume and component type:

- Relau oksigen asas (Bof): The most common method for large-scale production (Mis., Rasuk jambatan, Bahagian saluran paip). Molten iron is mixed with alloying elements (Cr, Mo, Dalam), Kemudian oksigen ditiup untuk menghilangkan kekotoran. Fast and cost-effective for bulk orders.

- Relau arka elektrik (EAF): Ideal for small batches or custom parts (Mis., specialized gears or shafts). Keluli sekerap cair menggunakan arka elektrik, and alloying elements are added to hit SA 723’s chemical specs. Offers tighter control over composition for high-precision parts.

Rawatan haba

Heat treatment is critical to unlocking SA 723’s strength and toughness. Key processes:

- Menormalkan: Heats to 880–950°C, holds for 1–2 hours, then air-cools. Refines grain structure and prepares the steel for tempering.

- Pelindapkejutan dan pembajaan: After normalizing, the steel is quenched (water-cooled) to 200°C, then tempered at 600–680°C for 2–4 hours. This forms a “tempered martensite” structure that boosts kekuatan tegangan dan ketangguhan.

- Penyepuhlindapan: Heats to 820–870°C, menyejukkan perlahan. Reduces stress after forming (used for precision parts like gears or shafts).

Proses membentuk

SA 723 is shaped into final products using techniques that preserve its strength:

- Rolling panas: Heats to 1150–1250°C, gulung ke dalam rasuk, paip, atau pinggan. The main method for construction components (Mis., I-beams or wide-flange columns).

- Rolling sejuk: Used for thin-walled pipes or precision parts (Mis., gear kecil). Creates smooth surfaces but requires post-heat treatment to restore ductility.

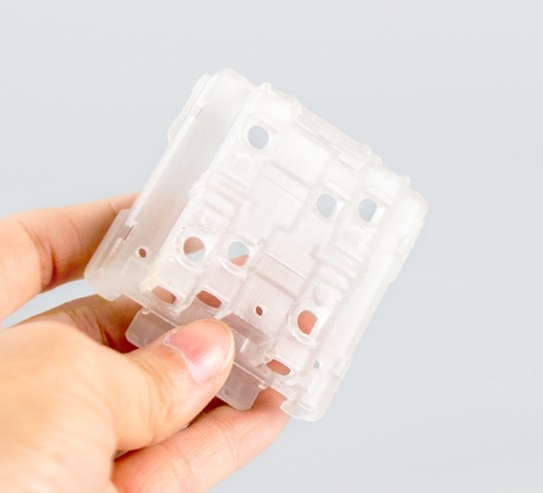

- Menunaikan: Hammers or presses hot steel into complex shapes (Mis., turbine shafts or custom machine parts). Improves grain alignment, meningkatkan kekuatan.

- Penyemperitan: Menolak keluli yang dipanaskan melalui mati untuk membuat bahagian kosong (Mis., pipeline segments or machine housings). Fast for custom shapes.

- Setem: Rarely used for SA 723—most applications need thickness, which stamping can’t provide.

Rawatan permukaan

Untuk meningkatkan ketahanan dan ketahanan kakisan:

- Galvanizing: Dips dalam zink cair. Ideal for outdoor parts (Mis., pagar jambatan) — lasts 30+ tahun tanpa karat.

- Lukisan: Applies high-temp epoxy or polyurethane paint. Used for marine components or industrial machinery to resist saltwater or chemicals.

- Tembakan letupan: Blasts with metal balls to remove rust, skala, or dirt. Prepares surfaces for welding or coating.

- Salutan: Uses fusion-bonded epoxy (FBE) for pipelines or ceramic coatings for high-heat parts (Mis., turbine components). Extends lifespan by 40+ tahun.

4. SA 723 Keluli struktur vs. Bahan lain

How does SA 723 compare to other common steels? Mari kita pecahkan untuk membantu anda memilih:

SA 723 vs. Keluli karbon (Mis., A36)

| Faktor | SA 723 Keluli struktur | Keluli karbon ringan (A36) |

|---|---|---|

| Kekuatan hasil | 380 MPa min | 250 MPa min |

| Ketangguhan | Cemerlang (-40° C.) | Adil (0°C only) |

| Kebolehkalasan | Baik (low-hydrogen consumables) | Sangat bagus |

| Prestasi kos | Better for high-stress projects | Cheaper for light use (Mis., bangsal) |

| Terbaik untuk | Jambatan, high-pressure pipes | Non-load-bearing parts |

SA 723 vs. Kekuatan tinggi rendah aloi (HSLA) Keluli (Mis., X80)

- Komposisi kimia: X80 has higher Mn (1.80 maks) for pressure resistance; SA 723 has more Ni (0.80 maks) for low-temperature toughness.

- Sifat: X80 has higher yield strength (551 MPa min) for ultra-high-pressure pipelines; SA 723 is more ductile and better for cold climates.

- Aplikasi: X80 = 12+ MPa pipelines; SA 723 = medium-pressure pipes, cold-climate bridges.

SA 723 vs. Keluli tahan karat (Mis., 304)

| Faktor | SA 723 Keluli struktur | Keluli tahan karat (304) |

|---|---|---|

| Rintangan kakisan | Baik (dengan salutan) | Cemerlang (Tiada salutan) |

| Kekuatan hasil | 380 MPa min | 205 MPa min |

| Kos | Lebih rendah ($1.30–$1.80/lb) | Lebih tinggi ($2.90–$3.90/lb) |

| Terbaik untuk | Heavy construction | Pemprosesan makanan, peralatan perubatan |

SA 723 vs. Aloi aluminium (Mis., 6061)

- Berat: Aluminium adalah 1/3 lebih ringan, but SA 723 adalah 3x lebih kuat (critical for load-bearing structures).

- Prestasi Temp Tinggi: Aluminum weakens above 150°C; SA 723 works at 65°C+.

- Kos: SA 723 is cheaper for large construction projects (aluminum is pricier for bulk use).

- Aplikasi: SA 723 = beams, paip; aluminum = lightweight parts (Mis., bingkai pesawat).

5. Yigu Technology’s Perspective on SA 723 Keluli struktur

Di Yigu Technology, we’ve supplied SA 723 untuk jambatan, saluran paip, and machinery globally. We see SA 723 as a “high-value workhorse”: its balance of strength, ketangguhan, and cost makes it ideal for clients needing reliability in harsh conditions. For cold-climate projects, its -40°C impact toughness eliminates brittleness risks. Untuk pembinaan, its weldability cuts on-site time. We optimize SA 723’s heat treatment (pelindapkejutan/pembajaan) to match project needs and provide coating guidance for corrosion protection. For high-stress, diverse-environment projects, SA 723 is our top recommendation.

FAQ About SA 723 Keluli struktur

1. Can SA 723 be used for seismic-resistant buildings?

Ya! SA 723’s highKemuluran danKekuatan patah make it excellent for seismic zones. It can bend slightly during earthquakes without breaking—we’ve supplied it for 15-story buildings in Japan that withstood minor tremors with no damage.

2. Do I need special welding materials for SA 723?

Use low-hydrogen welding consumables (Mis., E7018 electrodes for stick welding) untuk mengelakkan retak. Tiada peralatan khusus diperlukan, but preheating to 150–200°C helps preserve weld strength—we provide detailed welding guidelines to clients.

3. How long does SA 723 last in offshore environments?

With a zinc-aluminum coating or marine-grade paint, SA 723 lasts 15–20 years offshore. We supplied coated SA 723 for an offshore platform in the Gulf of Mexico that’s still in good condition after 12 years—minimal rust, Tiada masalah struktur.