Di alam pembuatan aditif, Pengacuan pemendapan gabungan (FDM) berdiri sebagai salah satu teknologi yang paling mudah diakses dan digunakan secara meluas. Terkenal dengan keberkesanan kosnya, fleksibiliti material, dan kemudahan operasi, FDM telah mengubah bagaimana prototaip dicipta dan pengeluaran batch kecil dikendalikan di seluruh industri. Panduan Komprehensif ini meneroka semua yang anda perlu ketahui mengenai percetakan 3D FDM, dari prinsip kerja ke aplikasinya, kelebihan, dan batasan.

Bagaimana pengurangan pemendapan gabungan (FDM) 3D kerja percetakan?

Pengacuan pemendapan gabungan (FDM) adalah Pembuatan tambahan berasaskan penyemperitan proses yang membina objek tiga dimensi dengan mendepositkan lapisan bahan termoplastik lebur. Teknologi bergantung pada kawalan suhu yang tepat, kadar penyemperitan, dan pemendapan lapisan untuk mengubah reka bentuk digital menjadi bahagian fizikal.

Komponen utama pencetak 3D FDM

Pencetak 3D FDM terdiri daripada beberapa komponen penting yang bekerjasama untuk memastikan percetakan yang tepat dan konsisten:

- Filament Spool: Memegang filamen termoplastik pepejal, yang berfungsi sebagai bahan mentah untuk mencetak.

- Mekanisme extruder: Termasuk gear pemacu yang memberi makan filamen ke dalam cecair dan pemanas yang mencairkan termoplastik.

- Cecair/muncung: Ruang yang dipanaskan di mana filamen pepejal dicairkan ke dalam keadaan separa cecair dan diekstrusi melalui muncung kecil (biasanya 0.2-0.8 diameter mm).

- Membina platform: Permukaan yang dipanaskan atau tidak panas di mana bahan cair disimpan dan kukuh untuk membentuk setiap lapisan bahagian.

- Sistem gerakan X-Y-Z: Mengawal pergerakan platform extruder dan membina untuk memastikan pemendapan lapisan yang tepat mengikut model CAD.

- Lembaga Kawalan: Otak elektronik pencetak yang mengawal suhu, kadar penyemperitan, dan pergerakan berdasarkan data model 3D yang dihiris.

Proses Percetakan FDM Langkah demi Langkah

Proses percetakan FDM dibentangkan dalam satu siri langkah yang diselaraskan dengan baik yang mengubah reka bentuk digital menjadi objek fizikal:

- Penyediaan model CAD: Model 3D dibuat menggunakan reka bentuk bantuan komputer (CAD) perisian. The model is then exported in STL format, which is compatible with 3D printing software.

- Slicing: The STL file is processed by slicing software, which divides the model into thin horizontal layers (usually 0.1-0.4 mm thick) and generates a toolpath for the printer.

- Filament Feeding and Melting: The solid thermoplastic filament is fed from the spool into the extruder. The extruder’s heater melts the filament to a semi-liquid state (typically at temperatures between 180-300°C, bergantung pada bahan).

- Layer Deposition: The molten material is extruded through the nozzle onto the build platform. The nozzle moves in the X-Y plane to deposit the material according to the toolpath, forming the first layer of the part.

- Layer-by-Layer Building: After completing each layer, the build platform lowers (or the extruder rises) by the layer height. The next layer is deposited on top of the previous one, with the molten material bonding to the existing layer as it cools and solidifies.

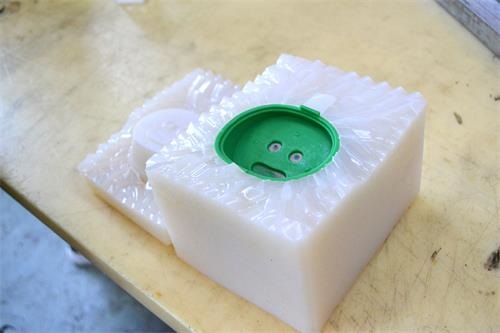

- Support Structure Deposition (jika diperlukan): For designs with overhangs or complex geometries, the printer deposits support structures using either the same material as the part or a soluble support material.

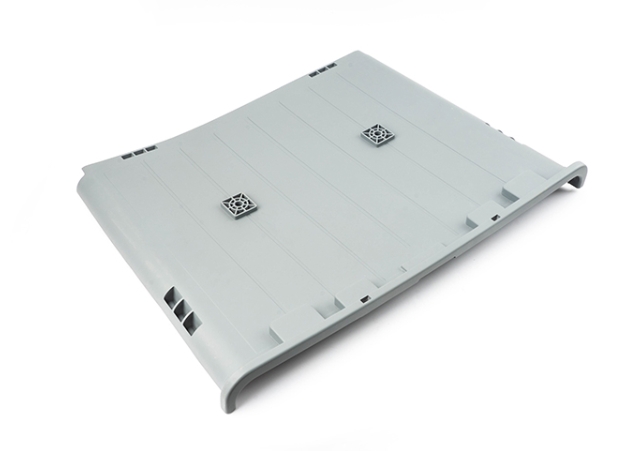

- Pasca pemprosesan: Once printing is complete, the part is removed from the build platform. Supports are removed manually or dissolved (for soluble supports). The part may undergo additional post-processing such as sanding, lukisan, or annealing to improve surface finish or mechanical properties.

FDM 3D Printing Materials

One of the key strengths of FDM 3D printing is its wide range of compatible materials. These thermoplastic filaments come in various formulations, each offering unique properties suited to specific applications.

Common Types of FDM Filaments

The most commonly used FDM materials include:

- PLA (Polylactic Acid): A biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. PLA is easy to print with (melting temperature 180-220°C), has good dimensional stability, and produces smooth surfaces. It is ideal for prototypes, decorative items, and low-stress applications.

- Abs (Acrylonitrile butadiene styrene): A durable, impact-resistant plastic with higher temperature resistance than PLA (melting temperature 220-250°C). ABS is more challenging to print but offers better mechanical properties, making it suitable for functional parts, toys, and automotive components.

- Petg (Polyethylene Terephthalate Glycol): Combines the ease of printing of PLA with the durability of ABS. PETG has good chemical resistance, ketelusan, and layer adhesion, making it suitable for containers, bahagian mekanikal, and outdoor applications.

- Nylon (Polyamide): Available in various formulations (such as PA12), nylon offers excellent strength, fleksibiliti, dan rintangan kimia. It is often reinforced with carbon fiber or glass fiber for enhanced mechanical properties, making it suitable for functional prototypes and end-use parts.

- Pc (Polikarbonat): A high-performance thermoplastic with exceptional impact resistance, rintangan haba (melting temperature 250-300°C), dan ketelusan. PC is used for demanding applications such as protective gear, komponen automotif, dan peranti perubatan.

- Specialty Materials: FDM also supports advanced materials like PEEK (Polyether Ether Ketone) for high-temperature and biomedical applications, ULTEM (Polyetherimide) for aerospace and electrical components, and flexible materials like TPU (Poliuretana termoplastik) for rubber-like parts.

Material Properties Comparison

The following table compares the key properties of common FDM materials to help users select the right material for their application:

| Bahan | Tensile Strength (MPA) | Flexural Strength (MPA) | Heat Resistance (° C.) | Rintangan kesan (kJ /) | Main Applications |

| PLA | 30-60 | 50-90 | 50-60 | 2-6 | Prototaip, decorative items, low-stress parts |

| Abs | 20-40 | 40-70 | 80-100 | 10-20 | Bahagian berfungsi, toys, komponen automotif |

| Petg | 30-50 | 50-80 | 70-80 | 15-30 | Containers, bahagian mekanikal, outdoor items |

| Nylon PA12 | 40-60 | 60-90 | 80-100 | 5-15 | Prototaip fungsional, Bahagian tahan haus |

| Pc | 60-80 | 90-120 | 120-140 | 60-80 | Protective gear, high-strength components |

| TPU | 10-30 | 15-40 | 60-80 | 100-300 | Flexible parts, gaskets, genggaman |

Advantages of FDM 3D Printing Technology

FDM 3D printing offers numerous advantages that make it a popular choice for prototyping, Pengeluaran kecil, and custom manufacturing.

Keberkesanan kos

FDM is one of the most affordable additive manufacturing technologies available. Desktop FDM printers are significantly cheaper than SLA or SLS systems, making 3D printing accessible to hobbyists, educators, and small businesses. The materials are also relatively inexpensive compared to photopolymer resins or metal powders, with filaments typically costing $20-50 per kilogram. Di samping itu, FDM requires minimal consumables beyond the filament itself, reducing ongoing operational costs.

Fleksibiliti material

As highlighted earlier, FDM supports a wide range of thermoplastic materials, each with unique properties. This versatility allows users to select materials based on specific application requirements, such as strength, fleksibiliti, rintangan haba, or biocompatibility. From basic PLA for simple prototypes to high-performance PEEK for aerospace components, FDM can accommodate diverse manufacturing needs.

Fleksibiliti reka bentuk

FDM enables the production of geometri kompleks that would be difficult or impossible to 制造 using traditional manufacturing methods like machining or injection molding. The layer-by-layer deposition process allows for internal cavities, Potong, and intricate details without the need for complex tooling. This design freedom is particularly valuable for rapid prototyping, where designers can quickly iterate and test complex concepts.

Speed and Accessibility

FDM printers can produce parts relatively quickly compared to other 3D printing technologies, especially for simple geometries. Desktop FDM printers can typically produce small to medium-sized parts in a few hours, while industrial systems can handle larger parts or multiple parts simultaneously. Di samping itu, FDM technology is user-friendly, with intuitive software and minimal training required to operate basic systems. This accessibility has contributed to its widespread adoption in education, hobbyist communities, and small businesses.

Minimal Waste Production

FDM generates less waste compared to subtractive manufacturing processes like machining, which remove material from a solid block. The only waste in FDM comes from support structures (which can often be reused or recycled) and any excess material from failed prints. Some FDM systems also support the use of recycled filaments, further reducing material waste and environmental impact.

Limitations of FDM 3D Printing Technology

While FDM offers many advantages, it also has certain limitations that users should consider when selecting a 3D printing technology for their application.

Surface Finish and Layer Visibility

FDM parts typically have a visible layer structure, which can result in a rough surface finish compared to technologies like SLA or SLS. The layer lines are most noticeable on curved surfaces and can affect the aesthetic appearance of the part. While post-processing techniques like sanding or vapor smoothing can improve surface finish, they add time and cost to the production process.

Dimensional Accuracy

FDM parts may exhibit lower dimensional accuracy compared to SLA or CNC-machined parts. Factors such as material shrinkage during cooling, layer height variations, and nozzle wear can affect the precision of the final part. Typical dimensional tolerances for FDM parts range from ±0.1 mm to ±0.5 mm, bergantung pada bahan, part size, and printer calibration. This makes FDM less suitable for applications requiring extremely tight tolerances.

Mechanical Property Anisotropy

FDM parts exhibit anisotropic mechanical properties, meaning their strength varies depending on the direction of the applied force. Parts are strongest in the plane of the layers (X-Y direction) due to the strong bonding between adjacent extruded lines, but weaker in the layer stacking direction (Z-axis) where bonding between layers is more limited. This anisotropy can be a concern for structural applications, though it can be mitigated by optimizing print orientation and infill patterns.

Limited Material Performance

While FDM offers a wide range of materials, their performance is generally inferior to parts produced using traditional manufacturing methods like injection molding. FDM parts may have lower strength, rintangan kesan, and heat resistance due to the layer-by-layer construction and potential voids between layers. While advanced materials like PEEK and ULTEM offer improved performance, they require specialized printers and higher processing temperatures, increasing costs and complexity.

Support Structure Requirements

Complex geometries with overhangs (typically greater than 45 degrees) require support structures to prevent sagging or collapse during printing. These supports must be removed post-printing, which can be time-consuming and may leave marks on the part surface. While soluble support materials eliminate the need for manual removal, they require additional equipment (like a cleaning station) and increase material costs.

Applications of FDM 3D Printing

FDM 3D printing finds applications across a wide range of industries, thanks to its versatility, affordability, and ease of use.

Rapid Prototyping

One of the most common applications of FDM is rapid prototyping, where designers and engineers use 3D printed parts to test form, Sesuai, and function during product development. FDM allows for quick iteration of designs, reducing the time and cost associated with traditional prototyping methods. Dari model konsep hingga prototaip berfungsi, FDM enables teams to validate designs early in the development cycle, accelerating time to market.

Education and Research

FDM 3D printers are widely used in educational institutions to teach design, kejuruteraan, and manufacturing concepts. Students can create physical models of their designs, gaining hands-on experience with additive manufacturing. In research settings, FDM is used to fabricate custom 实验装置,prototypes for testing new concepts, and even low-cost scientific equipment in resource-constrained environments.

Custom Manufacturing

FDM enables on-demand custom manufacturing of low-volume parts, eliminating the need for expensive tooling and reducing inventory costs. This is particularly valuable for industries like aerospace, Automotif, and healthcare, where custom components are often required. Examples include custom jigs and fixtures for manufacturing processes, personalized medical devices, and one-off replacement parts for legacy equipment.

Biomedical Applications

In the biomedical field, FDM is used to create custom implants, surgical guides, and anatomical models. Materials like PLA and PETG are biocompatible, making them suitable for certain medical applications. FDM has also been used to fabricate drug delivery systems and tissue engineering scaffolds, though these applications often require specialized materials and post-processing.

Consumer Products and Hobbyists

FDM 3D printing has gained popularity among hobbyists and makers for creating custom consumer products, art, and DIY projects. From custom phone cases and jewelry to replacement parts for household appliances, FDM enables individuals to produce personalized items at home. The availability of affordable desktop printers and open-source designs has fueled this growing community of makers.

Comparison of FDM with Other 3D Printing Technologies

To better understand FDM’s position in the additive manufacturing landscape, let’s compare it with other popular 3D printing technologies:

| Technology | Jenis Bahan | Kemasan permukaan | Dimensional Accuracy | Mechanical Properties | Kos (Printer) | Kos bahan | Terbaik untuk |

| FDM | Thermoplastic Filaments | Layered, rough (requires post-processing) | ±0.1-0.5 mm | Sederhana (anisotropic) | \(200-\)50,000+ | \(20-\)100/kg | Prototaip, low-volume production, custom parts |

| SLA | Photopolymer Resins | Smooth, glass-like | ±0.05-0.1 mm | Baik (but brittle) | \(1,000-\)100,000+ | \(50-\)200/L | High-detail prototypes, Perhiasan, dental models |

| SLS | Polyamide Powders | Slightly rough | ±0.1-0.3 mm | Baik (isotropic) | \(50,000-\)200,000+ | \(80-\)200/kg | Bahagian berfungsi, geometri kompleks, low-volume production |

| MJF | Nylon Powders | Smooth to slightly rough | ±0.1-0.2 mm | Baik (isotropic) | \(100,000-\)500,000+ | \(60-\)150/kg | Pengeluaran volum tinggi, bahagian berfungsi |

| DLP | Photopolymer Resins | Smooth | ±0.05-0.1 mm | Similar to SLA | \(500-\)50,000+ | \(50-\)200/L | High-speed prototyping, Perhiasan, dental models |

Yigu Technology’s Perspective on FDM 3D Printing

Yigu Technology views FDM as a cornerstone of accessible additive manufacturing. Its material versatility and cost-effectiveness make it indispensable for rapid prototyping and custom production. While surface finish and anisotropy pose challenges, ongoing advances in materials and printer tech are expanding its capabilities, solidifying FDM’s role in driving innovation across industries.

Soalan yang sering ditanya (Soalan Lazim)

- What is the typical layer height used in FDM 3D printing?

FDM printers typically use layer heights ranging from 0.1 mm to 0.4 mm. Smaller layer heights (0.1-0.2 mm) produce finer details and smoother surface finishes but increase print time. Larger layer heights (0.3-0.4 mm) reduce print time but result in more visible layer lines.

- Can FDM 3D printed parts be used for functional applications?

Ya, FDM parts can be used for functional applications, especially when using durable materials like ABS, Petg, atau nilon. Walau bagaimanapun, their mechanical properties are generally inferior to injection-molded parts, and they exhibit anisotropic strength. For high-stress applications, optimizing print orientation and using reinforced materials can improve performance.

- How long does it take to 3D print a part using FDM technology?

Print time depends on factors like part size, layer height, infill density, and printing speed. Kecil, simple parts can be printed in 1-2 jam, while large, complex parts may take 10-20 hours or more. Industrial FDM printers with multiple extruders or larger build volumes can reduce print time for batch production.