For small and medium – perusahaan bersaiz, cost control is crucial during new product research and development, and prototype model proofing is an important link that cannot be ignored. Many enterprises have suffered losses because they did not choose the right prototype production process, while some enterprises have achieved successful product development by reasonably controlling the cost of prototype proofing. Jadi, in the process of making a prototype model, which process is more cost – effective? This article will conduct an in – depth analysis from multiple angles to help you find the most suitable and economical prototype production method.

3D Percetakan: A Cost – Effective Choice for Prototype Proofing

In recent years, with the continuous maturity of 3D printing technology, it has become a preferred option for many enterprises in prototype model proofing, and its cost – effectiveness has been increasingly recognized.

Advantages in Material Utilization

3D printing belongs to additive manufacturing. Unlike traditional processing methods that remove materials from a whole piece, 3D printing builds the prototype by adding materials layer by layer according to the designed 3D model. Cara ini, except for the necessary technical support, there is almost no problem of material waste as much as the prototype model needs. Sebaliknya, other processing processes often produce a lot of waste materials, and in some cases, the wasted materials may even be more than the materials of the prototype model itself. Contohnya, when producing a small and complex prototype, traditional subtractive manufacturing may need to cut a large piece of raw material, resulting in a lot of leftover materials that cannot be used, which greatly increases the material cost. 3D Percetakan, Sebaliknya, can accurately use materials according to the shape of the prototype, reducing material waste and thus saving material costs.

Price Advantage with Technological Maturity

In addition to the prototype of new product research and development, 3D printing is also widely used in fields such as 3D printing figures, 3D printing medical devices, and biological 3D printing. With the expansion of application fields and the maturity of technology, the price of 3D printing has dropped again and again. In the early days, 3D printing was considered a high – cost technology, but now, for many types of prototypes, choosing 3D printing is undoubtedly more preferential. Especially for small – batch prototype production, the cost advantage of 3D printing is more obvious.

Strong Adaptability to Complex Structures

3D printing has unique advantages in processing complex shapes and special – shaped structures, such as curves, hollow structures, dll. Traditional processing methods may encounter great difficulties in processing these complex structures, requiring multiple processes and special tools, which not only increases the processing time but also raises the cost. 3D printing can directly print these complex structures in one go without the need for multiple processing steps, reducing the difficulty and cost of processing. Contohnya, for a prototype with a complex internal hollow structure, 3D printing can easily complete the production, while traditional processing may require tedious operations such as drilling and cutting, and the accuracy is difficult to guarantee.

Choosing a Good 3D Printing Platform: Saving Costs and Improving Efficiency

Choosing a good 3D printing platform is an important part of ensuring the cost – effectiveness of 3D printing prototype proofing. A good platform can not only provide better service but also save a lot of money for enterprises.

Advantages of Online Automatic Quotation System

Qile Industrial’s online automatic quotation system is a good example. It can realize 1 – minute automatic quotation, price comparison, and automatic ordering. Enterprises only need to enter their part information, bahan, color, surface treatment process, and quantity, and they can quickly know the price and delivery time. Sebaliknya, the general offline manual quotation takes 4 hours or even longer. This not only saves the time for enterprises to wait for quotations but also allows enterprises to compare prices in a timely manner and choose the most cost – effective solution. The fast quotation speed also helps enterprises to arrange the research and development schedule more efficiently.

Transparent and Affordable Prices

In addition to the speed advantage, online 3D printing platforms like Qile Industrial also have the characteristics of cheaper and more transparent prices. Enterprises can clearly know the composition of the cost through the self – service quotation system, avoiding the situation of being overcharged due to opaque prices. If you have any questions about the self – service quotation of 3D printing models, you can consult Qile Industry, and their professional staff will provide you with detailed answers.

Fast Delivery Speed

Online printing can be shipped as fast as 24 jam, which is much faster than the delivery time of traditional offline processing. For enterprises in the urgent stage of new product research and development, fast delivery can accelerate the progress of product testing and improvement, shorten the research and development cycle, and indirectly save costs for enterprises.

Other Alternative Processes: Choosing According to Specific Needs

Although 3D printing has many advantages, it is not a panacea, and not all prototypes are suitable for 3D printing. When encountering prototypes that cannot be produced by 3D printing or when 3D printing is more expensive due to the special structure and special requirements of the prototype model, we can consider other alternative processing techniques, such as CNC machining, sheet metal, silicone lamination, dll. Among them, CNC machining is a widely used alternative process.

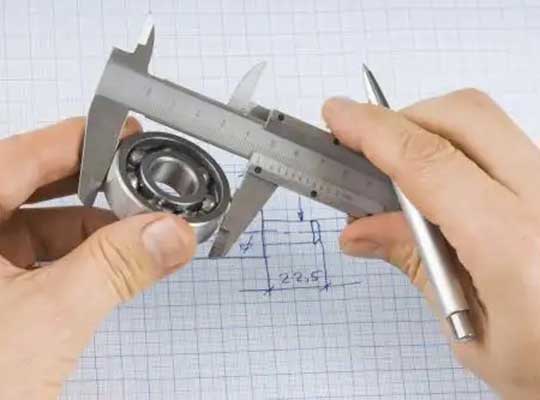

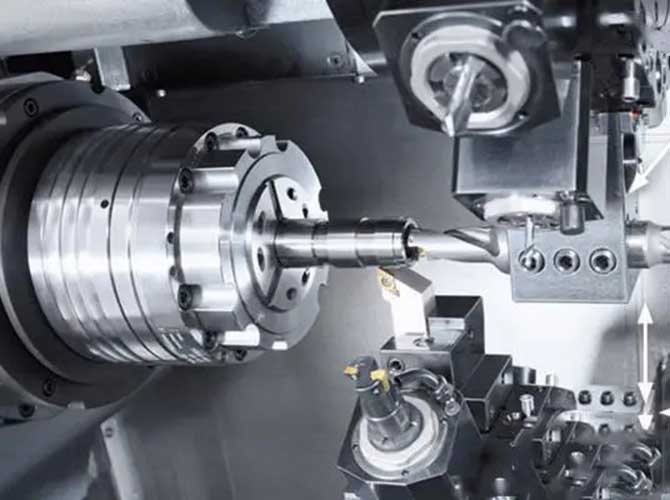

Overview of CNC Machining

CNC (Computer Numerical Control) is a computer numerical control machine tool that performs subtractive manufacturing from a whole plate according to a numbered program. CNC milling machines can process some irregular objects, while lathes are used to process circular objects. CNC can process relatively large workpieces, with the maximum molding size of the whole piece reaching 30001200850mm, which is cheaper than SLA and meets the needs of many types of prototypes.

CNC Prototype Production Process

The CNC prototype production process includes the following steps: accepting drawings – writing the tool path – transmitting the tool path to the CNC machining center – automatic machine processing – manual post – processing (pengisaran, lukisan, percetakan, dll.). This process is mature and stable, ensuring the quality of the prototype.

Material Selection and Advantages of CNC Machining

At present, CNC machining is the most widely used in China, and the tolerance of product materials is also higher, including plastic processing and metal processing.

- Plastic processing materials include: Abs (off – white/black/transparent); PMMA Acrylic (Colorless Transparent / Colored Transparent / Pearlescent / Embossed); Bakelite (Opaque Dark, Brown / Black); Pc, PA Nylon, PA+Glass Fiber; Race Steel (Pom) White/Black; PP Milky White.

- Metal materials include: aloi aluminium, Tembaga (with purple – red luster), Keluli tahan karat, titanium alloy, aloi magnesium, and zinc alloy.

CNC machining can process relatively high – precision product samples, and bakelite and aluminum alloys are commonly used in the production of jigs and fixtures. The advantages of CNC prototypes are: good toughness, high tension, kos rendah, and a wide selection of materials.

Suitable Scenarios for CNC Machining

Contohnya, if you just need to make a prototype model with a simple structure, such as a board with a few openings in it and a not small size, then CNC machining can be used. Because CNC is a subtractive manufacturing method on a solid board material, it is easy to cut a few small openings, and the processing time is also short. If 3D printing is used, it needs to stack and shape layer by layer, which will take more time and the price is relatively more expensive. Jadi, in such simple structure and large – size prototype production, CNC machining has more cost advantages.

Industri Qile: Providing Cost – Effective Prototype Production Solutions

Qile Industry has its own factory, dengan 260 professional management and technical personnel and more than 300 CNC and 3D printing equipment. It has many years of experience in prototype production, small batch production, 3D printing models, replica molds, Pemesinan CNC, and other processing technologies. Enterprises can consult Qile Industry, tell their needs to customer service, and customer service will provide the most cost – effective product prototype model production plan according to the specific needs of enterprises. Whether it is 3D printing or CNC machining, Qile Industry can give reasonable suggestions based on factors such as the structure, keperluan bahan, precision requirements, and production quantity of the prototype, helping enterprises save costs while ensuring the quality of the prototype.

Yigu Technology’s Viewpoint

In prototype manufacturing, choosing the right process is key to cost – effectiveness. 3D printing excels in complex structures and material efficiency, while CNC shines in simple, besar – size prototypes. Enterprises should assess needs like structure, bahan, and precision. Cooperating with professional platforms like Qile Industry ensures optimal, kos – saving solutions for R&D success.

Soalan Lazim

- What factors should enterprises consider when choosing a prototype manufacturing process?

Enterprises should consider factors such as the structure complexity of the prototype, saiz, keperluan bahan, precision requirements, production quantity, dan masa penghantaran. For complex structures, 3D printing may be more suitable; for simple structures and large sizes, CNC machining may be more cost – effective.

- How to ensure the cost – effectiveness of 3D printing prototype proofing?

Choosing a good 3D printing platform with an online automatic quotation system can help. Such platforms offer fast quotation, transparent prices, and fast delivery, which can save time and cost. Juga, making full use of 3D printing’s material utilization advantage can reduce material waste.

- Is CNC machining suitable for all types of prototype production?

Tidak, CNC machining is more suitable for prototypes with simple structures, large sizes, and high material tolerance requirements. For complex special – shaped structures, 3D printing may be a better choice. Enterprises need to choose according to their specific prototype characteristics.