In the dynamic landscape of manufacturing, choosing the right production method can make or break a project’s success. Two prominent techniques that often stand at the center of this decision are Pemesinan CNC dan silicone molding. Each offers unique benefits tailored to specific applications, bahan, and production requirements. Whether you’re prototyping a new design, producing low-volume parts, or scaling up to mass production, understanding the respective advantages of CNC machining and silicone molding is crucial for making informed decisions that balance cost, quality, and efficiency. Dalam panduan komprehensif ini, we’ll explore how these two manufacturing processes compare across key performance metrics and applications.

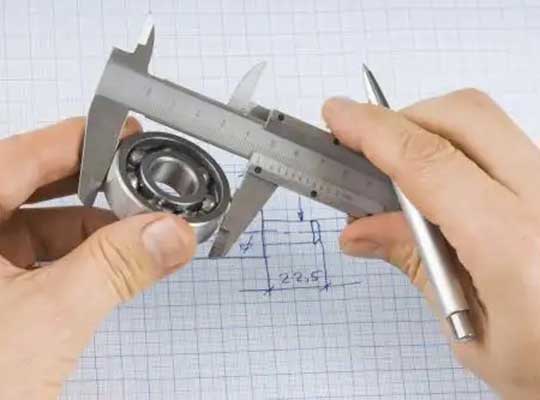

Precision and Tolerance: The Foundation of Quality Manufacturing

When it comes to producing parts with accurate dimensions and consistent quality, both CNC machining and silicone molding have distinct capabilities, but CNC machining holds a clear advantage in precision-critical applications.

CNC Machining’s Precision Prowess

Pemesinan CNC is renowned for its exceptional precision, delivering results that meet the most demanding engineering standards. Key precision advantages include:

- Micron-level accuracy: CNC machines can achieve tolerances as tight as ±0.0005 inches (0.0127 mm), making them ideal for components where even the smallest deviation could affect performance.

- Tight dimensional tolerances: Computer-controlled operations ensure consistent dimensions across multiple parts, eliminating the variability often seen in manual manufacturing processes.

- Repeatable precision: Once a CNC program is optimized, it can produce identical parts with minimal variation, crucial for assembly-line production and interchangeable components.

- Compliance with GD&T standards: CNC machining easily meets Geometric Dimensioning and Tolerancing specifications, ensuring parts function correctly within larger assemblies.

- Minimal post-processing needs: The high precision of CNC machining reduces the need for additional finishing operations, saving time and reducing costs.

These precision capabilities make CNC machining indispensable in industries like aerospace, medical device manufacturing, and automotive engineering, where component accuracy directly impacts safety and performance.

Silicone Molding’s Precision Limitations

While silicone molding can produce parts with good accuracy for many applications, it faces inherent limitations:

- Typical tolerances range from ±0.005 to ±0.010 inches (0.127 ke 0.254 mm), significantly wider than CNC machining capabilities.

- Material shrinkage during curing can introduce dimensional variations, especially with complex geometries.

- Mold wear over time can gradually reduce precision, requiring more frequent mold maintenance or replacement.

Silicone molding’s precision is sufficient for many consumer products, gaskets, and non-critical components but falls short for applications demanding the highest accuracy.

Fleksibiliti material: Adapting to Diverse Manufacturing Needs

The ability to work with various materials is a key consideration in manufacturing, and here again, CNC machining and silicone molding differ significantly in their capabilities.

CNC Machining’s Material Range

One of the most significant advantages of Pemesinan CNC is its exceptional versatility across materials:

- Wide range of machinable metals: From aluminum and brass to stainless steel, Titanium, and exotic alloys, CNC machines handle metallic materials with ease.

- Engineering-grade plastics: Materials like ABS, Nylon, Mengintip, and Delrin can be precisely machined to tight tolerances.

- Aerospace alloys compatibility: CNC machining excels with high-strength, heat-resistant materials used in aerospace applications.

- Medical-grade stainless steel: The precision and material control of CNC machining make it ideal for producing medical instruments and implants.

- Exotic material capability: Even difficult-to-machine materials like Inconel and Hastelloy can be processed effectively with CNC technology.

This versatility allows manufacturers to use end-use materials during prototyping, ensuring test results accurately reflect real-world performance.

Silicone Molding’s Material Focus

Silicone molding, as the name suggests, is primarily limited to:

- Elastomers and silicone compounds: The process is optimized for rubber-like materials with specific durometers and properties.

- Limited compatibility with other materials: While some thermoplastics can be processed with similar molding techniques, silicone molding itself is restricted to elastomeric materials.

- Specialty silicone formulations: Options include food-grade, medical-grade, and high-temperature silicone, but the overall material range remains narrow compared to CNC machining.

This specialization makes silicone molding ideal for parts requiring elasticity, rintangan haba, or flexibility but limits its application in projects requiring rigid or high-strength materials.

Speed of Prototyping: Accelerating the Design Cycle

In today’s fast-paced development environments, the speed at which prototypes can be produced often determines how quickly products reach the market.

CNC Machining’s Rapid Turnaround

Pemesinan CNC has revolutionized prototyping with its speed advantages:

- Rapid CNC prototyping turnaround: Simple parts can often be produced within 24 hours of design finalization.

- Same-day CNC machining quotes: Digital quoting systems allow manufacturers to receive pricing instantly.

- 24-hour machined prototypes: Many service providers offer expedited services for urgent prototyping needs.

- Iterative design validation: Quick turnaround enables multiple design iterations in a short timeframe.

- Fast design change implementation: Modifying a CNC program is significantly faster than altering a mold.

- No tooling lead time: Unlike molding processes, CNC machining requires no time-consuming mold fabrication before production begins.

These advantages make CNC machining the preferred choice for rapid prototyping, allowing design teams to test and refine concepts quickly.

Silicone Molding’s Prototyping Timeline

Silicone molding faces longer lead times for prototyping:

- Mold creation can take several days to weeks, depending on complexity.

- Each design change requires mold modifications or new mold creation.

- Cure times for silicone materials add additional production time.

- While production runs can be fast once molds are ready, the initial setup delays prototyping.

Silicone molding becomes more time-efficient for larger production runs but struggles to match CNC machining’s speed for early-stage prototyping.

Cost Efficiency: Balancing Investment and Production Needs

Cost considerations play a pivotal role in manufacturing decisions, with each process offering distinct cost advantages depending on production volume.

CNC Machining for Low-Volume Cost Savings

Pemesinan CNC shines when it comes to low-volume production economics:

- Economical short runs: CNC machining avoids the high upfront costs of mold creation, making it cost-effective for small production quantities.

- No mold investment: Eliminating mold costs is a significant advantage for prototypes and low-volume production.

- Favorable break-even volume: CNC machining remains cost-effective until production volumes reach the thousands, depending on part complexity.

- Tooling cost amortization avoided: Unlike molding, there’s no need to spread expensive tooling costs across production runs.

- Pay-per-part CNC pricing: Flexible pricing models allow manufacturers to pay only for the parts they need.

- Prototype cost transparency: CNC machining costs are easily predictable based on material, machine time, dan kerumitan.

For prototyping, custom parts, and low-volume production, CNC machining typically offers lower total costs than silicone molding.

Silicone Molding for High-Volume Efficiency

Silicone molding becomes more cost-effective at higher production volumes:

- Lower per-unit costs once molds are created

- Efficient material usage with minimal waste

- Faster cycle times for large production runs

- Reduced labor requirements compared to CNC machining for high volumes

Walau bagaimanapun, the significant upfront investment in mold creation means silicone molding requires larger production volumes to achieve cost parity with CNC machining.

Surface Finish and Detail Quality: Meeting Aesthetic and Functional Requirements

The quality of a part’s surface finish and its ability to replicate fine details can be critical for both aesthetic and functional purposes.

CNC Machining’s Surface Excellence

Pemesinan CNC delivers exceptional surface quality:

- Fine surface finish capabilities: CNC machines can achieve surface finishes as smooth as 8-16 Ra (microinches) with standard processes, and even better with specialized techniques.

- Low Ra values achievable: By adjusting cutting parameters and using appropriate tooling, extremely smooth surfaces can be produced.

- Sharp internal corners machining: CNC tools can create precise, sharp corners that would be challenging or impossible with molding processes.

- Surface polishing options: Machined surfaces can be further enhanced with polishing, anodizing, or other finishing processes.

- Cosmetic-grade finishes: CNC machining consistently produces parts with the high-quality surfaces required for visible components.

These capabilities make CNC machining ideal for parts where surface smoothness affects performance, such as seals, galas, and optical components.

Silicone Molding’s Surface Characteristics

Silicone molding offers good but more limited surface capabilities:

- Typical surface finishes range from 32-125 Ra (microinches)

- Excellent replication of mold surfaces for texturing and patterns

- Texturing limitations compared to CNC machining: While silicone can replicate mold textures, creating complex surface variations is more challenging than with CNC programming.

- Potential for surface defects like air bubbles or flow lines

- Flash removal may be required, affecting surface consistency

Silicone molding’s surface quality is suitable for many functional components but often requires secondary processes for cosmetic applications.

Durability and Functional Testing: Ensuring Real-World Performance

The ability to produce parts that accurately represent end-use performance is crucial for effective testing and validation.

CNC Machining’s Testing Advantages

Pemesinan CNC excels in producing parts for durability and functional testing:

- End-use material prototypes: CNC machining uses the same materials as final production, ensuring test results are accurate.

- Functional testing under load: Machined parts maintain their properties under stress, providing reliable performance data.

- Thermal cycling resistance: CNC-machined parts made from production materials withstand temperature testing better than prototype materials.

- Chemical resistance validation: Testing can be performed on the actual materials that will be used in the final product.

- Fatigue test accuracy: Machined parts accurately replicate the fatigue characteristics of production components.

- Real-world performance data: CNC-machined prototypes provide the most reliable data for predicting final product performance.

These advantages make CNC machining invaluable for critical testing phases where accurate performance data is essential.

Silicone Molding’s Testing Capabilities

Silicone molding offers good testing capabilities for elastomeric components:

- Accurate representation of silicone part performance

- Excellent for testing flexibility, compression, and sealing properties

- Suitable for environmental resistance testing of silicone materials

- Limited ability to test multi-material assemblies or rigid components

While silicone molding produces accurate functional prototypes for elastomeric parts, it can’t match CNC machining’s versatility for testing across different material types.

Design Flexibility and Complexity: Realizing Innovation

The ability to produce complex geometries and adapt to design changes is essential for innovative product development.

CNC Machining’s Design Freedom

Pemesinan CNC offers exceptional design flexibility:

- Complex 3D geometry capabilities: Modern CNC machines can produce intricate shapes from solid blocks of material.

- Deep cavity machining: Specialized tooling allows CNC machines to create deep, precise cavities.

- Undercut features milling: With multi-axis CNC machines, complex undercuts can be produced accurately.

- Thin wall machining feasibility: Advanced techniques enable machining of thin-walled structures with minimal distortion.

- Quick adaptation to design changes through programming modifications

CNC machining’s ability to handle complex geometries without the constraints of mold-based production makes it ideal for innovative designs and custom components.

Silicone Molding’s Design Constraints

Silicone molding faces several design limitations:

- Draft angle constraints: Parts typically require 1-5° draft angles for proper ejection from molds.

- Undercut challenges: Undercuts often require complex, multi-piece molds that increase cost and complexity.

- Organic shape limitations: While silicone can produce curved shapes, sharp corners and fine details are more difficult.

- Wall thickness restrictions: Variations in wall thickness can cause uneven curing and warping.

- Higher cost and time for design changes due to mold modifications

These constraints make silicone molding better suited for simpler geometries and designs that can accommodate molding requirements.

Scalability and Production Transition: From Prototype to Production

The ability to scale production efficiently is a key consideration for product development.

CNC Machining’s Scalability Path

Pemesinan CNC offers flexible scalability options:

- Bridge tooling with CNC: Machining can serve as a bridge between prototyping and mass production.

- Smooth transition to injection molding: CNC-machined prototypes can validate designs before investing in expensive production molds.

- CNC to production parity: Using the same materials ensures consistency between prototypes and production parts.

- Design lock before mold investment: CNC machining allows thorough design validation before committing to expensive molds.

- Risk reduction via CNC validation: Identifying design issues with CNC prototypes reduces the risk of costly mold modifications.

- Production intent material testing: CNC machining enables testing with actual production materials.

This scalability makes CNC machining an excellent choice for companies looking to validate designs thoroughly before committing to high-volume production methods.

Silicone Molding’s Production Scalability

Silicone molding offers its own scalability advantages:

- Excellent for scaling within silicone production (from prototype molds to production molds)

- Consistent part quality across production runs

- Lower per-unit costs at higher volumes

- Limited material flexibility when scaling to different production methods

While silicone molding scales well within its own process, it offers less flexibility when transitioning to other production methods compared to CNC machining.

Lead Time Comparison: Meeting Time-to-Market Goals

In competitive markets, production speed often directly impacts a product’s commercial success.

CNC Machining’s Rapid Delivery

Pemesinan CNC delivers significant lead time advantages:

- Instant quote to ship capabilities: Digital workflows enable quick quoting and production scheduling.

- Days vs. weeks delivery: Simple CNC parts can often be delivered in days rather than weeks.

- Expedited CNC options: Emergency services can produce critical parts in 24-48 jam.

- No mold fabrication delays: Production can begin immediately after design finalization.

- Ideal for rush prototype scenarios and time-sensitive projects

For time-critical applications, CNC machining’s ability to deliver parts quickly without mold preparation is a major advantage.

Silicone Molding’s Lead Time Profile

Silicone molding involves longer but more predictable lead times:

- Silicone molding tooling schedule: Mold creation typically takes 1-4 weeks depending on complexity.

- Consistent production cycle times once molds are ready

- Longer setup time but faster per-unit production for large runs

- Less flexibility for rush orders due to mold requirements

While silicone molding can achieve faster production for large volumes once molds are prepared, it can’t match CNC machining’s speed for initial production and small batches.

CNC Machining vs. Silicone Molding: A Comparative Overview

| Faktor | Pemesinan CNC | Silicone Molding |

| Toleransi | ±0.0005″ (0.0127mm) | ±0.005-0.010″ (0.127-0.254mm) |

| Julat bahan | Logam, Plastik, composites, exotic materials | Primarily silicone and elastomers |

| Prototyping Speed | 1-3 hari | 2-4 minggu (including mold creation) |

| Cost Efficiency | Better for low volumes (<1,000 unit) | Better for high volumes (>10,000 unit) |

| Kemasan permukaan | 8-16 Ra (excellent) | 32-125 Ra (good) |

| Kerumitan reka bentuk | Handles complex geometries easily | Limited by draft angles and undercuts |

| Masa utama | Short (no tooling required) | Long (requires mold fabrication) |

| Ujian fungsional | Accurate with end-use materials | Good for elastomeric properties |

Yigu Technology’s Perspective on CNC Machining and Silicone Molding

Di Yigu Technology, we recognize CNC machining and silicone molding as complementary manufacturing technologies. CNC excels in precision prototyping, geometri kompleks, and low-volume production with diverse materials. Silicone molding shines in high-volume elastomer production. We guide clients to choose based on volume, material needs, and precision requirements, leveraging each technology’s strengths to deliver optimal manufacturing solutions.

Soalan yang sering ditanya (Soalan Lazim)

- When should I choose CNC machining over silicone molding?

Choose CNC machining for prototypes, low-volume production, parts requiring high precision or complex geometries, and projects using metals or rigid plastics. It offers faster turnaround and lower upfront costs for small quantities.

- For which applications is silicone molding more suitable than CNC machining?

Silicone molding is better for high-volume production of elastomeric parts, components requiring flexibility or rubber-like properties, and projects where consistent material elasticity is critical. It becomes cost-effective for large production runs.

- Can I use both CNC machining and silicone molding for the same project?

Sudah tentu. Many projects use CNC machining for prototyping and design validation, then transition to silicone molding for high-volume production once the design is finalized. This approach balances speed, kos, and performance throughout the product lifecycle.