Sekiranya anda sedang menjalankan pembinaan, Kejuruteraan Mekanikal, or pipeline projects that need a balance of strength, ketahanan, dan kebolehkerjaan, SA 455 keluli struktur adalah penyelesaian yang boleh dipercayai. Defined by ASTM A455 standards, this low-alloy steel is engineered to perform in diverse conditions—from heavy-duty building frames to industrial machinery. This guide will walk you through everything you need to select, gunakan, and maximize SA 455 for your critical tasks.

1. Material Properties of SA 455 Keluli struktur

SA 455’s performance is rooted in its carefully balanced properties, designed to meet ASTM A455’s requirements for structural and pressure-containing applications. Mari kita pecahkan mereka dengan jelas.

Komposisi kimia

TheKomposisi kimia of SA 455 is optimized to enhance strength and toughness while maintaining workability. Di bawah adalah kerosakan biasa (per ASTM A455):

| Elemen | Julat Kandungan (wt%) | Peranan utama |

|---|---|---|

| Karbon (C) | 0.22 maks | Boosts strength without making the steel too brittle for welding/forming |

| Mangan (Mn) | 1.50 maks | Improves toughness and prevents cracking during hot rolling or welding |

| Silikon (Dan) | 0.50 maks | Bertindak sebagai deoxidizer (membuang oksigen untuk mengelakkan kecacatan berliang dalam produk akhir) |

| Fosforus (P) | 0.030 maks | Ketat terhad (high P causes brittleness, Terutama dalam persekitaran sejuk) |

| Sulfur (S) | 0.035 maks | Minimized to avoid hot cracking during welding or forging |

| Chromium (Cr) | 0.50 maks | Enhances mild corrosion resistance (useful for outdoor or marine applications) |

| Molybdenum (Mo) | 0.20 maks | Meningkatkan kekuatan suhu tinggi (ideal for parts exposed to heat, Seperti komponen enjin) |

| Nikel (Dalam) | 0.40 maks | Meningkatkan ketangguhan suhu rendah (performs well in freezing regions like Canada or Northern Europe) |

| Vanadium (V) | 0.08 maks | Refines grain structure to enhance both strength and ductility |

Sifat fizikal

These traits determine how SA 455 behaves in real-world conditions—from weight calculations to temperature changes:

- Ketumpatan: 7.85 g/cm³ (selaras dengan keluli struktur yang paling banyak, simplifying project weight estimates)

- Titik lebur: ~1450–1510°C (compatible with standard welding and manufacturing processes)

- Kekonduksian terma: 43 W/(m · k) (spreads heat evenly, reducing warping during welding or heat treatment)

- Pekali pengembangan haba: 13.3 × 10⁻⁶/° C. (low enough to handle seasonal temperature swings in buildings or machinery)

- Resistiviti elektrik: 0.18 × 10⁻⁶ Ω · m (not used for electrical applications, but useful for safety planning in industrial settings)

Sifat mekanikal

SA 455’s mechanical strength makes it suitable for load-bearing and high-stress applications. Here are its key performance metrics:

- Kekuatan tegangan: 515–655 MPa (can withstand intense pulling forces without breaking—ideal for bridge cables or structural beams)

- Kekuatan hasil: 345 MPa min (maintains shape under heavy loads—critical for columns and machine shafts)

- Kekerasan: 160-200 HB (resists wear from friction or soil, making it durable for gears or plows)

- Kesan ketangguhan: ≥ 35 J pada -20 ° C. (performs reliably in cold weather, mengelakkan kegagalan rapuh)

- Kemuluran: ≥ 20% pemanjangan (can bend or form into shapes like curved beams or pipes without cracking)

- Rintangan Keletihan: Good for cyclic stress (suitable for machine parts that move repeatedly, like conveyor belts)

- Kekuatan patah: Tinggi (prevents sudden, catastrophic failure in high-pressure pipelines or load-bearing structures)

Sifat utama lain

- Kebolehkalasan yang baik: Works with standard methods (Saya, TIG, Kimpalan tongkat) without specialized equipment—saves time and labor on construction sites.

- Kebolehbaburan yang baik: Boleh digulung panas, cold-bent, atau dipalsukan menjadi bentuk yang kompleks (Mis., custom machine parts or curved bridge components).

- Rintangan kakisan: Performs well in dry, ringan, or slightly humid environments (add a coating like galvanizing for coastal or industrial areas with heavy moisture).

- Ketangguhan: Maintains strength across a wide temperature range—from -20°C (freezing) to 60°C (hot deserts).

2. Applications of SA 455 Keluli struktur

SA 455’s versatility makes it a top choice across industries that need reliable, cost-effective steel. Begini cara menyelesaikan masalah dunia nyata:

Pembinaan

The primary use of SA 455 adalahpembinaan, where it’s trusted for heavy-duty structural components:

- Komponen keluli struktur: Supports for industrial warehouses, kilang, and power plants.

- Rasuk dan lajur: For commercial buildings (Mis., pusat membeli -belah), parking garages, dan lebuh raya lebuh raya.

- Jambatan: Deck supports and trusses (handles heavy traffic loads, including trucks and buses).

- Bingkai bangunan: Mid-rise apartments and office buildings (balances strength and cost better than high-alloy steels).

- Kajian kes: A construction firm in Texas used SA 455 beams for a 10-span highway overpass. Keluli kekuatan hasil supported daily traffic (including 80,000-lb trucks) dan itu Kemuluran allowed for slight bending during temperature changes. Selepas 7 tahun, inspections showed no signs of wear or deformation.

Kejuruteraan Mekanikal

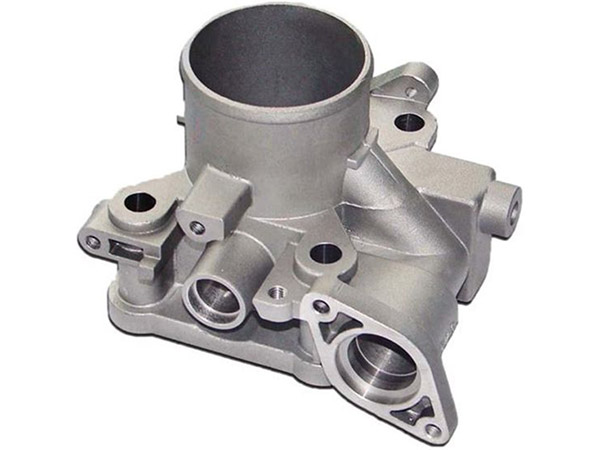

Mechanical engineers rely on SA 455 for durable, Bahagian berprestasi tinggi:

- Gear: Itu kekerasan dan Rintangan Keletihan prevent wear in industrial machinery (Mis., factory assembly lines or mining equipment).

- Aci: Handles rotational stress in pumps, motor, dan turbin (common in manufacturing plants).

- Bahagian mesin: Kurungan, perumahan, dan pengikat (cost-effective for high-volume production).

- Contoh: A machinery manufacturer switched to SA 455 for conveyor shafts in a mining facility. The SA 455 shafts lasted 4x longer than mild steel shafts—cutting downtime by 35% dan penjimatan $120,000 setiap tahun dalam penggantian.

Industri Pipeline

SA 455 digunakan untukoil and gas pipelines in medium-pressure applications:

- Ideal for regional or short-distance pipelines (Mis., natural gas distribution lines to residential areas) where ultra-high-pressure steels (like X80) are unnecessary.

- Itu Rintangan kakisan (with a fusion-bonded epoxy coating) protects against soil moisture, dan itu kebolehkalasan simplifies on-site pipeline assembly.

Industri Marin

For marine environments that need cost-effective durability:

- Struktur kapal: Deck supports, hull frames, and cargo hold components (resists mild saltwater corrosion with regular painting).

- Platform luar pesisir: Low-stress components like walkways, rak penyimpanan, or handrails (more affordable than stainless steel).

- Kajian kes: A shipyard in Florida used SA 455 for a cargo ship’s deck frames. Selepas 6 tahun di laut (with annual paint touch-ups), the frames showed only minor surface rust—far less than the 3-year lifespan of the previous mild steel frames.

Jentera pertanian

Farmers trust SA 455 for heavy-duty equipment that faces rough terrain:

- Tractor parts: Bingkai, komponen penghantaran, and axle housings (handles bumps and vibrations in fields).

- Bajak dan Harrows: Resists wear from rocks, soil, dan sisa tanaman (cheaper than stainless steel but more durable than mild steel).

3. Manufacturing Techniques for SA 455 Keluli struktur

Producing SA 455 requires precision to meet ASTM A455 standards. Berikut adalah pecahan langkah demi langkah proses:

Proses pembuatan keluli

Two main methods are used to produce SA 455, depending on volume and raw materials:

- Relau oksigen asas (Bof): The most common method for large-scale production (Mis., rasuk, paip, atau lembaran). Besi cair (dari relau letupan) is mixed with alloying elements (Mn, Cr, Mo), then pure oxygen is blown into the furnace to remove impurities. Fast and cost-effective for bulk orders.

- Relau arka elektrik (EAF): Ideal for small batches or custom parts (Mis., specialized gears or shafts). Keluli sekerap cair menggunakan arka elektrik, and alloying elements are added to reach SA 455’s chemical specs. More flexible than BOF for low-volume or custom projects.

Rawatan haba

Heat treatment fine-tunes SA 455’s properties for specific applications:

- Menormalkan: Heats the steel to 860–960°C, holds it for 1–2 hours, then cools it in air. Improves ductility and makes the steel’s grain structure uniform (used for parts that need bending, seperti balok jambatan melengkung).

- Pelindapkejutan dan pembajaan: Heats to 900–950°C, quenches (sejuk dengan cepat) dalam air atau minyak, then tempers (reheats) to 550–650°C. This process boosts kekuatan tegangan dan kekerasan—critical for high-stress parts like gears or shafts.

- Penyepuhlindapan: Memanaskan hingga 800-850 ° C., cools slowly in a furnace. Reduces stress from forming or welding (used for precision parts like machine housings).

Proses membentuk

SA 455 is shaped into final products using these techniques:

- Rolling panas: Heats the steel to 1100–1200°C, then rolls it through machines to make beams, paip, atau lembaran. The primary method for construction components (Mis., I-beams or wide-flange columns).

- Rolling sejuk: Rolls the steel at room temperature. Creates smoother surfaces and tighter dimensions (used for precision parts like shafts or gears).

- Menunaikan: Hammers or presses hot steel into complex shapes (Mis., custom machine parts or turbine components). Improves strength by aligning the steel’s grain structure.

- Penyemperitan: Pushes heated steel through a die to make tubes or hollow parts (Mis., small-diameter pipeline sections or machine housings).

- Setem: Uses high-pressure presses to cut or bend flat steel into parts like brackets or fasteners (common in construction and machinery).

Rawatan permukaan

To boost corrosion resistance and lifespan, SA 455 undergoes these surface treatments:

- Galvanizing: Dips the steel in molten zinc. Creates a protective layer that prevents rust (bertahan 25+ years outdoors—ideal for bridge railings or outdoor machinery).

- Lukisan: Applies epoxy or polyurethane paint. Used for marine components or industrial machinery to resist saltwater, bahan kimia, or dirt.

- Tembakan letupan: Blasts the steel with tiny metal balls to remove rust, skala, or dirt. Prepares the surface for welding or coating.

- Salutan: Uses fusion-bonded epoxy (FBE) for pipelines or ceramic coatings for high-heat parts (Mis., Komponen enjin). Extends the steel’s life by 30+ tahun.

4. SA 455 Keluli struktur vs. Bahan lain

How does SA 455 compare to other common steels? Let’s break it down to help you choose the right material for your project:

SA 455 vs. Keluli karbon (Mis., A36)

| Faktor | SA 455 Keluli struktur | Keluli karbon ringan (A36) |

|---|---|---|

| Kekuatan hasil | 345 MPa min | 250 MPa min |

| Ketangguhan | Baik (-20° C.) | Adil (0°C only) |

| Kebolehkalasan | Baik | Sangat bagus |

| Prestasi kos | Better for medium-stress projects | Cheaper for light use (Mis., fencing or small sheds) |

| Terbaik untuk | Lebuh raya melampau, aci mesin | Non-load-bearing parts, residential fences |

SA 455 vs. Kekuatan tinggi rendah aloi (HSLA) Keluli (Mis., X70)

- Komposisi kimia: X70 has more alloying elements (Mn, Dalam) than SA 455, menjadikannya lebih kuat (kekuatan hasil: 483 MPa min vs. SA 455’s 345 MPa min).

- Sifat: X70 excels at high pressure (ideal for oil/gas pipelines), while SA 455 is more formable and cheaper for non-high-pressure applications.

- Aplikasi: X70 = long-distance, Talian paip tekanan tinggi; SA 455 = construction, medium-pressure pipes, bahagian jentera.

SA 455 vs. Keluli tahan karat (Mis., 304)

| Faktor | SA 455 Keluli struktur | Keluli tahan karat (304) |

|---|---|---|

| Rintangan kakisan | Baik (dengan salutan) | Cemerlang (Tiada salutan) |

| Kekuatan hasil | 345 MPa min | 205 MPa min |

| Kos | Lebih rendah ($1.10–$1.50/lb) | Lebih tinggi ($2.80–$3.80/lb) |

| Terbaik untuk | Pembinaan, jentera | Pemprosesan makanan, coastal parts |

SA 455 vs. Aloi aluminium (Mis., 6061)

- Berat: Aluminium adalah 1/3 the weight of SA 455 (great for aircraft or lightweight vehicles), but SA 455 adalah 2x lebih kuat.

- Rintangan kakisan: Aluminum resists rust better, but SA 455 (dengan salutan) handles heavy loads better.

- Kos: SA 455 is cheaper for large construction projects (aluminum is pricier for bulk use).

- Aplikasi: SA 455 = beams, lajur, aci; aluminum = lightweight parts (Mis., bingkai pesawat, bingkai basikal).

5. Yigu Technology’s Perspective on SA 455 Keluli struktur

Di Yigu Technology, we’ve supplied SA 455 structural steel for construction, jentera, and pipeline projects globally. We see SA 455 as a “versatile workhorse”: Ia mengimbangi kekuatan, Kebolehbaburan, dan kos, making it ideal for clients who don’t need ultra-high-strength steels but demand reliability. Bagi pelanggan pembinaan, itukebolehkalasan cuts on-site labor time, dan ituketangguhan works in diverse climates. For machinery makers, it’s cost-effective for high-volume parts without sacrificing durability. We optimize its manufacturing—using BOF for bulk construction parts and EAF for custom machinery components—to meet tight deadlines. For projects that need a reliable, budget-friendly steel, SA 455 is our top recommendation.

FAQ About SA 455 Keluli struktur

1. Can SA 455 be used for offshore oil platforms?

Yes—but it needs a corrosion-resistant coating (like zinc-aluminum alloy or 3-layer polyethylene). Offshore saltwater is harsh, so without coating, SA 455 will rust quickly. We’ve supplied coated SA 455 for offshore walkways that have lasted 10+ tahun dengan penyelenggaraan yang minimum.

2. Is SA 455 suitable for high-temperature applications (Mis., power plant boilers)?

It’s best for moderate temperatures (sehingga 300 ° C.). For high-temperature use (500° C+), choose heat-resistant steels like P91 or P22—they have more chromium and molybdenum to retain strength at extreme heat. SA 455 works well for power plant auxiliary parts (Mis., Sokongan paip) but not for boiler tubes.

3. How long does SA 455 last in outdoor construction?

Dengan rawatan permukaan yang betul (Galvanizing atau salutan epoksi), SA 455 Berlahan 20-30 tahun di luar rumah. Contohnya, galvanized SA 455 beams in a park pavilion in Canada have lasted 22 years with only minor paint touch-ups. Tanpa rawatan, it may rust in 5–8 years in wet climates.