If you’ve ever wondered what happens after the CNC machine finishes cutting, milling, or turning your part, you’re not alone. While CNC machining is celebrated for its precision in shaping raw materials into intricate components, the journey from a rough workpiece to a ready-to-use product doesn’t end there. 後処理 is the unsung hero that transforms functional but imperfect parts into high-quality, performance-ready components. このガイドで, we’ll explore the essential post-processing processes in CNC machining, why they matter, and how they elevate your parts to meet strict aesthetic, functional, and quality standards.

Why Post-Processing is a Non-Negotiable Step in CNC Machining

Imagine receiving a CNC-machined part that’s technically the right shape but covered in sharp burrs, ツールマーク, and has inconsistent surface texture. Would it meet your product’s requirements? おそらくそうではありません. Post-processing bridges the gap between a “machined part” and a “finished product” by addressing three critical areas:

- Surface Imperfections: CNC cutting, 掘削, and milling leave behind burrs, sharp edges, and tool marks that can compromise safety, 機能, and aesthetics.

- 機械的特性: Raw machined parts often lack the hardness, ductility, or corrosion resistance needed for their intended use.

- Quality Assurance: Without inspection, even minor dimensional deviations can lead to assembly failures or performance issues in critical applications.

In short, post-processing ensures your CNC parts aren’t just accurate—they’re reliable, 耐久性, and ready to perform in real-world conditions. 今, let’s dive into the key processes that make this transformation possible.

Essential Post-Processing Techniques in CNC Machining

1. Deburring: Eliminating Imperfections for Safety and Functionality

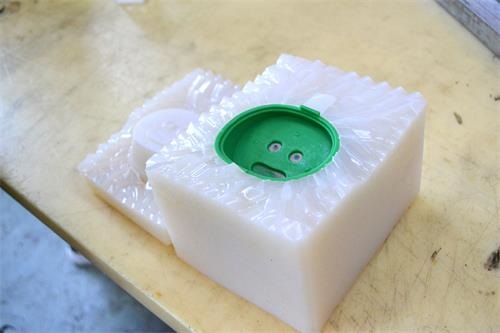

Burrs—those tiny, sharp protrusions left by cutting tools—might seem insignificant, but they’re a major concern. They can cause injuries during handling, damage mating components, and even create friction that reduces part lifespan. Deburring is the process of removing these imperfections, and there’s no one-size-fits-all method. The table below breaks down the most common deburring techniques, their best uses, and automation levels:

| Deburring Technique | 説明 | に最適です | Automation Level |

| Manual Deburring | Hand tools like scrapers, ファイル, or sandpaper are used. | Low-volume, complex, or delicate parts | 低い |

| Mechanical Deburring | Includes grinding, tumbling, or abrasive brushes. | 大量生産, metal parts | Medium to High |

| Thermal Deburring (TEM) | Uses explosive gas in a chamber to blast off burrs. | Hard-to-reach internal burrs | 中くらい |

| Cryogenic Deburring | Freezes components to make burrs brittle, then blasts them with media. | 金属, soft plastics | Medium to High |

| Electrochemical Deburring | Removes burrs via controlled electrochemical reactions. | 精密部品, small features | 中くらい |

| Ultrasonic Deburring | Uses ultrasonic energy in liquid to dislodge burrs. | Small and fragile parts | Low to Medium |

| High-Pressure Water Jet | Focused high-pressure water cleans away small burrs. | Internal channel burrs | Medium to High |

例えば, if you’re producing medical instruments with tiny internal channels, thermal or high-pressure water jet deburring would be ideal for reaching those hard-to-access areas. For bulk production of simple metal parts, mechanical tumbling offers a cost-effective, automated solution.

2. Surface Finishing: Enhancing Aesthetics and Performance

A part’s surface finish isn’t just about looks—it directly impacts performance. A rough surface can increase friction, reduce corrosion resistance, or even interfere with seals in hydraulic components. Surface finishing techniques transform raw surfaces into ones that meet specific functional and aesthetic needs. Here’s a breakdown of the most popular methods:

| 方法 | 説明 | Surface Result | 一般的な材料 | Typical Use Cases |

| 研磨 | Abrasive substances and wheels create a smooth, reflective surface. | Mirror finish or high gloss | 金属 (アルミニウム, 鋼鉄), プラスチック | Aesthetic components, optical instruments |

| サンディング | Abrasive belts or paper smooth surfaces and remove tool marks. | Matte or semi-gloss finish | プラスチック, 木材, soft metals | Furniture parts, plastic prototypes |

| Bead Blasting | Glass or ceramic beads are blasted at high speed to create texture. | Uniform matte finish | アルミニウム, ステンレス鋼 | ツーリング, aerospace hardware, エンクロージャー |

| Tumbling | Parts rotate with abrasive materials to smooth edges and polish. | Smooth edges, consistent finish | プラスチック, 金属 | Bulk finishing of small to medium parts |

| Anodizing | Electrochemical process forms a protective oxide layer (mainly for aluminum). | Clear or color-coated finish | アルミニウム | Consumer electronics, 航空宇宙, 建築 |

| 電気めっき | Metal is deposited onto the surface via electrolysis. | Shiny, corrosion-resistant | 鋼鉄, 銅, 真鍮 | Decorative parts, electrical components |

| Powder Coating | Dry powder is sprayed and cured under heat to form a hard coating. | Colored, durable finish | 金属 | 自動車部品, industrial equipment |

| 絵画 | Liquid paint is sprayed manually or automatically for color and protection. | Matte, 光沢, or textured | プラスチック, 金属 | Casings, 装飾的な部分, 看板 |

Consider the aerospace industry: aluminum components often undergo anodizing to create a hard, corrosion-resistant surface that can withstand extreme conditions. 対照的に, consumer electronics might use powder coating for a durable, colored finish that resists scratches and fingerprints. For medical devices requiring a sterile, easy-to-clean surface, electropolishing (a process that removes a thin material layer via electrochemistry) delivers a bright, corrosion-resistant finish ideal for stainless steel or titanium parts.

3. Heat Treatment: Optimizing Mechanical Properties

For metal parts, especially those made from steel, チタン, or aluminum alloys, heat treatment is critical for achieving the right balance of hardness, 強さ, and ductility. Raw machined metals often have internal stresses or inconsistent grain structures from the manufacturing process. Heat treatment relieves these stresses and modifies the material’s properties to meet specific performance requirements. Here’s how different techniques stack up:

| Heat Treatment Process | 説明 | Purpose | 一般的な材料 | Typical Use Cases |

| アニーリング | Material is heated and slowly cooled to remove stress. | Softens material, improves ductility | 鋼鉄, アルミニウム, 銅, 真鍮 | 航空宇宙コンポーネント, structural materials |

| 硬化 | Material is heated to high temperatures and quickly cooled (クエンチ). | Increases hardness and wear resistance | Carbon steels, tool steels | ギア, ベアリング, cutting tools |

| 焼き戻し | Hardened material is reheated to a lower temperature and slowly cooled. | Reduces brittleness, maintains toughness | Carbon steels, tool steels | 自動車部品, ツーリング |

| 消光 | Rapid cooling (in oil, 水, or air) after heating. | Enhances hardness and tensile strength | 鋼鉄, iron, alloys | Machine parts, ギア |

| Stress Relieving | Heating to low temperatures and gradual cooling. | Reduces internal stress, prevents warping | アルミニウム, ステンレス鋼 | 精密部品, welded frames |

| Normalizing | Heating to critical temperature and cooling in air. | Refines grain structure, restores ductility | 鋼鉄, cast iron | Forgings, castings, steel parts |

| 浸炭 | Infusing carbon into low-carbon steel surfaces in a carbon-rich atmosphere. | Enhances surface hardness | 低炭素鋼 | ギア, シャフト, camshafts |

| ニトリッド | Diffusing nitrogen into surfaces at low temperatures. | Improves surface hardness and corrosion resistance | 鋼鉄, チタン, aluminum alloys | 航空宇宙, ツーリング, 自動車部品 |

例えば, gears in automotive transmissions undergo carburizing to harden their surfaces (耐摩耗性のため) while keeping the core ductile (to absorb impact). Meanwhile, stress relieving is essential for precision parts like aerospace brackets, where even minor warping could lead to catastrophic failure.

4. Grinding: Achieving Ultra-Precise Dimensions and Surfaces

When your part requires extreme precision—think tolerances as tight as ±0.0001 inches—研削 is the post-processing technique of choice. This high-precision method uses abrasive wheels to remove tiny amounts of material, refining both surface finish and dimensional accuracy. Unlike milling or turning, which shape the part, grinding polishes and perfects it.

Grinding is particularly valuable for:

- Removing tool marks left by CNC cutting processes

- Achieving mirror-like surface finishes on metal parts

- Ensuring tight tolerances on critical dimensions (例えば。, bearing races)

- Processing hard materials that can’t be easily machined with traditional tools

In industries like aerospace and medical device manufacturing, where precision is non-negotiable, grinding ensures parts fit together perfectly and perform reliably under demanding conditions. 例えば, the bearing surfaces in jet engines require grinding to achieve the smoothness needed to reduce friction and extend service life.

5. Threading and Tapping: Creating Secure Connections

Many CNC machined parts need to connect with other components via screws, bolts, or fasteners—and that’s where threading and tapping お入りください. These processes create precise internal (タッピング) and external (threading) threads that ensure secure, reliable assemblies.

- Threading: Involves cutting helical grooves on the outside of a cylindrical part (例えば。, a bolt) using a die or CNC thread mill.

- Tapping: Creates internal threads in a hole using a tap, a tool with pre-formed threads that cuts into the material.

In industries like electronics, where components are small and lightweight, precise threading ensures screws don’t strip or loosen during use. In automotive manufacturing, where vibrations are constant, high-quality threads prevent parts from coming apart over time. Even a minor thread imperfection can lead to leaks in hydraulic systems or electrical failures in connectors, making these processes critical for safety and reliability.

6. クリーニング: Removing Contaminants for Quality and Safety

After machining and other post-processing steps, parts are often covered in coolants, oils, metal shavings, or residual chemicals. クリーニング isn’t just about making parts look good—it’s about ensuring they perform as intended. Contaminants can interfere with surface treatments (like painting or plating), cause corrosion, or even damage sensitive components during assembly.

Here are the most effective cleaning methods for CNC parts:

| Cleaning Method | 説明 | Best Used For |

| Compressed Air Cleaning | Uses high-pressure air to blow off chips, ほこり, and debris. | Quick surface cleaning after machining |

| Ultrasonic Cleaning | High-frequency sound waves in a cleaning solution dislodge contaminants. | Delicate or complex parts with fine features |

| Solvent Cleaning | Chemical solvents dissolve oils, coolants, and tough residues. | Removing lubricants or machining fluids |

| Aqueous Cleaning | Water-based solutions with detergents, often heated, for general cleaning. | Eco-friendly bulk cleaning |

| Steam Cleaning | High-temperature steam loosens grime and oils. | Effective degreasing without harsh chemicals |

| Manual Wiping/Brushing | Physical scrubbing with cloths, brushes, or pads. | Spot-cleaning or sensitive surfaces |

| Vacuum Cleaning | Industrial vacuums remove dry chips and dust. | Initial chip removal before detailed cleaning |

| CO₂ Snow Cleaning | Dry ice particles blast off particles and oils. | Precision cleaning without moisture or residue |

| Vapor Degreasing | Solvent vapors condense on parts and dissolve contaminants. | High-performance cleaning of critical metals |

For medical devices, where sterility is paramount, ultrasonic cleaning or CO₂ snow cleaning ensures no residues are left behind. For automotive parts, aqueous cleaning offers an eco-friendly way to remove heavy oils and grime in bulk.

7. Inspection and Quality Control: Ensuring Perfection

The final step in post-processing is inspection and quality control—the safety net that catches any issues before parts reach the customer. Even the most advanced CNC machines and post-processing techniques can have minor variations, so thorough inspection is essential to verify that parts meet design specifications.

Here are the key inspection techniques used in CNC machining:

| Inspection Technique | 説明 | 応用 |

| 目視検査 | Manual check for surface defects, バリ, or discoloration. | Quick assessment of obvious flaws |

| Calipers and Micrometers | Handheld tools measure internal and external dimensions. | Validating critical dimensions and tolerances |

| Coordinate Measuring Machine (CMM) | Automated 3D measurement via a probe. | High-precision inspection of complex parts |

| Optical Comparators | Magnified images compare parts to design overlays. | Examining contours and small features |

| Surface Roughness Testers | Devices measure surface texture in microns. | Evaluating surface finish quality |

| Go/No-Go Gauges | Fixed tools check if parts meet acceptable tolerances. | Fast pass/fail checks for high-volume parts |

| Laser Scanning / 3D Scanning | Non-contact capture of 3D geometry. | Comparing complex parts to CAD models |

| Hardness Testing | Measures resistance to deformation (例えば。, Rockwell, Brinell tests). | Verifying heat treatment effectiveness |

| Thread Gauges | Check internal and external thread precision. | Ensuring thread compatibility |

| Bore Gauges | Measure hole diameter and roundness. | Inspecting tight-tolerance internal features |

大量生産用, Go/No-Go gauges offer a fast way to ensure parts are within tolerance. For complex aerospace components, CMMs or 3D laser scanning provide detailed data to compare against CAD models, ensuring every curve and dimension is perfect. Hardness testing is critical after heat treatment to confirm that parts like gears or tools have the required strength.

Yigu Technology’s Perspective on CNC Post-Processing

Yiguテクノロジーで, we believe post-processing is the cornerstone of CNC machining excellence. It’s where raw precision transforms into reliable performance. Our engineers combine technical expertise with tailored solutions—whether it’s choosing the right deburring method for delicate parts or optimizing heat treatment for aerospace durability. We prioritize every post-processing step to ensure your components meet not just specifications, but real-world demands, delivering quality you can trust.

よくある質問 (よくある質問)

- Why is post-processing necessary in CNC machining?

Post-processing addresses surface imperfections, enhances mechanical properties, and ensures quality, transforming rough machined parts into functional, durable products that meet safety and performance standards.

- How do I choose the right surface finishing technique?

Consider your part’s material, intended use, and aesthetic needs. 例えば, anodizing works best for aluminum in consumer electronics, while powder coating is ideal for durable, colored metal parts in automotive applications.

- What’s the difference between deburring and surface finishing?

Deburring focuses on removing sharp protrusions and imperfections left by machining, while surface finishing improves texture, 外観, and performance (例えば。, 耐食性, smoothness) of the part’s surface.