In modern manufacturing, low-pressure infusion molding stands out for its ability to produce complex, high-performance plastic parts—from automotive components to medical devices. But to fully leverage its benefits, you first need to understand its core principle: how it transforms liquid raw materials into finished products. This article breaks down the principle of low-pressure infusion molds step by step, explains the key technologies that support it, and shares real-world examples to help you apply this knowledge to your projects.

1. Core Principle of Low-Pressure Infusion Mold: Built on RIM Technology

At its heart, low-pressure infusion molding is based on RIM (反応射出成形) テクノロジー—a process that relies on chemical reactions and gentle pressure to shape parts. Unlike high-pressure injection molding (which forces molten plastics into molds), low-pressure infusion uses liquid components that react and solidify inside the mold. Here’s a detailed breakdown of the principle’s step-by-step workflow:

ステップ 1: Storage of Liquid Raw Materials

The process starts with storing two or more liquid components (the “stock solution”) in separate, specialized 圧力容器. These vessels maintain the liquids at a precise temperature (typically 25–40°C) and low pressure (0.5–1.5 bar) to keep them in a stable, flowable state. This stability is critical—if the liquids thicken or react prematurely, the entire process fails. 例えば, a automotive parts manufacturer might store a polyol and an isocyanate (two common RIM components) in these vessels, keeping them ready for mixing.

ステップ 2: Precise Metering & Uniform Mixing

次, a metering pump (a key piece of equipment for accuracy) delivers the liquid components to a ミキシングヘッド in exact proportions (例えば。, 1:1 または 2:1, depending on the material formula). The mixing head then spins at high speeds (1,500–3,000 rpm) to blend the components evenly. This step is non-negotiable for the principle’s success: uneven mixing would lead to inconsistent curing and weak spots in the final product. A study by the Society of Plastics Engineers found that metering accuracy (error ≤ ±1%) improves part quality by 40%.

ステップ 3: Low-Pressure Perfusion & Mold Filling

Once mixed, the liquid blend is injected into a closed mold—but at a much lower pressure than traditional methods (usually 5–30 bar, far below injection molding’s 100–2,000 bar). For the mold to fill completely, the mixed liquid must have 低粘度 (50–500 cP, similar to motor oil). This low viscosity lets the liquid flow into every detail of the mold—even complex cavities, 薄い壁, or intricate textures—without leaving air bubbles or gaps. 例えば, a furniture maker uses this step to fill molds for curved chair armrests, ensuring the final product has no surface defects.

ステップ 4: Chemical Reaction & 硬化

Inside the closed mold, the mixed liquid components undergo a chemical reaction (usually polymerization). This reaction causes the liquid to cross-link (form strong molecular bonds) and solidify into the shape of the mold. Curing is fast—typically 5–20 minutes—because the reaction generates its own heat (exothermic), accelerating solidification. A medical device manufacturer, 例えば, relies on this quick curing to produce 500+ plastic instrument housings per day, meeting tight production deadlines.

ステップ 5: demolding & 後処理

Once fully cured, the mold opens, and the finished part is removed (demolding). The part then goes through simple post-processing: deburring (removing small plastic flashes), sanding (smoothing surfaces), または 絵画 (adding color or protection). Unlike injection-molded parts (which often need extensive finishing), low-pressure infusion parts require minimal post-processing—thanks to the mold’s precision and the liquid’s even flow.

2. Key Technical Elements That Support the Principle

The principle of low-pressure infusion molding doesn’t work in a vacuum—it depends on three critical technical elements. These elements ensure the process runs smoothly and produces high-quality parts. The table below outlines their roles and requirements:

| Key Technical Element | Core Role in the Principle | Critical Requirements |

| Liquid Components | Provide the “building blocks” for the chemical reaction | Low viscosity (50–500 cP), good chemical compatibility, fast curing (5–20 mins) |

| Pressure Vessels | Keep raw materials stable before mixing | 温度制御 (25–40°C), pressure control (0.5–1.5 bar), corrosion-resistant (for acidic/alkaline liquids) |

| Mixing Head | Ensure uniform blending of components | High-speed rotation (1,500–3,000 rpm), easy cleaning (to prevent cross-contamination), 耐久性 (for daily use) |

| Closed Mold | Shape the liquid into the final product | 耐熱性 (to handle curing heat), sealed (no liquid leakage), smooth inner surface (for high-quality parts) |

例えば, a toy manufacturer once struggled with uneven part strength. After checking their setup, they realized their mixing head was rotating too slowly (1,000 RPM instead of 2,000 RPM), leading to poor component blending. By adjusting the mixing head to meet the requirement, they fixed the strength issue and reduced part defects by 35%.

3. Why the Principle Delivers Unmatched Advantages

The unique principle of low-pressure infusion molding directly translates to four core advantages—making it a top choice for many industries. Here’s how each advantage stems from the principle:

アドバンテージ 1: Strong Ability to Make Complex-Shaped Products

Because the process uses low-viscosity liquid components (per Step 3), the mixture can fill even the most complex mold cavities—like parts with undercuts, 薄い壁 (down to 1mm), or intricate patterns. Traditional molding methods (例えば。, 圧縮成形) often fail here, as their thicker materials can’t flow into small spaces. A European automotive supplier uses this advantage to produce complex dashboard frames with integrated wiring channels—something high-pressure injection molding couldn’t achieve without splitting the part into 3 作品.

アドバンテージ 2: Short Production Cycles

The fast chemical curing (ステップ 4) cuts down production time dramatically. From mixing to demolding, a single part takes just 15–30 minutes—2–3x faster than traditional RIM or injection molding for complex parts. A furniture company reported reducing production time for a curved sofa leg from 1 hour (射出成形) に 20 分 (low-pressure infusion), boosting daily output by 150%.

アドバンテージ 3: High Degree of Automation

Every step of the principle—from storage (圧力容器) to metering (pumps) to mixing (heads)—can be automated. This reduces human error and increases consistency: automated systems maintain precise temperature, プレッシャー, and mixing ratios 24/7. A medical device plant achieved 98% part consistency after automating their low-pressure infusion line—up from 85% when using manual mixing.

アドバンテージ 4: Good Physical & 機械的特性

The chemical cross-linking (ステップ 4) creates strong, 耐久性のある部分. These parts have high impact resistance (まで 25 KJ /), good heat resistance (can withstand 80–120°C), and stable dimensions (low shrinkage, ≤ 1%). A construction equipment maker uses this to produce plastic hydraulic valve covers—these covers survive years of vibration and temperature changes, with a failure rate 60% lower than injection-molded alternatives.

4. Real-World Industry Applications of the Principle

The principle of low-pressure infusion molding is used across four key industries—each leveraging a different part of the process. Here are practical examples:

- 自動車産業: Producing interior parts (例えば。, door panels, armrests) and exterior parts (例えば。, bumper covers). A U.S. carmaker uses the process to make lightweight, impact-resistant bumper ends—thanks to the principle’s ability to use reinforced liquid components (例えば。, glass-fiber-filled resins) for extra strength.

- Furniture Industry: Creating curved or sculpted parts (例えば。, chair backs, table legs). A Scandinavian furniture brand uses low-pressure infusion to make seamless, curved chair shells—no seams mean easier cleaning and a more modern look.

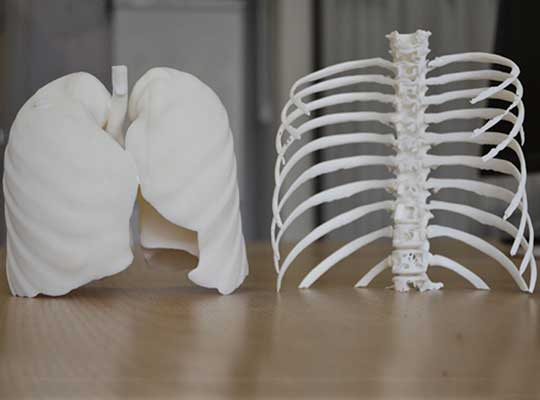

- Medical Equipment Industry: Manufacturing sterile, high-strength parts (例えば。, instrument housings, wheelchair armrests). The principle’s closed mold (ステップ 3) prevents contamination, and the cured parts meet medical-grade standards (例えば。, ISO 10993 生体適合性のため).

- Toy Industry: Making large, complex toys (例えば。, ride-on toy frames). The short production cycle (アドバンテージ 2) lets toy makers quickly scale up for holiday demand—one toy company produced 10,000 ride-on car frames in 2 weeks using low-pressure infusion.

Yigu Technology’s Perspective on Low-Pressure Infusion Mold Principle

Yiguテクノロジーで, we believe the principle of low-pressure infusion molding is a game-changer for manufacturers chasing complexity and efficiency. We focus on optimizing the key steps of the principle: we design high-precision metering pumps (error ≤ ±0.5%) to ensure component accuracy, and customize mixing heads for different liquid viscosities. For clients in automotive and medical fields, we tailor pressure vessel temperature control to their materials, ensuring stable reactions. By aligning our solutions with the core principle, we help clients cut defects by 30–40% and boost production efficiency by 50%—turning the principle into real business value.

よくある質問: Common Questions About Low-Pressure Infusion Mold Principle

1. What pressure range is used in the “low-pressure perfusion” step of the principle?

The pressure ranges from 5–30 bar—far lower than high-pressure injection molding (100–2,000 bar). This low pressure protects delicate molds and ensures the liquid component flows gently into all mold cavities without causing damage.

2. Can the liquid components in the principle be recycled if they’re not used immediately?

Most liquid components (例えば。, polyols, isocyanates) can be recycled if stored properly in the pressure vessels (per Step 1). しかし, once mixed in the mixing head (ステップ 2), they start reacting and can’t be reused—so it’s critical to meter only the amount needed for each mold.

3. How does the principle handle mold release? Do I need to use release agents?

Because the cured part has low adhesion to most mold materials (例えば。, アルミニウム, 鋼鉄), minimal release agent is needed—often just a light spray before the first use of the mold. This is a big advantage over injection molding, which requires frequent release agent applications (adding cost and time).