In the fast-paced world of healthcare, the demand for high-quality, reliable medical devices and components continues to grow. Medical parts manufacturing plays a critical role in bringing these life-saving innovations to market, from initial concept to final production. This comprehensive guide explores the essential strategies, technologies, and best practices that drive successful medical parts manufacturing, helping you navigate the complex landscape of regulations, quality requirements, and production challenges.

The Importance of Strategic Medical Parts Manufacturing

Medical parts manufacturing is not just about producing components—it’s about creating solutions that improve patient outcomes, enhance surgical precision, and streamline healthcare delivery. With the global medical device market projected to reach $602.8 billion by 2028, the pressure to develop innovative products quickly while maintaining strict quality standards has never been greater.

Successful medical parts manufacturing requires a delicate balance between innovation, regulatory compliance, dan keberkesanan kos. By implementing the right strategies and partnering with experienced manufacturers, medical device companies can accelerate time-to-market, reduce development risks, and ensure their products meet the highest standards of performance and safety.

8 Key Strategies for Optimizing Medical Parts Manufacturing

1. Implement Design for Manufacturability (DFM) Analysis

Design for Manufacturability (DFM) is a critical first step in optimizing medical parts manufacturing. This analytical process evaluates the design of a part to ensure it can be produced efficiently and cost-effectively while meeting all performance requirements.

At Protolabs, contohnya, every online quote includes a free, automated DFM analysis that identifies potential manufacturing challenges. Di samping itu, dedicated design review teams provide expert consultation for various manufacturing processes, termasuk:

- Pengacuan suntikan

- Pemesinan CNC

- Industrial-grade 3D printing

- Sheet metal fabrication

For more complex projects, Consultative Design for Manufacturability (CDFM) offers an in-depth analysis with specific recommendations for improving geometries and maximizing functionality. This proactive approach helps avoid costly redesigns and production delays later in the development cycle.

2. Leverage Injection Molding for Medical Applications

Injection molding remains a cornerstone of medical parts manufacturing, offering numerous advantages for both prototyping and production. When implemented correctly, it can significantly accelerate product development while maintaining the highest quality standards.

Key benefits of medical injection molding include:

- Rapid turnaround from prototype to production

- High-quality aluminum tooling that reduces lead times to just days

- Ability to produce complex geometries with consistent precision

- Scalability from low-volume production to millions of parts

Quality considerations for medical injection molding include:

- ISO 13485 certification, the international standard for medical device quality management

- Process validation through standardized qualification packages

- Class 8 cleanroom production environments

- Access to P20 and hardened steel tooling options

Advanced mold flow analysis software further enhances the process by optimizing gate placement, identifying potential knit lines, locating difficult-to-fill areas, and recommending appropriate materials.

3. Accelerate Prototyping with Multi-Cavity Tooling

In the fast-paced world of medical parts manufacturing, the ability to iterate quickly can make all the difference in bringing innovative products to market. Multi-cavity tooling enables manufacturers to produce multiple versions of the same prototype simultaneously using end-use materials.

This approach offers several advantages:

- Faster testing and validation of design variations

- Improved ability to compare performance across multiple prototypes

- Increased production volume efficiency

- Reduced per-part costs for higher volume runs

During the COVID-19 pandemic, this capability became especially valuable, allowing manufacturers to rapidly develop and test critical medical components for ventilators, respiratory masks, and diagnostic equipment.

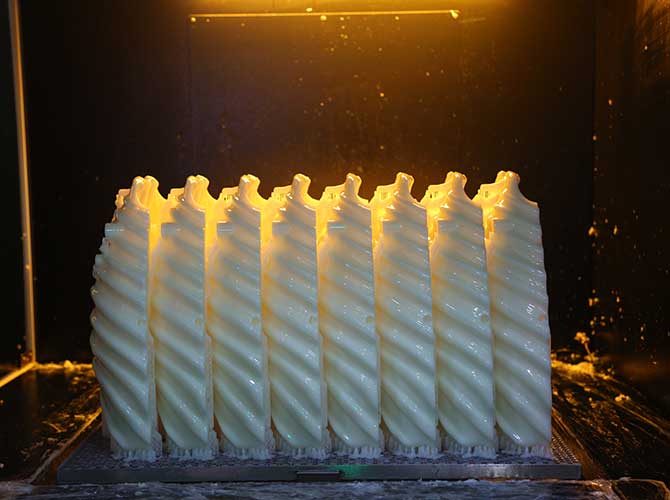

4. Utilize Metal 3D Printing for Complex Components

Direct Metal Laser Sintering (DMLS) has emerged as a game-changer in medical parts manufacturing, particularly for complex, high-precision components. This additive manufacturing technology builds parts layer by layer using metal powders, enabling geometries that would be impossible with traditional manufacturing methods.

Common materials used in medical metal 3D printing include:

- Keluli tahan karat (17-4 PH & 316L)

- Aluminium (AlSi10Mg)

- Cobalt chrome (CoCr)

- Inconel (IN718)

- Titanium (Ti-6Al-4V)

DMLS offers significant advantages for medical applications, termasuk:

- Production of surgical tools with ultrafine features

- Creation of medical components with organic, patient-specific shapes

- Reduced tooling costs compared to traditional manufacturing

- Rapid turnaround, with prototypes often available within days

This technology is particularly valuable for creating custom implants and specialized surgical instruments that require exacting specifications.

5. Enhance Performance with Strategic Finishing Options

Post-processing and finishing play a crucial role in medical parts manufacturing, enhancing both the functionality and aesthetics of molded components. The right finishing techniques can strengthen parts, improve biocompatibility, and enable precise customization.

Common finishing options for medical parts include:

- Mold texturing for improved grip or reduced friction

- Threaded inserts for secure assembly

- Pad printing for clear identification and labeling

- Heat staking for strong, reliable joints

- Laser engraving for permanent part marking

- Basic assembly services for simplified production

Hemosonics, a medical device company, recently utilized heat staking and pad printing services for their Quantra System blood analysis machine, demonstrating how strategic finishing can enhance both function and usability.

6. Select the Right Materials for Medical Applications

Material selection is a critical decision in medical parts manufacturing, directly impacting performance, biocompatibility, sterilization capability, dan kos. The ideal material depends on the specific application, with considerations including strength, fleksibiliti, rintangan kimia, and thermal properties.

| Jenis Bahan | Sifat utama | Common Applications |

| High-temp Plastics (Mengintip, PEI) | High-temperature resistance, creep resistance | Parts requiring autoclave sterilization |

| Medical-grade Silicone Rubber | Excellent thermal/chemical resistance, biocompatibility | Skin-contact applications, anjing laut |

| Carbon RPU/FPU | Rigidity, ketahanan | Late-stage prototypes, end-use devices |

| Micro-Resolution ABS-Like | Fine detail capability (0.0025 in. features) | Precision instrumentation, diagnostics |

| Transparent ABS-Like/PC-Like | Optical clarity | Kanta, microfluidic components, perumahan |

| Medical Alloys | Kekuatan, Rintangan kakisan, temperature tolerance | Surgical instruments, implants |

For companies with proprietary materials, working with manufacturers who can match key material properties—such as elasticity, kekerasan, and strength—ensures prototypes accurately represent final production parts.

7. Establish a Robust Quality Management System

Dalam medical parts manufacturing, quality is non-negotiable. A comprehensive quality management system ensures consistency, reliability, and compliance with regulatory requirements throughout the production process.

Key elements of an effective quality system include:

For injection molding:

- Bar coding for enhanced traceability

- Strict part-number and material controls

- Calibrated drying equipment for thermoplastic resins

- Documented dimensional inspections at start and during production

- Hourly visual inspections to maintain standards

- Recorded press settings for repeatable production

- Scientific molding methodology for process optimization

For 3D printing:

- Software-enabled production instructions

- Comprehensive pre-build material verification checklists

- Real-time temperature monitoring and adjustment

- Digital tracking of all parts through production

- ISO 9001 certification for all 3D printing services

- AS9100 certification for selective laser sintering, Multi Jet Fusion, and DMLS processes

These quality measures ensure that every medical part meets the exacting standards required for healthcare applications.

8. Streamline Quality Inspections

Effective inspection processes are essential to verify part conformity and maintain quality in medical parts manufacturing. A robust inspection strategy combines statistical sampling, periodic checks, and advanced measurement technologies to ensure compliance.

Inspection capabilities should include:

- Customized inspection reports based on service and inspection level requirements

- Statistical and periodic sampling for cosmetics and dimensions

- Calibrated measurement equipment with documented calibration programs

- Enhanced digital inspection for critical dimensions (up to 12 measurements)

- High-speed 3D scanning with CAD comparison for visual quality reporting

- Third-party conventional inspection reports for first article inspection (FAI)

- Material testing for tensile strength and hardness

- Porosity and grain structure analysis for metal 3D-printed parts

These inspection methods provide the documentation and verification needed to support regulatory submissions and ensure patient safety.

Yigu Technology’s Perspective on Modern Medical Parts Manufacturing

Yigu Technology recognizes that medical parts manufacturing demands precision, compliance, and innovation. By integrating advanced technologies like DFM analysis, Percetakan 3D logam, and strict quality systems, manufacturers can meet healthcare’s evolving needs. We believe successful partnerships between device companies and manufacturers, focusing on material expertise and rapid prototyping, will drive the next generation of life-saving medical technologies.

Soalan yang sering ditanya (Soalan Lazim)

Q1: What certifications should a medical parts manufacturer hold?

A1: Reputable medical parts manufacturers should hold ISO 13485 certification, the international standard for medical device quality management. For 3D printing services, ISO 9001 and AS9100 certifications demonstrate commitment to quality.

S2: How can medical parts manufacturing accelerate time-to-market?

A2: Accelerated time-to-market is achieved through strategies like DFM analysis to prevent redesigns, rapid prototyping with 3D printing, multi-cavity tooling for fast iterations, and integrated end-to-end manufacturing processes.

Q3: What materials are best for medical parts requiring sterilization?

A3: High-temperature plastics like PEEK and PEI (Ultem) are excellent choices for parts requiring autoclave sterilization. Medical-grade silicone rubbers also withstand repeated sterilization cycles while maintaining biocompatibility.