If you’re designing vehicles, 航空機, または重機, 強い素材が必要ですそして 軽量. それがここですうーん (Ultra High Strength Steel) 入ってくる. With tensile strength exceeding 1,000 MPA, UHSS delivers the durability to handle extreme stress while cutting weight—solving key challenges for modern engineering. このガイドは、そのプロパティを分解します, 実世界の使用, 製造方法, and how it compares to other materials—so you can make informed choices for your projects.

1. Core Material Properties of UHSS (Ultra High Strength Steel)

UHSS owes its performance to a precise blend of chemistry and processing. Let’s break down its key traits:

1.1 化学組成

UHSS uses controlled amounts of carbon and alloying elements to balance strength and workability:

- 炭素 (c): 0.10–0.30% (kept moderate to avoid brittleness while boosting strength).

- マンガン (Mn): 1.50–3.00% (硬化性と引張強度を向上させます).

- シリコン (そして): 0.15–0.50% (improves formability and resistance to oxidation).

- 合金要素: クロム (cr) (0.50–1.50%) 腐食抵抗用; モリブデン (MO) (0.10–0.50%) 高温強度の場合; ニッケル (で) (0.50–2.00%) タフネスのために; バナジウム (v) (0.02–0.10%) for fine-grain structure (疲労抵抗を高めます).

- Harmful impurities: リン (p) (<=0.025%) そして 硫黄 (s) (<=0.010%) are minimized to prevent cracking.

1.2 物理的特性

UHSS retains steel’s familiar physical traits while offering superior strength:

| 財産 | 典型的な値 |

|---|---|

| 密度 | 7.85 g/cm³ |

| 融点 | 1450–1500°C |

| 熱伝導率 | 42–45 w/(M・k) |

| 熱膨張係数 | 12.5–13.0×10⁻⁶/°C (20–100°C) |

| 電気抵抗率 | 0.20–0.22 μΩ·m |

1.3 機械的特性

This is where UHSS stands out—its strength metrics redefine what steel can do:

- 超高引張強度: 1,000-2,000 MPa (2–5x higher than standard carbon steel).

- 高降伏強度: 800–1,800 MPa (resists permanent deformation even under heavy loads).

- 高い硬度: 30–50 HRC (hard enough for crash-resistant parts, soft enough for limited forming).

- 影響力の高い靭性: 20-40°Cで–50 j (performs well in cold climates, critical for automotive and aerospace).

- 低延性 & low elongation: 5–15%伸び (can bend slightly but not as much as mild steel—trade-off for strength).

- 高疲労抵抗: Withstands 10⁷+ stress cycles (ideal for rotating parts like gears or landing gear).

- High fracture toughness: Resists sudden cracking (essential for safety-critical parts like aircraft engine components).

1.4 その他の重要なプロパティ

- 優れた耐摩耗性: Harder than HSLA steel, making it last longer in high-abrasion tasks (例えば。, pipeline interiors).

- 良好な腐食抵抗: Alloying elements like Cr protect against rust (炭素鋼よりも優れています, ステンレス鋼ほど良くはありませんが).

- 高温強度: 最大600°Cの強度を維持します (useful for aerospace engine parts).

- Poor weldability: High strength increases risk of cracking during welding (needs pre-heating and specialized fillers).

- Poor formability: Requires high-pressure stamping or hot forming (harder to shape than mild steel, but advancing techniques are improving this).

2. Real-World Applications of UHSS (Ultra High Strength Steel)

UHSS’s strength-to-weight ratio makes it indispensable across industries. Here are its most impactful uses, backed by case studies:

2.1 自動車

The auto industry relies on UHSS to make cars safer and more fuel-efficient:

- ボディ・イン・ホワイト (ピュー) コンポーネント, 柱 (a-pillar, Bピラー, Cピル), とドアリング: Absorb crash energy to protect passengers. ケーススタディ: Toyota used UHSS for the B-pillars of its Camry—crash test scores improved by 20%, and vehicle weight dropped by 8%.

- Roof rails and cross-members: Reinforce the vehicle frame without adding weight. ケーススタディ: Ford’s F-150 uses UHSS for its roof rails—load capacity increased by 15% while weight decreased by 10%.

- クラッシュ耐性構造: Reduce injury risk in collisions. ケーススタディ: Volkswagen’s ID.3 electric vehicle uses UHSS in its front crash zone—battery protection improved, and range increased by 5% (due to weight savings).

2.2 航空宇宙

UHSS handles the extreme demands of flight:

- 航空機のエンジンコンポーネント (タービンブレード, シャフト): Withstand high temperatures and torque. ケーススタディ: Boeing used UHSS for the engine shafts of its 787 Dreamliner—shaft lifespan doubled vs. 伝統的な鋼.

- 着陸装置: Supports the plane’s weight during takeoff and landing. ケーススタディ: Airbus integrated UHSS into the A350’s landing gear—weight reduced by 12%, 燃料消費量を削減します 3%.

- ファスナー: Secure critical parts (例えば。, wing panels) 失敗することなく. ケーススタディ: A aerospace supplier reported 0 fastener failures in 5 years of using UHSS, vs. 5% failure rate with standard steel.

2.3 機械工学

For machines that need to handle heavy loads:

- ギアとシャフト: Transmit power without bending or breaking. ケーススタディ: A wind turbine manufacturer used UHSS for gearboxes—gear lifespan increased by 30%, メンテナンスコストの削減.

- 機械部品: Tolerate high pressure (例えば。, hydraulic press components). ケーススタディ: A manufacturing plant switched to UHSS for press platens—downtime due to part failure dropped by 40%.

2.4 パイプライン

UHSS excels in harsh pipeline environments:

- 石油およびガスパイプライン: Withstand high pressure and corrosion. ケーススタディ: The TransCanada Pipeline used UHSS for sections in cold regions—leak rates fell by 90% vs. standard steel pipelines.

2.5 海兵隊

Tough enough for ocean conditions:

- Ship structures and offshore platforms: Resist waves, 塩水, と重い負荷. ケーススタディ: A Norwegian shipyard used UHSS for offshore platform legs—platform weight reduced by 18%, lowering installation costs.

2.6 スポーツ用品

For high-performance equipment:

- ゴルフクラブ (clubheads): Deliver more power on impact. ケーススタディ: A golf brand used UHSS for driver heads—ball speed increased by 5 MPH, improving distance by 15 yards.

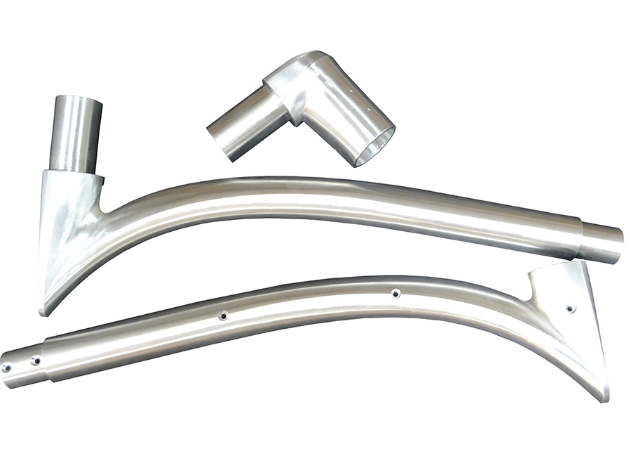

- 自転車フレーム: Lightweight yet strong. ケーススタディ: A bike manufacturer used UHSS for mountain bike frames—frame weight dropped by 20% while handling rough terrain better.

3. Manufacturing Techniques for UHSS (Ultra High Strength Steel)

Making UHSS requires advanced processes to unlock its full strength. これがどのように生産されているかです:

3.1 スチール製造プロセス

Two methods dominate UHSS production:

- 電気弧炉 (EAF): Uses scrap steel and precise alloy additions (cr, MO, で) to reach UHSS chemistry. Ideal for small to medium batches and sustainable production (lower emissions).

- 基本的な酸素炉 (bof): Converts iron ore to steel, 次に、合金を追加します. Used for large-scale UHSS production (例えば。, 自動車用鋼鉄).

3.2 熱処理

Heat treatment is critical to achieving UHSS’s strength:

- クエンチングと焼き戻し: Heats steel to 800–900°C, quenches in water/oil (hardens it), then tempers at 300–500°C (reduces brittleness while keeping strength). This creates the ultra-high tensile strength.

- アニーリング: Heats to 700–800°C, ゆっくりと冷却します. Softens UHSS temporarily for machining or forming (then re-heat-treated to restore strength).

- 正規化: Heats to 900–950°C, air-cools. Improves uniformity in the steel’s structure, making heat treatment more effective.

- 降水硬化: Adds elements like Cu or Al to form tiny precipitates during heat treatment—boosts strength without losing too much toughness (used for aerospace UHSS).

3.3 プロセスの形成

Forming UHSS requires specialized techniques due to its low ductility:

- ホットローリング: 鋼を1100〜1200°Cに加熱します, rolls into sheets or bars (used for automotive BIW components).

- コールドローリング: Done at room temperature with high pressure (creates thin, smooth sheets for precision parts like fasteners).

- 鍛造: 加熱された鋼を複雑な形に押し込んだり押したりします (used for landing gear and gears).

- 押し出し: Pushes steel through a die (makes hollow parts like bicycle frame tubes).

- スタンピング: Uses high-pressure presses (1,000+ トン) to shape UHSS sheets (common for automotive pillars—often paired with “hot stamping” to improve formability).

3.4 表面処理

To enhance durability and performance:

- メッキ (例えば。, クロムメッキ): Adds wear resistance (used for gears and fasteners).

- コーティング (例えば。, 窒化チタン): Reduces friction (ideal for engine components).

- ピーニングを撃った: Blasts the surface with small metal balls—creates compressive stress, 疲労抵抗の改善 (used for landing gear).

- 研磨: Smooths the surface (reduces corrosion risk for marine parts).

4. How UHSS (Ultra High Strength Steel) 他の素材と比較します

Choosing the right material depends on your project’s priorities (強さ, 重さ, 料金). Here’s how UHSS stacks up:

| 材料 | 抗張力 (MPA) | 密度 (g/cm³) | 耐食性 | 溶接性 | 料金 (vs. うーん) | に最適です |

|---|---|---|---|---|---|---|

| うーん | 1,000–2,000 | 7.85 | 良い | 貧しい | 100% | Automotive BIW, 着陸装置 |

| 炭素鋼 (A36) | 400–550 | 7.85 | 貧しい | 素晴らしい | 40% | 低ストレス部品 (パイプ) |

| HSLAスチール | 600–1,000 | 7.85 | 良い | 良い | 70% | 橋, トラックフレーム |

| ステンレス鋼 (304) | 500–700 | 7.85 | 素晴らしい | 素晴らしい | 250% | 食品装備, 医療ツール |

| アルミニウム合金 (6061) | 310–380 | 2.70 | 良い | 良い | 180% | Aircraft bodies, 自転車フレーム |

キーテイクアウト:

- vs. 炭素鋼: UHSS is 2–4x stronger—worth the extra cost for safety-critical parts (例えば。, crash structures).

- vs. HSLAスチール: UHSS has 40–100% higher tensile strength—better for applications needing extreme durability (例えば。, 着陸装置).

- vs. ステンレス鋼: UHSS is 2–3x stronger and 60% cheaper—use stainless steel only if maximum corrosion resistance is needed.

- vs. アルミニウム: UHSS is 3–6x stronger (重いですが)—choose aluminum for weight-sensitive projects where strength needs are lower (例えば。, non-critical aircraft parts).

5. Yigu Technology’s Perspective on UHSS (Ultra High Strength Steel)

Yiguテクノロジーで, UHSS is our go-to for clients prioritizing strength, 安全性, と体重の節約. その 1,000+ MPa tensile strength transforms automotive and aerospace designs—we’ve helped auto manufacturers cut vehicle weight by 8–15% (燃料効率の向上) while improving crash safety. While UHSS’s poor formability and weldability pose challenges, our team optimizes processes (例えば。, ホットスタンピング, specialized welding) to overcome them. For projects where “stronger and lighter” isn’t just a goal but a requirement, UHSS remains unmatched—and we’re excited to support its growing use in sustainable engineering.

FAQ About UHSS (Ultra High Strength Steel)

1. Can UHSS be formed into complex shapes (like automotive pillars)?

Yes—but it requires specialized techniques. Hot stamping (heating UHSS to 900°C, forming it, then quenching) is the most common method. It softens the steel during forming, then restores its ultra-high strength afterward—ideal for complex parts like A-pillars.

2. Is UHSS expensive to use in manufacturing?

It’s more expensive than carbon or HSLA steel (2–3x the cost), but it delivers long-term value. 例えば, UHSS automotive parts reduce weight (cutting fuel costs for drivers) and last longer (lowering warranty claims for manufacturers). The total cost of ownership often ends up lower than cheaper steels.

3. How does UHSS perform in cold weather?

素晴らしい. UHSS has high impact toughness (20-40°Cで–50 j), so it doesn’t become brittle in freezing temperatures. This makes it perfect for automotive parts in cold regions, aerospace components at high altitudes, and pipelines in northern climates.