Low-pressure infusion processing is a game-changer for small-batch manufacturing—offeringhigh efficiency, short production cycles, danlow costs for products like automotive accessories, medical device shells, and digital product covers. But to avoid common issues (like incomplete mold filling, product defects, or equipment failures), following strict precautions is non-negotiable. Whether you’re new to the process or looking to refine your workflow, this guide breaks down the critical precautions for every stage of low-pressure infusion, with real examples and data to keep your production on track.

1. Penyediaan bahan: Lay the Foundation for High-Quality Products

The success of low-pressure infusion starts with proper material handling—since even small mistakes here can ruin entire batches. The process relies ontwo-component PU polyurethane materials, and ignoring their requirements leads to curing failures or weak product structures.

Key Precautions for Material Prep

- Verify material compliance: Ensure the two-component PU meets your product’s specs (Mis., kekerasan, rintangan haba). Contohnya, medical device shells need PU with biocompatibility certifications—using uncertified material could lead to regulatory rejects.

- Accurate measurement: Use calibrated tools (like digital scales with ±0.1g precision) to measure the two components. A 5% error in the mixing ratio can reduce product strength by up to 30%, according to industry tests.

- Controlled mixing conditions: Mix the components at the recommended temperature (20-25 ° C.) dan tekanan (0.1–0.3 MPa). Cold temperatures (below 18°C) slow down chemical reactions, while high temperatures (above 28°C) cause premature curing—both leading to uneven material consistency.

Case Example: A toy manufacturer once used PU that was stored at 10°C (too cold) and skipped temperature adjustment. The mixed material cured unevenly, resulting in 80% of the toy shells having cracks—costing them $2,000 in wasted materials and a 1-week production delay.

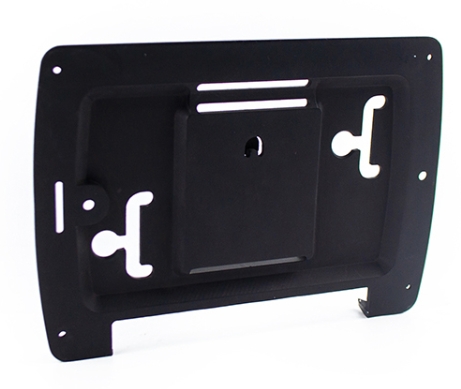

2. Mold Design & Preparation: Avoid Filling Failures & Product Defects

Molds are the backbone of low-pressure infusion—poor design or preparation leads toincomplete filling, gelembung, atauuneven wall thickness. Since the process is ideal for large thick-walled or uneven-thickness products, molds must be tailored to these needs.

Critical Mold Precautions (Table)

| Aspect of Mold | Precaution Details | Kenapa pentingnya |

|---|---|---|

| Design for Flow | Addfillets (tepi bulat) dangradual thickness transitions; avoid sharp corners. | Sharp corners create dead zones where material can’t flow—causing voids in the product. |

| Ventilation | Drill small vent holes (0.5-1mm diameter) at the highest points of the mold. | Vents release trapped air, preventing bubbles that weaken the product and ruin its surface finish. |

| Surface Cleanliness | Wipe the mold with a lint-free cloth and alcohol (99% purity) before each use. | Dust or oil residues stick to the PU, creating blemishes on the product—no need for extra post-processing. |

| Material Compatibility | Use molds made of materials resistant to PU (Mis., aluminium, steel-coated resin). | Low-quality molds (Mis., uncoated plastic) can react with PU, leading to mold damage and product contamination. |

Real-World Impact: An automotive model shop redesigned their mold to add 0.8mm vents and fillets. Before the change, 35% of their models had bubbles; after, the defect rate dropped to 2%—saving them 15 hours of rework per week.

3. Process Control: Master Temperature, Tekanan, & Filling to Ensure Consistency

Low-pressure infusion’s “low pressure” doesn’t mean “no control”—temperature, tekanan, and filling speed are make-or-break factors. Even small deviations can lead to undercured products or mold damage.

Key Process Control Precautions

- Kawalan suhu: Maintain the mold at 35–45°C during infusion (varies by PU type). Use a mold temperature controller with ±1°C accuracy. Contohnya, if the mold is too cold (30° C.), the PU takes 50% longer to cure—delaying production. If it’s too hot (50° C.), the material cures before filling the mold, causing voids.

- Pressure adjustment: Set the infusion pressure to 0.2–0.5 MPa (low enough to avoid mold damage, high enough for full filling). A furniture manufacturer once used 0.6 MPA (too high) for a thick-walled chair armrest mold—the pressure cracked the mold, kos $1,500 to replace.

- Filling monitoring: Watch the material flow in real time (use transparent mold sections if possible) and adjust the filling speed to 5–10 mL/s. Fast filling (berakhir 12 mL/s) traps air, while slow filling (under 3 mL/s) causes the material to cure mid-flow.

- Demolding time: Follow the PU’s recommended demolding time (usually 15–30 minutes). Demolding too early (Mis., 10 minit) leads to soft, deformable products; demolding too late (Mis., 40 minit) makes the product stick to the mold—requiring force that damages edges.

4. Pasca pemprosesan, Safety, & Maintenance: Protect Products, Workers, & Equipment

The process doesn’t end with demolding—post-processing ensures final quality, while safety and maintenance prevent accidents and downtime.

Langkah berjaga-jaga selepas pemprosesan

- Pengamplasan & pembersihan: Use 240-grit sandpaper for rough edges (avoid 180-grit, which scratches the surface) and wipe products with a damp cloth to remove PU residue. For medical device shells, add a final disinfection step (using FDA-approved cleaners) to meet hygiene standards.

- Quality checks: Inspect each product for cracks, gelembung, or uneven thickness (use a caliper with ±0.02mm precision). Reject products that don’t meet specs—sending defective items to clients costs more in returns than rework.

Safety Precautions

- Protective gear: Operators must wear nitrile gloves (PU can irritate skin), safety glasses (prevents splashes), and a respirator (avoids inhaling PU fumes). A factory once had an operator skip gloves—they developed a skin rash, leading to a 3-day absence and a safety audit.

- Ventilation: Keep the workspace well-ventilated (use exhaust fans with 10 air changes per hour) to reduce fume buildup. Poor ventilation causes headaches and dizziness—lowering productivity.

Equipment Maintenance Precautions

- Daily checks: Inspect hoses for leaks, clean the material mixing chamber, and test pressure gauges. A leaking hose can waste 5–10% of PU per day—adding up to $500 in monthly material costs.

- Monthly servicing: Lubricate moving parts (Mis., mold clamps) and calibrate temperature/pressure controllers. A shop that skipped monthly servicing had their pressure gauge fail—leading to over-pressurization and a 2-day production stop.

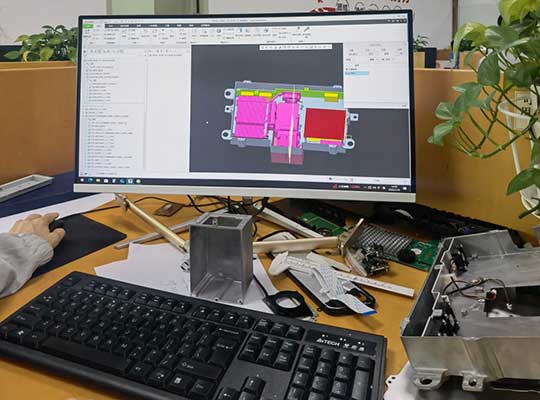

5. Mold Trial & Debugging: Test Before Mass Production

Never jump into mass production without trial runs—mold trial and debugging catch issues early, saving time and money. Before producing 100+ unit, run 5–10 test parts and:

- Check if the mold fills completely (no voids).

- Verify product dimensions (use a coordinate measuring machine for precision).

- Test product strength (Mis., drop tests for toys, pressure tests for medical shells).

- Adjust parameters (Mis., increase temperature, add vents) if issues arise.

Contoh: A digital product manufacturer did 8 test runs for their tablet cover mold. The first 3 runs had uneven thickness—they adjusted the mold’s flow channels, and the 4th run was perfect. Mass production then proceeded with zero defects.

Yigu Technology’s Perspective on Low-Pressure Infusion Precautions

Di Yigu Technology, we believe low-pressure infusion’s value lies in precision—every precaution directly impacts product quality and cost. For small-batch industries (like automotive models or medical devices), cutting corners on material prep, mold design, or process control leads to avoidable losses. We help clients optimize these steps: from recommending compatible PU materials to designing mold vents and calibrating equipment. By following these precautions, businesses turn low-pressure infusion into a reliable, cost-effective solution—meeting design goals and client expectations consistently.

Soalan Lazim

1. What happens if the two-component PU mixing ratio is wrong?

A wrong ratio (even 3–5% off) ruins curing: too much of one component makes the product soft and brittle (if under-cured) or hard and cracked (if over-cured). Contohnya, a 7% ratio error reduced a medical shell’s strength by 40%—it failed a pressure test, leading to a client return.

2. How often should I replace mold vents?

Mold vents (0.5–1mm) can clog with PU residue over time—replace them every 50–100 production cycles. Clogged vents trap air, causing bubbles: a toy shop used clogged vents for 120 kitaran, resulting in 40% defective toys before replacing the vents.

3. Can I use the same mold temperature for all PU types?

No—different PU formulations need different temperatures. Flexible PU (for soft toys) uses 35–40°C, while rigid PU (for automotive parts) uses 40–45°C. Using 45°C for flexible PU causes it to cure too hard, losing its flexibility. Always check the PU manufacturer’s temperature guidelines.