If you’re turning a product idea into reality, understanding the prototype making process is essential to avoid delays, wasted materials, and design flaws. A well-executed prototype bridges the gap between digital designs and physical products—helping you test functionality, refine aesthetics, and validate ideas before mass production. 下に, we break down every key stage of the process, データ付き, ツール, and tips to ensure your prototype meets your goals.

1. Design Phase: Lay the Groundwork with Precise Digital Models

The design phase is where your idea becomes a structured plan—this stage sets the tone for the entire prototype making process. Rushing through design leads to 40% of prototype reworks later, so take time to get it right.

Key Steps in the Design Phase

- 3D Modeling: Use professional software to create a detailed digital model of your product. The most popular tools include:

- CAD (コンピューター支援設計): Ideal for 2D sketches and 3D models of mechanical parts (例えば。, ギア, ブラケット).

- SOLIDWORKS: Best for complex 3D designs with moving components (例えば。, a folding chair or a small appliance).

- 融合 360: Great for startups or small teams—combines 3D modeling, simulation, and collaboration tools in one platform.

Data spotlight: 85% of professional product developers use SolidWorks or CAD for 3D modeling, as these tools reduce design errors by 35% compared to basic software.

- デザインレビュー: Gather feedback from engineers, デザイナー, and potential users to refine the 3D model. Ask critical questions:

- Does the design meet all technical specifications (例えば。, サイズ, weight, material compatibility)?

- Are there any hard-to-manufacture features (例えば。, overly thin walls that might break during processing)?

- Will the prototype be easy to test for functionality (例えば。, can buttons be pressed or hinges moved freely)?

ヒントの場合: Conduct 2–3 design reviews—each review catches an average of 10–15 small flaws that would otherwise ruin the prototype.

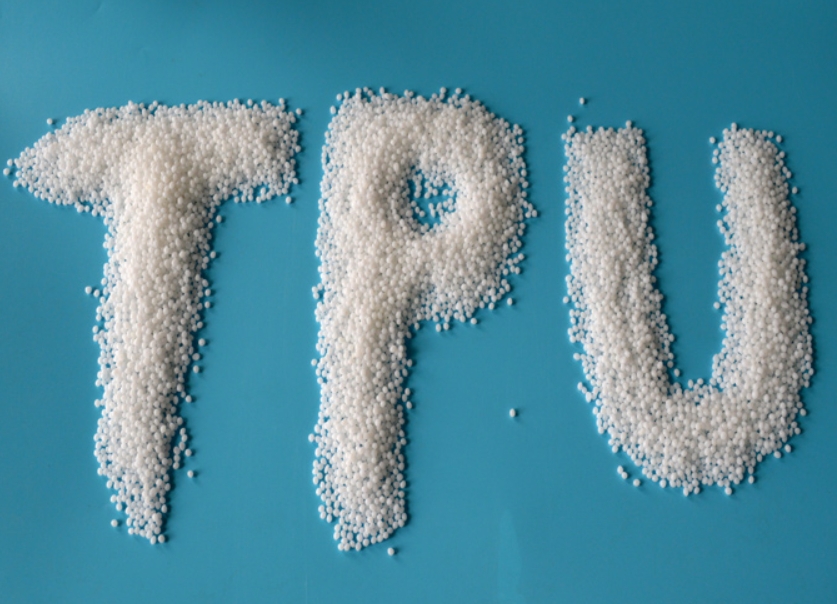

2. 材料の選択: Choose the Right Material for Your Prototype Goals

Selecting the right material is make-or-break for your prototype—it affects durability, 外観, and how well the prototype mimics the final product. The table below compares the most common prototype materials:

| 材料 | キープロパティ | に最適です | 料金 (kgあたり) | Processing Difficulty |

| 腹筋 | 強い, 耐衝撃性, easy to paint | Electronics prototypes (例えば。, 電話ケース, リモートコントロール) | \(2.50- )4.00 | 低い (works with CNC and 3D printing) |

| PC (ポリカーボネート) | 耐熱性, 透明, shatterproof | Prototypes needing clarity (例えば。, lamp shades, 安全ゴーグル) | \(3.80- )5.50 | 中くらい (requires higher temperatures for 3D printing) |

| ナイロン | フレキシブル, 耐摩耗性, 化学耐性 | Prototypes with moving parts (例えば。, ジッパー, ギア) | \(4.20- )6.00 | 中くらい (水分を吸収します, needs pre-drying before processing) |

| アルミニウム | 軽量, strong, corrosion-resistant | Metal prototypes (例えば。, ラップトップフレーム, small tool bodies) | \(2.00- )3.50 | 中くらい (works with CNC machining, needs sanding for smoothness) |

How to choose: If your prototype is for a consumer electronic device (例えば。, a wireless speaker), ABS is a great pick—it’s affordable and easy to customize. For a heat-resistant prototype (例えば。, a coffee mug handle), PC or nylon is better.

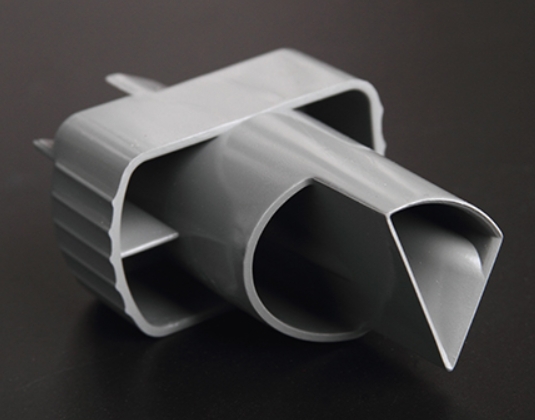

3. Processing Stage: Turn Digital Models into Physical Prototypes

The processing stage transforms your 3D model and chosen material into a tangible prototype. This phase uses a mix of manual and automated techniques to balance precision and flexibility.

Common Processing Methods

- Hand Making: Best for simple, low-cost prototypes (例えば。, a foam model of a furniture design). It involves cutting, gluing, and shaping materials by hand with basic tools (例えば。, scissors, サンドペーパー, hot glue guns). Hand making is fast (1–2 days for small prototypes) but less precise—tolerances range from ±1mm to ±3mm. It’s ideal for early-stage “proof of concept” prototypes, not functional tests.

- CNC加工: The most popular method for high-precision prototypes. CNC (Computer Numerical Control) machines use computer code to carve solid blocks of material (プラスチック, 金属, 木材) into the exact shape of your 3D model. Key benefits include:

- 精度: Tolerances as tight as ±0.01mm—critical for prototypes that need to fit together (例えば。, a phone case and a screen protector).

- 汎用性: Works with all common prototype materials (腹筋, PC, アルミニウム, ナイロン).

- スピード: Takes 3–5 days for most prototypes (faster than 3D printing for large parts).

Data note: CNC machining produces 60% of functional prototypes, as it mimics the manufacturing process of final products more closely than 3D printing.

- Hand Grinding: CNC加工後, use sandpaper (180–600 grit) to smooth rough edges, remove burrs (small pieces of material left from cutting), and refine the surface. Start with coarse grit (180) to fix large imperfections, 次に、細かいグリットに移動します (600) 滑らかな仕上げのため. Hand grinding improves the prototype’s aesthetics and prevents scratches during testing.

- 組み立て: If your prototype has multiple parts (例えば。, a toy with a body, ホイール, and axles), assemble them with precision. Use appropriate fasteners:

- Screws: For parts that need to be taken apart (例えば。, a prototype laptop for internal testing).

- Adhesives: For permanent bonds (例えば。, gluing a logo to a prototype water bottle).

- Snap Fits: For parts that click together (例えば。, a plastic container lid and body).

警告: Poor assembly leads to 25% of prototype failures—always test if parts fit snugly but can move (必要に応じて) before finalizing.

4. Surface Treatment: Enhance Aesthetics and Functionality

Surface treatment makes your prototype look and perform like the final product. The right treatment can boost durability, improve grip, or add brand-specific colors—key for user testing and stakeholder presentations.

Most Common Surface Treatments

| Treatment Type | それがどのように機能するか | に最適です | 処理時間 |

| Grinding | Use sandpaper or a grinding machine to smooth the surface (finer than hand grinding). | Prototypes needing a matte finish (例えば。, a tool handle for better grip) | 1-2時間 |

| スプレー | Apply paint or coating with a spray gun. Choose from matte, 光沢, or metallic finishes. | Prototypes for aesthetic testing (例えば。, a phone case with a brand color) | 2–3 hours (plus drying time) |

| 電気めっき | Deposit a thin metal layer (例えば。, クロム, ニッケル) on the prototype surface. | Metal prototypes needing corrosion resistance (例えば。, a prototype faucet) | 1–2日 |

| Anodizing | Create a protective oxide layer on aluminum prototypes (adds color and prevents scratches). | Aluminum prototypes (例えば。, a laptop frame or a bike handlebar) | 1 日 |

| Silk Screen Printing | Transfer patterns, 文章, or logos onto the prototype using a silk screen stencil. | Prototypes needing labels (例えば。, a control panel with “on/off” text) | 3–4時間 |

| Laser Engraving | Use a laser to carve permanent designs (例えば。, serial numbers, ロゴ) into the surface. | Prototypes needing unique identifiers (例えば。, a medical device prototype) | 1-2時間 |

ヒントの場合: For user testing, combine 2–3 treatments (例えば。, anodizing + silk screen printing) to make the prototype feel like a real product—this leads to more accurate feedback.

5. Inspection and Testing: Validate the Prototype

Inspection and testing ensure your prototype meets design goals and is ready for the next stage (例えば。, investor pitches, mass production planning). Skipping this step risks moving forward with a flawed design.

Quality Inspection

Check the prototype against your original design specs:

- Size: Use a caliper or ruler to verify dimensions (例えば。, Is the prototype 10cm long, as designed?).

- 外観: Look for scratches, uneven surfaces, or misaligned parts (例えば。, Is the sprayed color consistent across the entire prototype?).

- 材料: Confirm the correct material was used (例えば。, Is the prototype made of ABS, not a cheaper plastic?).

Standard: A good prototype should meet 95% of the design specs—any deviations should be small and non-impacting (例えば。, a 0.1mm difference in length).

機能テスト

Test how well the prototype works for its intended use. Examples include:

- For a phone case: Drop it from 1.5 meters to test durability (does it protect a dummy phone inside?).

- For a water bottle: Fill it with water and check for leaks (does the lid seal properly?).

- For a small appliance: Plug it in (if electric) and test its core function (does a prototype blender mix ingredients?).

データポイント: 70% of prototypes fail their first functional test—this is normal! Use the feedback to refine the design (例えば。, add more support to a weak part of the phone case).

6. Packaging & Delivery: Protect and Transport the Prototype

Once your prototype passes inspection and testing, package it properly to avoid damage during transportation—whether you’re sending it to a client, a testing lab, or your own team.

Packaging Steps

- Wrap the Prototype: Use bubble wrap or foam to cover the prototype—pay extra attention to fragile parts (例えば。, a transparent PC screen on a prototype device).

- Choose the Right Box: Use a rigid cardboard box that’s 2–3 inches larger than the prototype on all sides. Fill empty space with packing peanuts or crumpled paper to prevent movement.

- Label Clearly: Add labels like “Fragile,” “Handle with Care,” and the destination address. Include a packing slip with details (例えば。, prototype name, number of parts, intended use).

Delivery Tips

- For local delivery (within the same city): Use a courier service (例えば。, FedEx, UPS) with same-day or next-day delivery—this reduces the risk of long-term storage damage.

- For international delivery: Choose a service with tracking and insurance (例えば。, DHL)—international shipping can take 5–7 days, and insurance covers damage or loss.

Yigu Technologyの視点

Yiguテクノロジーで, we see the prototype making process as a collaborative journey—each stage relies on the previous one to create a useful prototype. We advise clients to invest time in the design and material selection phases, as these steps reduce reworks later. 機能的なプロトタイプ用, we often recommend CNC machining over hand making, as it delivers the precision needed for accurate testing. We also emphasize surface treatment: a well-finished prototype not only impresses stakeholders but also helps users provide honest feedback. Our team works closely with clients to tailor each step to their product type—whether it’s a small electronics prototype or a large industrial part.

よくある質問

- How long does the entire prototype making process take?

It depends on the prototype’s complexity. A simple hand-made prototype (例えば。, a foam cup design) takes 2–3 days. A complex CNC-machined prototype (例えば。, a small appliance with multiple parts) takes 2–3 weeks. On average, most prototypes are completed in 1–2 weeks.

- Can I skip the design review stage to save time?

No—skipping design review often leads to costly reworks. 例えば, if a design has a hard-to-machine feature, you’ll waste time and material making a prototype that can’t be tested. Design reviews take 1–2 days but save 1–2 weeks of rework later.

- Which surface treatment is best for a prototype that will be user-tested?

Combine spraying (for color) and silk screen printing (for labels) for most user-tested prototypes. This makes the prototype look like the final product, so users give feedback on real-world use (例えば。, “The logo is hard to read” or “The red color is too bright”). If the prototype is metal, add anodizing for durability during repeated handling.