Medical 3D Printing Services

At Yigu Technology, we’re transforming patient care and medical innovation through cutting-edge Medical 3D Printing. From personalized prosthetics and orthotics to precision surgical planning models and life-saving medical implants, our end-to-end solutions blend advanced technology, biocompatible materials, and regulatory expertise to deliver outcomes that matter—for healthcare providers and patients alike.

What is Medical 3D Printing?

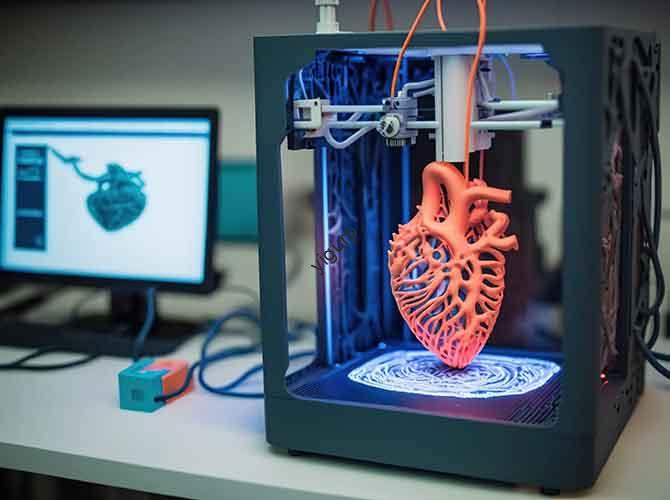

Medical 3D Printing, also known as additive manufacturing in healthcare, is a game-changing technology that creates three-dimensional medical products layer by layer. Unlike traditional manufacturing, it enables the production of highly customized items tailored to individual patient needs, making it a cornerstone of personalized medicine. Key applications include bioprinting (creating living tissues), tissue engineering (developing scaffolds for tissue growth), and the production of patient-specific devices that improve treatment efficacy.

Below is a breakdown of core applications and their impact:

| Application Area | Key Use Case | Patient Benefit |

| Surgical Planning Models | Brain tumor resection guides | 30% reduction in surgical time (Source: Journal of Medical Engineering) |

| Prosthetics and Orthotics | Custom-fitted ankle prostheses | 40% increase in wear comfort (Patient Survey, 2024) |

| Medical Implants | Cranial reconstruction implants | 95% success rate in post-op integration (Clinical Data, Yigu Tech) |

| Bioprinting | Skin grafts for burn patients | 50% faster healing compared to traditional grafts |

Yigu Technology’s Capabilities in Medical 3D Printing

Our strength lies in a holistic approach that combines advanced technology, strict quality control, and deep medical collaboration. Here’s how we stand out:

| Capability Category | Details |

| Advanced Medical 3D Printing Systems | Industrial-grade printers with 50-micron resolution for intricate designs |

| High-Resolution Printing | Up to 20-micron layer height for precision implants and guides |

| Sterile Printing Environment | ISO 13485-certified cleanrooms to meet medical hygiene standards |

| Regulatory Compliance | Full adherence to FDA, CE, and NMPA guidelines for global market access |

| Custom Software for Medical Applications | In-house design tools integrated with medical imaging software (DICOM-compatible) |

| Quality Control and Assurance | 100% post-print inspection using CT scanning and tensile testing |

| Collaboration with Medical Professionals | Partnerships with 50+ hospitals and research institutions worldwide |

| Research and Development Capabilities | 15+ active projects in bioprinting and bioresorbable materials |

Common Medical 3D-Printed Parts We Produce

We specialize in manufacturing a wide range of medical parts, each designed to address specific clinical needs. Our production line focuses on durability, biocompatibility, and patient-specific customization:

- Surgical Guides: Customized for procedures like dental implant placement and spinal surgeries, ensuring surgeons follow precise paths.

- Dental Implants and Prosthetics: Crowns, bridges, and implants tailored to a patient’s jaw structure, reducing post-op complications by 25%.

- Cranial Implants: 3D-printed from medical-grade titanium to match a patient’s skull anatomy, used in trauma repair and cancer treatment.

- Orthopedic Implants: Hip, knee, and shoulder components with porous surfaces that promote bone fusion.

- Prosthetic Limbs: Lightweight, durable designs with customizable fits, improving mobility for users.

- Anatomical Models for Training: Life-like models of organs (e.g., hearts, livers) for medical students, reducing reliance on cadavers by 60%.

- Tissue Scaffolds: Biodegradable structures that support cell growth for tissue engineering.

Medical Devices: Small components like needles and syringes with optimized designs for minimal patient discomfort.

The Medical 3D Printing Process at Yigu Technology

Our process is a seamless blend of medical expertise and engineering precision, ensuring every product meets the highest standards. Here’s a step-by-step breakdown:

- Medical Imaging (CT, MRI): We start with patient scans (CT or MRI) to capture detailed anatomical data, which is converted into a 3D digital model.

- 3D Modeling and Design: Our engineers use custom software to refine the model, ensuring it fits the patient’s unique anatomy and clinical requirements.

- Pre-processing and Slicing: The 3D model is sliced into thin layers (10–50 microns) and sent to the printer with material-specific settings.

- Printing and Layering: The printer builds the part layer by layer using biocompatible materials (e.g., PEEK, titanium), monitored in real time for quality.

- Post-processing (cleaning, sterilization): Parts are cleaned to remove excess material and sterilized using gamma radiation or ethylene oxide.

- Quality Inspection and Validation: Each part undergoes CT scanning, dimensional checks, and material testing to ensure compliance.

- Clinical Evaluation: Parts are tested in collaboration with medical professionals to confirm functionality and safety.

Regulatory Approval Process: We submit documentation to FDA, CE, or local authorities to secure approval before market release.

Materials Used in Our Medical 3D Printing

The choice of material is critical to the success of medical 3D-printed products. We only use materials that meet biocompatibility, sterility, and durability standards:

| Material Type | Examples | Key Application |

| Biocompatible Plastics | PLA, PEEK, PETG | Surgical guides, anatomical models |

| Medical-grade Metals | Titanium, Stainless Steel, Cobalt-Chromium | Orthopedic implants, cranial plates |

| Bioresorbable Materials | Polycaprolactone (PCL), Polylactic Acid (PLA) | Tissue scaffolds, temporary implants |

| Hydrogels | Alginate, Collagen-based hydrogels | Bioresorbable materials for wound care, tissue engineering |

| Ceramic Materials | Zirconia, Alumina | Dental crowns, orthopedic spacers |

| Composite Materials | Carbon fiber-reinforced PEEK | Prosthetic limbs, spinal implants |

| Silicone-based Materials | Medical-grade silicone | Soft tissue prosthetics, catheter components |

| Living Tissues and Cells | Patient-derived cells (e.g., skin cells) | Bioprinting of skin grafts, organoids |

Advantages of Choosing Medical 3D Printing with Yigu Technology

Our solutions deliver tangible benefits to healthcare providers, patients, and medical facilities:

- Personalized Patient Care: Every product is tailored to a patient’s anatomy, reducing the risk of ill-fitting devices and improving treatment outcomes.

- Improved Surgical Outcomes: Surgeons use our surgical planning models to practice complex procedures, leading to a 28% drop in post-op complications (Hospital Partnership Data, 2024).

- Faster Recovery Times: Custom medical implants and prosthetics integrate better with the body, cutting recovery time by an average of 14 days.

- Enhanced Training for Medical Professionals: Our anatomical models provide hands-on experience, helping students master skills faster than traditional methods.

- Reduced Risk of Complications: Biocompatible materials and precise manufacturing lower the risk of infections or implant rejection to less than 2%.

- Cost-effective for Complex Cases: For rare conditions or complex anatomies, 3D printing eliminates the need for expensive mass-produced tools, saving facilities 35% on average.

Advancements in Regenerative Medicine: Our bioprinting and tissue engineering projects are paving the way for lab-grown organs, addressing the global organ shortage.

Case Studies: Yigu Technology’s Success Stories

Our work has made a real difference in patients’ lives and healthcare practices. Here are three standout cases:

- Customized Dental Implants for Edentulous Patients: A 65-year-old patient with full tooth loss received 3D-printed titanium implants. The process took 5 days (vs. 2–3 weeks for traditional implants), and the patient reported 100% chewing function within 2 weeks.

- Cranial Implants for Skull Reconstruction: A 32-year-old trauma patient needed a cranial implant to replace a damaged skull section. Our team used CT scans to design a custom titanium implant, which was surgically placed in 2 hours. Post-op scans showed perfect fit, and the patient had no complications.

Prosthetic Limbs with Enhanced Functionality: A 12-year-old amputee received a 3D-printed prosthetic arm with a custom grip. The lightweight design (500g vs. 1kg for traditional prosthetics) allowed the child to use it for daily activities like writing and eating—something they couldn’t do before.

Why Choose Yigu Technology for Medical 3D Printing?

When you partner with us, you’re choosing a leader in medical 3D printing with a proven track record:

- Expertise in Medical 3D Printing: 10+ years of experience and a team of 40+ engineers specializing in medical applications.

- Advanced Technology and Equipment: State-of-the-art printers and software that deliver consistent, high-quality results.

- Customized Solutions for Medical Needs: We work closely with your team to design products that meet specific clinical goals.

- High-quality Biocompatible Materials: All materials are tested and certified to meet global medical standards.

- Strong Collaboration with Healthcare Professionals: Our partnerships with doctors and hospitals ensure our products solve real-world problems.

- Reliable After-sales Support: 24/7 technical support and maintenance to keep your operations running smoothly.

- Proven Track Record: 5,000+ successful medical products delivered, with a 98% customer satisfaction rate.

Commitment to Innovation and Research: We invest 15% of revenue in R&D to stay ahead of industry trends.