AISI 309S stainless steel is a low-carbon austenitic alloy celebrated for its exceptional high-temperature resistance and corrosion protection. As a309S low-carbon variant, it avoids sensitization (a major cause of intergranular corrosion) while delivering strength—making it a top choice for furnaces, heat treatment equipment, and petrochemical facilities. Panduan ini memecah spesifikasi utamanya, Ciri -ciri prestasi, and real-world uses to help you select it with confidence.

1. Gambaran Keseluruhan Bahan & Spesifikasi utama

Understanding AISI 309S’s core composition and standards is the first step to leveraging its full potential. Di bawah adalah pecahan jelas sifat pentingnya.

Komposisi kimia & Piawaian

TheAISI 309S composition is defined by high chromium (22–24%) and nickel (12-15%) content—these elements boost oxidation resistance. It also has a low carbon content (≤0.08%), earning it the “S” designation. Tidak ada single309S chemical formula; sebaliknya, ia mematuhi piawaian global untuk konsistensi:

- 309S UNS S30908 (Sistem penomboran bersatu)

- 309S ASTM A240 / 309S ASME SA-240 (untuk plat, helaian, dan jalur)

- 309S EN 1.4833 setara (Standard Eropah untuk prestasi yang sepadan)

Fizikal & Sifat mekanikal

AISI 309S delivers reliable strength and stability across high-temperature applications. Metrik utama dianjurkan dalam jadual di bawah:

| Harta | Nilai |

|---|---|

| Ketumpatan | 7.98 g/cm³ |

| Titik lebur | 1397 ° C. |

| Kekuatan hasil minimum | 205 MPA |

| Kekuatan tegangan minimum | 515 MPA |

| Kekerasan Brinell | 217 Hb (maksimum) |

A German heat treatment company, contohnya, penggunaan309S ASTM A240 sheets for annealing covers—they rely on the 205 MPa yield strength to withstand 900 °C heat without deformation.

2. Sifat suhu tinggi & Rintangan pengoksidaan

AISI 309S’s biggest advantage is its performance under extreme heat. It outperforms most austenitic alloys in long-term high-temperature service.

Ciri-ciri suhu tinggi kritikal

- Rintangan pengoksidaan: It resists rust and scaling up to 1000 ° C.-309S oxidation resistance up to 1000 ° C. makes it ideal for furnace radiant tubes and burner tips. Even in cyclic heating (Mis., daily furnace on/off cycles), 309S cyclic oxidation performance remains strong.

- Kekuatan Creep: The 309S 1000-hour creep strength is ~80 MPa at 800 ° C., Bermakna ia tidak akan berubah dengan mudah di bawah tekanan jangka panjang. Untuk tugas yang lebih pendek, 309S short-time tensile at 900 ° C. is ~180 MPa.

- Had perkhidmatan: The 309S continuous service limit adalah 980 ° C., dan yang 309S intermittent service limit (pecah panas yang pendek) adalah 1095 ° C..

- Thermal Shock Resistance: 309S thermal shock resistance is excellent—it handles rapid temperature changes (Mis., dari 900 °C to room temperature) tanpa retak.

Kajian kes: A U.S.. power plant installed309S power plant boiler baffles (beroperasi di 950 ° C.). Selepas 10 tahun, the baffles showed no oxidation or creep, Menyimpan tumbuhan $120,000 dalam kos penggantian.

3. Rintangan kakisan & Prestasi alam sekitar

AISI 309S’s high chromium-nickel content makes it resistant to a wide range of corrosive environments—beyond just high heat.

Ciri-ciri tahan karat utama

- High-Temperature Corrosion: It resists 309S sulfidation resistance (common in refineries), 309S carburization resistance (in furnace atmospheres), dan 309S nitridation resistance (in ammonia-rich environments).

- General Corrosion: It handles 309S oxidation in humid air (no rust in coastal areas) dan 309S corrosion in hydrogen atmospheres (ideal for petrochemical reformers).

- 309S vs 310S corrosion comparison: 310S has higher nickel (19–22%) and resists higher temperatures (hingga 1150 ° C.), but 309S is more cost-effective for 1000 °C and below. Both resist 309S molten salt corrosion (Mis., in solar thermal plants).

- Kakisan intergranular: As a low-carbon alloy, it offers 309S intergranular corrosion prevention—no sensitization even after welding.

A Saudi Arabian refinery switched from 304 to 309S for reformer tubes—309S sulfidation resistance eliminated tube failures, cutting maintenance downtime by 60%.

4. Rawatan haba & Kawalan Mikrostruktur

Proper heat treatment ensures AISI 309S maintains its strength, Rintangan kakisan, and microstructure stability.

Proses rawatan haba penting

- Penyelesaian Penyepuh: Heat to 1040-1100 ° C., Tahan selama 30-60 minit, Kemudian air-quench. This dissolves unwanted carbides and restores a uniform austenitic structure—critical for 309S carbide precipitation avoidance.

- Kerja panas: Gunakan 1150-900 ° C. as the 309S hot working range for forging or rolling. Ini menjadikan mulur material dan mengelakkan retak.

- Pelepasan tekanan sisa: Panaskan hingga 450-600 ° C untuk mengurangkan tekanan dari kimpalan atau pembentukan. Ini 309S residual stress relief anneal doesn’t affect corrosion resistance.

Pertimbangan lain

- Penghindaran pemekaan: Its low carbon content means no 309S sensitization temperature range to worry about—unlike high-carbon 309.

- Risiko fasa Sigma: 309S sigma phase formation kinetics is slow, but avoid prolonged heating at 600–800 °C (boleh membuat bahan rapuh).

- Kerja sejuk: 309S cold working limitations are minimal—it can be bent or stamped, but avoid excessive cold working (may reduce ductility).

5. Kimpalan, Fabrikasi & Garis Panduan Pemesinan

Welding and machining AISI 309S is straightforward, with simple adjustments to preserve its properties.

Petua kimpalan

- Logam pengisi: Gunakan 309S filler metal ER309L (karbon rendah) atau ER309LSi (for better flow) to match the base metal. This ensures the weld has the same corrosion and heat resistance.

- Panaskan & Pwht: 309S preheat temperature is typically not required for thicknesses up to 25 mm. 309S post-weld heat treatment is optional—only needed for thick parts to relieve stress.

- Kebolehkalasan: 309S weldability rating is “excellent”—it has strong 309S hot cracking resistance and works well for 309S dissimilar welding to carbon steel (Mis., in boiler piping).

Pemesinan & Membentuk

- Kelajuan & Suapan: 309S machining speeds and feeds should be 10–15% lower than carbon steel. Contohnya, use 70–90 m/min speed with 309S tool life with coated carbide (TiAlN coatings last 2x longer than uncoated tools).

- Membentuk: 309S forming and bending limits are good—it can be deep-drawn or rolled into complex shapes (Mis., 309S thermal processing trays). Gunakan 309S distortion control techniques (Mis., Mengapit semasa kimpalan) to keep parts true to size.

6. Borang produk, Saiz & Rantaian bekalan

AISI 309S is available in a wide range of forms to fit nearly any high-temperature or corrosive project.

Borang produk biasa

- Plat & Helaian: 309S stainless steel plate thicknesses terdiri dari 3 mm ke 200 mm; 309S sheet gauge chart includes 16 Tolok (1.5 mm) ke 1/2 inci (12.7 mm) for furnace liners.

- Paip & Tiub: 309S seamless pipe ASTM A312 (for high-pressure, high-heat piping) dan 309S welded tube dimensions (for low-pressure applications).

- Bar & Kelengkapan: 309S round bar stock (10 mm ke 300 diameter mm), 309S angle iron sizes (20×20 mm hingga 100×100 mm), dan 309S refractory anchors (for securing furnace linings).

- Borang khusus: 309S coil slit widths (10 mm ke 1250 mm), 309S flat bar tolerances (± 0.1 mm), dan 309S custom forgings (Mis., burner tips).

Petua Rantaian Bekalan

Work with suppliers who stock309S perforated sheet patterns (for filtration in high-heat systems) dan309S refractory anchors—these specialty forms can be hard to source quickly.

7. Aplikasi industri & Kajian kes

AISI 309S’s versatility makes it a top choice across high-heat industries. Here are key use cases:

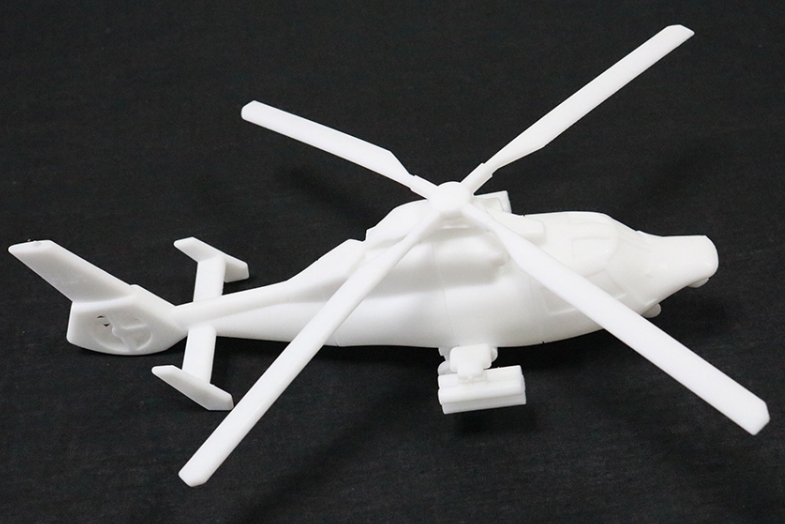

- Rawatan haba: 309S heat treatment baskets (hold parts during annealing) dan 309S annealing covers (retain heat in furnaces).

- Furnace & Kiln: 309S furnace parts, 309S radiant tubes, dan 309S kiln linings (handle 900–1000 °C continuous heat).

- Petrokimia: 309S petrochemical reformer tubes (resist sulfidation and hydrogen corrosion).

- Penjanaan kuasa: 309S power plant boiler baffles (direct steam flow in high-temperature boilers).

Contoh sebenar: A Chinese automotive manufacturer uses309S automotive exhaust manifolds—the alloy resists 850 °C exhaust heat and road salt corrosion, doubling manifold lifespan vs. 409 Keluli tahan karat.

Perspektif Teknologi Yigu

Di Yigu Technology, we recommend AISI 309S for clients needing cost-effective high-temperature and corrosion resistance. Kami sumber309S ASTM A240 plat dan309S seamless pipe ASTM A312 dari kilang yang disahkan, memastikan pematuhan standard global. For furnace and refinery clients, Kami mengutamakan309S sulfidation resistance danrintangan pengoksidaan sehingga 1000 ° C. checks. Our team advises on welding (menggunakanER309L filler) to avoid post-weld issues. Untuk 1000 °C and below applications, AISI 309S balances performance and cost perfectly.

Soalan Lazim

- Apa perbezaan antara Aisi 309 and 309S?

309S is a 309S low-carbon variant (≤0.08% carbon), manakala 309 has higher carbon (0.15% maks). 309S offers 309S intergranular corrosion prevention (no sensitization after welding), making it better for corrosive environments. 309 has slightly higher strength but is prone to intergranular corrosion. - Can AISI 309S be used in seawater?

Yes—its high chromium content resists 309S oxidation in humid air and mild seawater spray (Mis., coastal power plants). Walau bagaimanapun, 316L is better for fully submerged parts (more molybdenum resists pitting from saltwater). - What filler metal should I use for welding AISI 309S?

Gunakan 309S filler metal ER309L (karbon rendah) for most applications—it matches 309S’s corrosion resistance and avoids sensitization. For better weld flow (Mis., thin sheets), gunakan ER309LSi. Never use 304 filler—its lower chromium-nickel content reduces high-temperature performance.