Whether you’re developing a new automotive part, a medical device, or an electronic enclosure, sheet metal prototype making is a vital step to turn design ideas into tangible, testable products. A well-made sheet metal prototype not only verifies if your design works but also helps you spot production challenges early—saving time and money down the line. This guide covers everything from material selection to collaboration tips, giving you the tools to create top-notch sheet metal prototypes.

1. 材料の選択 & Application for Sheet Metal Prototypes

Choosing the right material is the first (and often most critical) ステップインします sheet metal prototype making. The material you pick affects the prototype’s strength, 外観, コスト, so it needs to match your end product’s needs. Below’s a breakdown of common materials and their uses:

Common Sheet Metal Materials & Their Properties

| 材料 | キープロパティ | Typical Thickness Range | Industry Applications | 料金 (USD/sq.ft) |

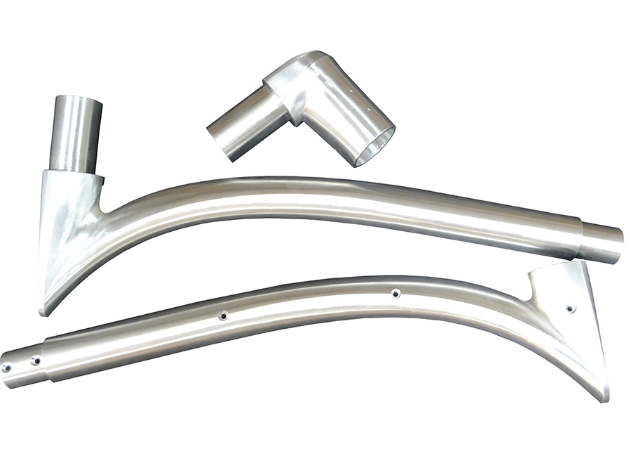

| アルミニウム合金 | 軽量, 耐性耐性, 機械加工しやすい | 0.5mm – 6mm | 航空宇宙部品, 電子エンクロージャー | \(2.0 - \)5.5 |

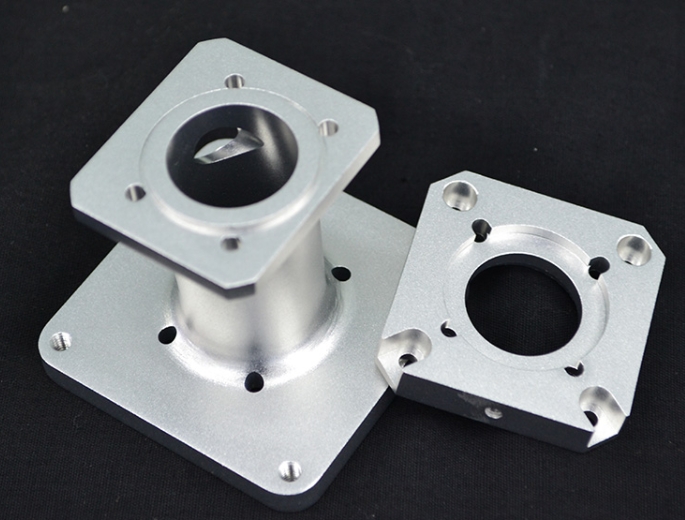

| ステンレス鋼 | 高強度, rust-proof, 耐久性 | 0.3mm – 10mm | 医療機器, food processing equipment | \(3.5 - \)8.0 |

| 銅 | 優れた導電率, 順応性 | 0.2mm – 5mm | 電気コンポーネント, 熱交換器 | \(8.0 - \)15.0 |

Material Treatment Matters

Beyond the base material, surface treatments impact both performance and look. 例えば:

- 陽極酸化: Adds a protective layer to aluminum prototypes, making them more scratch-resistant—perfect for outdoor gear prototypes.

- メッキ: Zinc or nickel plating boosts corrosion resistance for stainless steel prototypes used in wet environments (like marine parts).

- スプレー: A powder coat finish gives prototypes a smooth, uniform color—ideal for consumer products where appearance matters.

実世界の例: A medical device startup needed a prototype for a surgical instrument tray. 彼らは選んだ ステンレス鋼 for its corrosion resistance (critical for sterilization) and added a matte powder coat to prevent glare in operating rooms. The prototype passed all durability tests, and the design moved to mass production with no major changes.

2. デザイン & Process Planning for Sheet Metal Prototype Making

Modern sheet metal prototype making relies on advanced tools and smart process choices to ensure accuracy. Here’s how to get your design and planning right:

CAD/CAE/CAM: The Backbone of Modern Prototyping

Gone are the days of hand-drawn designs—CAD/CAE/CAM technologies are now standard for sheet metal prototypes:

- CAD (コンピューター支援設計): Software like SolidWorks or AutoCAD lets you create 3D models of your prototype, so you can visualize every detail (例えば。, 穴, 曲がり) before cutting metal.

- CAE (Computer-Aided Engineering): Simulates how the prototype will perform under stress. 例えば, a car door prototype can be tested for impact resistance digitally, avoiding costly physical tests.

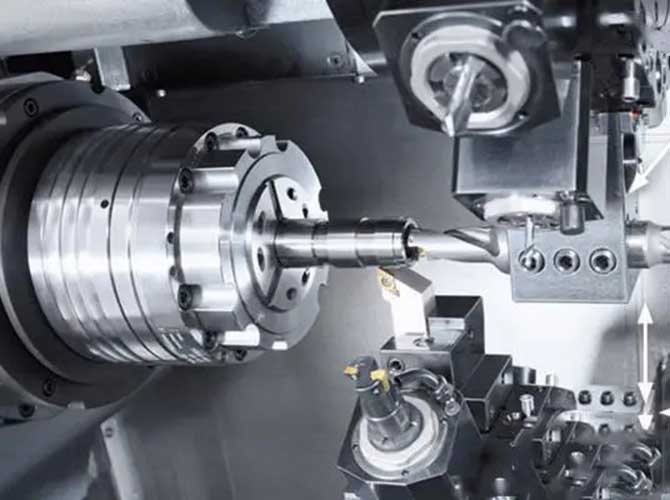

- カム (コンピューター支援の製造): Converts your CAD model into machine-readable code, ensuring the CNC machine cuts the metal exactly as designed.

Choosing the Right Processing Method

Not all sheet metal processes work for every prototype. Here’s when to use each:

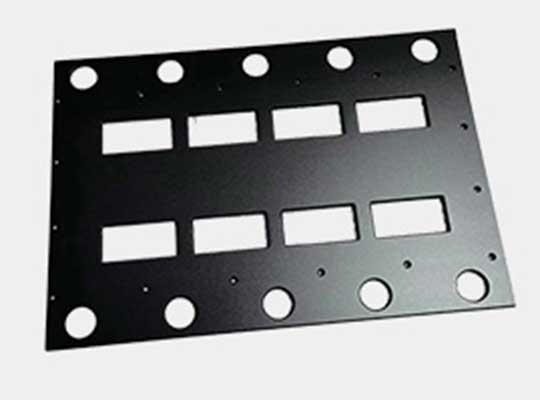

- レーザー切断: Best for precise, 複雑な形 (例えば。, a prototype with intricate holes for sensors). It cuts cleanly and works with thin to medium-thickness metals (up to 20mm for steel).

- CNC Stamping: Great for prototypes that will later be mass-produced. It’s fast for repetitive cuts—like making 50 identical bracket prototypes.

- 曲げ: Used to create angles or curves (例えば。, a prototype for a metal shelf). A CNC press brake can bend metal with ±0.1mm accuracy, ensuring consistency.

ケーススタディ: An automotive supplier needed a prototype for a new hood hinge. 彼らは使用しました CAD to design the hinge, CAE to test if it could support the hood’s weight, そして CNC stamping 作る 10 prototypes quickly. The process took 3 days—half the time of traditional methods.

3. Precision Control & Quality Management

で sheet metal prototype making, even small errors (like a 0.2mm misalignment) プロトタイプを台無しにする可能性があります. Here’s how to keep precision high and quality consistent:

How to Maintain Precision

- マシンキャリブレーション: Regularly calibrate CNC machines and tools. A laser cutter that’s off by 0.1mm can make a prototype that doesn’t fit with other parts.

- Operator Skill: Experienced operators know how to adjust for material quirks. 例えば, thin stainless steel can warp during cutting—an expert will slow the feed rate to prevent this.

- Real-Time Monitoring: Use sensors to track the machining process. If a tool starts to wear, the sensor alerts the operator before it causes errors.

Building a Quality Management System

A strong quality check process ensures your prototype meets standards:

- 目視検査: Check for scratches, へこみ, or uneven edges—these can affect both look and function.

- 寸法測定: Use tools like calipers or coordinate measuring machines (CMMS) to verify every dimension matches the CAD model.

- 機能テスト: Test if the prototype works as intended. 例えば, a prototype latch should open and close smoothly 100+ 時代.

例: A electronics company made a sheet metal prototype for a router enclosure. During quality checks, they found the holes for cables were 0.5mm too small—too tight for the cables to fit. They adjusted the laser cutter and reworked the prototype, avoiding a costly design flaw in production.

4. コミュニケーション & Cooperation for Smooth Prototyping

Sheet metal prototype making isn’t a one-person job—it requires teamwork across departments and with suppliers. Here’s how to collaborate effectively:

Cross-Departmental Collaboration

- Sales & デザイン: Sales teams know customer needs (例えば。, a client might want a lightweight prototype), so they should share this with designers early.

- エンジニアリング & 品質管理: Engineers and QC teams should work together to set quality standards. 例えば, engineers might specify a 0.1mm tolerance, and QC will check to ensure it’s met.

- Regular Meetings: Weekly check-ins keep everyone on the same page. A 15-minute call can resolve misunderstandings (like a designer forgetting to note a bend angle) before they delay the prototype.

Supplier Management

Your material suppliers and outsourcing partners play a big role too:

- Choose suppliers with a track record of delivering quality sheet metal. Ask for samples to test before placing a large order.

- Share your prototype timeline with suppliers. 例えば, if you need aluminum sheets in 3 日, make sure they can meet that deadline—delays here hold up the entire process.

Success Story: A startup working on a smart thermostat prototype had issues with delayed material deliveries. They switched to a local supplier who guaranteed 2-day delivery for aluminum sheets. With reliable supplies, their sheet metal prototype making process went from 3 数週間 10 日.

5. Innovation & Continuous Improvement in Sheet Metal Prototyping

To stay ahead, sheet metal prototype making needs to evolve with new technologies and feedback. Here’s how to keep improving:

Embrace New Technologies

- 3D Scanning: If you’re modifying an existing part, 3D scanning can create a digital model of the old part—saving time on redesign.

- Automated Bending: New CNC press brakes with AI can adjust bending parameters automatically, reducing human error and speeding up production.

Learn from Feedback

- Customer Feedback: If a client says a prototype is too heavy, revisit your material choice (例えば。, switch from steel to aluminum).

- Internal Audits: After each prototype project, review what went well and what didn’t. 例えば, if laser cutting caused delays, consider investing in a faster machine.

Yigu Technology’s View on Sheet Metal Prototype Making

Yiguテクノロジーで, わかります sheet metal prototype making as the link between design innovation and real-world usability. 以上 8 年, 私たちは助けました 300+ clients—from small startups to big manufacturers—build prototypes. We focus on matching materials to end-use needs (例えば。, 軽量部品用のアルミニウム, stainless steel for medical gear) and use CAD/CAE/CAM to cut errors by 35%. Our team also works closely with suppliers to ensure fast deliveries, getting clients their prototypes in 5–7 days on average. 私たちのために, a good sheet metal prototype isn’t just a test—it’s a step toward seamless mass production.

FAQ About Sheet Metal Prototype Making

Q1: How long does sheet metal prototype making usually take?

a: It depends on complexity and material. A simple aluminum prototype (like a small enclosure) takes 3–5 days. 複雑なステンレス鋼のプロトタイプ (with multiple bends and cuts) can take 1–2 weeks.

Q2: Can sheet metal prototypes be used for small-batch production?

a: はい! Many sheet metal processes (like CNC stamping) let you scale from 1 prototype to 100+ units without retooling. This is great for pre-launch tests with real users.

Q3: What’s the average cost of a sheet metal prototype?

a: Costs vary by size, 材料, and process. 小さなアルミニウムプロトタイプ (100x150mm) 費用 \(30- )80. A large stainless steel prototype (300x400mm) with complex cuts can cost \(150- )300.