If you’re a product designer, エンジニア, or entrepreneur gearing up for prototype development, one of the first and most critical questions you’ll face is: What materials can be used for prototype processing? The right material choice directly impacts your prototype’s functionality, 耐久性, 料金, and even how well it represents the final product. このガイドで, we’ll break down all common prototype materials—from metals to plastics and beyond—explain their key properties, 理想的なユースケース, and processing tips, so you can make an informed decision for your project.

Why Material Choice Matters for Prototype Processing

Before diving into specific materials, let’s clarify why this decision is so important. A prototype isn’t just a “test piece”—it’s a tool to validate design, テストパフォーマンス, and showcase your product to stakeholders. The wrong material can lead to:

- Inaccurate performance tests: 例えば, using a weak plastic for a structural part prototype won’t reflect how the final metal version will hold up.

- Wasted time and money: If a material is too hard to machine or doesn’t meet your project’s needs, you’ll have to restart the prototype process.

- Poor stakeholder perception: A low-quality prototype (例えば。, a brittle plastic that cracks easily) can undermine confidence in your design.

That’s why understanding the pros, cons, and best uses of each material is essential. 下に, we’ll cover the three main categories of prototype materials: metal alloys, ステンレス鋼, そして プラスチック—plus special materials for unique needs.

金属合金: Strong and Durable Prototype Materials

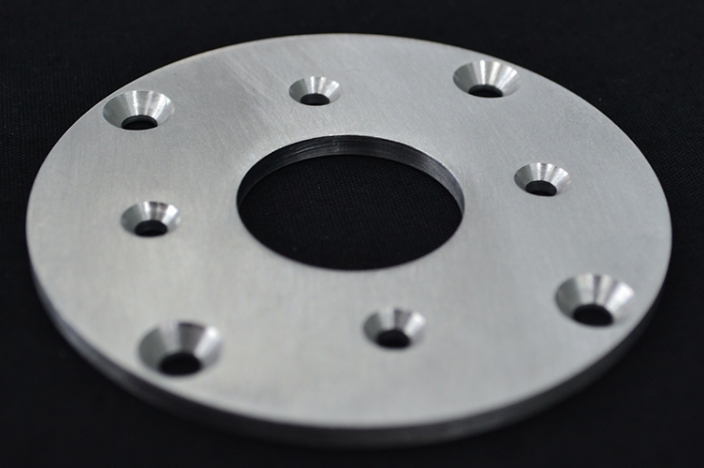

Metal alloys are a top choice for prototypes that need strength, 硬度, or resistance to wear. They’re commonly used for industrial parts, 自動車コンポーネント, and structural prototypes. Let’s break down the most popular metal alloys for prototype processing, their properties, そして理想的なアプリケーション.

| Metal Alloy Type | Common Grades | キープロパティ | Processing Method (CNC/3D Printing) | 表面処理オプション | Ideal Prototype Use Cases |

| Aluminum Alloys | 2024, 6061, 6063, 6082, 7075, ADC12 | 軽量 (density: 2.7 g/cm³), good strength, corrosion-resistant | CNC加工 (最も一般的です); 3D印刷 (for complex shapes) | サンドブラスト, anodizing, 絵画 | Aerospace parts, 自動車ブラケット, electronic enclosures |

| Bronze | C51000, C54400 | High ductility, good electrical conductivity | CNC加工 | 研磨, plating | 電気コネクタ, 装飾的な部分 |

| 真鍮 | C26000 (Cartridge Brass) | Machinable, corrosion-resistant, golden appearance | CNC加工 | 研磨, lacquering | Decorative prototypes, hardware components |

| Copper | Electrolytic Copper (C11000) | Excellent electrical conductivity, malleable | CNC加工, 3D印刷 (金属) | 研磨, tin plating | Heat sinks, electrical prototypes |

| Titanium Alloy | Ti-6Al-4V | 高強度と重量の比率, corrosion-resistant (even in saltwater) | CNC加工 (slow, due to hardness); 3D印刷 | Anodizing, passivation | 医療機器, aerospace components |

| マグネシウム合金 | AZ31B, AZ91D | Ultra-lightweight (density: 1.8 g/cm³), good stiffness | CNC加工 | Chemical conversion coating | Lightweight automotive parts, 家電 |

| Zinc Alloy | ZA-8, ZA-12 | Low melting point, キャストしやすい | Die Casting (for small batches), CNC加工 | Chromate conversion coating | Toy prototypes, 小さな構造部品 |

Key Notes on Aluminum Alloys

Aluminum alloys are the most widely used metal materials for prototypes—and for good reason. Grades like 6061 そして 6063 are easy to machine (CNC machining can finish a 6061 prototype in 1–3 days) and offer a great balance of strength and cost. 7075 aluminum is stronger (used for high-stress parts) but slightly harder to machine, so it may add 1–2 days to your prototype lead time.

機械加工後, aluminum prototypes are often sandblasted to remove tool marks and anodized (a process that adds a protective oxide layer) to improve surface quality and durability. Anodizing also lets you add color (例えば。, 黒, 銀, 青) to your prototype—perfect for presentation.

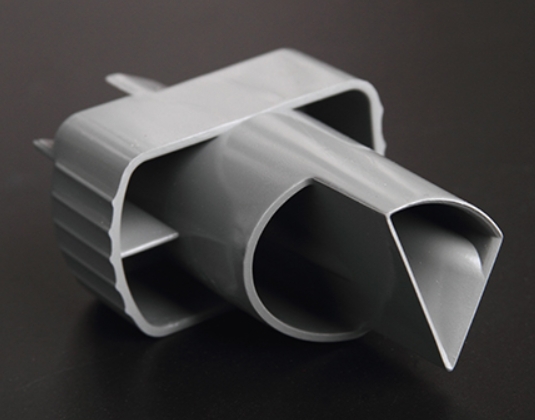

Stainless Steel: High-Strength and Corrosion-Resistant

Stainless steel is a subset of steel that contains chromium (at least 10.5%), which gives it excellent corrosion resistance. It’s ideal for prototypes that will be exposed to moisture, 化学物質, or high temperatures. Below are the most common stainless steel types for prototypes.

| Stainless Steel Type | Common Grades | キープロパティ | 加工性 (1=Easy, 5=Hard) | Magnetic? | Ideal Prototype Use Cases |

| Austenitic (Most Common) | 304, 316 | Non-magnetic, high corrosion resistance, ductile | 3 (適度) | いいえ | Food processing equipment, medical tools, marine parts |

| Ferritic | 409, 430 | Magnetic, good corrosion resistance, lower cost | 2 (簡単) | はい | Automotive exhaust parts, 家電製品 |

| Martensitic | 410, 420 | Magnetic, hardenable (via heat treatment), 高強度 | 4 (Hard) | はい | Cutting tools, バルブ, high-stress mechanical parts |

| Galvanized Steel | G90, G60 | Zinc-coated (prevents rust), 低コスト | 2 (簡単) | はい | Outdoor prototypes, structural brackets |

| Mild Steel (Low Carbon Steel) | 1018, 1020 | 低コスト, 機械加工しやすい, good weldability | 1 (簡単) | はい | Basic structural prototypes, ブラケット |

なぜ 304 そして 316 Stainless Steel Are Top Choices

304 ステンレス鋼 is the most popular for prototypes—it’s affordable, 機械加工しやすい, and works for most non-extreme environments. 316 ステンレス鋼 is more corrosion-resistant (thanks to added molybdenum) but costs 20–30% more. It’s worth the extra cost for prototypes that will be exposed to saltwater (例えば。, marine parts) or chemicals (例えば。, laboratory equipment).

One unique benefit of stainless steel is its magnetic absorption (for ferritic and martensitic grades). This makes it ideal for prototypes that need to attach to magnetic surfaces—like a tool prototype that needs to stick to a workshop magnet board.

Plastic Materials: Versatile and Cost-Effective for Prototypes

Plastics are the most versatile prototype materials—they come in a wide range of hardness, 柔軟性, 透明性, と耐熱性. They’re perfect for consumer products, エレクトロニクス, 医療機器, and prototypes where weight or cost is a concern. Let’s break down the most common plastics for prototype processing, plus when to choose 3D printing vs. CNC加工.

Common Plastic Materials for Prototypes

| Plastic Type | Common Grades/Variants | キープロパティ | Processing Suitability (3D Printing/CNC) | 温度抵抗 (Max) | Ideal Prototype Use Cases |

| 腹筋 | Standard ABS, High-Temperature ABS | 耐衝撃性, 機械加工しやすい, 低コスト | CNC加工 (excellent); 3D印刷 (FDM) | 80–100°C | Consumer electronics enclosures, toy prototypes |

| pp (ポリプロピレン) | PP Homo, PP Copolymer | 化学耐性, フレキシブル, 軽量 | CNC加工; 3D印刷 (FDM) | 100–120°C | 食品容器, 医療機器ハウジング |

| PC (ポリカーボネート) | Lexan (brand name) | 影響力の高い強度, 透明, 耐熱性 | CNC加工; 3D印刷 (SLA/FDM) | 120–135°C | Safety goggles, electronic display covers |

| PMMA (アクリル) | Plexiglas (brand name) | 透明 (92% 光伝達), スクラッチ耐性 | CNC加工; 3D印刷 (SLA) | 80–90°C | Display cases, transparent prototypes |

| ポン (酢酸) | Delrin (brand name) | Low friction, 高い剛性, 耐摩耗性 | CNC加工 | 100–110°C | ギア, ベアリング, 機械コンポーネント |

| PU (Polyurethane) | Domestic PU, Imported PU, Transparent PU, Soft PU | フレキシブル (Shore hardness: 30A–90D), 耐久性 | 3D印刷 (SLA for soft variants); CNC加工 (for rigid variants) | 80–100°C | Cushioned parts, グリップ, flexible enclosures |

| シリコーン | Translucent 905, 918; Transparent T-4, 8678 | 耐熱性, フレキシブル, 生体適合性 | 3D印刷 (SLA); Mold Casting | 200–250°C | Medical seals, ガスケット, flexible prototypes |

3D印刷対. CNC Machining for Plastic Prototypes

When should you use 3D printing vs. CNC machining for plastic prototypes? It depends on your batch size, precision needs, and design complexity:

- 3D印刷: Best for 1–5 unit prototypes with complex shapes (例えば。, lattice structures, アンダーカット). It’s faster for small batches (1–2日) and doesn’t require expensive tooling. しかし, 3D printed plastics may have slightly lower precision (許容範囲: ±0.1mm) CNC加工と比較.

- CNC加工: に最適です 小さなバッチ (5–50ユニット) that need high precision (許容範囲: ±0.05mm) or better mechanical properties. CNC machined plastics have smoother surfaces (less post-processing needed) and are more durable for functional tests. The downside? It takes longer (3–5日) and costs more for very complex designs.

Special Materials for Unique Prototype Needs

While metal alloys, ステンレス鋼, and plastics cover most prototype needs, some projects require special materials. These are used when the final product will operate in extreme conditions (例えば。, 高熱, 化学物質) or has unique requirements (例えば。, biocompatibility). Examples include:

- Special Alloys: Inconel (for high-temperature aerospace parts), Hastelloy (for chemical resistance), and Titanium Grade 23 (biocompatible for medical implants). These are more expensive and harder to machine but essential for specialized prototypes.

- High-Performance Plastics: ピーク (polyetheretherketone) – heat-resistant (max temp: 260°C) and biocompatible, used for medical and aerospace prototypes; PTFE (Teflon) – non-stick and chemical-resistant, used for lab equipment prototypes.

- Composite Materials: Carbon fiber-reinforced plastics (CFRP) – lightweight and ultra-strong, used for high-performance prototypes like racing car parts or drone frames.

How to Choose the Right Material for Your Prototype

With so many options, how do you pick the best material for your project? Follow these four steps:

- Define Your Prototype’s Purpose:

- Is it for visual presentation (例えば。, a client demo)? Prioritize materials with a nice finish (例えば。, polished brass, transparent PMMA).

- Is it for 機能テスト (例えば。, stress tests)? Choose a material with properties matching the final product (例えば。, 6061 aluminum for a structural part that will be aluminum in production).

- Is it for environmental testing (例えば。, moisture resistance)? Pick corrosion-resistant materials (例えば。, 316 ステンレス鋼, PP plastic).

- Consider Mechanical Property Requirements:

- Need strength? Go for 7075 aluminum or 304 ステンレス鋼.

- Need flexibility? Choose soft PU or silicone.

- Need transparency? Opt for PMMA or transparent PC.

- Set a Cost Budget:

- Low budget: ABSプラスチック, mild steel, または 6063 アルミニウム.

- Mid budget: 6061 アルミニウム, 304 ステンレス鋼, or PC plastic.

- High budget: Titanium alloy, 316 ステンレス鋼, or PEEK plastic.

- Check Processing Feasibility:

- If your design has complex curves or undercuts, 3D印刷 (with plastic or metal) may be the only option.

- If you need high precision, CNC machining is better than 3D printing for most materials.

Yigu Technology’s Perspective on Prototype Material Selection

Yiguテクノロジーで, we believe prototype material selection is a collaborative process—we don’t just “supply materials” but help clients match materials to their goals. Our team: 1) Provides material samples (例えば。, 6061 アルミニウム, 304 ステンレス鋼, 腹筋) so clients can test feel and finish; 2) Recommends cost-effective alternatives (例えば。, 6061 instead of 7075 if strength needs are moderate); 3) Optimizes processing (CNC/3D printing) for each material to cut lead time by 15–20%. We prioritize transparency—sharing material costs, machining challenges, and performance trade-offs upfront to avoid rework. For most projects, we help clients narrow down 2–3 ideal materials in 1–2 days.

よくある質問:

1. Can I use a different material for my prototype than the final product?

はい, but only if it doesn’t affect your prototype’s purpose. 例えば, using ABS plastic for a visual prototype of a metal part is fine—since you’re only showcasing the design. But for functional testing (例えば。, stress or heat tests), the prototype material should match the final product’s key properties (例えば。, 強さ, 耐熱性) to get accurate results.

2. Which is more cost-effective: metal or plastic prototypes?

Plastic prototypes are usually cheaper—ABS or PP plastic costs 30–50% less than aluminum or stainless steel. They also require less machining time (faster turnaround) and lower post-processing costs. しかし, if your prototype needs strength (例えば。, a structural part), metal may be worth the extra cost to avoid testing failures.

3. How do I know if a material is suitable for 3D printing vs. CNC加工?

Check two things: 1) Design complexity: If your prototype has undercuts, lattice structures, または内部チャネル, 3D printing is better (CNC can’t reach these areas easily). 2) Batch size: For 1–5 units, 3D printing is faster and cheaper. のために 5+ ユニット, CNC machining is more cost-effective (it has higher per-unit speed once set up). Most plastics and some metals (アルミニウム, チタン) work for both methods—ask your manufacturer for guidance if you’re unsure.