When it comes to manufacturing medical device shells, choosing the right material is a critical decision that impacts patient safety, device performance, and regulatory compliance. The 外壳 (シェル) of medical devices serve as protective enclosures, structural supports, and barriers between internal components and external environments. This guide explores the most commonly used materials for medical device shell machining, their properties, アプリケーション, and selection criteria to help manufacturers make informed choices.

Essential Materials for Medical Device Shell Machining

Medical device shells require a unique combination of properties—biocompatibility, 耐久性, sterilizability, and often aesthetic appeal. Here are the primary materials used in their production:

Medical-Grade Plastics

Plastics are widely favored for non-implantable medical device shells due to their versatility, cost-effectiveness, and ease of machining.

- 腹筋 (アクリロニトリルブタジエンスチレン): A popular choice for diagnostic equipment housings and instrument casings. It offers good impact resistance, dimensional stability, and can be easily colored or textured. ABS has a tensile strength of 3,000–5,000 psi and withstands autoclaving at 121°C for limited cycles.

- ポリカーボネート (PC): Valued for its transparency, 耐衝撃性が高い, and rigidity. Medical-grade PC is used in 外壳 (シェル) of surgical lights, endoscope housings, and medication delivery devices. It can withstand repeated autoclaving and meets USP Class VI biocompatibility standards.

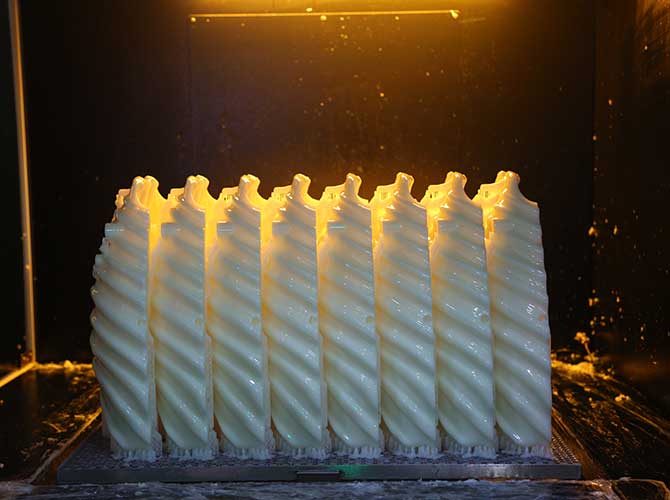

- ピーク (Polyetheretherketone): An advanced high-performance plastic suitable for demanding applications. PEEK offers excellent chemical resistance, 熱安定性 (up to 260°C), and radiolucency. It’s used in 外壳 (シェル) of implantable devices, surgical instruments, and MRI-compatible equipment.

- Ultem (PEI – ポリutimide): Known for its strength, broad chemical resistance, and ability to withstand repeated sterilization cycles (autoclave, EtO, gamma). Ultem is commonly used for reusable instrument trays, surgical device (シェル), and diagnostic equipment components.

Stainless Steels

Stainless steels are preferred for medical device shells requiring strength, 耐食性, および耐久性.

- 316L Stainless Steel: The gold standard for many medical applications. This low-carbon stainless steel offers excellent corrosion resistance in bodily fluids and harsh cleaning environments. It has a tensile strength of 70,000–90,000 psi and is easily machinable. 316L is used in 外壳 (シェル) of surgical instruments, patient monitors, and reusable medical equipment.

- 17-4 PH Stainless Steel: A precipitation-hardening stainless steel providing higher strength (tensile strength up to 170,000 psi) than 316L. It offers good corrosion resistance and is used for 外壳 (シェル) of heavy-duty medical devices, 手術ツール, and equipment requiring high durability.

Titanium Alloys

Titanium alloys are chosen for their exceptional strength-to-weight ratio and biocompatibility.

- Ti-6Al-4V (Grade 5 チタン): A versatile alloy used in 外壳 (シェル) of portable medical devices, surgical instruments, and some implantable device housings. It has a tensile strength of 130,000–140,000 psi while being 40% lighter than steel. Titanium offers superior corrosion resistance in physiological environments.

- Commercially Pure Titanium (Grades 1-4): Used when extreme strength isn’t required but biocompatibility and corrosion resistance are critical. Grade 2 titanium is commonly used for 外壳 (シェル) of pacemakers, defibrillators, and other implantable device casings.

Aluminum Alloys

Aluminum is valued for its lightweight properties and cost-effectiveness.

- 6061 アルミニウム: A popular choice for non-sterile medical device 外壳 (シェル) such as MRI machine enclosures, hospital bed components, and equipment frames. It offers good machinability, 耐食性, and can be anodized for enhanced durability. 6061 has a tensile strength of 30,000–40,000 psi.

- 7075 アルミニウム: Used when higher strength is needed. This alloy is employed in 外壳 (シェル) of portable medical devices and equipment requiring a strong, lightweight structure.

| 材料 | 抗張力 | Biocompatibility | Sterilization Methods | Common Applications |

| ABSプラスチック | 3,000–5,000 psi | Limited contact | Limited autoclave, EtO | Diagnostic equipment housings |

| ポリカーボネート | 9,000–11,000 psi | USP Class VI | Autoclave, gamma, EtO | Surgical light shells, endoscope housings |

| ピーク | 10,000–15,000 psi | ISO 10993 compliant | Autoclave, gamma | Implantable device shells, 手術ツール |

| 316L Stainless Steel | 70,000–90,000 psi | 素晴らしい | All methods | Surgical instrument shells, monitors |

| Ti-6Al-4V | 130,000–140,000 psi | Superior | All methods | Portable device shells, implant housings |

| 6061 アルミニウム | 30,000–40,000 psi | Good for external use | Limited autoclave | MRI enclosures, equipment frames |

Critical Factors in Material Selection for Medical Device Shells

Choosing the right material for a medical device shell involves evaluating several key factors to ensure safety, パフォーマンス, and regulatory compliance:

Biocompatibility

Biocompatibility is non-negotiable for any material in contact with patients or medical staff. The material must not cause adverse reactions, toxicity, or inflammation. Standards like ISO 10993 and USP Class VI provide guidelines for evaluating biocompatibility. For 外壳 (シェル) in direct contact with skin or bodily fluids, materials like 316L stainless steel, チタン, and medical-grade PEEK are preferred due to their proven biocompatibility.

Sterilization Compatibility

Medical device shells must withstand repeated sterilization without degradation. Common sterilization methods include:

- Autoclaving (steam): Requires materials to withstand high temperatures (121–134°C) and pressure. 金属, ピーク, Ultem, and certain polycarbonates handle autoclaving well.

- Gamma radiation: Can cause degradation in some plastics. ピーク, Ultem, and metals are radiation-stable.

- Ethylene Oxide (EtO): Compatible with most plastics and metals but requires proper outgassing.

機械的特性

The material must possess the necessary strength, rigidity, and impact resistance for its intended use:

– 外壳 (Shells) of portable devices need lightweight materials with good strength (チタン, アルミニウム).

– 外壳 (Shells) protecting delicate internal components require impact resistance (ポリカーボネート, 腹筋).

- Reusable device 外壳 (シェル) demand high durability and wear resistance (ステンレス鋼, Ultem).

Corrosion Resistance

Exposure to cleaning agents, disinfectants, and bodily fluids makes corrosion resistance essential. Titanium and 316L stainless steel offer superior corrosion resistance, making them ideal for reusable devices. For plastic 外壳 (シェル), PEEK and Ultem provide excellent chemical resistance.

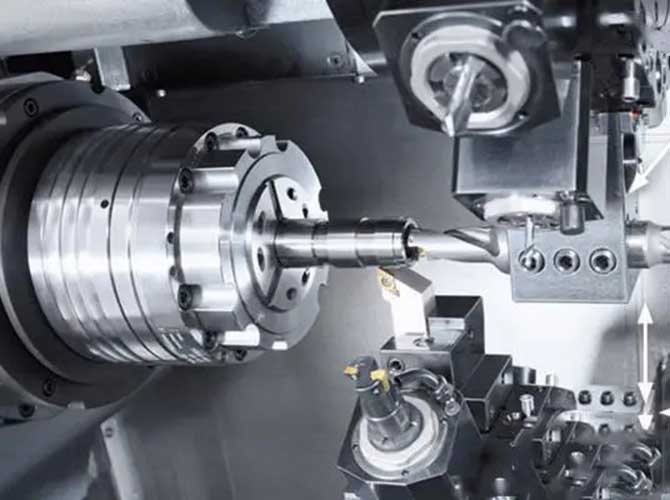

Machinability and Manufacturing Costs

Material machinability affects production efficiency and costs:

- Aluminum and 316L stainless steel are relatively easy to machine, reducing production time and costs.

- Titanium and PEEK are more challenging to machine, requiring specialized tools and slower speeds, which increases manufacturing costs.

- While some plastics have low material costs, their machining costs can vary based on required precision and complexity.

Regulatory Compliance

Materials must meet relevant regulatory standards for medical devices, such as FDA, CE, or ISO requirements. Using materials with established regulatory acceptance simplifies the approval process. Most medical-grade plastics, stainless steels, and titanium alloys have a proven regulatory track record.

Application-Specific Material Recommendations for Medical Device Shells

Different medical device types have unique requirements that influence material selection for their 外壳 (シェル):

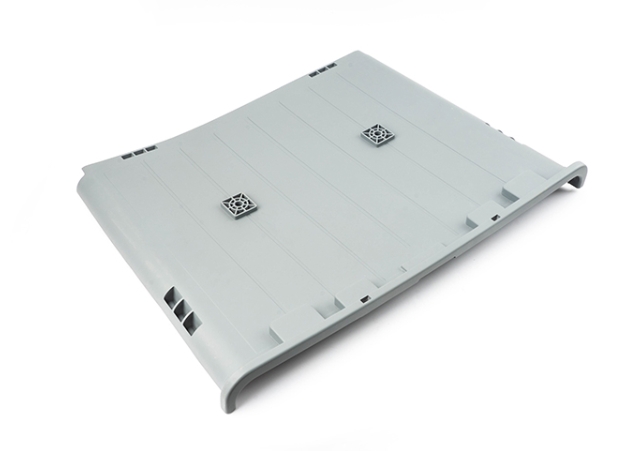

Diagnostic Equipment Shells

Diagnostic devices like ultrasound machines, blood analyzers, and imaging equipment require 外壳 (シェル) that are durable, aesthetically pleasing, and often lightweight.

- Recommended Materials: 腹筋 (for cost-sensitive components), ポリカーボネート (for transparent sections), and aluminum alloys (for structural frames).

- キープロパティ: 寸法安定性, 耐衝撃性, and compatibility with internal electronics.

Surgical Instrument Housings

Surgical instruments and handpieces need 外壳 (シェル) that can withstand repeated sterilization, provide a secure grip, and protect internal mechanisms.

- Recommended Materials: 316L stainless steel (for reusable instruments), ピーク (for lightweight, high-performance tools), and Ultem (for handles and casings).

- キープロパティ: Corrosion resistance, 耐熱性, and ergonomic design flexibility.

Implantable Device Casings

外壳 (Shells) for implantable devices like pacemakers, defibrillators, and neurostimulators must be biocompatible, hermetically sealed, and resistant to bodily fluids.

- Recommended Materials: Titanium alloys (Grade 2 and Grade 5) and PEEK.

- キープロパティ: Biocompatibility, 耐食性, and radiolucency (for imaging compatibility).

Portable Medical Device Shells

Portable devices such as insulin pumps, portable monitors, and handheld diagnostic tools require lightweight, durable 外壳 (シェル).

- Recommended Materials: Titanium alloys (for strength-to-weight ratio), アルミニウム (for cost-effectiveness), and reinforced plastics like Ultem.

- キープロパティ: 軽量, 耐衝撃性, and battery compatibility.

Yigu Technologyの視点

Yiguテクノロジーで, we prioritize material selection that balances performance, safety, and cost for medical device shells. We recommend 316L stainless steel for reusable devices requiring durability and 316L 不锈钢 for reusable 设备外壳,while PEEK excels in high-performance applications. Our engineering team collaborates with clients to evaluate specific needs, ensuring each 外壳材料 meets regulatory standards and application requirements for optimal device performance.

よくある質問 (よくある質問)

- What is the most biocompatible material for medical device shells?

Titanium alloys (especially Grade 2 and Grade 5) and 316L stainless steel are among the most biocompatible materials, meeting ISO 10993 standards. They are ideal for 外壳 (シェル) in direct or prolonged contact with the human body.

- Which materials can withstand repeated autoclaving for medical device shells?

Materials that handle repeated autoclaving include 316L stainless steel, titanium alloys, ピーク, Ultem, and certain medical-grade polycarbonates. These maintain their properties after multiple cycles of high-temperature steam sterilization.

- Are plastic shells suitable for reusable medical devices?

はい, certain plastics like PEEK and Ultem are suitable for reusable device 外壳 (シェル). They offer good chemical resistance, withstand repeated sterilization, and provide a lightweight alternative to metals for appropriate applications.