In the complex world of manufacturing, metal forming companies play a pivotal role in transforming raw metal into functional components that power industries worldwide. From automotive parts to aerospace components, medical devices to architectural structures, the expertise of these companies directly impacts product quality, prestasi, dan ketahanan. This guide will help you understand what metal forming companies do, how to select the right one for your project, and why their role is indispensable in modern manufacturing.

The Role of Metal Forming Companies in Modern Manufacturing

Metal forming is one of the oldest and most essential metalworking processes, dating back thousands of years but evolving dramatically with technological advancements. Today’s metal forming companies combine traditional craftsmanship with cutting-edge technology to shape metal into precise configurations without removing material, unlike machining processes.

Core Functions of Metal Forming Companies

Metal forming companies specialize in transforming metal through various techniques that reshape materials using force rather than cutting. Their core functions include:

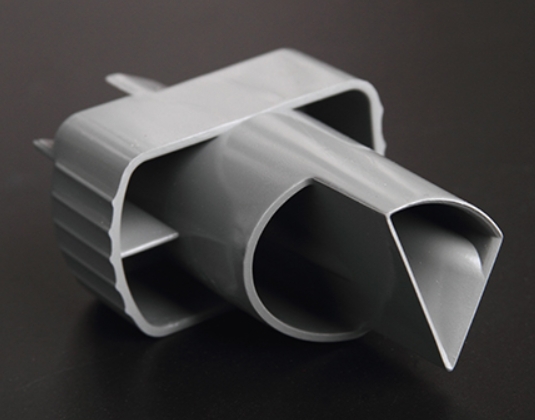

- Shaping raw metal materials into specific geometries using processes like bending, rolling, stamping, and deep drawing.

- Ensuring dimensional accuracy and consistency across production runs, often within tolerances as tight as ±0.002 inches.

- Providing value-added services such as welding, penamat, and assembly to deliver complete components.

- Collaborating with clients from design stages to optimize manufacturability and reduce production costs.

Industry Impact

The work of metal forming companies touches nearly every major industry:

- Automotif: Producing chassis components, body panels, and engine parts.

- Aeroangkasa: Creating lightweight, high-strength components for aircraft and spacecraft.

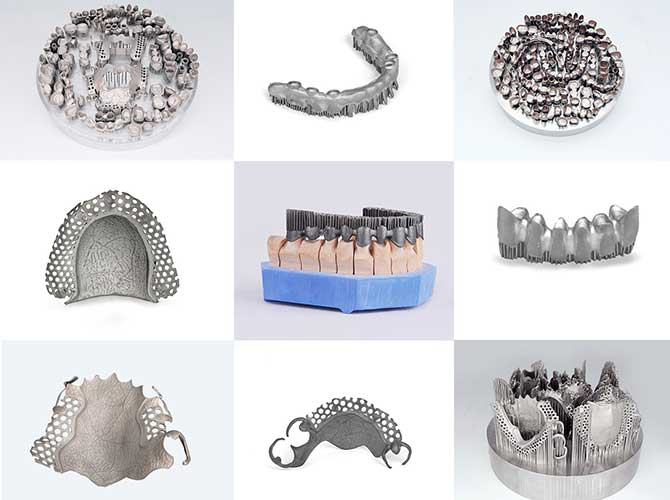

- Medical: Manufacturing precision parts for medical devices and equipment.

- Construction: Supplying structural elements and architectural hardware.

- Energy: Fabricating components for power generation and transmission systems.

According to industry data, berakhir 80% of all manufactured metal products require some form of metal forming process, highlighting the critical role these companies play in the global supply chain.

Types of Metal Forming Services Offered by Leading Companies

Top metal forming companies offer a comprehensive range of services to meet diverse client needs. These services can be categorized into two primary types: heavy fabrication and light fabrication.

Heavy Fabrication Services

Heavy fabrication focuses on large-scale metal components used in infrastructure and heavy machinery. Key services include:

- Roll forming: A continuous process where metal is passed through a series of rollers to create consistent cross-sectional shapes. Ideal for producing long lengths of metal with complex profiles.

- Press braking: Using hydraulic presses to bend metal sheets into precise angles, often used for structural components.

- Large-scale stamping: Creating large metal parts using high-tonnage presses, commonly used in truck manufacturing and industrial equipment.

Heavy fabrication companies typically handle materials thicker than 0.25 inches and produce components for bridges, ships, and industrial machinery.

Light Fabrication Services

Light fabrication deals with smaller, more intricate components. Common services include:

- Precision bending: Achieving tight tolerances (dalam 1 degree of accuracy) for small to medium-sized parts.

- Sheet metal stamping: Producing detailed parts from thin metal sheets using dies and presses.

- Deep drawing: Creating hollow shapes by stretching metal over dies, used for containers and enclosures.

- Laser cutting: Using laser technology for precise cutting of sheet metal before forming.

Light fabrication companies often work with materials thinner than 0.25 inci, producing parts for electronics, Peranti perubatan, and consumer products.

Value-Added Services

Leading metal forming companies complement their core services with value-added offerings:

- Finishing services: Including powder coating, anodizing, plating, and painting to enhance durability and appearance.

- Hardware insertion: Adding fasteners, nuts, and other hardware during production.

- Deburring and polishing: Removing sharp edges and improving surface finish.

- Assembly services: Combining multiple components into finished products.

Key Factors to Consider When Choosing Metal Forming Companies

Selecting the right metal forming company is critical to project success. Several factors should influence your decision to ensure you partner with a provider that meets your specific needs.

Technical Capabilities

Evaluate the technical capabilities of potential partners by assessing:

- Equipment inventory: Look for companies with state-of-the-art machinery, including CNC presses, laser cutters, and 3D modeling software. Contohnya, companies with 700-ton hydraulic presses can handle larger projects than those with smaller equipment.

- Material expertise: Ensure the company has experience working with your required materials, whether aluminum, Keluli tahan karat (termasuk 316 Keluli tahan karat), carbon steel, or exotic alloys.

- Process capabilities: Verify they offer the specific forming processes your project requires, from basic bending to complex deep drawing.

Quality Assurance

Quality control is paramount in metal forming. Pertimbangkan:

- Certifications: Look for ISO 9001 certification and industry-specific qualifications relevant to your sector (Mis., aerospace certifications for aviation components).

- Proses kawalan kualiti: Inquire about inspection protocols, testing procedures, and how they ensure consistency across production runs.

- Tolerance capabilities: Confirm they can meet your required tolerances, especially for precision applications.

Production Capacity and Lead Times

Assess whether the company can meet your volume and timeline requirements:

- Production volume: Some companies specialize in low-volume, high-precision runs, while others excel at high-volume production.

- Lead times: Ask about standard lead times and whether they offer expedited services for urgent projects. Some companies, like SendCutSend, offer delivery in as little as 2 days for custom parts.

- Scalability: Ensure the company can scale production up or down as your needs change.

Customer Service and Support

Strong customer service can significantly impact your experience:

- Technical support: Look for companies that offer design assistance and engineering support to optimize your parts for manufacturing.

- Komunikasi: Evaluate their responsiveness and clarity in communication, especially regarding project updates and potential issues.

- Flexibility: Choose a company willing to accommodate custom requirements and last-minute changes when possible.

Cost and Value

While cost is important, it should be balanced against quality and service:

- Pricing structure: Compare quotes, but ensure you’re comparing similar services and quality levels.

- Value-added services: Consider the total value provided, including additional services that may reduce your overall production costs.

- Long-term savings: A slightly higher initial cost from a quality-focused company may result in long-term savings through reduced waste and better performance.

Case Studies: Leading Metal Forming Companies and Their Specialties

The metal forming industry includes companies of various sizes, each with unique specialties and capabilities. Here are profiles of notable companies highlighted in industry data:

Weldmac Manufacturing Co.

With over 50 tahun pengalaman, Weldmac stands out for its expertise in draw forming and custom metal fabrication. Key strengths include:

- Advanced finite element analysis to simulate forming processes and prevent issues like localized thinning.

- Solid modeling capabilities that enable precise tooling design and press settings.

- In-house capabilities for forming sheet metal parts of all shapes and sizes using equipment like 700-ton hydraulic presses.

- A track record of successfully forming complex parts that other processes can’t achieve.

SendCutSend

SendCutSend has made a name for itself in digital manufacturing with a focus on speed and accessibility:

- Offers a wide range of services including laser cutting, Pemesinan CNC, membongkok, and finishing.

- Provides instant pricing through online file uploads, making it easy for clients to get quotes.

- Maintains a large inventory of over 170 bahan, including various grades of aluminum, Keluli tahan karat, and exotic metals.

- Boasts a 5-star customer rating with over 2,000 positive reviews, highlighting their quality and service.

- Serves over 100,000 companies, termasuk 59.8% of Fortune 500 companies, demonstrating their reliability for large and small clients alike.

Accurate Metal Fabricating

With over 80 years in business, Accurate Metal Fabricating specializes in high-volume sheet metal fabrication for OEMs:

- Handles light gauge metal fabricating in steel, aluminium, and stainless steel.

- Offers additional services including welding and assembly.

- Serves industries such as power generation, food processing, and cabinet manufacturing.

- Provides consistent quality for large production runs, making them a trusted partner for OEMs with high-volume needs.

Technological Advancements in Metal Forming Companies

Technology continues to transform metal forming, with leading companies adopting innovations that improve precision, kecekapan, and capabilities.

Computer-Aided Design and Simulation

Modern metal forming companies use advanced software for:

- 3D modeling to visualize parts before production.

- Finite element analysis (FEA) to simulate forming processes and identify potential issues like stress concentrations and thinning.

- Computer-aided manufacturing (CAM) to program machinery for precise execution.

These tools enable companies to optimize designs, reduce trial-and-error, and ensure first-time success with complex parts.

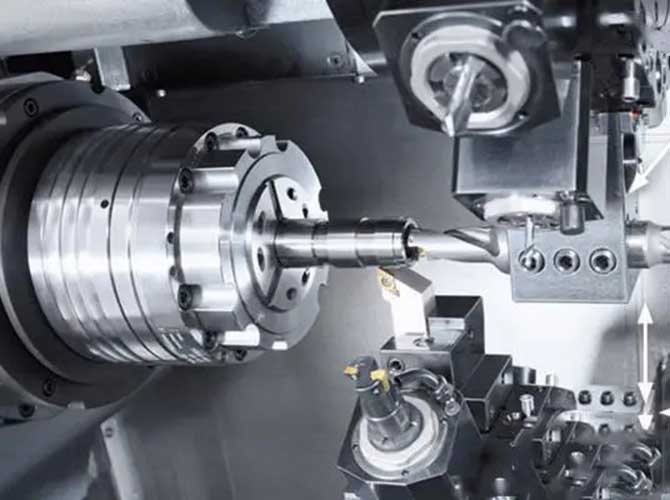

Automation and CNC Technology

Automation has revolutionized metal forming:

- CNC (Computer Numerical Control) machines provide precise, repeatable forming operations.

- Robotic systems handle material handling and part loading/unloading, increasing efficiency and consistency.

- Automated inspection systems verify dimensions and quality throughout production.

These technologies reduce human error, increase production speeds, and enable tighter tolerances.

Advanced Materials Handling

Metal forming companies are increasingly working with advanced materials:

- High-strength alloys for lightweight, durable components.

- Corrosion-resistant materials like 316 stainless steel for harsh environments.

- Composite materials that combine metals with other substances for enhanced properties.

Companies invest in specialized equipment and expertise to handle these materials effectively.

Trends Shaping the Future of Metal Forming Companies

The metal forming industry is evolving in response to market demands and technological innovations. Several key trends are shaping its future:

Sustainability in Metal Forming

Environmental considerations are becoming increasingly important:

- Companies are adopting energy-efficient machinery to reduce carbon footprints.

- Waste reduction initiatives, including better material utilization and recycling of scrap metal.

- Development of forming processes that require less energy and produce fewer emissions.

- Use of environmentally friendly finishing processes and materials.

Digitalization and Industry 4.0

The integration of digital technologies is transforming operations:

- IoT (Internet of Things) sensors on machinery for real-time monitoring and predictive maintenance.

- Cloud-based platforms for managing production data and enabling remote monitoring.

- Digital twins that create virtual replicas of production processes for optimization.

- Artificial intelligence for process optimization and quality control.

Customization and Small-Batch Production

Market demands are shifting toward more customized products:

- Metal forming companies are adapting to handle smaller batch sizes with quick changeovers.

- Digital manufacturing platforms make it easier to produce custom parts economically.

- Flexible manufacturing systems enable rapid prototyping and short production runs.

This trend is driven by industries like aerospace, perubatan, and consumer products that require specialized components.

Yigu Technology’s Perspective on Metal Forming Companies

Yigu Technology recognizes that partnering with the right metal forming company is crucial for manufacturing success. The integration of advanced simulation tools and material expertise in modern metal forming processes directly impacts product reliability. We believe companies that combine technical precision with responsive customer service create the greatest value—whether for high-volume OEM needs or custom low-volume projects. As manufacturing evolves, the ability to balance traditional craftsmanship with digital innovation will define the leading metal forming partners of tomorrow.

Soalan yang sering ditanya (Soalan Lazim)

What is the difference between heavy fabrication and light fabrication?

Heavy fabrication focuses on large-scale, thick-gauge metal components for infrastructure and heavy machinery, using processes like large-scale stamping and roll forming for thick materials. Light fabrication produces smaller, more intricate parts from thinner materials (typically under 0.25 inci) using precision bending, sheet metal stamping, and laser cutting, serving industries like electronics and medical devices.

How do I determine if a metal forming company can meet my tolerance requirements?

Start by checking the company’s technical specifications and asking for documentation of their tolerance capabilities. Reputable companies will specify tolerances for different processes (Mis., ±0.002 inches for precision forming). Request examples of previous work similar to your project and ask about their quality control processes, including inspection methods and equipment used to verify dimensions.

What materials can metal forming companies work with?

Metal forming companies handle a wide range of materials, including various steels (carbon steel, stainless steel like 316 dan 304), aluminum alloys (5052, 6061), Tembaga, tembaga, Titanium, and exotic alloys. The specific materials depend on the company’s equipment and expertise. Leading companies like SendCutSend offer over 170 bahan, including specialty options like AR400 steel, serat karbon, and phenolic materials.