Invar steel (a nickel-iron alloy with ~36% nickel) そのために祝われる専門の資料です ultra-low coefficient of thermal expansion—a trait that makes it uniquely stable across temperature changes. 標準鋼とは異なります, which expand or contract significantly with heat, Invar retains its shape even in extreme temperature swings, making it indispensable for precision-focused industries like aerospace, scientific research, およびコンシューマーエレクトロニクス. このガイドで, 重要なプロパティを分類します, 実世界の使用, 生産技術, そして、それが他の素材とどのように比較されますか, helping you select it for projects where dimensional stability is non-negotiable.

1. Key Material Properties of Invar Steel

Invar’s performance hinges on its nickel-iron composition, which creates a unique crystalline structure (face-centered cubic) that minimizes thermal expansion—its defining feature for precision applications.

化学組成

Invar’s formula prioritizes low thermal expansion, 重要な要素の厳格な範囲があります (per ASTM F1684 standards):

- ニッケル (で): 35.00-37.00% (core element—combines with iron to suppress thermal expansion, forming the alloy’s signature stability)

- 鉄 (fe): バランス (ベースメタル, provides structural strength while enabling the low-expansion microstructure)

- マンガン (Mn): ≤0.50% (modest addition improves workability and prevents hot cracking during manufacturing)

- 炭素 (c): ≤0.05% (ultra-low to avoid carbide formation, which would disrupt the low-expansion structure)

- シリコン (そして): ≤0.30% (aids deoxidation during steelmaking without compromising thermal stability)

- 硫黄 (s): ≤0.010% (ultra-low to maintain ductility and avoid brittleness in precision-machined parts)

- リン (p): ≤0.020% (冷たい脆性を防ぐために厳密に制御されます, critical for low-temperature scientific equipment)

物理的特性

| 財産 | Typical Value for Invar Steel |

| 密度 | ~8.05 g/cm³ (slightly higher than carbon steel, but negligible for small precision parts) |

| 融点 | ~1430-1450°C (suitable for hot working and casting of specialized components) |

| 熱伝導率 | ~10 W/(M・k) (at 20°C—very low, reducing heat transfer and minimizing local temperature swings) |

| 比熱容量 | ~0.46 kJ/(kg・k) (20°Cで) |

| 熱膨張係数 (CTE) | ~1.2 x 10⁻⁶/°C (20-100°C) - 10x lower than carbon steel (12 x10⁻⁶/°C), its most critical property |

機械的特性

Invar balances dimensional stability with sufficient strength for precision components, though it is softer than standard structural steels:

- 抗張力: 〜450-550 MPa (suitable for lightweight precision parts like aerospace sensors or watch springs)

- 降伏強度: ~200-250 MPa (low enough for forming complex shapes, high enough to retain dimensional stability under light loads)

- 伸長: ~30-40% (で 50 mm—excellent ductility, enabling bending and machining of intricate parts like instrument frames)

- 硬度 (ブリネル): ~130-150 HB (soft enough for precision machining, though harder than copper or aluminum)

- 耐衝撃性 (シャルピーv-notch, 20°C): 〜60-80 j (精密な部品に適しています, avoiding brittle failure during handling or assembly)

- 疲労抵抗: ~180-220 MPa (at 10⁷ cycles—suitable for dynamic precision parts like hard drive read/write arms)

その他のプロパティ

- Low thermal expansion: 例外的 (CTE ~1.2 x 10⁻⁶/°C)—the core advantage, ensuring parts retain shape from -200°C (space) to 200°C (エンジンベイ)

- 磁気特性: 強磁性 (磁気を保持します, making it ideal for magnetic cores in precision transformers)

- 寸法安定性: 素晴らしい (minimal creep or shrinkage over time—critical for calibration devices that require long-term accuracy)

- 耐食性: 適度 (さび保護のための合金の追加はありません; prone to oxidation in moist environments—requires plating or coating for outdoor use)

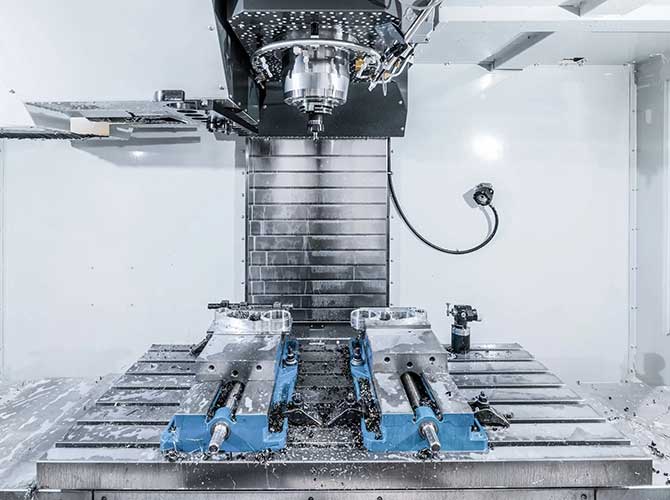

- 加工性: 良い (softness enables precise CNC machining to tight tolerances ±0.001 mm, though tools wear faster than with aluminum)

2. Real-World Applications of Invar Steel

Invar’s low thermal expansion makes it irreplaceable in industries where even tiny dimensional changes would ruin performance. ここに最も一般的な用途があります:

Precision Instruments

- Clocks & Watches: High-end mechanical watch balance wheels and springs use Invar—低熱膨張 ensures accurate timekeeping across temperatures (例えば。, from 10°C to 35°C), reducing time loss/gain by 90% vs. brass components.

- Precision measuring instruments: キャリパー, マイクロメートル, and laser measurement tool frames use Invar—dimensional stability maintains accuracy (±0.0001 mm) in factory or laboratory environments with temperature fluctuations.

- Optical instruments: Telescope mirrors and camera lens mounts use Invar—熱安定性 prevents mirror warping, ensuring sharp images even when outdoor temperatures shift (例えば。, from night to day).

ケースの例: A watch manufacturer used brass for balance wheels but faced customer complaints about time inaccuracies (±5 seconds/day) in temperature changes. Switching to Invar reduced error to ±0.5 seconds/day—improving customer satisfaction and positioning the brand as a premium precision watchmaker.

Electrical Engineering

- トランス: High-precision transformer cores and coils use Invar—磁気特性 and low thermal expansion ensure consistent voltage output, even when the transformer heats up during operation.

- Electrical contacts: High-frequency circuit board contacts use Invar—dimensional stability prevents contact loosening from temperature cycles, reducing signal loss in telecom equipment.

- Inductors: Radio frequency (RF) inductor frames use Invar—低熱膨張 maintains coil spacing, ensuring stable inductance values in smartphones or satellite communication devices.

航空宇宙

- 航空機コンポーネント: Avionics sensor mounts (例えば。, GPS receivers, altitude sensors) use Invar—熱安定性 ensures sensor alignment, even when aircraft transition from cold high altitudes (-50°C) to warm ground temperatures (30°C).

- 宇宙船コンポーネント: Satellite antenna reflectors and solar panel frames use Invar—低熱膨張 withstands extreme space temperature swings (-200°C〜120°C), preventing antenna deformation and ensuring signal accuracy.

- 精密部品: Aircraft engine fuel injection system components use Invar—stability under heat (最大150°C) maintains fuel flow precision, エンジン効率の向上.

科学研究

- Laboratory equipment: Cryogenic storage tank liners (for liquid nitrogen, -196°C) use Invar—低熱膨張 prevents tank cracking from extreme cold, ensuring safe storage of samples.

- Calibration devices: Standard weight holders and length calibration bars use Invar—dimensional stability ensures these reference tools remain accurate for decades, serving as industry-wide measurement benchmarks.

- Particle accelerators: Beam guide components in particle accelerators use Invar—stability under radiation and temperature changes (from 20°C to 80°C) keeps particle beams on track, enabling accurate scientific experiments.

家電

- Hard drives: Hard disk drive (HDD) read/write arm pivots use Invar—低熱膨張 maintains the arm’s position relative to the disk, reducing data read/write errors (critical for enterprise-grade HDDs with terabytes of data).

- Disk drives: Optical disk drive (ODD) laser lens mounts use Invar—stability prevents lens misalignment, ensuring reliable CD/DVD reading/writing even when the drive heats up.

- 精密コンポーネント: Smartphone camera image stabilization (OIS) parts use Invar—dimensional stability enhances OIS performance, reducing blurriness in photos taken in varying temperatures.

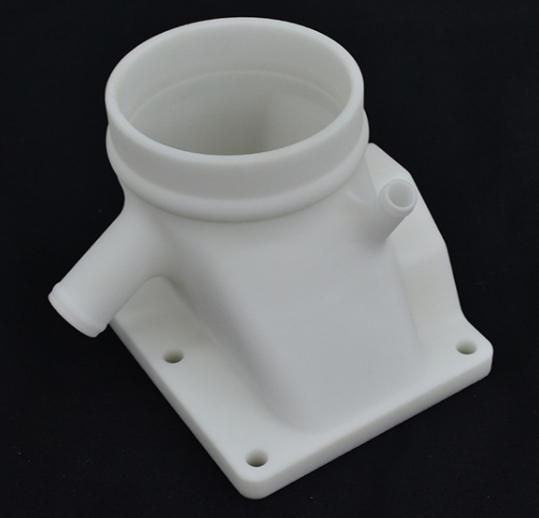

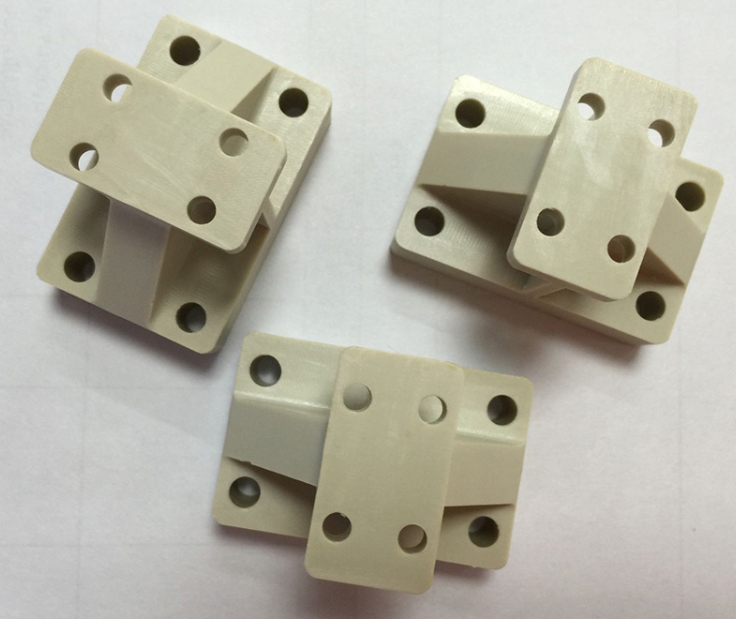

3. Manufacturing Techniques for Invar Steel

Producing Invar requires precise control of nickel content and thermal processing to preserve its low-expansion microstructure—any deviation ruins its key property. 詳細なプロセスは次のとおりです:

1. 一次生産

- スチール製造:

- 電気弧炉 (EAF): Primary method—high-purity iron and nickel (99.9% 純粋な) are melted at 1500-1550°C. Nickel content is carefully adjusted to 35-37% リアルタイム分光法の使用, 偶数 0.5% deviation increases CTE by 20%.

- 真空アークリメルティング (私たちの): Used for premium Invar (例えば。, 航空宇宙部品)—molten steel is remelted in a vacuum to remove impurities (酸素, 窒素), which would disrupt the low-expansion structure. This step ensures 99.99% 純度.

- 継続的なキャスト: Molten Invar is cast into slabs (50-100 厚さmm) 連続鋳造を介して - スロウリング (10°C/min) preserves the face-centered cubic microstructure needed for low expansion.

2. 二次処理

- ローリング: Cast slabs are heated to 900-950°C and hot-rolled into sheets or bars—hot rolling refines grain structure without altering the low-expansion properties. コールドローリング (室温) is then used to achieve precise thicknesses (に 0.1 mm) for precision parts like watch springs.

- 鍛造: 複雑な形の場合 (例えば。, satellite antenna mounts), ホット鍛造 (900-950°C) shapes Invar into blanks—forging improves material density, enhancing dimensional stability over time.

- 熱処理:

- アニーリング: Critical step—parts are heated to 800-850°C for 1-2 時間, slow-cooled to 200°C. This relieves internal stress from rolling/forging and locks in the low-expansion microstructure. Fast cooling would disrupt the structure, increasing CTE.

- ストレス緩和アニーリング: Applied after machining—heated to 300-350°C for 30 分, 空冷. Reduces residual stress from cutting, preventing long-term dimensional drift in precision parts.

3. 表面処理

- メッキ: Nickel or gold plating is applied to Invar parts (例えば。, 電気接点, コンポーネントを見る)—enhances corrosion resistance and improves electrical conductivity (エレクトロニクス用) または美学 (for luxury watches).

- 絵画: Epoxy paints are used for outdoor parts (例えば。, telescope mounts)—protects against moisture, though Invar’s low expansion ensures paint doesn’t crack with temperature changes.

- 爆破: Fine sandblasting is used to create a smooth surface (ra 0.2-0.4 μm) for optical components—ensures proper adhesion of coatings (例えば。, anti-reflective films on telescope mirrors).

4. 品質管理

- 検査: 目視検査は表面欠陥のチェックをチェックします (傷, ひび割れ) in precision parts—even tiny flaws can cause dimensional instability in high-precision applications.

- テスト:

- CTE testing: Dilatometry measures thermal expansion (ターゲット: ~1.2 x 10⁻⁶/°C)—parts with CTE outside 1.0-1.4 x 10⁻⁶/°C are rejected.

- 化学分析: 質量分析はニッケル含有量を検証します (35-37%)—ensures compliance with ASTM F1684.

- Dimensional accuracy testing: 測定機を調整します (CMM) check tolerances (±0.001 mm) for parts like HDD components—critical for functionality.

- 非破壊検査: 超音波検査は、内部欠陥を検出します (ボイド) in thick parts like spacecraft frames—avoids failure in extreme environments.

- 認証: Each batch of Invar receives an ASTM F1684 certificate, verifying CTE, 化学組成, and dimensional stability—mandatory for aerospace and scientific applications.

4. ケーススタディ: Invar Steel in Satellite Antenna Frames

A space technology company used aluminum for satellite antenna frames but faced a critical issue: antenna deformation (0.5 mm) in space temperature swings (-200°C〜120°C) caused signal loss. Switching to Invar delivered transformative results:

- 寸法安定性: Invar’s CTE (~1.2 x 10⁻⁶/°C) reduced deformation to 0.02 mm—eliminating signal loss and meeting NASA’s strict accuracy requirements.

- Mission Reliability: The satellite’s antenna maintained performance for its 5-year mission, whereas aluminum frames would have required mid-mission adjustments (impossible in space).

- コスト効率: Despite Invar’s 3x higher material cost, the company avoided a $5 million satellite redesign—achieving ROI before launch.

5. Invar Steel vs. その他の材料

How does Invar compare to other materials for precision, low-expansion applications? 以下の表は、重要な違いを強調しています:

| 材料 | 料金 (vs. Invar) | CTE (x10⁻⁶/°C, 20-100°C) | 抗張力 (MPA) | 寸法安定性 | 磁気特性 |

| Invar Steel | ベース (100%) | 1.2 | 450-550 | 素晴らしい | 強磁性 |

| 炭素鋼 (A36) | 20% | 12.0 | 400-550 | 貧しい | 強磁性 |

| ステンレス鋼 (304) | 40% | 17.3 | 500-700 | 貧しい | 強磁性 |

| アルミニウム合金 (6061-T6) | 30% | 23.1 | 310 | とても貧しい | 非磁性 |

| チタン合金 (TI-6AL-4V) | 800% | 8.6 | 860-1100 | 良い | 非磁性 |

アプリケーションの適合性

- Ultra-Precision Applications: Invar is the only choice—its CTE is 10x lower than carbon steel, making it essential for watches, satellite antennas, and calibration tools.

- Magnetic Applications: Invar’s ferromagnetism makes it better than titanium or aluminum for transformer cores or magnetic sensors.

- 費用に敏感, Low-Precision: Carbon steel or aluminum are cheaper but only suitable for parts where thermal expansion (12-23 x10⁻⁶/°C) won’t impact performance.

- 高強度, Moderate Precision: Titanium is stronger but has 7x higher CTE than Invar—better for aerospace structural parts, not precision sensors.

Yigu Technology’s View on Invar Steel

Yiguテクノロジーで, Invar steel is a critical material for precision-driven clients in aerospace, エレクトロニクス, および科学研究. その unmatched low thermal expansion and dimensional stability solve problems no other material can—from satellite antennas to high-end watches. We recommend Invar for applications where even 0.1 mm of deformation would fail a project, though we advise pairing it with corrosion-resistant plating for longevity. While Invar costs more upfront, its ability to avoid costly redesigns or failures delivers long-term value, aligning with our goal of reliable, future-ready solutions.

よくある質問

1. Can Invar steel be used for outdoor applications (例えば。, outdoor telescope mounts)?

Yes— but it requires surface treatment (nickel plating or epoxy painting) さびを防ぐため. Invar’s low thermal expansion ensures the coating won’t crack with temperature changes, and the treated part will maintain stability for 10+ 何年も屋外.

2. Is Invar steel machinable to very tight tolerances (例えば。, ±0.0001 mm)?

Yes—Invar’s softness (130-150 HB) and ductility enable precision CNC machining to ±0.0001 mm, making it ideal for micrometers, HDD parts, and other ultra-precision components. Use carbide tools and slow cutting speeds to avoid tool wear.

3. How does Invar steel compare to titanium for aerospace parts?

Invar is better for precision parts (例えば。, センサー, antennas) due to its 7x lower CTE, but titanium is stronger and lighter for structural parts (例えば。, 着陸装置). Choose Invar for dimensional stability; titanium for load-bearing applications.