石油とガスで働いている場合, 工事, または機械工学, you’ve probably heard of X52 pipeline structural steel. It’s a go-to material for projects that need strength, 耐久性, and reliability—but what exactly makes it stand out? このガイドは、あなたが知る必要があるすべてを分解します, そのコアプロパティから現実世界の使用まで, so you can make informed decisions for your next project.

1. Material Properties of X52 Pipeline Structural Steel

X52’s popularity starts with its well-balanced properties. Let’s break them down into chemical, 物理的な, 機械, その他の重要な特徴.

化学組成

The化学組成 of X52 steel is carefully formulated to boost strength and resistance. これが典型的な内訳です (per industry standards like API 5L):

| 要素 | コンテンツ範囲 (wt%) | 役割 |

|---|---|---|

| 炭素 (c) | 0.26 マックス | 延性を犠牲にすることなく強度を向上させます |

| マンガン (Mn) | 1.40 マックス | Improves toughness and weldability |

| シリコン (そして) | 0.40 マックス | 鋼製造中の脱酸化の援助 |

| リン (p) | 0.030 マックス | 脆性を避けるために制御されます (kept low for harsh environments) |

| 硫黄 (s) | 0.030 マックス | Minimized to prevent cracking during forming and welding |

| クロム (cr) | 0.50 マックス | 耐食性を高めます (critical for pipelines) |

| モリブデン (MO) | 0.15 マックス | 高温強度を強化します |

| ニッケル (で) | 0.30 マックス | 低温靭性を改善します |

| バナジウム (v) | 0.08 マックス | 機械的性能を向上させるために、穀物構造を改良します |

物理的特性

These traits affect how X52 behaves in different environments:

- 密度: 7.85 g/cm³ (ほとんどの炭素鋼と同じです, デザインの重量を簡単に計算できます)

- 融点: ~1450–1500°C (suitable for high-heat manufacturing processes)

- 熱伝導率: 45 w/(M・k) (helps with heat distribution in welding and outdoor use)

- 熱膨張係数: 13.5 ×10⁻⁶/°C (low enough to reduce stress from temperature changes in pipelines)

- 電気抵抗率: 0.17 ×10⁻⁶Ω・m (not used for electrical parts, but good to note for safety)

機械的特性

This is where X52 really shines—its mechanical strength meets the demands of tough industries:

- 抗張力: 450–600 MPa (can handle heavy loads without breaking)

- 降伏強度: 最小 355 MPA (stays strong even when stretched)

- 硬度: 150–180 HB (resists wear without being too brittle)

- 衝撃の靭性: ≥ 27 j -40°Cで (performs well in cold climates, like northern oil pipelines)

- 延性: ≥ 22% 伸長 (can bend or form without cracking)

- 疲労抵抗: Excellent for cyclic loads (ideal for machine parts that move repeatedly)

- 骨折の靭性: 高い (prevents sudden failure in high-pressure pipelines)

その他の重要なプロパティ

- 良い溶接性: Joins easily with common welding methods (自分, ティグ, スティック), saving time on projects.

- 優れた形成性: 転がすことができます, 曲がっています, or forged into shapes like pipes or beams.

- 耐食性: Performs well in soil, 水, and mild chemical environments (though extra coating helps for harsh conditions).

- タフネス: 極端な温度で強度を維持します, from freezing winters to hot deserts.

2. Applications of X52 Pipeline Structural Steel

X52 isn’t just for pipelines—it’s versatile enough for multiple industries. Here’s how it’s used:

パイプライン業界

The #1 use for X52 isoil and gas pipelines. Its strength and corrosion resistance make it perfect for transporting crude oil, 天然ガス, and refined products over long distances.

ケーススタディ: A major pipeline project in Canada used X52 steel for a 1,200 km natural gas line. スチール抗張力 そして衝撃の靭性 helped it withstand freezing temperatures (-30°C) and soil pressure. 後 10 年, inspections showed no signs of corrosion or cracking—saving the company millions in maintenance.

建設業界

建設中, X52 is used for:

- 構造鋼コンポーネント (supports for large buildings)

- ビーム そして 列 (for bridges and skyscrapers)

- 構築フレーム (residential and commercial projects)

なぜ? It’s cost-effective compared to higher-grade steels, yet still strong enough for most structural needs. 例えば, a highway bridge in Texas used X52 beams—they handled heavy truck traffic and extreme heat (最大45°C) without deforming.

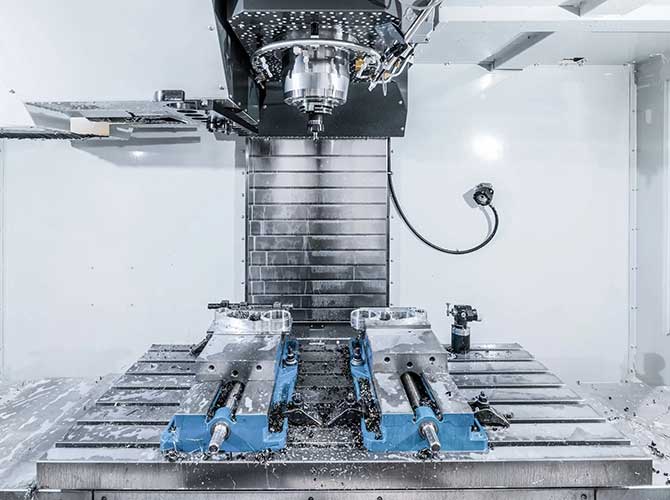

機械工学

Mechanical engineers rely on X52 for:

- ギア (その 硬度 そして 疲労抵抗 prevent wear)

- シャフト (handles rotational loads in motors and pumps)

- 機械部品 (durable for factory equipment)

A farm equipment manufacturer used X52 for tractor shafts. スチール 延性 let them shape the shafts precisely, そしてその タフネス meant the parts lasted 3x longer than cheaper carbon steel alternatives.

海洋産業

X52 works well in marine environments for:

- 船の構造 (hulls and frames)

- オフショアプラットフォーム (supports for oil rigs)

ケーススタディ: An offshore platform in the Gulf of Mexico used X52 steel for its support legs. スチール 耐食性 (paired with a galvanized coating) protected it from saltwater, そしてその 強さ handled strong waves and wind. 後 15 年, the legs showed minimal rust.

農業機械

Farmers trust X52 for:

- Tractor parts (engines and frames)

- プラウ そして ハロー (resist wear from soil and rocks)

A plow manufacturer switched to X52 from mild steel. The X52 plows lasted 2 seasons longer, and farmers reported less downtime—saving them money on replacements.

3. Manufacturing Techniques for X52 Pipeline Structural Steel

Making X52 steel requires precise processes to ensure its properties are consistent. これが段階的な内訳です:

スチール製造プロセス

Two main methods are used to produce X52:

- 電気弧炉 (EAF): 電気を使用して、スクラップスチールと合金要素を溶かします. Great for recycling and small-batch production.

- 基本的な酸素炉 (bof): 酸素を溶融鉄に吹き込み、不純物を除去します. Faster and more cost-effective for large volumes (most X52 is made this way).

熱処理

Heat treatment fine-tunes X52’s mechanical properties:

- 正規化: 鋼を850〜950°Cに加熱します, then cools it in air. Improves ductility and uniformity.

- クエンチングと焼き戻し: Heats to 900°C, 水中のクエンチ (hardens quickly), then tempers at 500–600°C. Boosts strength and toughness.

- アニーリング: 800〜850°Cに加熱します, ゆっくりと冷却します. Reduces stress (good for parts that need bending).

プロセスの形成

X52 is shaped into final products using:

- ホットローリング: Heats steel to 1100°C, rolls it into pipes, ビーム, またはシート. Fast and cost-effective.

- コールドローリング: Rolls steel at room temperature. Creates smoother surfaces (used for precision parts).

- 鍛造: Hammers or presses hot steel into shapes (for gears or shafts). Improves strength.

- 押し出し: Pushes steel through a die to make complex shapes (used for custom parts).

- スタンピング: Uses presses to cut or bend steel into flat parts (for machine components).

表面処理

腐食抵抗を高めるため, X52 gets surface treatments:

- 亜鉛メッキ: 溶融亜鉛に鋼を浸します. Creates a protective layer (持続します 20+ 何年も屋外).

- 絵画: Applies epoxy or polyurethane paint. Ideal for pipelines in wet soil.

- ショットブラスト: Blasts steel with tiny metal balls. Removes rust and cleans the surface before coating.

- コーティング: Uses specialized coatings (like fusion-bonded epoxy) for oil pipelines—resists chemicals and soil corrosion.

4. X52 vs. その他の材料: 比較分析

How does X52 stack up against other common materials? 比較しましょう:

X52 vs. 炭素鋼

| 要素 | X52 Pipeline Steel | 軽度の炭素鋼 (A36) |

|---|---|---|

| 強さ (収率) | 355 MPa min | 250 MPa min |

| タフネス | 素晴らしい (-40°C) | 良い (0°C only) |

| 溶接性 | 良い | とても良い |

| コストパフォーマンス | Better for heavy loads | Cheaper for light use |

| に最適です | パイプライン, 橋 | フェンシング, small structures |

X52 vs. 高強度の低合金 (HSLA) 鋼

- 化学組成: HSLA steels have more alloying elements (like niobium or titanium) than X52.

- プロパティ: HSLA has higher strength (yield 400+ MPA) but is less ductile than X52.

- アプリケーション: HSLA is for skyscrapers or heavy machinery; X52 is better for pipelines (needs ductility for bending).

X52 vs. ステンレス鋼

| 要素 | X52 Pipeline Steel | ステンレス鋼 (304) |

|---|---|---|

| 耐食性 | 良い (コーティング付き) | 素晴らしい (コーティングなし) |

| 強さ | 355–600 MPa | 205–515 MPa |

| 料金 | より低い ($0.80–$1.20/lb) | より高い ($2.50–$3.50/lb) |

| に最適です | Oil pipelines | 食品加工, 医療機器 |

X52 vs. アルミニウム合金

- 重さ: アルミニウムはです 1/3 the weight of X52 (good for aircraft), but X52 is stronger.

- 耐食性: Aluminum resists rust better, but X52 (コーティング付き) is more durable in soil.

- 料金: X52 is cheaper than high-grade aluminum alloys.

- 製造: Aluminum is easier to form, but X52 handles high temperatures better.

5. Yigu Technology’s Perspective on X52 Pipeline Structural Steel

Yiguテクノロジーで, we’ve worked with X52 pipeline structural steel for over a decade, supporting clients in oil and gas, 工事, と機械. We believe X52’s biggest advantage is its balance—It offers the strength needed for critical projects without the high cost of premium steels. We often recommend X52 for long-distance pipelines and mid-rise building frames, as its溶接性 そして耐食性 (適切なコーティングで) cut maintenance costs. For clients in cold climates, X52’s衝撃の靭性 at -40°C is a game-changer. We also help optimize manufacturing—using BOF for large orders and EAF for custom parts—to keep lead times short.

FAQ About X52 Pipeline Structural Steel

1. Can X52 steel be used for offshore pipelines?

はい! X52 is ideal for offshore pipelines when paired with a corrosion-resistant coating (like fusion-bonded epoxy). その強さ handles wave loads, そしてそのタフネス resists cold ocean temperatures. Many offshore projects (like those in the North Sea) use X52.

2. What’s the difference between X52 and X60 pipeline steel?

X60 has a higher yield strength (414 MPa min vs. X52’s 355 MPA) and is used for high-pressure pipelines. X52 is more cost-effective for medium-pressure applications (like natural gas lines) and projects that need more ductility (例えば。, bending around terrain).

3. How long does X52 steel last in outdoor environments?

適切な表面処理で (like galvanizing or painting), X52 can last 20–30 years outdoors. For pipelines buried in soil, a fusion-bonded epoxy coating can extend its life to 50+ 年. 定期的な検査 (超音波検査のように) also help maintain its performance.