Our Metal 3D Printing Services

Unlock the future of manufacturing with Metal 3D Printing—where precision meets flexibility. At Yigu Technology, we leverage advanced Metal Additive Manufacturing techniques to deliver tailored Metal Printing Solutions, from rapid prototyping to high-volume production. Whether you’re in aerospace, automotive, or medical fields, our expertise turns complex designs into durable metal parts, backed by strict tolerance control and top-tier surface finishing. Experience the benefits of faster lead times, cost savings, and unlimited customization—choose Yigu for your next metal fabrication project.

What is Metal 3D Printing?

Metal 3D Printing, also known as Metal Additive Manufacturing or Metal Additive Fabrication, is a revolutionary technology that builds three-dimensional metal parts layer by layer. Unlike traditional subtractive manufacturing (which removes material), this process uses metal feedstocks to create complex geometries that are often impossible with casting or machining.

At its core, the Metal 3D Printing Concept focuses on precision and efficiency: it transforms digital designs into physical parts by fusing or sintering metal materials—such as powders or filaments—with heat sources like lasers or electron beams. This technology has redefined modern manufacturing, enabling industries to reduce waste, speed up production, and innovate product designs.

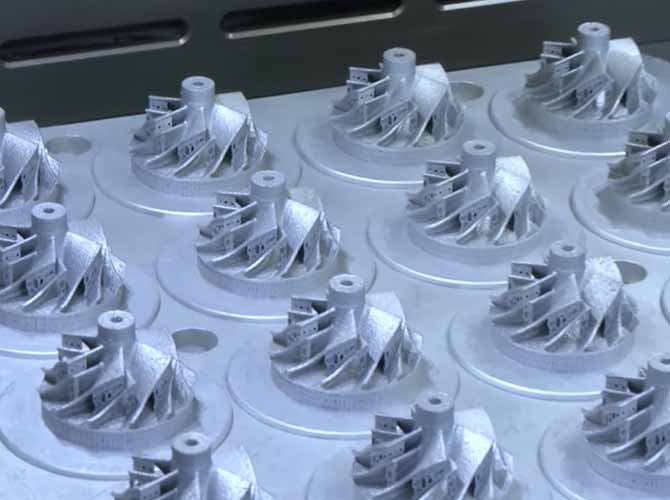

Our Metal 3D Printing Capabilities

At Yigu Technology, we pride ourselves on delivering end-to-end Metal 3D Printing Services tailored to your unique needs. Our capabilities span from small-batch prototypes to large-scale production, supported by state-of-the-art equipment and a team of experts.

| Capability Area | Details |

| Printing Capacity | 24/7 production with 15+ industrial-grade printers (laser & electron beam) |

| Metal Printing Expertise | 10+ years of experience in aerospace, medical, and automotive sectors |

| Material Compatibility | Supports 20+ metal alloys for printing (titanium, stainless steel, aluminum, etc.) |

| Lead Time | Prototypes: 3–5 business days; Mass production: 10–15 business days |

We don’t just print parts—we provide full Metal Printing Solutions, including design optimization, material selection, and post-processing, to ensure your project meets the highest standards.

The Metal 3D Printing Process

The Metal 3D Printing Process follows a structured workflow to ensure accuracy and consistency. Below is a step-by-step breakdown of our standard Printing Workflow:

- Design & Preparation: Convert 3D models into printable files (STL/STEP) and optimize for additive manufacturing (e.g., adding support structures).

- Material Loading: Load chosen metal powders or metal filaments into the printer.

- Layer-by-Layer Printing: Use techniques like laser sintering or electron beam melting to fuse material layers according to the design.

- Post-Processing: Remove support structures, then apply surface finishing (e.g., polishing, coating) and heat treatment if needed.

- Quality Inspection: Test for dimensional accuracy and tolerance levels using 3D scanners and metrology tools.

This Additive Manufacturing Process is highly flexible—we adapt Metal Printing Techniques (such as binder jetting or directed energy deposition) to match your part’s size, material, and performance requirements.

Metal 3D Printing Materials

Choosing the right material is critical for part performance. Yigu Technology offers a wide range of Metal Printing Materials, each selected for its strength, durability, and compatibility with additive processes.

| Material Type | Common Alloys | Key Applications |

| Metal Powders | Titanium Ti-6Al-4V, Stainless Steel 316L | Aerospace components, medical implants |

| Metal Alloys | Aluminum AlSi10Mg, Inconel 718 | Automotive parts, high-temperature tools |

| Metal Filaments | Bronze-filled PLA, Stainless Steel 304 | Low-volume prototypes, decorative parts |

Our team provides expert Material Selection guidance: for example, we recommend titanium for lightweight, biocompatible medical parts, and Inconel for aerospace components that need to withstand extreme heat.

Metal 3D Printing Surface Treatment & Post-Processing

Post-Processing is essential to enhance the functionality and appearance of 3D-printed metal parts. Yigu Technology offers a full suite of Metal Surface Treatment services to meet your specifications:

- Surface Finishing: Polishing (achieves Ra 0.8–1.6 μm roughness) and sandblasting (for matte, uniform texture).

- Surface Enhancement: Heat treatment (to improve strength) and shot peening (to reduce fatigue).

- Surface Coating: Ceramic or PTFE coatings for corrosion resistance or lubricity.

These steps not only improve aesthetics but also boost part performance—for example, a polished medical implant reduces bacterial adhesion, while a coated automotive part resists wear and tear.

Tolerances & Precision in Metal Printing

Tolerance in Metal Printing refers to the acceptable deviation from a part’s designed dimensions. At Yigu Technology, we prioritize precision printing to ensure parts fit and function as intended.

Our typical tolerance levels and dimensional accuracy metrics are:

- Standard tolerance: ±0.1 mm for parts up to 100 mm (±0.1% for larger parts).

- High-precision option: ±0.05 mm for critical components (e.g., aerospace fasteners).

- Accuracy verification: 3D scanning with a resolution of 0.02 mm to validate every part.

We use advanced tolerance control tools—such as in-process monitoring and automated inspection—to maintain consistency, even across large production runs.

Advantages of Metal 3D Printing

Metal 3D Printing offers transformative benefits for manufacturers, making it a preferred choice over traditional methods:

- Cost-Effective Printing: Reduces material waste (up to 70% less than machining) and eliminates the need for expensive molds.

- Customization Advantages: Enables one-off or low-volume custom parts—ideal for medical implants (tailored to a patient’s anatomy) or aerospace prototypes.

- Rapid Prototyping Benefits: Cuts prototyping lead times from weeks to days, accelerating product development cycles.

- Design Freedom: Creates complex geometries (e.g., internal channels, lattice structures) that are impossible with casting.

For example, an automotive client reduced their prototype costs by 40% using our 3D printing service, while a medical client delivered patient-specific implants 2x faster than with traditional methods.

Metal 3D Printing Applications Across Industries

Industrial Applications of metal 3D printing are vast, with Yigu Technology supporting key sectors:

| Industry | Key Applications | Example Project |

| Aerospace | Engine components, brackets, satellite parts | Titanium fuel nozzles for a commercial jet |

| Automotive | Custom gears, lightweight frames, tooling | Aluminum heat exchangers for electric vehicles |

| Medical | Orthopedic implants, surgical tools | Titanium hip replacements (patient-specific) |

| Dental | Crowns, bridges, implant abutments | Custom zirconia dental crowns |

Our Application Examples demonstrate how metal 3D printing solves industry-specific challenges—from reducing aircraft weight (to save fuel) to improving patient outcomes (with biocompatible implants).

Metal 3D Printing Manufacturing Techniques

Yigu Technology employs leading Metal Printing Techniques and Additive Manufacturing Techniques to match diverse project needs:

| Technique | How It Works | Best For |

| Laser Sintering (SLM) | Uses a high-power laser to fuse metal powders | Small, high-precision parts (e.g., dental crowns) |

| Electron Beam Melting (EBM) | Uses an electron beam to melt metal powders | Large, strong parts (e.g., aerospace brackets) |

| Binder Jetting | Deposits a binder onto metal powders, then sinters | High-volume, low-cost parts (e.g., automotive brackets) |

Each technique has unique advantages—EBM, for example, works with high-temperature alloys like tungsten, while binder jetting is ideal for mass production.

Metal 3D Printing Case Studies & Success Stories

Our Metal Printing Case Studies highlight how we’ve helped clients achieve their goals:

Case Study 1: Aerospace Component Optimization

- Challenge: A client needed a lightweight, high-strength engine bracket (traditional machining wasted 60% of material).

- Solution: Used laser sintering with titanium Ti-6Al-4V; optimized the design with lattice structures.

- Result: 30% weight reduction, 40% material savings, and parts that met aerospace tolerance levels (±0.08 mm).

Case Study 2: Medical Implant Production

- Challenge: A hospital needed patient-specific knee implants with fast lead times.

- Solution: Used EBM to print cobalt-chromium implants; applied surface finishing (polishing) for biocompatibility.

Result: Implants delivered in 5 days (vs. 2 weeks traditionally); 98% patient satisfaction rate.

Why Choose Yigu Technology Metal 3D Printing?

When you partner with us, you gain more than a Metal 3D Printing Service—you gain a trusted manufacturing partner. Here’s why clients choose Yigu:

- Our Unique Selling Points: In-house design optimization, 24/7 production, and a 100% quality guarantee.

- Our Competitive Edge: Access to 20+ metal alloys for printing and advanced post-processing (e.g., ceramic coating).

- End-to-End Support: We handle every step—from material selection to tolerance control—so you can focus on innovation.

We don’t just meet industry standards—we exceed them. Our team works closely with you to understand your goals and deliver parts that drive success.