多才なものを探している場合, cost-effective tool steel that balances hardness and toughness, W2ツールスチール あなたの注意に値します. Widely used in cold work tools, cutting implements, and precision dies, this material delivers reliable performance across industries like automotive, 製造, とメタルワーク. このガイドで, 重要なプロパティを分類します, 実世界の使用, 生産方法, and how it stacks up against other materials—so you can decide if it’s the right choice for your project.

1. Material Properties of W2 Tool Steel

W2 Tool Steel is a water-hardening (W-group) ツールスチール, known for its simple yet effective composition and balanced mechanical traits. 以下は、そのプロパティの詳細な内訳です.

化学組成

W2’s performance starts with its carefully calibrated mix of elements, which prioritizes hardness and machinability. 典型的な構成 (重量で) は:

- 炭素 (c): 0.80 – 1.00% – The primary hardening agent; higher carbon content boosts wear resistance for cutting and forming tools.

- マンガン (Mn): 0.20 – 0.40% – Improves heat treatment response and reduces brittleness, 鋼の形を容易にします.

- リン (p): ≤0.03% – Minimized to avoid weakening the steel or causing cracks during hardening.

- 硫黄 (s): ≤0.03% – Kept low to maintain toughness, critical for tools that endure repeated impact.

- クロム (cr): 0.10 – 0.30% – Enhances hardenability and adds mild corrosion resistance, protecting tools from rust in workshop environments.

- タングステン (w): 0.10 – 0.30% – Boosts 赤い硬度 (ability to retain hardness at high temperatures), ideal for cutting tools that generate heat.

物理的特性

These traits define how W2 behaves under physical stress, 熱や圧力のように, and are key for tool design:

| 財産 | 典型的な値 | なぜそれが重要なのか |

| 密度 | 〜7.85 g/cm³ | Consistent with most carbon steels, making it easy to calculate tool weight and balance. |

| 融点 | 〜1450 – 1500°C | High enough to withstand machining and heat treatment without melting or deforming. |

| 熱伝導率 | ~38 W/(M・k) | Efficiently dissipates heat, 切削工具の過熱を防ぎます (例えば。, せん断刃). |

| 熱膨張係数 | 〜11 x10⁻⁶/°C | Low expansion means tools retain their shape when heated, critical for precision dies. |

機械的特性

適切な熱処理の後 (硬化 + 焼き戻し), W2 delivers the strength and durability needed for heavy-duty tools:

- 硬度: 58 – 62 HRC (ロックウェルCスケール) – Hard enough to resist wear in cold work tools (例えば。, パンチ) but not so hard that it chips easily.

- 抗張力: 〜1800 – 2100 MPA - 緊張の下で壊れることに抵抗します, so tools like stamping dies don’t snap during use.

- 降伏強度: ~1500 – 1800 MPA - 永続的な変形を防ぎます, ensuring tools hold their shape after repeated use.

- 耐衝撃性: Moderate – Can absorb small shocks (例えば。, from stamping metal sheets) 割れずに, 脆い高炭素鋼とは異なり.

- タフネス: Good – Balances hardness and flexibility, making it suitable for tools that need to bend slightly (例えば。, cold heading tools) 壊れずに.

その他の重要なプロパティ

- 耐摩耗性: Excellent for cold work applications – Stands up to abrasion from metal sheets or workpieces, ツールの寿命を延ばします.

- 耐食性: Mild – Protects against light rust but requires oiling or coating for long-term storage in humid environments.

- 加工性: 良い (熱処理の前) – Soft enough to be drilled, 製粉, or turned into complex shapes (例えば。, custom dies) with standard workshop tools.

2. Applications of W2 Tool Steel

W2’s balance of hardness, タフネス, and cost makes it a top choice for tools that don’t require extreme heat resistance (like high-speed cutting). 以下は、最も一般的な用途です.

コールドワークツール

W2 excels here because it hardens quickly with water and retains toughness—perfect for tools that shape cold metal:

- Shear Blades: Cut through metal sheets (例えば。, aluminum or steel) without dulling. W2’s wear resistance ensures blades stay sharp for thousands of cuts.

- Cold Heading Tools: Form metal into bolts, 爪, or screws by squeezing it at room temperature. The steel’s toughness prevents it from cracking under pressure.

- コールド押出ツール: Push metal through dies to create shapes like pipes or rods. W2’s hardness resists wear from the metal’s friction.

ホットワークツール (Light-Duty)

While not as heat-resistant as H13 steel, W2 works for low-heat hot work applications:

- Low-Temperature Forging Dies: Shape metals like brass or copper (forging temp: 600 – 800°C). その 赤い硬度 keeps the die hard during use.

切削工具

Ideal for low-to-medium speed cutting, where heat buildup is minimal:

- Handheld Cutting Tools: ノミ, パンチ, and woodworking blades. W2’s hardness keeps edges sharp, while its toughness prevents chipping if the tool hits a nail.

- Machine Cutting Tools: Small milling cutters or lathe tools for soft metals (例えば。, アルミニウム). Its thermal conductivity prevents overheating.

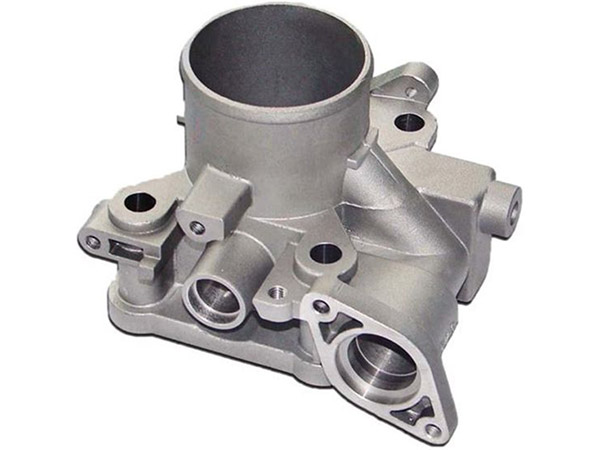

Punches and Dies

Critical for manufacturing, where precision and durability are key:

- スタンピングダイ: Create holes or shapes in metal sheets (例えば。, 自動車用ボディパネル). W2’s low thermal expansion ensures dies retain their precision.

- Blanking Dies: Cut flat parts (例えば。, ワッシャー) from metal sheets. The steel’s wear resistance ensures consistent cuts across thousands of parts.

型と死

For non-high-heat molding applications:

- プラスチック射出型 (Small Parts): Mold small plastic components (例えば。, おもちゃの部品). W2’s machinability lets manufacturers create detailed mold cavities.

3. Manufacturing Techniques for W2 Tool Steel

Producing high-quality W2 tools requires careful control of each step, from melting the steel to finishing the tool. Below’s a step-by-step breakdown.

融解とキャスティング

- プロセス: W2 is typically melted in an 電気弧炉 (EAF). Scrap steel and pure elements (例えば。, 炭素, タングステン) are mixed to hit the exact chemical composition. The molten steel is then cast into ingots (大きなブロック) またはビレット (小さなバー) for further processing.

- 重要な目標: Ensure uniform mixing of elements to avoid weak spots in the steel (例えば。, phosphorus clusters that cause cracks).

ホットワーキング (鍛造 + ローリング)

- 鍛造: インゴットは加熱されます 1100 – 1200°C (赤熱) and hammered or pressed into rough tool shapes (例えば。, ブランク). これにより、鋼の穀物構造が揃っています, 靭性を高める.

- ローリング: For flat tools (例えば。, せん断刃), the steel is passed through hot rollers to reduce thickness and create a smooth surface. Cold rolling may also be used for precision parts to achieve tighter tolerances (±0.05 mm).

熱処理

Heat treatment is critical to unlock W2’s full potential—done incorrectly, the steel may be too soft or brittle:

- アニーリング: 加熱されています 800 – 850°C, のために開催されます 2 – 3 時間, その後、ゆっくりと冷却されました. 機械加工のために鋼を柔らかくします (hardness drops to ~20 HRC).

- 硬化: 加熱されています 780 – 820°C, 制服まで開催されます, その後、水で癒されます. This hardens the steel to ~63 HRC but makes it brittle.

- 焼き戻し: に再加熱されました 180 – 220°C, のために開催されます 1 – 2 時間, その後、冷却しました. Reduces brittleness while keeping hardness at 58 – 62 HRC—this step is vital for preventing tool breakage.

機械加工

- 予熱治療: W2 is soft (20 – 25 HRC), so it can be machined with standard high-speed steel (HSS) ツール. 一般的なプロセスには含まれます:

- 旋回: 円筒形の部分を形成します (例えば。, punch shafts) 旋盤に.

- ミリング: Creates complex cavities in dies (例えば。, mold for plastic parts).

- 研削: 表面仕上げを改良します (ra≤ 0.8 μm) for precision tools like stamping dies.

- 加熱後の治療: Machining is limited to grinding (since the steel is hard), used to correct small errors or sharpen cutting edges.

表面処理

Optional treatments to boost performance:

- コーティング: PVD (物理的な蒸気堆積) coatings like TiN (窒化チタン) ハードを追加します, low-friction layer. This extends tool life by 30 – 50% 切削工具用.

- ニトリッド: Heated in ammonia gas to create a hard surface layer (~50 μm thick). 強化 耐摩耗性 for punches and dies.

品質管理と検査

To ensure W2 tools meet standards, メーカーはパフォーマンスを発揮します:

- 硬度テスト: Use a Rockwell tester to confirm hardness (58 – 62 HRC).

- 寸法検査: Use calipers or laser scanners to check tool size (例えば。, punch diameter) against design specs.

- 微細構造分析: Examine the steel under a microscope to ensure no cracks or uneven grain structure (which weakens tools).

4. ケーススタディ: W2 Tool Steel in Action

Real-world examples show how W2 solves common tooling challenges. Below are three practical cases.

ケーススタディ 1: W2 Shear Blades for Automotive Sheet Metal

A small automotive parts shop struggled with frequent blade replacements—their existing carbon steel shear blades dulled after cutting 500 アルミニウムシート, causing rough edges and downtime.

解決: They switched to W2 Tool Steel shear blades, に和らげられた 60 HRC.

結果:

- ブレードの寿命は増加しました 2,000 シート (a 300% 改善).

- Reduced downtime by 75% (fewer blade changes).

- Cut quality improved—edges were smooth, eliminating the need for secondary grinding.

なぜそれがうまくいったのか: W2’s 耐摩耗性 stood up to aluminum’s abrasion, while its toughness prevented chipping during cutting.

ケーススタディ 2: W2 Cold Heading Tools for Bolt Manufacturing

A fastener manufacturer needed tools to form steel bolts (cold heading). Their previous HSS tools cracked after 10,000 ボルト, leading to costly rejections.

解決: They switched to W2 Tool Steel tools, with a nitrided surface.

結果:

- ツール寿命は拡張されました 35,000 ボルト (a 250% 改善).

- Rejection rate dropped from 8% に 1% (tools held their shape better).

- 低コスト: W2 is 20% cheaper than HSS, reducing tooling expenses.

なぜそれがうまくいったのか: W2’s タフネス absorbed the pressure of cold heading, while nitriding boosted surface wear resistance.

ケーススタディ 3: Failure Analysis of W2 Stamping Dies

A metal stamping shop had W2 dies that cracked after 5,000 用途. The dies were supposed to stamp steel brackets but failed prematurely.

Investigation: Testing showed the dies were quenched too quickly (in cold water) 熱処理中, leading to internal cracks. Hardness was uneven (55 – 63 HRC), making weak spots prone to breaking.

修理: The shop adjusted the heat treatment—slower quenching (in warm water) and longer tempering (2 hours at 200°C). They also added a grinding step to ensure uniform hardness.

結果:

- Dies lasted 18,000 用途 (a 260% 改善).

- No more cracking—hardness was consistent at 60 HRC.

5. W2 Tool Steel vs. その他の材料

How does W2 compare to other common tool materials? Below’s a side-by-side breakdown to help you choose.

W2 vs. 高速スチール (HSS)

| 要素 | W2ツールスチール | HSS (例えば。, M2) |

| 硬度 | 58 – 62 HRC | 60 – 65 HRC |

| 赤い硬度 | 適度 (up to 350°C) | 素晴らしい (最大600°C) |

| タフネス | 良い | 適度 |

| 料金 | より低い (≈\(8 – \)12/kg) | より高い (≈\(15 – \)20/kg) |

| に最適です | コールドワークツール, low-speed cutting | 高速切断 (例えば。, ミリング), ホットワークツール |

When to choose W2: For cold work or low-heat applications where cost and toughness matter more than extreme heat resistance.

W2 vs. 炭化物

| 要素 | W2ツールスチール | 炭化物 (例えば。, WC-CO) |

| 硬度 | 58 – 62 HRC | 85 – 90 hra (much harder) |

| 耐摩耗性 | 良い | 素晴らしい |

| タフネス | 良い (resists chipping) | 貧しい (脆い) |

| 料金 | 低い (≈\(8 – \)12/kg) | 非常に高い (≈\(80 – \)100/kg) |

| に最適です | General cold work, インパクトツール | ハードメタルの高速切断 (例えば。, ステンレス鋼) |

When to choose W2: For tools that need to withstand impact (例えば。, パンチ) or when carbide’s cost is prohibitive.

W2 vs. ステンレス鋼 (440c)

| 要素 | W2ツールスチール | 440Cステンレス鋼 |

| 硬度 | 58 – 62 HRC | 58 – 60 HRC |

| 耐食性 | 軽度 (needs oiling) | 素晴らしい (錆びない) |

| タフネス | 良い | 適度 |

| 料金 | より低い (≈\(8 – \)12/kg) | より高い (≈\(18 – \)22/kg) |

| に最適です | Workshop tools, コールドワーク | Food industry tools, 海洋アプリケーション |

When to choose W2: For dry workshop environments where corrosion isn’t a major risk—saves cost without sacrificing performance.

W2 vs. 炭素鋼 (1095)

| 要素 | W2ツールスチール | 1095 炭素鋼 |

| 硬度 | 58 – 62 HRC | 55 – 60 HRC |

| ハーデン剤 | より良い (hardens evenly) | 貧しい (may have soft spots) |

| タフネス | 良い | 低い (脆い) |

| 赤い硬度 | 適度 | 貧しい |

| に最適です | Heavy-duty tools | Light-duty tools (例えば。, ナイフ) |

When to choose W2: For tools that need consistent hardness and durability (例えば。, 死ぬ) instead of just basic cutting ability.

Yigu Technology’s Perspective on W2 Tool Steel

Yiguテクノロジーで, we recommend W2 Tool Steel for clients seeking a cost-effective, versatile solution for cold work tools and light-duty hot work applications. そのバランス 耐摩耗性, タフネス, and machinability makes it ideal for small to medium manufacturers—especially those making punches, せん断刃, or cold heading tools. We often help clients optimize W2’s performance through custom heat treatment (例えば。, tailored tempering for specific tools) and surface coatings (ブリキのように) to extend tool life. While W2 isn’t suited for high-speed cutting, its low cost and reliability make it a top choice for most workshop tool needs.

よくある質問: Common Questions About W2 Tool Steel

1. Can W2 Tool Steel be welded?

Welding W2 is possible but requires caution. その高い炭素含有量は、ひび割れを起こしやすくします. 安全に溶接します: スチールを予熱します 300 – 400°C, use a low-hydrogen welding rod (例えば。, E7018), and post-weld anneal at 600°C to relieve stress. For critical tools (例えば。, precision dies), we recommend avoiding welding—machining from a single piece of W2 is more reliable.

2. What’s the best heat treatment for W2 Tool Steel?

The optimal process is: anneal at 820°C (ゆっくり涼しい) to soften for machining, harden at 800°C (quench in warm water), then temper at 180 – 220°C for 1 – 2 時間. This achieves 58 – 62 HRC—balanced hardness and toughness. For tools needing more toughness (例えば。, cold heading tools), temper at 250°C (硬度が低下します 55 – 58 HRC but toughness increases).