If you’re working on low-stress projects like small buildings, lightweight machinery, or everyday metal parts—where affordability, Kemuluran, dan bahan fabrikasi yang mudah-Q195 structural steel adalah praktikal, penyelesaian kos efektif. As a low-carbon steel (setiap gb/t standard Cina 700), it balances basic strength with workability, but how does it perform in real-world tasks like making reinforcement bars or simple machine parts? Panduan ini memecah sifat utamanya, aplikasi, dan perbandingan dengan bahan lain, so you can make smart decisions for budget-friendly, low-to-medium stress projects.

1. Material Properties of Q195 Structural Steel

Q195’s value lies in its simplicity—low carbon content makes it easy to shape and weld, while still delivering enough strength for everyday structural needs. Mari kita meneroka ciri -cirinya yang menentukan.

1.1 Komposisi kimia

The Komposisi kimia of Q195 is optimized for ductility and weldability, with minimal alloy additions (Untuk gb/t 700):

| Elemen | Julat Kandungan (%) | Fungsi utama |

| Karbon (C) | ≤ 0.12 | Low content for high ductility (easy to bend and weld) |

| Mangan (Mn) | 0.25 - 0.50 | Enhances basic strength without reducing workability |

| Silikon (Dan) | ≤ 0.30 | Meningkatkan rintangan haba semasa bergulir (avoids warping in thin sheets) |

| Sulfur (S) | ≤ 0.040 | Diminimumkan untuk mengelakkan titik lemah (avoids tearing during forming) |

| Fosforus (P) | ≤ 0.045 | Controlled to balance strength and ductility (Sesuai untuk iklim sederhana) |

| Unsur jejak lain | ≤ 0.10 (Mis., Tembaga) | Tiada kesan yang signifikan terhadap prestasi teras; Rangsangan kecil ke kualiti permukaan |

1.2 Sifat fizikal

Ini sifat fizikal make Q195 stable for basic fabrication and everyday use:

- Ketumpatan: 7.85 g/cm³ (Selaras dengan keluli struktur karbon yang paling rendah)

- Titik lebur: 1490 - 1530 ° C. (mengendalikan proses rolling panas dan kimpalan standard)

- Kekonduksian terma: 48 - 52 W/(m · k) pada 20 ° C. (fast heat transfer for quick welding and cooling)

- Kapasiti haba tertentu: 460 J/(kg · k)

- Pekali pengembangan haba: 13.2 × 10⁻⁶/° C. (20 - 100 ° C., minimal warping for simple parts like brackets)

1.3 Sifat mekanikal

Q195’s mechanical traits prioritize workability over high strength—ideal for low-stress applications:

| Harta | Julat nilai |

| Kekuatan tegangan | 315 - 430 MPA |

| Kekuatan hasil | ≥ 195 MPA |

| Pemanjangan | ≥ 33% |

| Pengurangan kawasan | ≥ 50% |

| Kekerasan | |

| – Brinell (Hb) | 100 - 130 |

| – Rockwell (Skala b) | 60 - 70 HRB |

| – Vickers (Hv) | 105 - 135 Hv |

| Kesan ketangguhan | ≥ 27 J pada 0 ° C. |

| Kekuatan keletihan | ~140 MPa (10⁷ kitaran) |

1.4 Sifat lain

- Rintangan kakisan: Miskin (uncoated steel rusts easily in moisture; needs galvanizing or paint for outdoor use like fences or small bridges)

- Kebolehkalasan: Cemerlang (Tidak ada pemanasan yang diperlukan untuk bahagian nipis; works with standard arc welding or spot welding—ideal for on-site fabrication)

- Kebolehkerjaan: Sangat bagus (lembut dan mulur; Potong dengan mudah dengan alat keluli berkelajuan tinggi-alat yang rendah untuk bahagian yang dihasilkan secara besar-besaran)

- Sifat magnet: Ferromagnet (works with basic magnetic inspection tools for simple defect checks)

- Kemuluran: Sangat tinggi (can be bent into 180° angles without cracking—perfect for making wire, kuku, or small brackets)

2. Applications of Q195 Structural Steel

Q195’s low cost and easy fabrication make it a staple in small-scale construction, lightweight manufacturing, and everyday metal products. Berikut adalah kegunaan utamanya, dengan contoh sebenar:

2.1 Pembinaan

- Struktur bangunan: Light steel frames for small residential buildings (1–2 story houses). A Chinese rural builder used Q195 for a village’s 20+ single-family homes—frames were easy to assemble and cut construction time by 30% vs. kayu.

- Bar tetulang: Low-strength rebars for non-load-bearing concrete (Mis., Dinding taman). A Thai landscaping firm used Q195 rebars for decorative concrete walls—cost 20% less than higher-grade steel.

- Jambatan: Small pedestrian footbridges (≤ 10 meter). A Vietnamese community used Q195 for a village footbridge—withstood 500 beban kg (pedestrians and small carts) dan kos $1,500 kurang daripada menggunakan keluli Q235.

2.2 Automotif

- Bingkai kenderaan: Minor non-load-bearing brackets for compact cars (Mis., pemegang bateri). A Indian automaker uses Q195 for its small hatchback’s battery brackets—lightweight and cheap to stamp into shape.

- Komponen penggantungan: Small spring mounting plates (non-critical parts). A Malaysian automotive supplier uses Q195 for these plates—ductility absorbs minor vibration, and cost is 15% lower than Q215 steel.

- Enjin gunung: Simple rubber-to-metal mounts for low-power engines (Mis., small pickup trucks). A Pakistani truck maker uses Q195 for these mounts—easy to machine and meets basic performance needs.

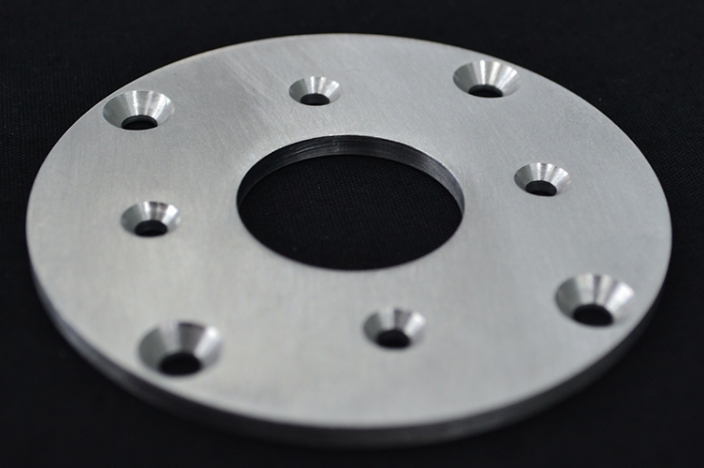

2.3 Kejuruteraan Mekanikal

- Bahagian mesin: Lightweight covers and guards for small industrial machines (Mis., sewing machines). A Bangladeshi textile machinery firm uses Q195 for machine guards—soft enough to cut into custom shapes and cheap to replace if damaged.

- Aci: Pendek, low-torque shafts for office equipment (Mis., printer rollers). A South Korean electronics brand uses Q195 for printer rollers—ductility ensures smooth rotation, and cost is 25% less than alloy steel.

- Galas: Simple bearing housings for low-speed fans (Mis., household exhaust fans). A Indonesian appliance maker uses Q195 for fan bearing housings—easy to cast and assemble.

2.4 Aplikasi lain

- Peralatan perlombongan: Lightweight wire mesh for sorting small ores (Mis., arang batu). A Colombian small-scale mine uses Q195 wire mesh—ductile enough to withstand minor impacts and cost 40% less than high-strength mesh.

- Jentera pertanian: Bahagian kecil untuk alat manual (Mis., mengendalikan bajak, rake tines). A Nigerian farm equipment brand uses Q195 for rake tines—easy to bend into shape and affordable for smallholder farmers.

- Sistem paip: Thin-walled pipes for non-pressure applications (Mis., garden irrigation). A Turkish gardening supply firm uses Q195 pipes—lightweight to transport and easy to cut to length.

- Everyday products: Nails, wire, and metal brackets for furniture or DIY projects. A German hardware brand uses Q195 for its nails—high ductility prevents bending during hammering.

3. Manufacturing Techniques for Q195 Structural Steel

Q195’s simple composition makes its manufacturing process straightforward and low-cost—ideal for mass production:

3.1 Pengeluaran utama

- Relau arka elektrik (EAF): Keluli sekerap (gred rendah karbon) is melted and refined—quick and cost-effective for small-batch production of Q195 sheets or wires.

- Relau oksigen asas (Bof): Pig iron with low carbon content is converted to steel—used for high-volume production of Q195 bars or rebars.

- Pemutus berterusan: Keluli cair dibuang ke dalam bilet (100-150 mm tebal) atau papak -Mempertahankan komposisi seragam dan kecacatan minimum untuk bahagian struktur asas.

3.2 Pemprosesan sekunder

- Rolling panas: Kaedah utama. Keluli dipanaskan hingga 1100 - 1200 ° C dan dilancarkan ke dalam helaian (0.5-5 mm tebal), bar (5-20 mm diameter), or rebars—enhances ductility for bending and forming.

- Rolling sejuk: Digunakan untuk lembaran nipis (≤1 mm thick) like those for appliance parts—done at room temperature for smooth surface finish and tight tolerances (± 0.05 mm).

- Rawatan haba: Jarang diperlukan (Q195’s low carbon content means it’s already soft and ductile). Penyepuhlindapan (dipanaskan ke 700 – 750°C, penyejukan perlahan) is only used for extra-soft parts like wire.

- Rawatan permukaan:

- Galvanizing: Mencelupkan zink cair (40–60 μm coating)—used for outdoor parts like fence posts or irrigation pipes to prevent rust.

- Lukisan: Simple enamel or latex paint—applied to indoor parts like furniture brackets for aesthetics.

3.3 Kawalan kualiti

- Analisis kimia: Basic spectrometry checks carbon and manganese content (ensures compliance with GB/T 700’s low-carbon requirements).

- Ujian mekanikal: Simple tensile tests measure strength and elongation; hardness tests confirm softness for machinability.

- Ujian tidak merosakkan (Ndt): Minimal—only ultrasonic testing for thick bars (Mis., rebar) to check for internal cracks.

- Pemeriksaan dimensi: Calipers or simple gauges verify thickness and diameter (±0.1 mm for sheets, ±0.2 mm for bars)—no need for precision laser scanners.

4. Kajian kes: Q195 in Action

4.1 Pembinaan: Chinese Rural Housing Project

A Chinese construction firm used Q195 for 25 single-family homes in a rural village. The homes needed to be affordable (target cost: \(15,000 masing -masing) and quick to build. Q195’s **low cost** (\)600/ton vs. $800/ton for Q235) cut material costs by 15%, sementara itu KEBERKESANAN KECUALI let crews assemble frames in 2 days per house. Selepas 5 tahun, the homes showed no structural issues—proving Q195 works for low-stress residential use.

4.2 Automotif: Indian Hatchback Battery Brackets

An Indian automaker switched from Q215 to Q195 for its small hatchback’s battery brackets. The brackets are non-load-bearing, so high strength wasn’t needed. Q195’s Kemuluran yang tinggi membuat stamping lebih mudah (Kecacatan yang lebih sedikit), and its lower cost (\(0.50 per bracket vs. \)0.65 for Q215) disimpan $150,000 setiap tahun (100,000 Kereta yang dihasilkan). Testing showed the Q195 brackets lasted the car’s 10-year lifespan without breaking.

4.3 Pertanian: Nigerian Rake Tine Production

A Nigerian farm equipment brand used Q195 for its manual rake tines. Petani pekebun kecil memerlukan alat yang berpatutan (harga sasaran: $5 setiap rake). Q195’s easy machinability let the brand cut tines from steel sheets quickly, dan itu Kemuluran allowed bending into the classic rake shape without cracking. The rakes sold 3x more than competitors using higher-grade steel—proving Q195’s value for low-cost, low-stress products.

5. Analisis perbandingan: Q195 vs. Bahan lain

How does Q195 stack up to alternatives for low-stress, projek mesra bajet?

5.1 Perbandingan dengan keluli lain

| Ciri | Q195 Structural Steel | Q235 Keluli Struktur | A36 Karbon Keluli (A.SSY) | Keluli tahan karat (304) |

| Kekuatan hasil | ≥ 195 MPA | ≥ 235 MPA | ≥ 250 MPA | ≥ 205 MPA |

| Pemanjangan | ≥ 33% | ≥ 26% | ≥ 20% | ≥ 40% |

| Rintangan kakisan | Miskin | Miskin | Miskin | Cemerlang |

| Kos (setiap nada) | \(600 - \)700 | \(700 - \)800 | \(800 - \)900 | \(4,000 - \)4,500 |

| Terbaik untuk | Tekanan rendah, kos rendah | Pembinaan tekanan sederhana | Pembinaan umum | Bahagian yang rawan kakisan |

5.2 Perbandingan dengan logam bukan ferus

- Keluli vs. Aluminium: Q195 has 1.5x higher yield strength than aluminum (6061-T6, ~ 276 MPa? No—Q195: ≥195 MPa; aluminum 6061-T6: ~ 276 MPa). Aluminum is lighter but costs 2x more. Q195 is better for low-cost, weight-insensitive parts like brackets.

- Keluli vs. Tembaga: Q195 is 3x stronger than copper and costs 80% kurang. Tembaga cemerlang dalam kekonduksian, but Q195 is superior for structural parts like small frames.

- Keluli vs. Titanium: Q195 costs 95% less than titanium and is easier to fabricate. Titanium is overkill for Q195’s target applications.

5.3 Perbandingan dengan bahan komposit

- Keluli vs. Polimer bertetulang gentian (Frp): FRP adalah tahan kakisan tetapi kos 3x lebih dan kurang kaku. Q195 is better for low-cost, indoor parts like furniture brackets.

- Keluli vs. Komposit serat karbon: Carbon fiber is lighter but costs 10x more. Q195 is more practical for mass-produced, low-stress items like nails or wire.

5.4 Perbandingan dengan bahan kejuruteraan lain

- Keluli vs. Seramik: Ceramics are brittle and cost 5x more. Q195 is better for parts needing ductility, like bent brackets.

- Keluli vs. Plastik: Plastics are cheaper but have 10x lower strength and melt at low temperatures. Q195 is ideal for parts needing basic structural support, like small machine guards.

6. Yigu Technology’s View on Q195 Structural Steel

Di Yigu Technology, we recommend Q195 for low-stress, budget-sensitive projects like small residential buildings, lightweight automotive brackets, and everyday metal products. Itu KEBERKESANAN KECUALI dan Kemuluran yang tinggi simplify fabrication, while its low cost makes it accessible for small businesses and rural projects. We offer Q195 in custom sheet/bar sizes and provide basic coating (galvanizing/painting) untuk kegunaan luaran. For clients who don’t need high strength but want reliability and affordability, Q195 is the perfect choice—no overengineering, just practical performance at a great price.

FAQ About Q195 Structural Steel

- Can Q195 be used for outdoor projects like small bridges?

Ya, but only with protection. Uncoated Q195 rusts quickly—apply galvanizing or thick paint to extend lifespan to 10+ tahun. It’s best for small footbridges (≤ 10 meter) with light loads (pedestrians only), not heavy traffic.

- Is Q195 strong enough for automotive frame parts?

Only for non-load-bearing parts like battery brackets, wire harness clips, or small covers. It’s too weak for main chassis frames or suspension components—use Q235 or higher-grade steel for those critical parts.

- How does Q195 compare to Q235 in cost and performance?

Q195 is 10–15% cheaper than Q235 but has lower yield strength (195 MPA vs. 235 MPA) and higher ductility. Choose Q195 for low-stress, cost-critical parts; Q235 for medium-stress applications like small building beams or load-bearing brackets.