Di dunia pembuatan plastik, kecekapan, keberkesanan kos, dan skalabiliti sangat penting. Antara pelbagai teknik yang ada, pengacuan suntikan pelbagai rongga menonjol sebagai penyelesaian yang kuat untuk keperluan pengeluaran volum tinggi. Kaedah lanjutan ini telah merevolusikan bagaimana pengeluar memenuhi tuntutan pasaran, Menawarkan kelebihan yang ketara ke atas acuan rongga tunggal tradisional. Dalam panduan komprehensif ini, Kami akan meneroka semua yang perlu anda ketahui pengacuan suntikan pelbagai rongga-Dari prinsip asas dan kelebihan utama untuk merancang pertimbangan, faktor kos, Dan apabila ia adalah pilihan yang tepat untuk projek anda. Sama ada anda pemaju produk, Jurutera Pembuatan, atau pemilik perniagaan, Panduan ini akan membantu anda membuat keputusan yang tepat mengenai penggabungan pelbagai rongga teknologi ke aliran kerja pengeluaran anda.

Memahami jenis rongga suntikan suntikan

Sebelum menyelam jauh pengacuan suntikan pelbagai rongga, it’s essential to understand the different types of mold cavities available and how they compare. Injection molding tools primarily fall into three categories, each designed to address specific production requirements:

Single Cavity Tools: The Foundation

A single cavity tool is the most basic form of injection molding tooling. Seperti namanya, it features a single cavity that shapes one part per production cycle. This simplicity makes it the go-to choice for certain scenarios:

- Fastest to manufacture: Dengan hanya satu rongga untuk merancang dan mesin, Alat rongga tunggal mempunyai masa memimpin terpendek -selalunya 30-50% lebih cepat menghasilkan daripada pelbagai rongga alternatif.

- Kos awal terendah: Untuk bentuk asas, Alat rongga tunggal mewakili pilihan yang paling mesra bajet, dengan kos perkakas biasanya 50-70% lebih rendah daripada setanding pelbagai rongga acuan.

- Pemprosesan stabil: Mengawal parameter pencetakan lebih mudah dengan satu rongga, mengakibatkan kualiti bahagian yang lebih diramalkan dan konsisten.

- Sesuai untuk jumlah yang rendah: Apabila keperluan pengeluaran berada di bawah 10,000 unit, Alat rongga tunggal sering memberikan nisbah kos kepada nilai terbaik.

Walau bagaimanapun, Keterbatasan mereka menjadi jelas dalam senario volum tinggi, kerana mereka menghasilkan hanya satu bahagian setiap kitaran, membawa kepada masa pengeluaran yang lebih lama dan kos per unit yang lebih tinggi.

Alat rongga pelbagai: Pengeluaran skala

Pengacuan suntikan pelbagai rongga Alat mengambil kecekapan pengeluaran ke peringkat seterusnya dengan memasukkan pelbagai rongga yang sama ke dalam satu acuan. Alat ini:

- Mengandungi sekurang -kurangnya dua rongga dan dua teras, with practical limits reaching hundreds for small components.

- Produce multiple identical parts per cycle, directly increasing output without extending cycle time.

- Feature balanced, even-numbered cavity configurations to ensure uniform filling and cooling.

- Are engineered with complex gate and runner systems to distribute molten plastic evenly across all cavities.

The key distinction between pelbagai rongga tools and other types lies in their focus on producing identical parts efficiently, making them indispensable for high-volume manufacturing.

Family Tools: Versatility with Trade-offs

Family tools represent a hybrid approach, featuring multiple cavities of different shapes and sizes within a single mold. This design allows manufacturers to produce various components of an assembly in one cycle, offering unique benefits:

- Exact color matching: All components from a family tool share the same material batch and processing conditions, ensuring uniform appearance—critical for consumer products like household appliances.

- Assembly efficiency: Producing all assembly components simultaneously streamlines downstream manufacturing processes.

Walau bagaimanapun, family tools come with significant challenges:

- Balancing issues: Different cavity shapes create uneven pressure distributions, increasing the risk of defects.

- Higher complexity: Require sophisticated gate and runner systems, often incorporating hot-tip runners to manage thermal stresses.

- Increased labor: Manual separation of different parts adds production time and cost.

Advantages of Multi Cavity Injection Molding

The decision to invest in pengacuan suntikan pelbagai rongga is driven by its compelling advantages, particularly for high-volume production scenarios. Let’s explore these benefits in detail:

Increased Production Output

The most obvious advantage of pelbagai rongga tools is their ability to produce more parts per cycle. While a single cavity tool generates one part per cycle, a pelbagai rongga tool with, say, 8 cavities produces 8 parts in the same amount of time. This translates to:

- 800% higher output compared to a single cavity tool with the same cycle time

- Faster time-to-market for large orders

- Ability to meet tight delivery deadlines for high-demand products

Contohnya, a medical device manufacturer producing 100,000 plastic components monthly could reduce production days from 25 to just 5 by switching from a single cavity to a 5-cavity mold, assuming equal cycle times.

Lower Cost Per Part

While pelbagai rongga tools require a higher initial investment, they deliver significant cost savings at scale. The economics work like this:

- Tooling costs are spread across more parts

- Labor costs per part decrease as output increases

- Energy and material waste per part are reduced through efficient runner system design

Studies show that for production runs exceeding 50,000 unit, pelbagai rongga tools can reduce per-part costs by 30-60% compared to single cavity alternatives. Contohnya, a part with a \(0.50 production cost using a single cavity tool might drop to \)0.20 per part with an 8-cavity tool when producing 100,000 unit.

Improved Part Consistency

Pengacuan suntikan pelbagai rongga offers superior consistency across production runs, particularly in terms of:

- Color uniformity: All parts from a pelbagai rongga tool are formed from the same material batch under identical processing conditions, minimizing color variation.

- Kestabilan dimensi: Balanced cavity design ensures uniform pressure and cooling, reducing part-to-part dimensional variation to as low as ±0.001 inches for precision components.

- Sifat bahan: Consistent filling and cooling rates across cavities result in uniform molecular structure and mechanical properties.

This level of consistency is critical for industries like automotive and aerospace, where part interchangeability is essential.

Efficient Use of Production Resources

Multi cavity tools maximize the utilization of expensive production resources:

- Machine time: More parts per cycle mean better utilization of injection molding machines, which are significant capital investments.

- Energy usage: Producing multiple parts in one cycle is more energy-efficient than producing them sequentially.

- Operator time: Less machine tending time per part reduces labor requirements.

A study by the Plastics Industry Association found that pelbagai rongga tools can improve overall equipment effectiveness (OEE) by 20-30% compared to single cavity tools in high-volume production.

Drawbacks of Multi Cavity Injection Molding

While the advantages are compelling, pengacuan suntikan pelbagai rongga isn’t without its challenges. Understanding these drawbacks is crucial for making informed decisions:

Higher Initial Investment

The most significant barrier to adopting pelbagai rongga tools is their higher upfront cost. Factors contributing to this include:

- More material required for mold construction

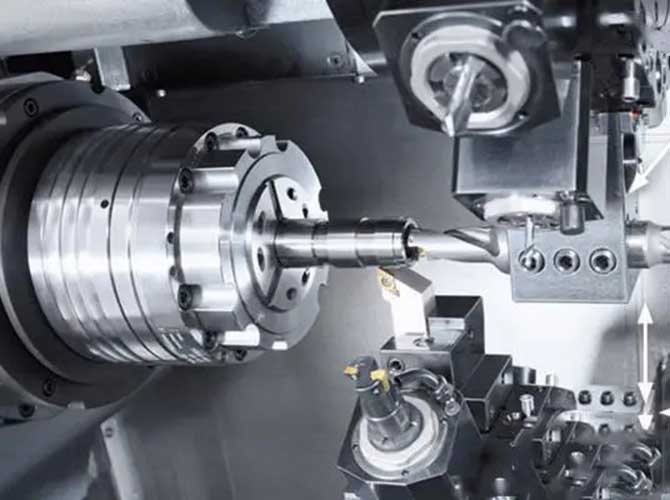

- Increased machining time for multiple cavities

- Complex design engineering, including MoldFlow analysis

- Sophisticated runner systems and cooling channel design

Multi cavity tooling costs typically range from 2-10 times more than single cavity tools, depending on the number of cavities and part complexity. Contohnya, an 8-cavity mold for a simple part might cost \(40,000 berbanding dengan \)8,000 for a single cavity version.

Longer Lead Times

Developing pelbagai rongga tools takes significantly longer than single cavity alternatives. The timeline extension comes from:

- More complex design engineering (2-3x longer design phase)

- Additional MoldFlow analysis to ensure balanced filling

- Longer machining and assembly time for multiple cavities

- More rigorous testing and validation

While a single cavity tool might be ready in 4-6 minggu, an 8-cavity tool could take 12-16 weeks to design and manufacture. This extended lead time must be factored into production schedules.

Increased Complexity in Design and Maintenance

Multi cavity tools introduce additional complexity throughout their lifecycle:

- Design challenges: Ensuring uniform filling across all cavities requires advanced flow analysis and careful gate placement.

- Maintenance issues: More cavities mean more potential points of failure. A flaw in one cavity can render the entire mold unusable.

- Repair difficulties: Fixing issues in one cavity often requires careful disassembly and reassembly to maintain cavity balance.

Maintenance costs for pelbagai rongga tools are typically 20-40% higher than for single cavity tools due to their complexity.

Potential for Magnified Defects

While pelbagai rongga tools can produce consistent parts, they also have the potential to magnify defects:

- A minor design flaw can affect all cavities simultaneously

- Uneven cooling can lead to consistent defects across multiple parts

- Gate placement issues are multiplied across all cavities

This means that thorough testing and validation are even more critical for pelbagai rongga tools than for single cavity designs.

Multi Cavity vs. Single Cavity vs. Family Molds: A Comparative Analysis

To better understand when to choose pengacuan suntikan pelbagai rongga, let’s compare it directly with single cavity and family molds across key performance indicators:

| Faktor | Single Cavity Molds | Multi Cavity Molds | Family Molds |

| Parts per cycle | 1 | 2+ (identical) | 2+ (different) |

| Tooling cost | Lowest | Highest | Tinggi |

| Lead time for tooling | Shortest (4-6 minggu) | Longest (12-16 minggu) | Long (8-12 minggu) |

| Cost per part | Highest | Lowest (at scale) | Medium |

| Best for volume | Rendah (<50,000 unit) | Tinggi (>50,000 unit) | Medium with assembly needs |

| Part consistency | Baik | Cemerlang (balanced design) | Miskin (uneven filling) |

| Maintenance cost | Lowest | Highest | Tinggi |

| Changeover flexibility | Tinggi | Rendah | Medium |

| Color consistency | Baik | Cemerlang | Cemerlang (same batch) |

| Labor per part | Highest | Lowest | Highest (separation needed) |

This comparison clearly shows that pengacuan suntikan pelbagai rongga excels in high-volume scenarios where consistency and low per-part costs are priorities, despite its higher initial investment and complexity.

Design Considerations for Multi Cavity Injection Molding

Successful pengacuan suntikan pelbagai rongga begins with thoughtful design. Several critical factors must be addressed during the design phase to ensure optimal performance:

Cavity Balance and Layout

Achieving balanced filling across all cavities is the cornerstone of effective pelbagai rongga design. Key considerations include:

- Symmetrical layout: Cavities should be arranged symmetrically around the sprue to ensure equal flow paths.

- Equal distance: Each cavity should be equidistant from the sprue to promote uniform filling pressure.

- Consistent cooling: Cooling channels must be identically sized and positioned relative to each cavity.

MoldFlow analysis is essential here, simulating the flow of molten plastic through the runner system and cavities to identify potential balancing issues before manufacturing begins.

Gate Design and Placement

Gates control the flow of plastic into each cavity and play a critical role in pelbagai rongga prestasi:

- Consistent gate size: All gates must be identical to ensure uniform filling rates.

- Optimal gate location: Gates should be placed to minimize weld lines and ensure complete filling.

- Gate type selection: Hot tips, edge gates, or sub-gates may be used depending on part geometry and material.

Poor gate design in pelbagai rongga tools can lead to uneven filling, dimensional variations, and increased scrap rates.

Runner System Design

The runner system delivers plastic from the sprue to each cavity and must be carefully engineered for pelbagai rongga alat:

- Balanced runner layout: Runner diameters and lengths should be identical for each cavity.

- Minimized pressure drop: Runner design should reduce pressure loss between sprue and cavities.

- Material efficiency: Hot runner systems can reduce material waste by 30-50% compared to cold runners in pelbagai rongga alat.

Advanced runner systems in pelbagai rongga tools often incorporate pressure sensors to monitor and adjust flow in real-time.

Material Selection Considerations

Not all materials perform equally well in pelbagai rongga alat. Key material factors include:

- Kelikatan: Materials with stable viscosity across processing temperatures work best in pelbagai rongga designs.

- Shrinkage rate: Materials with predictable shrinkage are easier to control across multiple cavities.

- Flow characteristics: Materials with good flow properties can fill multiple cavities more uniformly.

Engineering resins like ABS, polipropilena, and nylon are commonly used in pengacuan suntikan pelbagai rongga due to their consistent flow properties.

Cycle Times and Production Efficiency in Multi Cavity Molding

Cycle time—the time required to complete one full production cycle—has a profound impact on the efficiency of pengacuan suntikan pelbagai rongga. Let’s explore how cycle times interact with pelbagai rongga design:

The Relationship Between Cavity Count and Cycle Time

Contrary to what some might expect, adding more cavities doesn’t necessarily increase cycle time. Sebenarnya:

- Cooling time (the longest phase of most injection molding cycles) remains the same regardless of cavity count.

- Injection time increases slightly with more cavities but typically represents a small portion of total cycle time.

- Clamping and ejection times are minimally affected by cavity count in well-designed tools.

This means that a 16-cavity tool can produce 16 times more parts than a single cavity tool with nearly the same cycle time.

Strategies for Optimizing Cycle Times in Multi Cavity Molds

To maximize efficiency in pengacuan suntikan pelbagai rongga, consider these strategies:

- Optimize cooling channel design: Ensure uniform cooling across all cavities with properly sized and positioned channels.

- Use high-conductivity tool steels: Materials like H13 or S7 tool steel conduct heat more efficiently than standard steels.

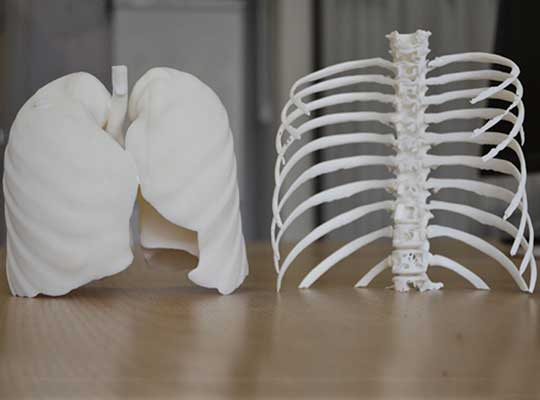

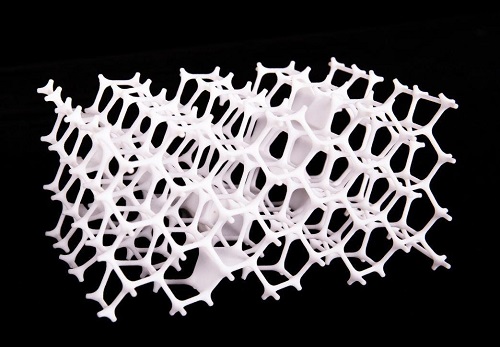

- Implement conformal cooling: 3D-printed cooling channels that follow part contours reduce cooling time by 20-40%.

- Optimize gate size: Properly sized gates balance filling time and pressure requirements.

- Use hot runner systems: Eliminating cold runners reduces cycle time and material waste.

A well-optimized 8-cavity tool can often produce parts with a cycle time only 5-10% longer than a single cavity tool for the same part.

Cost-Benefit Analysis of Increasing Cavity Count

Deciding on the optimal number of cavities requires careful analysis:

- Marginal cost increase: Each additional cavity adds less to the total tool cost than the previous one.

- Diminishing returns: At some point, adding more cavities provides smaller incremental benefits.

- Machine limitations: Injection molding machines have maximum tonnage and shot size limits that constrain cavity count.

Contohnya, while a 16-cavity tool costs more than an 8-cavity tool, it may not cost twice as much, yet it can double production output. Walau bagaimanapun, a 32-cavity tool might approach the machine’s maximum capabilities, leading to significant design compromises.

When to Choose Multi Cavity Injection Molding

Selecting the right cavity configuration depends on multiple factors. Here are clear indicators that pengacuan suntikan pelbagai rongga is the right choice for your project:

High Volume Production Requirements

Multi cavity tools shine when production volumes are high. As a general guideline:

- Ideal for volumes above 50,000 unit: At this scale, the higher tooling cost is offset by lower per-part production costs.

- Critical for volumes above 100,000 unit: The efficiency gains become substantial, often reducing total production costs by 40% atau lebih.

- Essential for million-unit productions: Without pelbagai rongga alat, meeting large volume requirements within reasonable timeframes would be impossible.

Contohnya, a consumer electronics manufacturer producing 500,000 plastic housings annually would see significant savings by using a 16-cavity tool instead of a single cavity alternative.

Consistent Part Design

Pengacuan suntikan pelbagai rongga works best when producing identical parts with:

- Simple to moderately complex geometries

- Consistent wall thicknesses

- Uniform cooling requirements

Parts with highly variable wall thicknesses or complex geometries may be more challenging to balance across multiple cavities, increasing design complexity and costs.

Long Production Runs

Multi cavity tools are excellent investments for long-term production:

- Their higher initial cost is amortized over more parts

- The longer the production run, the greater the return on investment

- Tooling durability becomes more important, dan pelbagai rongga tools are typically built to higher standards

Products with anticipated lifespans of 2+ years are often excellent candidates for pelbagai rongga perkakas.

Tight Delivery Schedules

When time-to-market is critical, pelbagai rongga tools can accelerate production:

- Faster accumulation of required inventory

- Ability to meet sudden demand spikes

- Reduced need for overtime or additional shifts

A 10-cavity tool can deliver 10 times the parts in the same timeframe as a single cavity tool, helping manufacturers meet tight deadlines.

Yigu Technology’s Perspective on Multi Cavity Injection Molding

Di Yigu Technology, Kami percaya pengacuan suntikan pelbagai rongga represents the pinnacle of efficient plastic manufacturing for high-volume applications. While the initial investment is significant, the long-term benefits in terms of production efficiency, pengurangan kos, and quality consistency make it indispensable for scaling operations. Our engineering team specializes in optimizing pelbagai rongga designs through advanced flow analysis and precision tooling, ensuring our clients achieve maximum return on their investment while maintaining the highest quality standards.

Soalan yang sering ditanya (Soalan Lazim)

1. What is the typical cost difference between a single cavity and multi cavity mold?

Multi cavity molds typically cost 2-10 times more than single cavity molds, depending on the number of cavities and part complexity. Walau bagaimanapun, this higher initial investment is often offset by lower per-part costs when producing more than 50,000 unit.

2. How many cavities can a multi cavity mold have?

Practical limits for cavity count depend on part size and machine capabilities, but multi cavity molds can have hundreds of cavities for small parts. Common configurations range from 2-32 cavities for most medium-sized components.

3. Are multi cavity molds suitable for prototyping or low-volume production?

Tidak, multi cavity molds are generally not cost-effective