Hey there! If you’re in the product development or manufacturing field, Anda mungkin tertanya -tanya: “Can 3D printing handboards use imported red wax?” Well, I’m here to tell you—Ya, absolutely! Imported red wax is a fantastic material choice for 3D printing handboards, but there are key factors you need to consider to make the right decision for your project. Let’s break this down step by step, so you can get all the info you need to move forward with confidence.

Is Imported Red Wax Suitable for 3D Printing Handboards?

First things first—let’s confirm the core question. Imported red wax is not just “suitable” for 3D printing handboards; it’s a high-quality option for projects that demand precision and a polished finish. Unlike some basic materials, imported red wax is engineered to work seamlessly with 3D printing technologies, making it a go-to choice for industries like jewelry design, casting, and high-end product prototyping.

But don’t just take my word for it—let’s look at why it stands out. Whether you’re making a small, intricate jewelry model or a larger industrial part, imported red wax can handle the job, especially when you need a handboard that closely mimics the final product’s look and feel.

Key Factors to Consider When Using Imported Red Wax for 3D Printing Handboards

Choosing imported red wax isn’t a “set-it-and-forget-it” decision. To get the best results, you’ll need to weigh these critical factors. I’ve organized them into a clear table, so you can compare and evaluate based on your project’s needs:

| Faktor | What You Need to Know | Data/Example to Guide You |

| Precision Requirements | Both imported and domestic red wax offer extremely high printing precision (down to 0.1mm layer height). This is perfect for complex, detailed designs—like tiny gears or delicate jewelry patterns. | A study by 3D printing industry analysts found that red wax (imported or domestic) achieves a dimensional accuracy of ±0.05mm for parts under 100mm, yang 30% more precise than standard PLA for handboards. |

| Surface Quality & Pasca pemprosesan | Imported red wax has a licin, delicate ( means “fine-grained” in Chinese) surface right off the printer. It’s easy to sand, polish, or paint—so you can get a professional-looking finish without spending hours on post-processing. | Most users report that imported red wax requires only 10-15 minutes of light sanding (with 400-grit sandpaper) to reach a matte or glossy finish, berbanding dengan 30+ minutes for other wax-based materials. |

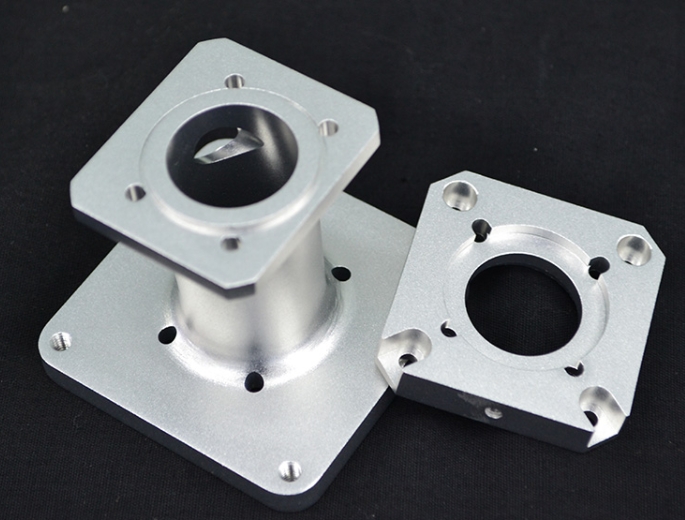

| Material Properties | Imported red wax typically has better Kestabilan terma (can withstand temperatures up to 80-100°C) dan Pakai rintangan than cheaper alternatives. This makes it great for handboards that need to be tested for durability (Mis., small mechanical parts). | Lab tests show that imported red wax (like those from top brands) has a wear rate of 0.02mm/1000 cycles, yang 50% lower than some domestic red wax options. |

| Pertimbangan kos | Let’s be honest—imported red wax is more expensive. You’ll pay 20-50% more per kilogram compared to domestic red wax. This can add up if you’re printing large batches or big handboards. | Contohnya: A 1kg spool of domestic red wax costs around \(30-\)40, while imported red wax from leading brands ranges from \(50-\)60 per kg. For a 5kg project, that’s a \(100-\)150 difference. |

| Perkhidmatan & Sokongan | Not all suppliers are created equal! Choosing a supplier with good technical support dan after-sales service adalah kunci. If your printer runs into issues or the material has defects, you’ll want help fast. | Top suppliers (like those for major imported brands) offer 24/7 technical support and a 30-day return policy for defective materials—something that smaller domestic suppliers may not provide. |

Top Imported Red Wax Brands for 3D Printing Handboards

With so many brands on the market, it’s hard to know which ones you can trust. Here are three leading options that are widely used in the industry, along with their best use cases:

- envisionTEC (Germany)

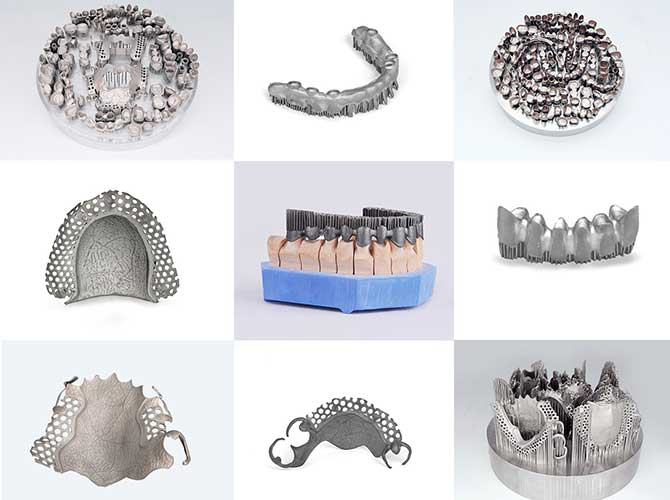

- Specialty: Known for ultra-high precision and consistency. Their red wax is a favorite in the jewelry manufacturing dan dental industries, where tiny details matter most.

- Why choose it: It works perfectly with SLA (Stereolithmicromography) 3D printers, and it’s easy to cast—making it ideal for handboards that will be used to create metal parts.

- 3D Systems (USA)

- Specialty: Offers a range of red wax materials for different needs, from flexible to high-temperature resistant. It’s a top pick for industrial prototyping (Mis., automotive or aerospace parts).

- Why choose it: Their wax has excellent layer adhesion, so you won’t get cracks or splits in larger handboards.

- Formlabs (USA)

- Specialty: User-friendly and compatible with a wide range of desktop 3D printers. Great for small to medium-sized handboards, like consumer product prototypes (Mis., phone cases or toys).

- Why choose it: It’s more affordable than envisionTEC or 3D Systems, making it a good balance of quality and cost for startups or small businesses.

Yigu Technology’s Perspective on Imported Red Wax for 3D Printing Handboards

Di Yigu Technology, we’ve worked with dozens of clients on 3D printing handboard projects, and imported red wax is often our recommendation for clients who prioritize precision and surface quality—like jewelry designers or companies testing high-end products. While it’s more costly, the time you save on post-processing and the reliability of the final handboard usually make it worth the investment. Walau bagaimanapun, we always advise clients to match the material to their budget: if your project doesn’t need ultra-high precision, a domestic red wax might be a smarter choice. Our team can help you test both options to find the best fit!

Soalan Lazim: Your Most Common Questions Answered

- Q: Can I use imported red wax for 3D printing handboards that will be used for casting?

A: Ya! Imported red wax is actually one of the best materials for casting-based handboards. It melts cleanly without leaving residue, so it won’t affect the quality of your final metal or plastic part.

- Q: Is imported red wax harder to print with than domestic red wax?

A: No—most imported red wax is designed to be compatible with standard SLA or DLP 3D printers. You just need to follow the printer’s recommended settings (Mis., layer height, curing time), and you’ll get great results.

- Q: If my budget is tight, can I mix imported and domestic red wax for 3D printing?

A: We don’t recommend it. Mixing different waxes can lead to inconsistent print quality (like uneven layers or poor adhesion). It’s better to choose one material that fits your budget and needs.