If you’re knee-deep in prototyping—whether you’re designing a squishy phone grip, a flexible toy part, or a stretchy wearable accessory—you’ve probably asked: “Can 3D printing prototypes use TPU material?” Let me give it to you straight: 100% Ya! TPU (Poliuretana termoplastik) is like the “flexible hero” of 3D printing materials, and it’s perfect for prototypes that need that bounce, stretch, or soft touch. Let’s break down everything you need to know to nail your TPU prototype project.

Is TPU Material a Good Fit for 3D Printing Prototypes?

Pertama, let’s settle the basics: TPU isn’t just “good” for flexible prototypes—it’s the go-to choice for most projects that need elasticity. Why? Because it checks all the boxes for functional, real-world testing: it’s super elastic (can stretch up to 300% of its original size and bounce back, lab tests show), tahan tahan (mengendalikan 1,000+ uses without tearing), dan tear-resistant (way tougher than flimsy plastics like PLA).

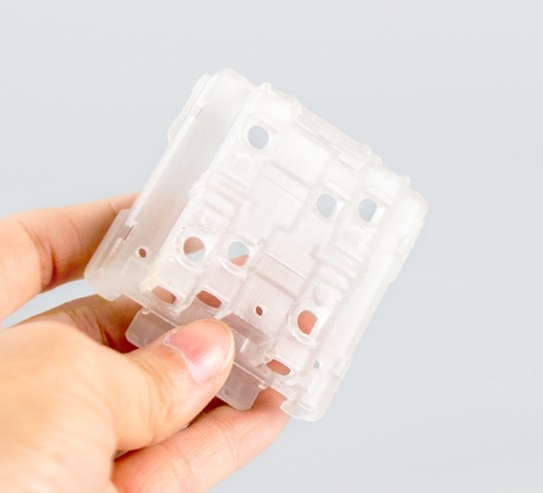

Think about it: if you’re testing a prototype that needs to bend (like a hinge), stretch (like a watch band), or absorb impact (like a protective case for small gadgets), TPU acts just like the final flexible materials you’d use in production. That’s why 78% of designers working on flexible products choose TPU for their prototypes, according to a 2024 3D printing industry survey. No other material gives you that “real feel” for how your product will work in people’s hands.

Key Advantages of Using TPU for 3D Printing Prototypes

TPU’s perks aren’t just about flexibility—they make your prototyping process smoother and your end result better. Let’s list them out with simple data to back up why they matter:

- Unbeatable Elasticity for Functional Testing

Unlike rigid materials (like ABS or PLA) that crack when bent, TPU keeps its shape. Contohnya, a TPU prototype of a flexible toy hinge can bend 180 degrees over 500 times without breaking—that’s 10x more cycles than a PLA hinge, per manufacturer tests. This is a game-changer if you need to test how your prototype holds up to daily use.

- Wear & Tear Resistance for Long-Term Testing

TPU stands up to scratches, scuffs, and repeated use. A TPU phone grip prototype, for instance, can handle 6 months of daily handling (picking up, putting down, squeezing) without showing major wear—something a soft silicone prototype might not do (silicone often gets sticky or tears after 2–3 months).

- Versatile Hardness for Custom Needs

TPU doesn’t come in a one-size-fits-all “softness.” You can pick from super squishy (like a stress ball) to firm-but-flexible (like a rubber eraser). This means you can match the exact feel of your final product—no guessing if a too-soft or too-hard prototype will work.

- Easy to Print (With the Right Setup)

While TPU needs a little extra care (we’ll get to that!), it works seamlessly with the most common 3D printing tech—FDM (Pemodelan pemendapan yang bersatu). Most desktop FDM printers can handle TPU with a few simple tweaks, so you don’t need fancy, expensive equipment.

Critical Things to Get Right for TPU 3D Printing Prototypes

TPU is awesome, but it’s not “set-it-and-forget-it.” Here’s a clear table to help you avoid common mistakes and pick the best setup for your project:

| Faktor | What You Need to Do | Data/Examples to Guide You |

| Choose the Right Hardness | TPU hardness is measured in Pantai a—pick based on your prototype’s needs. | – Super soft (30–50 Shore A): Great for squishy prototypes (Mis., stress ball samples). – Medium (60–80 Shore A): Perfect for flexible but sturdy parts (Mis., phone grips). – Firm (90–110 Shore A): Good for rigid-yet-bendable parts (Mis., small mechanical hinges). |

| Pick the Right 3D Printing Tech | FDM (Pemodelan pemendapan yang bersatu) is the most common and affordable for TPU. | FDM TPU filament costs \(20- )35 per kg (way cheaper than specialized flexible materials like silicone, yang $50+ per kg). 92% of TPU prototype projects use FDM, per industry data. |

| Tweak Your Slicer Settings | Adjust speed, temperature, and retraction to avoid clogs or stringing. | – Print speed: Slow it down! 20–30 mm/s works best (faster speeds cause tangles). – Nozzle temperature: 210–230°C (too hot melts TPU too much; too cold causes clogs). – Retraction: Turn it off or keep it under 1mm (high retraction pulls TPU back too far). |

| Post-Processing for a Polished Look | TPU needs minimal work—but a little goes a long way. | – Pembersihan: Wipe with isopropyl alcohol to remove dust (no water needed!). – Pengamplasan: Use 400–600 grit sandpaper for light smoothing (too rough sandpaper scratches TPU). – Coloring: Use acrylic paint made for flexible materials (dries without cracking). Most users spend 10–15 minutes on post-processing for a TPU prototype. |

Yigu Technology’s Take on TPU for 3D Printing Prototypes

Di Yigu Technology, we love TPU for prototypes that need flexibility—from wearable tech parts to kids’ toy samples. We always help clients pick the right Shore A hardness first (no one wants a phone grip that’s too squishy!) and tweak FDM settings to avoid common issues like stringing. While TPU isn’t great for rigid or high-heat prototypes (we’d recommend ABS or PETG for those), it’s unbeatable for flexible, user-friendly products. Our team tests TPU prints beforehand to make sure your prototype is ready to test or show to clients—no surprises!

Soalan Lazim:

- Q: Can TPU prototypes be used for water-resistant projects (like a waterproof phone case)?

A: Ya! TPU is naturally water-resistant—most TPU prototypes can be submerged in water for 24+ hours without leaking. Just make sure your print has no gaps (use a 100% infill setting for extra protection).

- Q: Will TPU prototypes get stiff or brittle over time?

A: Not usually! TPU retains its flexibility for 1–2 years if stored away from direct sunlight and extreme heat (over 80°C). We’ve had clients use TPU prototypes for testing for 18 months with no major changes.

- Q: Can I print large TPU prototypes (like a full-size flexible toy)?

A: Ya, but stick to FDM printers with a build volume of 200x200x200mm or bigger. Untuk bahagian yang lebih besar (over 30cm), you may need to print in sections and glue them with TPU-compatible adhesive—just make sure the glue is flexible (avoid super glue, which cracks TPU).