In the fast – paced world of manufacturing, the ability to create high – quality molds quickly can make all the difference in getting your product to market first. Rapid prototyping (RP) technology has revolutionized mold making, offering a range of innovative methods that save time, コストを削減します, and boost design flexibility. しかし、非常に多くのオプションが利用可能です, you might be wondering: just how many ways can rapid prototyping technology be applied to mold making? Let’s explore the diverse techniques that are transforming the industry.

Understanding Rapid Prototyping in Mold Making

Before diving into the specific methods, let’s clarify what we mean by rapid prototyping in the context of mold making. Rapid prototyping refers to a group of technologies that build physical objects layer by layer from digital 3D models. When applied to mold making, these technologies enable manufacturers to create molds faster, more affordably, and with greater design freedom compared to traditional methods like conventional machining.

The core advantage of using rapid prototyping for mold making is its ability to streamline the development process. Instead of waiting weeks or months for tooling, you can have functional molds in days. This speed is a game – changer for industries where time – に – market is critical, such as automotive, 医学, およびコンシューマーエレクトロニクス.

3D Printing Methods for Rapid Mold Prototyping

3D printing has emerged as a powerhouse in rapid mold prototyping, offering several distinct methods to create molds quickly. Let’s take a closer look at the most popular ones:

融合モデリング (FDM)

融合モデリング (FDM) is one of the most accessible 3D printing methods for mold prototyping. It works by extruding thermoplastic filaments layer by layer to build up the mold geometry.

Key Features:

- Ideal for basic prototype molds and low – volume production runs

- Materials commonly used include ABS, プラ, とナイロン

- Relatively low cost compared to other 3D printing methods

- Simple post – processing requirements

制限:

- Lower geometry complexity compared to other methods

- Reduced resolution in fine features

- Limited temperature resistance of polymers, making it unsuitable for high – melt – temperature plastic molding

FDM is a great choice when you need a quick, inexpensive mold for initial design validation or very small production runs.

ステレオリスム造影 (SLA)

ステレオリスム造影 (SLA) uses ultraviolet (UV) light to cure liquid resin layer by layer, creating highly detailed molds with smooth surface finishes.

Key Features:

- 高精度, making it ideal for intricate mold designs

- Excellent surface finish that reduces the need for post – processing

- Ability to produce complex geometries with fine details

- Wide range of resin materials available, including some with heat – resistant properties

SLA molds are perfect for prototypes that require a high level of detail or when you need to test the aesthetic appearance of your product. The high accuracy of SLA also makes it suitable for creating master patterns for other mold – making processes.

選択的レーザー焼結 (SLS)

選択的レーザー焼結 (SLS) works by using a laser to melt and fuse powdered materials, such as nylon, ポリカーボネート, or even some metals, layer by layer.

Key Features:

- Produces durable molds suitable for functional testing

- Excellent for achieving complex geometries and internal features

- No need for support structures, reducing material waste

- Good mechanical properties in the finished mold

SLS molds offer a balance between speed, 耐久性, and design complexity. They can withstand more production cycles than FDM or SLA molds, making them a good choice for small – to medium – volume production runs.

CNC加工: A Hybrid Rapid Prototyping Approach

While CNC machining is a traditional manufacturing method, it has evolved to become part of the rapid prototyping toolkit for mold making, especially when combined with modern technologies.

それがどのように機能するか:

Computer Numerical Control (CNC) machining uses computer – controlled machines to carve molds from solid blocks of material, typically metals like aluminum or steel, but also plastics and composites.

Key Features:

- High accuracy and precision, essential for molds that require tight tolerances

- Excellent durability, especially when using metal materials

- Multi – axis machining capabilities enable complex geometries and undercuts that traditional machining can’t achieve

- Metal molds can be used directly in injection molding presses, as they can withstand the press tonnage needed to clamp the mold closed

Advantages for Rapid Prototyping:

- Metal CNC molds have higher durability and longer cycle life compared to non – metal alternatives

- Can produce molds with superior surface finishes

- Suitable for both prototype and production – grade molds

制限:

- Generally slower than 3D printing methods for creating molds

- Higher tooling costs, especially for complex designs

- More material waste compared to additive manufacturing methods

CNC machining is often the go – to choice when you need a durable mold that can withstand multiple production cycles or when working with high – temperature materials that would damage 3D printed molds.

Hybrid Prototyping Approaches

As manufacturing technology advances, hybrid approaches that combine additive and subtractive manufacturing techniques are becoming increasingly popular for rapid mold prototyping.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) bridges the gap between 3D printing and CNC machining. It uses a laser to sinter powdered metals, creating durable metal molds with complex geometries.

Key Features:

- Combines the design freedom of 3D printing with the durability of metal

- Can produce molds with internal channels and complex features

- Reduces material waste compared to traditional CNC machining

- Faster than conventional metal machining for complex parts

Current Limitations:

- Feature size is still approximately 10 times larger than what can be achieved with precision micro – machining and EDM methods

- Higher cost compared to polymer 3D printing methods

DMLS is ideal for creating metal molds with complex geometries that would be difficult or expensive to produce with traditional machining.

Hybrid Prototyping Machines

Hybrid prototyping machines integrate additive and subtractive manufacturing in a single system, optimizing speed and precision based on the specific requirements of the mold.

それがどのように機能するか:

例えば, an additive method like SLA might be used to create the detailed cavity geometry of an injection mold, while the larger features of the metal mold base are fabricated using high – speed CNC machining. This combination leverages the strengths of both technologies: the design freedom of additive manufacturing for complex features and the precision and durability of subtractive manufacturing for structural components.

Benefits:

- Accelerates tool manufacturing time compared to using either method alone

- Reduces the need for multiple machines and setup changes

- Optimizes material usage and reduces waste

- Enables greater design flexibility while maintaining structural integrity

Hybrid approaches are particularly valuable for creating complex molds where different sections have varying requirements.

Soft Tooling Materials for Rapid Mold Prototyping

Soft tooling refers to the use of non – metallic materials to create molds quickly and affordably for prototype and low – volume production.

Silicone Rubber Molds

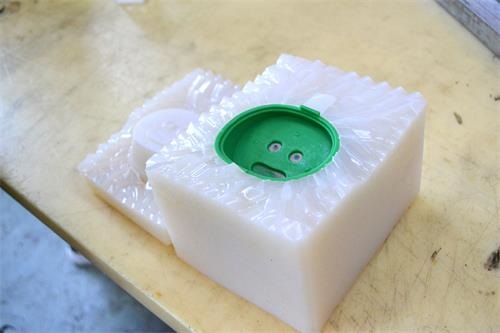

Silicone rubber molds are created by pouring liquid silicone over a master pattern, which can be 3D printed or CNC machined. 硬化したら, the silicone forms a flexible mold that can be used for casting various materials.

Key Features:

- Quick production time, often ready in a day or two

- Low cost compared to metal tooling

- Excellent for capturing fine details from the master pattern

- Can be used with a wide range of casting materials, including plastics, 樹脂, and even some metals

Ideal Applications:

- Short – run injection molding trials

- Prototyping parts with complex geometries

- Testing different material formulations before investing in hard tooling

- Creating visual prototypes for marketing or design reviews

Silicone rubber molds allow for quick adjustments to your design before committing to the higher cost and longer lead time of producing hard tooling from steel.

Aluminum Tooling

Aluminum tooling strikes a balance between cost, スピード, および耐久性. While not as soft as silicone, aluminum is much easier to machine than steel, making it a popular choice for rapid mold prototyping.

Key Features:

- Faster machining time compared to steel tooling

- Lower cost than steel while offering greater durability than silicone or 3D printed molds

- Good thermal conductivity, which helps with cooling in injection molding processes

- Suitable for small to medium production runs

利点:

- Enables faster time – に – market due to shorter lead times

- More durable than soft tooling, allowing for more production cycles

- Can be modified more easily than steel tooling if design changes are needed

Aluminum tooling is an excellent choice when you need a balance between prototype flexibility and production capability, especially for small to medium production runs where time to market is critical.

Comparing Rapid Prototyping Methods for Mold Making

To help you choose the right method for your project, let’s compare the key features of the rapid prototyping methods we’ve discussed:

| 方法 | スピード | 料金 | 耐久性 | Complexity | に最適です |

| FDM | 速い | 低い | 低い | Low to Medium | Basic prototypes, low – volume tests |

| SLA | 速い | 中くらい | Low to Medium | 高い | Detailed prototypes, master patterns |

| SLS | 中くらい | 中くらい | 中くらい | 高い | 機能プロトタイプ, small production runs |

| CNC加工 | Medium to Slow | 高い | 高い | Medium to High | Durable molds, production – grade tooling |

| DMLS | 中くらい | 高い | 高い | 高い | Complex metal molds |

| Hybrid | 中くらい | Medium to High | 高い | 非常に高い | Complex molds with varying requirements |

| Silicone Rubber | 速い | 低い | 低い | 高い | Short runs, design iterations |

| Aluminum Tooling | 中くらい | 中くらい | 中くらい | Medium to High | Small to medium production runs |

This table provides a general overview, but keep in mind that specific project requirements may influence which method is best for your needs.

The Advantages of Rapid Prototyping for Mold Making

No matter which rapid prototyping method you choose, you’ll enjoy several key advantages over traditional mold making:

- Accelerated Product Development Cycles: Lead times for rapid prototype tools can be measured in days instead of weeks, allowing you to get your product to market faster.

- Enhanced Design Flexibility: The ability to iterate through various designs quickly enables engineers to adjust their designs based on prototype testing and customer feedback without incurring significant additional costs.

- Reduced Costs for Small Batches: Rapid prototyping eliminates the need for extensive tooling, making it much more economical for small production runs or initial prototypes.

- Improved Accuracy and Reliability: 事前 – production prototype tools enable product development companies to ensure the accuracy and reliability of a product before it is commercially launched.

- Greater Innovation: By reducing the time and cost barriers to creating molds, rapid prototyping encourages experimentation and innovation in product design.

考慮すべき制限

While rapid prototyping offers many benefits, it’s important to be aware of its limitations when it comes to mold making:

- Material Considerations: Some rapid prototyping materials do not match the properties of production tool materials. This may require secondary process validation to ensure that prototype results translate to production.

- Temperature Constraints: The temperature requirements for certain injection molded plastics may exclude the use of 3D printed polymer molds, as they can’t withstand the high temperatures involved.

- Surface Finish Limitations: While some methods like SLA offer excellent surface finishes, traditional metal injection molds often still provide superior surface finish and texture.

- Production Scale Limitations: The largest scale and tonnage presses typically require the use of steel injection molds. Larger volume parts may also exceed the capabilities of some rapid prototyping machines.

Understanding these limitations will help you choose the right rapid prototyping method for your specific application and set realistic expectations for the results.

Yigu Technologyの視点

Yiguテクノロジーで, we believe rapid prototyping is reshaping mold making. It blends speed, flexibility and precision, crucial for modern manufacturing. We leverage diverse methods like SLA for details, CNC for durability, and hybrids for complex needs. It lets clients iterate fast, コストを削減します, and speed time – に – 市場, key to staying competitive in today’s industry.

よくある質問

What is the fastest rapid prototyping method for making molds?

融合モデリング (FDM) and silicone rubber molding are among the fastest methods, often producing molds in just a few days. These methods are ideal when you need to quickly validate a design concept or produce a small number of prototype parts.

Can rapid prototyping molds be used for mass production?

While some rapid prototyping methods like CNC machined aluminum or steel molds can handle small to medium production runs, most rapid prototyping molds are not designed for mass production. They typically lack the durability of traditional production tooling. しかし, they excel at bridge production, allowing you to start producing limited quantities while waiting for your production tooling to be completed.

How do I choose the right rapid prototyping method for my mold?

The right method depends on several factors: your timeline, 予算, design complexity, 材料要件, and production volume. For quick, low – cost prototypes with basic geometry, FDM or silicone rubber molds may be best. For detailed, 高い – precision molds, consider SLA or SLS. When durability and production capability are key, CNC machining or hybrid methods are often the way to go. Evaluate your specific needs against the strengths and limitations of each method to make the best choice.