In the world of additive manufacturing, resin light-curing (SLA) 3D printing stands out as a technology renowned for its precision, high resolution, and ability to produce smooth-surfaced parts. From rapid prototyping to low-volume production, SLA has revolutionized how industries approach product development and manufacturing. This comprehensive guide will delve into the intricacies of SLA 3D printing, exploring how it works, its materials, 利点, 制限, アプリケーション, and more.

How Does Resin Light-Curing (SLA) 3D印刷作業?

Resin light-curing (SLA) 3D printing is a vat photopolymerization technology that transforms liquid photopolymer resin into solid three-dimensional objects using ultraviolet (UV) light. The process involves several key components and a step-by-step workflow that ensures precision and accuracy.

Key Components of an SLA 3D Printer

An SLA 3D printer consists of four main parts that work together to create 3D-printed parts:

- Resin Tank: A container filled with liquid photopolymer resin, typically a clear liquid plastic that reacts to UV light.

- ビルドプラットフォーム: A perforated platform that is immersed in the resin tank and moves up and down along the Z-axis during the printing process.

- UV Laser: A high-power ultraviolet laser that selectively cures the resin to form each layer of the part.

- Computer Control Unit: The brain of the printer that controls the movement of the build platform and the UV laser, following the instructions from the digital 3D model.

The SLA Printing Process Step-by-Step

Once a CAD (コンピューター支援設計) model is prepared and sent to the printer, the SLA printing process unfolds in the following steps:

- First Layer Curing: The UV laser prints the first layer of the part by selectively curing the photosensitive resin in the tank. Wherever the laser shines, the liquid resin solidifies into a solid layer, following the exact coordinates dictated by the design.

- 層ごとの建物: After completing the first layer, the build platform rises by a distance equal to the layer thickness (usually around 0.05 に 0.10 mm). This allows fresh liquid resin to flow beneath the previously cured layer. The laser then cures the next layer, and this process repeats until the entire part is complete.

- Post-Printing Removal: Once the part is finished printing, the build platform rises from the resin tank, and any excess resin flows back into the tank. The uncured resin that hasn’t been touched by the laser remains in the tank and can be reused, minimizing waste.

- 後処理: The printed model is removed from the build platform. It is then washed with alcohol to remove any remaining uncured resin on the surface. After washing, the part is placed in a UV drying oven for final curing, which helps the object achieve its maximum strength and stability. ついに, any support structures used during printing are removed.

SLA 3D Printing Materials

The materials used in resin light-curing (SLA) 3D printing are photopolymer resins that cure when exposed to UV light. These resins come in a variety of formulations, each designed to meet specific application requirements.

Common Types of SLA Resins

Selective Technology offers a wide range of materials for SLA 3D printing, 含む:

- Rigid Plastics: Such as 9400E, 8200, imported ABS, black resin, そして 8100. These resins are known for their stiffness and structural integrity, making them suitable for parts that need to maintain their shape under moderate stress.

- Specialty Resins: Beyond rigid plastics, there are resins formulated for specific properties like flexibility, 透明性, 耐熱性, または生体適合性. These expanded material options have broadened the applications of SLA 3D printing across various industries.

Material Characteristics

SLA resins are thermoset materials, which means once they are cured by UV light, they undergo a chemical reaction that makes them rigid and unable to be melted and reshaped like thermoplastics. This characteristic gives SLA parts their unique properties but also limits the material options compared to other 3D printing technologies that use thermoplastics.

Advantages of Resin Light-Curing (SLA) Molding

Resin light-curing (SLA) 3D printing offers a host of advantages that make it a preferred choice for many prototyping and industrial-grade applications.

Fine Detail and High Accuracy

One of the most significant advantages of SLA is its ability to produce parts with fine detail and high accuracy. The technology uses very thin layer thicknesses (範囲から 0.05 に 0.10 mm) and an extremely fine laser beam, allowing it to create tiny and intricate features with remarkable realism. Whether producing high-definition small parts or large parts up to two meters long, SLA maintains high precision and tight tolerances, ensuring that the printed parts closely match the digital design.

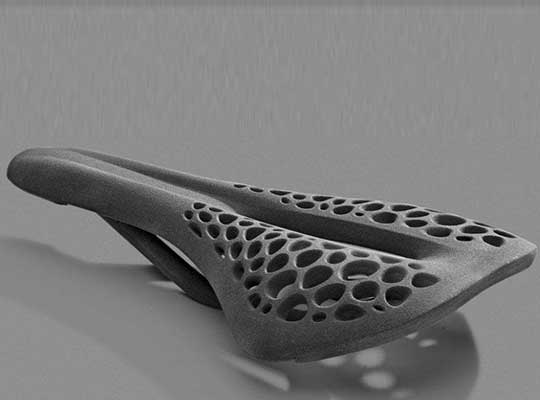

Suitability for Complex Designs

SLA is ideal for complex designs. While it does require the use of support structures, the liquid resin material allows for more fluidity in the design process compared to powder-based technologies like laser sintering molding (SLS) and HP nylon multi-flow fusion molding (MJF). This fluidity helps in achieving complex internal structural features that would be difficult or impossible to produce with other manufacturing methods.

Smooth Surface Finish

Thanks to the nature of the resin material and the curing process, SLA parts have a glass-smooth surface finish. This high-quality finish can replace common prototypes manufactured by HP Nylon Multi-Stream Fusion Molding (MJF) or Laser Sintering Molding (SLS). Both exterior and interior details are clearly visible, making SLA a great choice for functional prototypes where a polished look is important for design reviews or customer presentations.

Minimal Material Waste

SLA produces very little material waste. The thermosetting resin that is not cured during the printing process remains in the tank and can be reused for future prints. This lack of scrap is one of the key factors that make SLA a cost-effective option for many 3D printing projects, as it reduces material costs over time.

Limitations of Resin Light-Curing (SLA) Molding

While SLA 3D printing offers numerous benefits, it also has some limitations that are important to consider when choosing the right 3D printing technology for a project.

Limited Material Selection

Compared to thermoplastic fused deposition molding (FDM), the material options for SLA printing are not as extensive. SLA can only use thermoset resins, which restricts the range of construction materials available. While there are various resin formulations, they don’t offer the same diversity as the thermoplastics used in FDM, which include materials like PC, ナイロン, and PETG with different mechanical properties.

Lower Mechanical Properties

Most standard SLA resins are suitable for creating fine, detailed structures primarily used for display purposes or prototypes. しかし, in terms of strength and mechanical properties, SLA resins cannot compare to durable FDM materials like PC, ナイロン, or PETG. This makes SLA less recommended for applications where parts will be subjected to heavy stress or cyclic loads, as the parts may not hold up as well over time.

Lower Yields and Higher Costs

SLA 3D printing resins are generally more costly than FDM filaments or MJF powders. さらに, SLA printers typically produce fewer parts per unit of resin compared to the number of parts that can be produced from a roll of FDM wire or a batch of MJF powder. SLA printers also usually have a smaller build volume compared to FDM printers, which limits the size and number of parts that can be printed in a single job. これらの理由から, SLA is not the best choice for mass production due to time and cost constraints.

Applications of Resin Light-Curing (SLA) 3D印刷

Despite its limitations, SLA 3D printing finds applications in a wide range of industries, thanks to its precision, smooth surface finish, and ability to handle complex designs.

迅速なプロトタイピング

SLA is widely used in rapid prototyping. Designers and engineers can quickly turn their digital concepts into physical prototypes with fine details and smooth surfaces. These prototypes are invaluable for design reviews, 機能テスト, and getting feedback from stakeholders early in the product development process. The speed at which SLA can produce prototypes helps shorten the product development cycle.

Jewelry Making

The fine detail and high accuracy of SLA make it ideal for jewelry making. Jewelers can create intricate designs for rings, necklaces, and other pieces with precise dimensions and smooth surfaces. SLA-printed models can be used as masters for investment casting, allowing for the production of metal jewelry pieces with complex geometries.

Dental and Medical Applications

In the dental and medical fields, SLA is used to create custom models and devices. 例えば, dental professionals can use SLA to print accurate models of teeth for crown and bridge work, surgical guides for precise implant placement, and orthodontic appliances. The biocompatible resin options available for SLA make it suitable for certain medical applications where the printed parts come into contact with the body.

Architecture and Product Design

Architects use SLA to create detailed scale models of buildings and structures, showcasing design features with clarity. In product design, SLA prototypes help designers evaluate the form, フィット, and function of a product before moving to mass production. The smooth surface finish of SLA parts makes them look more like the final product, aiding in marketing and presentations.

Comparison with Other 3D Printing Technologies

To better understand the position of SLA 3D printing in the additive manufacturing landscape, let’s compare it with other popular 3D printing technologies:

| Technology | 材料タイプ | 表面仕上げ | Detail Resolution | Material Variety | に最適です |

| SLA | Photopolymer Resins | Glass-smooth | 高い (0.05-0.10 mm layer thickness) | 限定 (thermoset resins) | Prototypes with fine details, complex designs, 滑らかな表面 |

| FDM | Thermoplastic Filaments | Visible layer lines | 適度 (0.10-0.40 mm layer thickness) | 広範囲にわたる (PC, ナイロン, PETG, 等) | 機能部品, durable prototypes, mass production |

| SLS | Polyamide Powders | Grainy, slightly rough | 高い (0.06-0.15 mm layer thickness) | 良い (nylons, composites) | 強い, lightweight parts, functional prototypes |

| MJF | Nylon Powders | Smooth to slightly rough | 高い (0.08-0.12 mm layer thickness) | 良い (nylons) | 大量生産, 機能部品 |

Yigu Technology’s Perspective on SLA 3D Printing

Yigu Technology recognizes that resin light-curing (SLA) 3D printing is a game-changer in precision manufacturing. Its ability to produce detailed, smooth parts makes it vital for rapid prototyping and custom applications. While material and yield limitations exist, ongoing advancements in resins and printer tech are expanding its potential, making it a key tool for innovation across industries.

よくある質問 (よくある質問)

- Is SLA 3D printing suitable for mass production?

いいえ, SLA is not ideal for mass production. It has higher resin costs, lower yields per unit of material, and smaller build volumes compared to technologies like FDM or MJF, making it less cost-effective for large-scale production runs.

- Can SLA 3D printed parts be used in functional applications under stress?

Most standard SLA resins are not suitable for functional applications under heavy stress or cyclic loads. Their mechanical properties are inferior to durable FDM materials like PC or nylon, so they are better suited for prototypes or low-stress applications.

- Are SLA resins recyclable?

The uncured resin that remains in the tank after printing can be reused for future prints, 廃棄物を減らす. しかし, once resin is cured, it becomes a thermoset material that cannot be melted and reshaped, so cured SLA parts are not easily recyclable like some thermoplastic parts.